Compound starch special glue and preparation method of hollow capsule thereof

A technology for compounding starch and starch, applied in the direction of capsule transportation, etc., can solve the problems of preventing the development and market launch of starch source hollow capsules, difficult to achieve hollow capsule strength, toughness stability, lack of starch hollow capsules, etc. Disintegration, good dispersibility, low viscosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

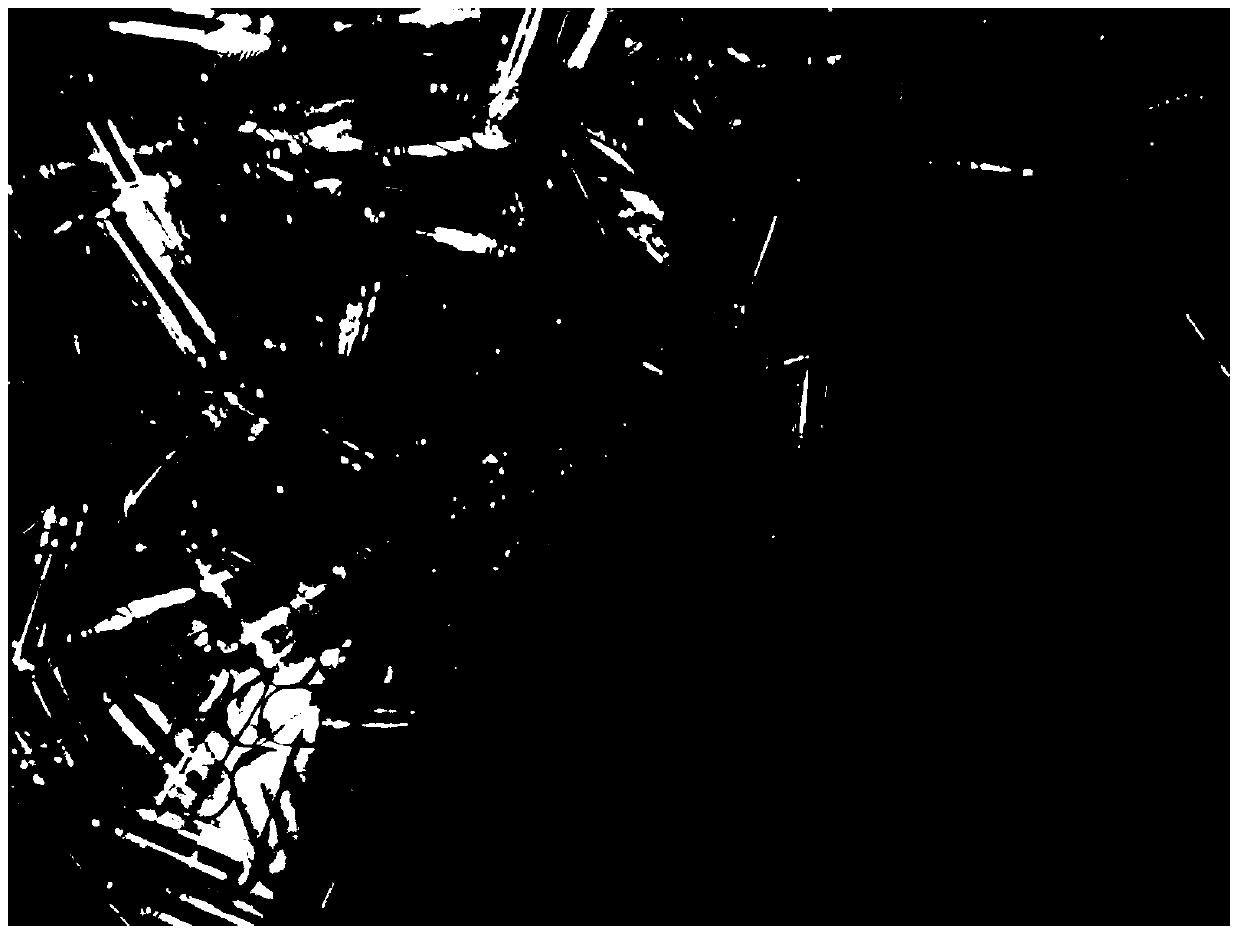

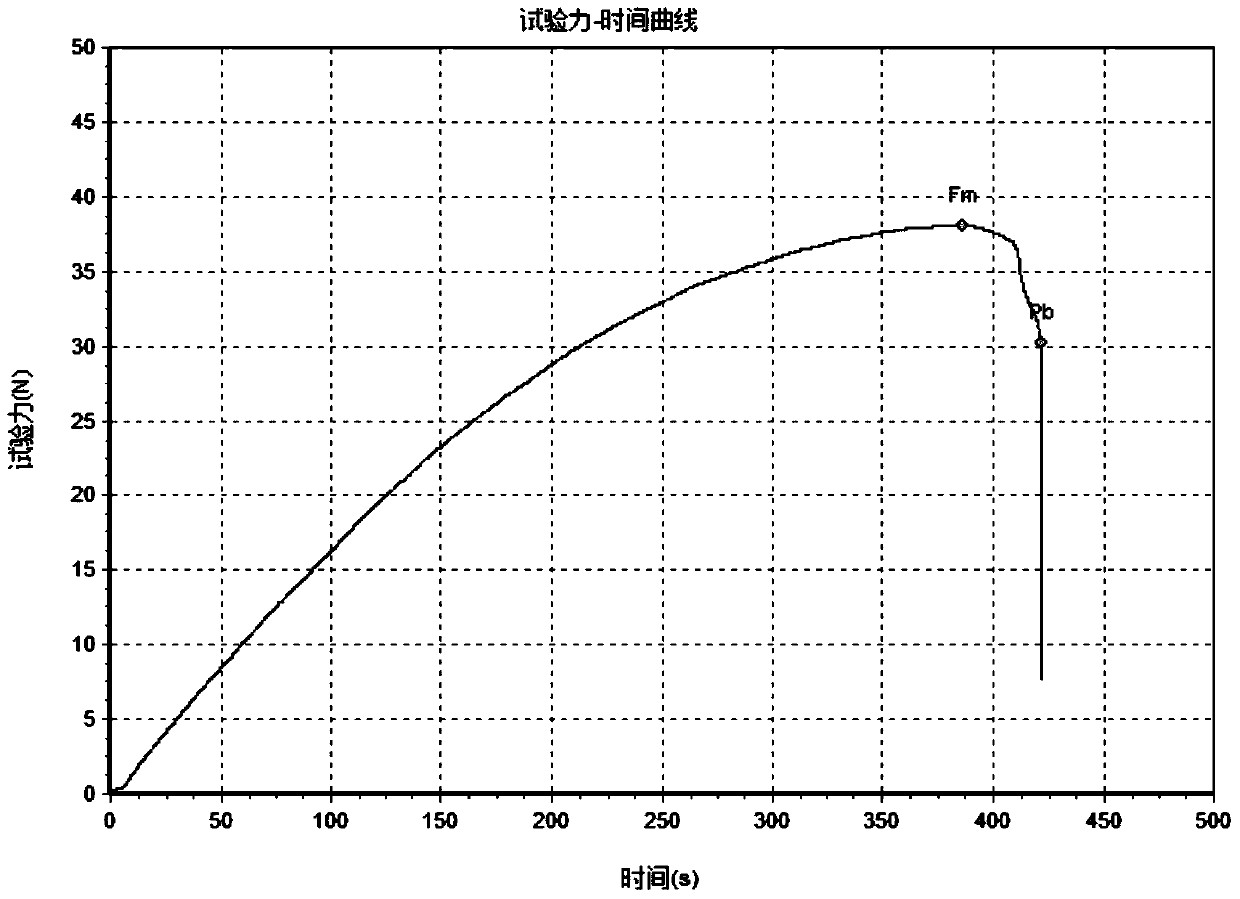

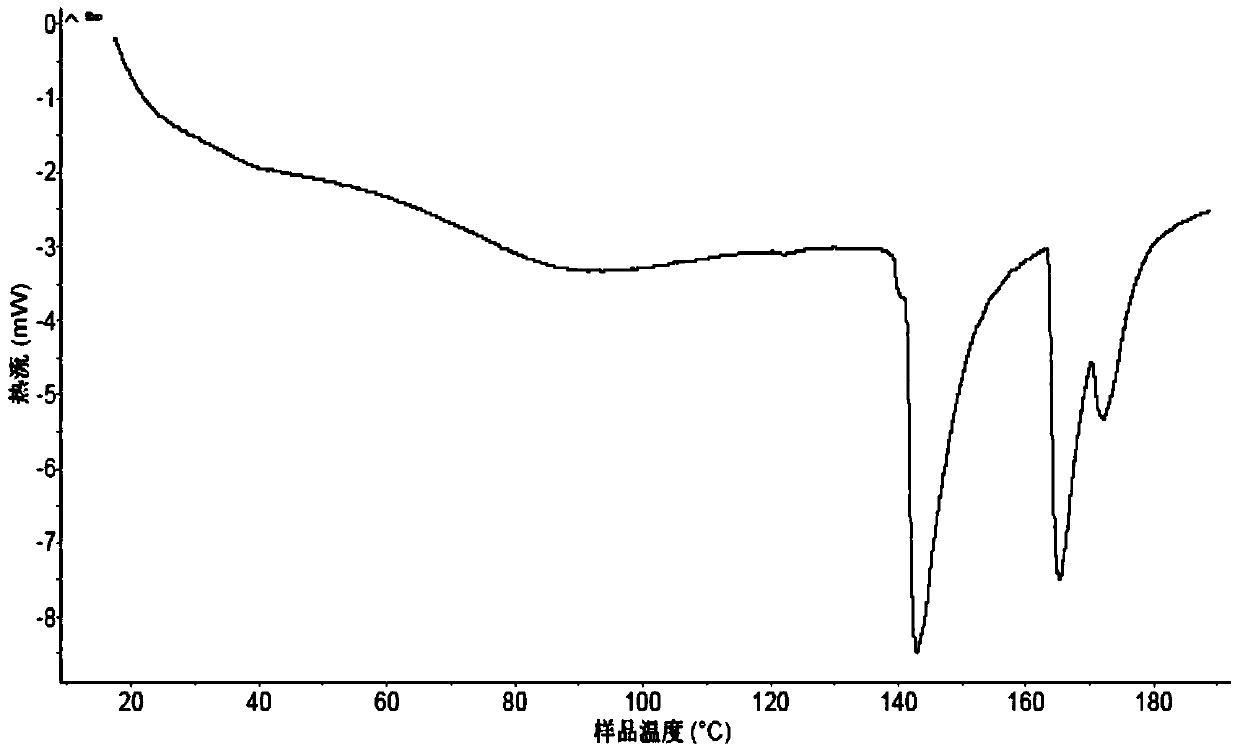

Image

Examples

Embodiment 1

[0037] Embodiment one: the preparation method of compound starch special glue, comprises the following steps:

[0038] 1) Raw material pretreatment: all raw materials are pulverized through a 100-mesh sieve and set aside;

[0039]2) Weighing: Weigh 3500g of acetate starch, 4000g of oxidized hydroxypropyl starch, 250g of hydroxypropyl starch, 600g of maltodextrin, 335g of κ-carrageenan, 825g of glycerin, and 105g of potassium chloride by weight percentage;

[0040] 3) Mixing: first mix a small amount of starch with maltodextrin, carrageenan, glycerin, and potassium chloride evenly, then add the rest of the starch according to the equal gradient addition method and mix evenly;

[0041] 4) Making soft materials and granules: using wet granulation technology, in a high-speed mixing granulator, spray the mixed raw materials with 50% ethanol aqueous solution to make soft materials, and pass through a 10-14 mesh sieve to obtain a particle size of 1 ~2mm wet particles;

[0042] 5) D...

Embodiment 2

[0043] Embodiment two: the method for preparing composite starch hollow capsules as a raw material with the special rubber particles obtained in embodiment one may further comprise the steps:

[0044] 1) Ingredients and sol: Weigh 12.95 kg of special rubber particles, disperse them into 20 kg of water, stir to obtain a starch emulsion, add the starch emulsion into 50 kg of boiling water in a trickle under constant stirring, stir evenly, and heat at 90°C Stir the glue until it becomes transparent. Take a certain amount of glue and dilute it to a glue with a solid content of 2%, and measure its light transmittance at 50°C and a wavelength of 500nm to be 82%;

[0045] 2) Degassing of gelatinization: After the sol is completed, degassing at a temperature of 50-65°C for 1-4 hours;

[0046] 3) Measure and adjust the viscosity: at 45-55°C, measure the viscosity of the glue to be 320-580mPa.S;

[0047] 4) Embryo making: Select a suitable type of capsule mold smeared with peanut oil,...

Embodiment 3

[0049] Embodiment three: the preparation method of composite starch special glue, comprises the following steps:

[0050] 1) Raw material pretreatment: all raw materials are pulverized through a 100-mesh sieve and set aside;

[0051] 2) Weighing: Weigh 5250g of acetate starch, 5460g of oxidized hydroxypropyl starch, 160g of hydroxypropyl distarch phosphate, 700g of maltodextrin, 420g of k-carrageenan, 600g of glycerin, and 140g of potassium chloride by weight percentage;

[0052] 3) Mixing: first mix a small amount of starch with maltodextrin, carrageenan, glycerin, and potassium chloride evenly, then add the rest of the starch according to the equal gradient addition method and mix evenly;

[0053] 4) Making soft materials and granules: using wet granulation technology, in a high-speed mixing granulator, spray the mixed raw materials with 50% ethanol aqueous solution to make soft materials, and pass through a 10-16 mesh sieve to obtain a particle size of 0.8 ~2mm wet particl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com