Integrated gas-liquid-solid continuous separation device

A separation device, gas-liquid-solid technology, applied in the field of oily sewage separation treatment device, to achieve the effect of convenient transportation, high-precision continuous separation, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing:

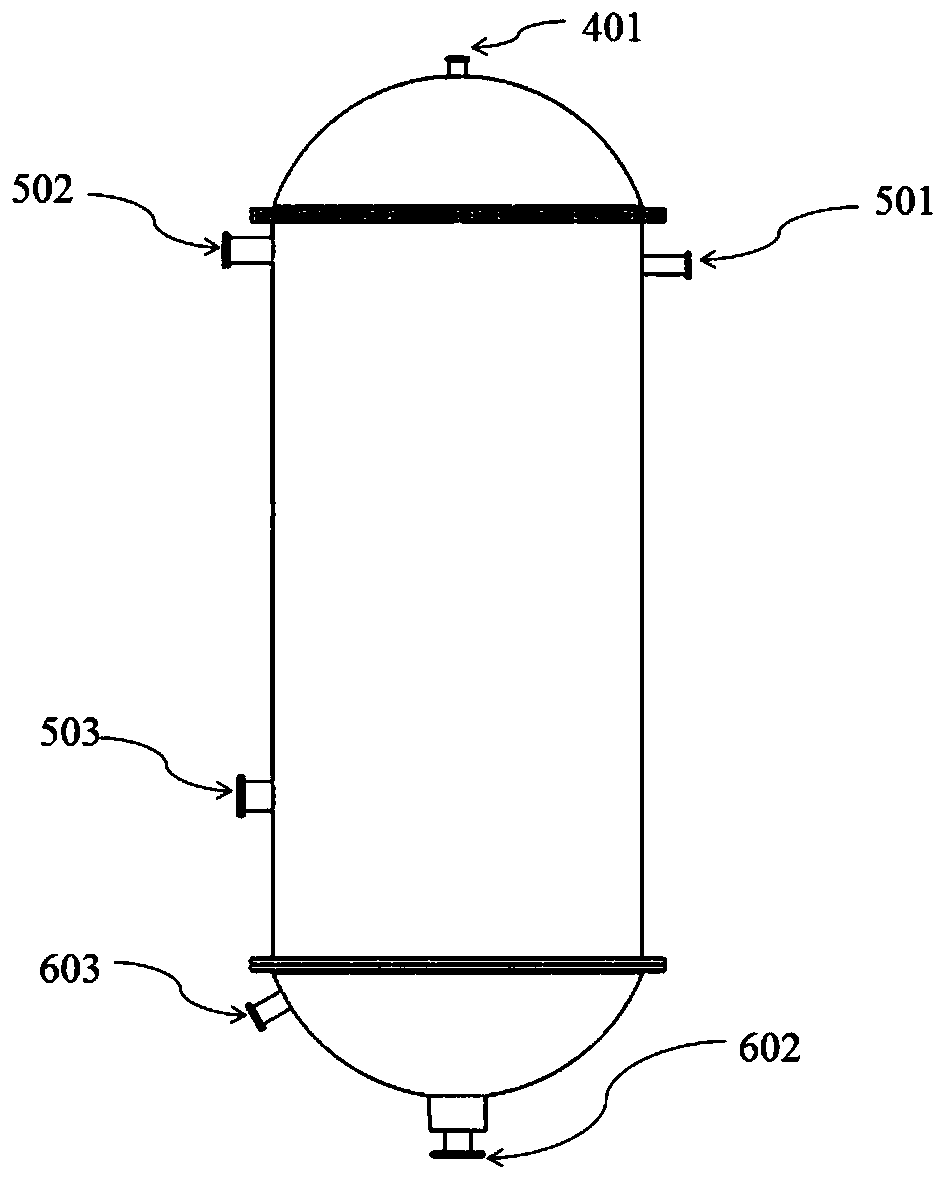

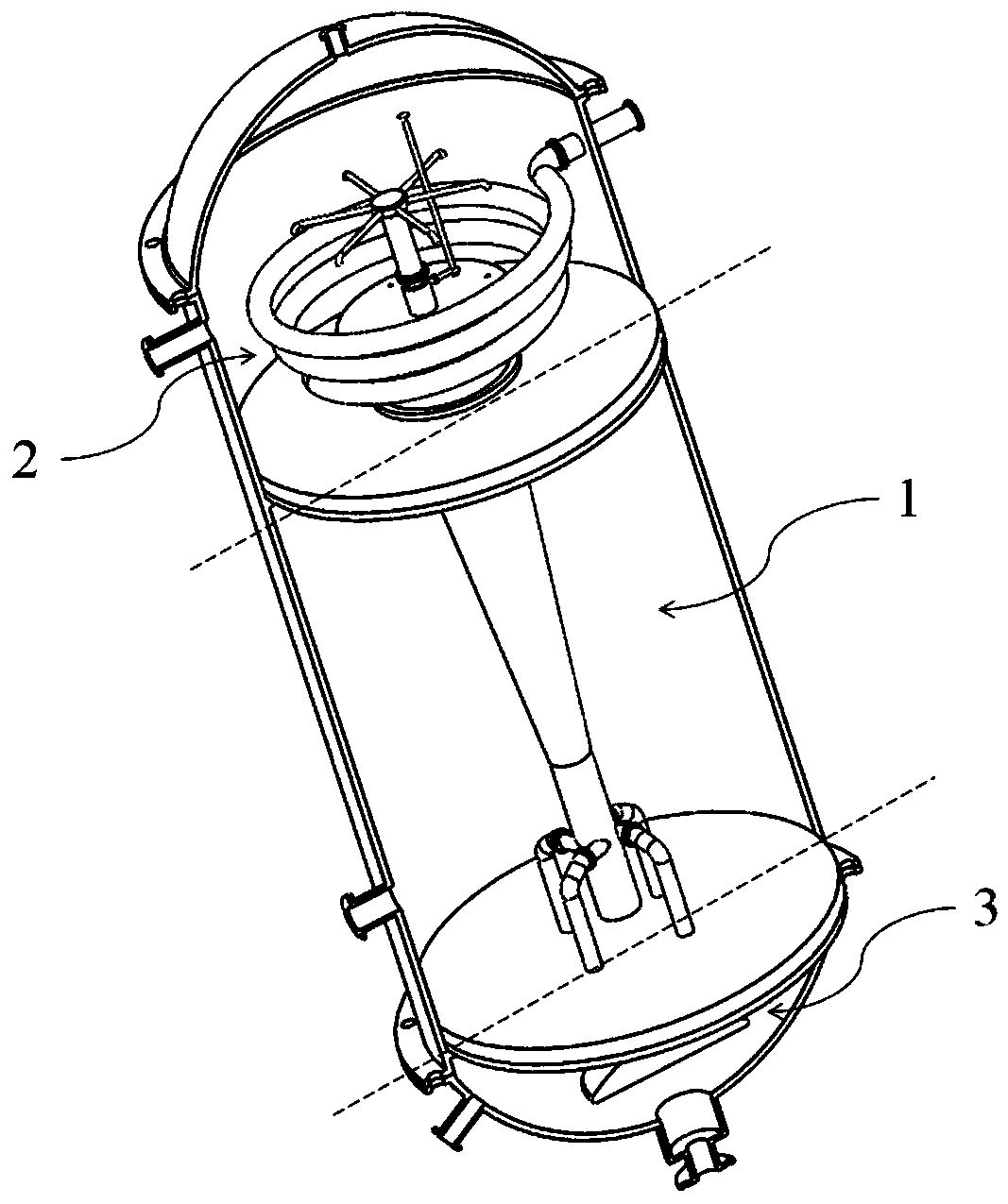

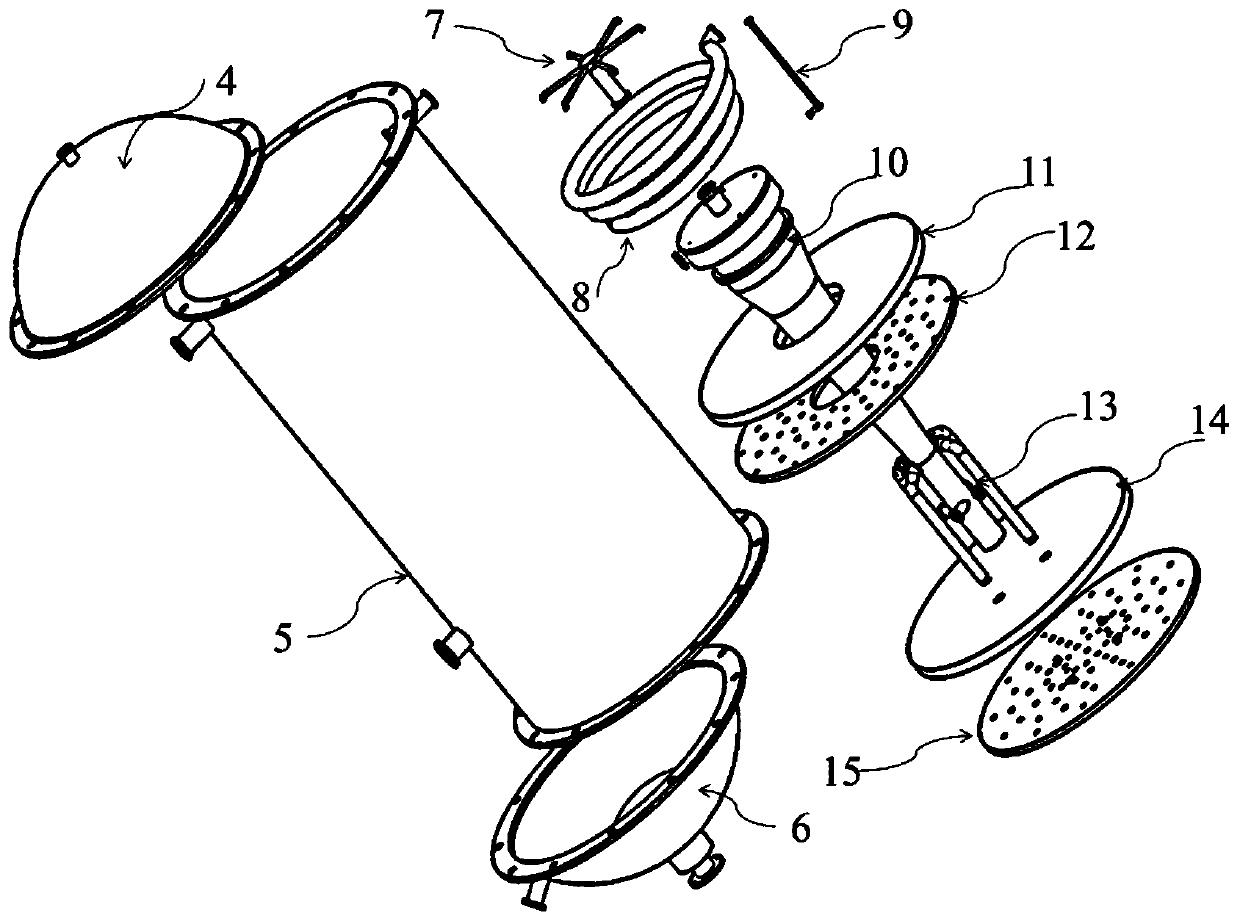

[0041] Depend on Figure 1 to Figure 21As shown, this kind of integrated gas-liquid-solid high-precision continuous separation device has a primary separation area 1, a secondary separation area 2, and a tertiary separation area 3, wherein the three separation areas are sequentially acted on by a separation tank 5 to separate The shape of the tank body 5 is generally a hollow cylindrical section, and the upper end of the right side is provided with a mixed liquid general inlet 501, and the upper and lower ends of the left side are respectively provided with a primary oil outlet 502 and a secondary oil outlet 503, and the middle is respectively in A deck is respectively arranged on the upper and lower sides to fix the upper baffle 504 and the lower baffle 505, wherein the lower deck has a gap at the opposite position to facilitate the removal of the lower baffle 15, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com