Oil spraying vacuum degassing device for online monitoring of oil chromatogram and application method

A vacuum degassing device and oil spraying technology, which is applied to measuring devices, instruments, scientific instruments, etc., can solve the problems of low degassing efficiency, complex structure, and long degassing time, so as to improve degassing efficiency and increase Speed of Diffusion, Effects of Simplified Devices and Methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

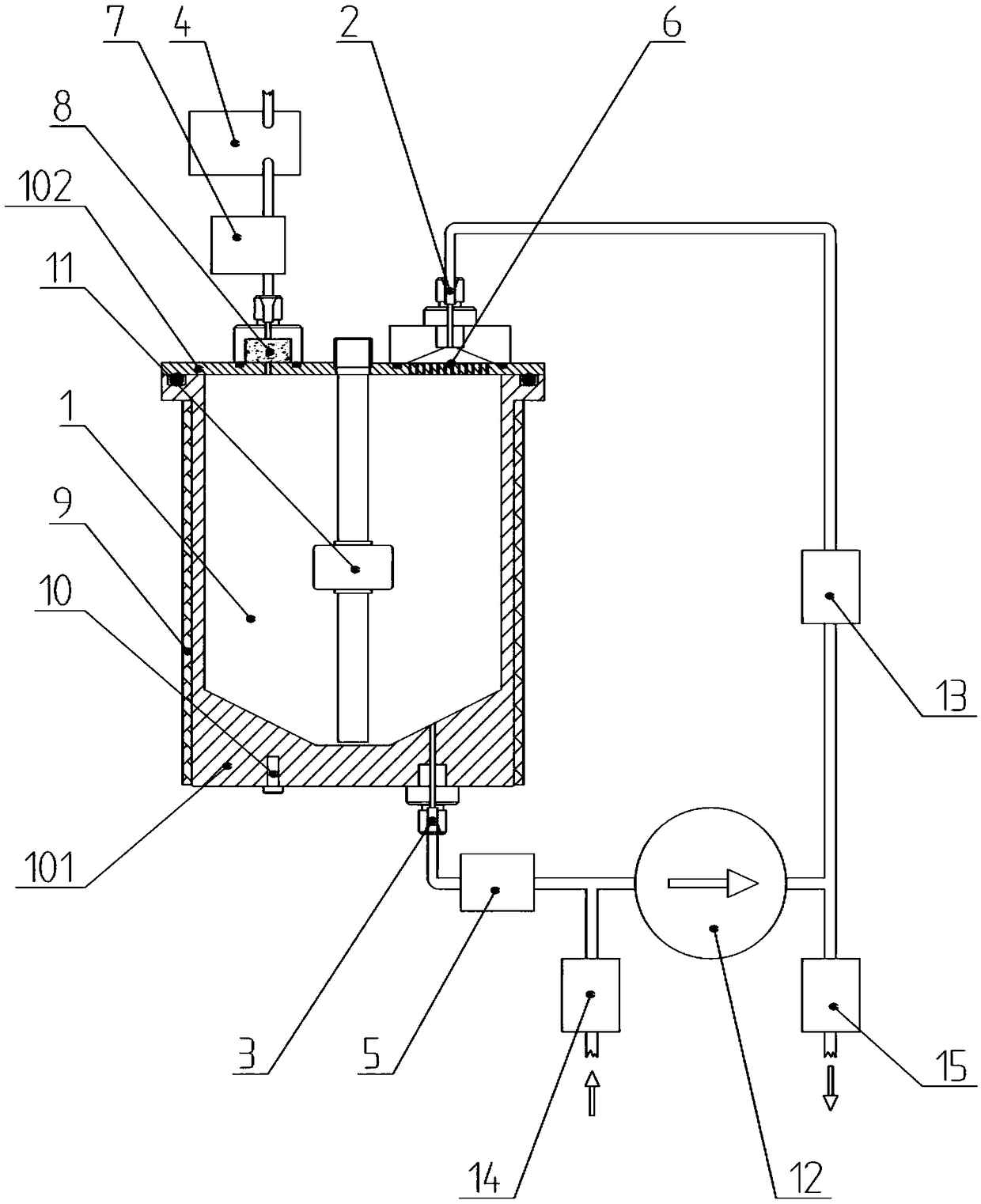

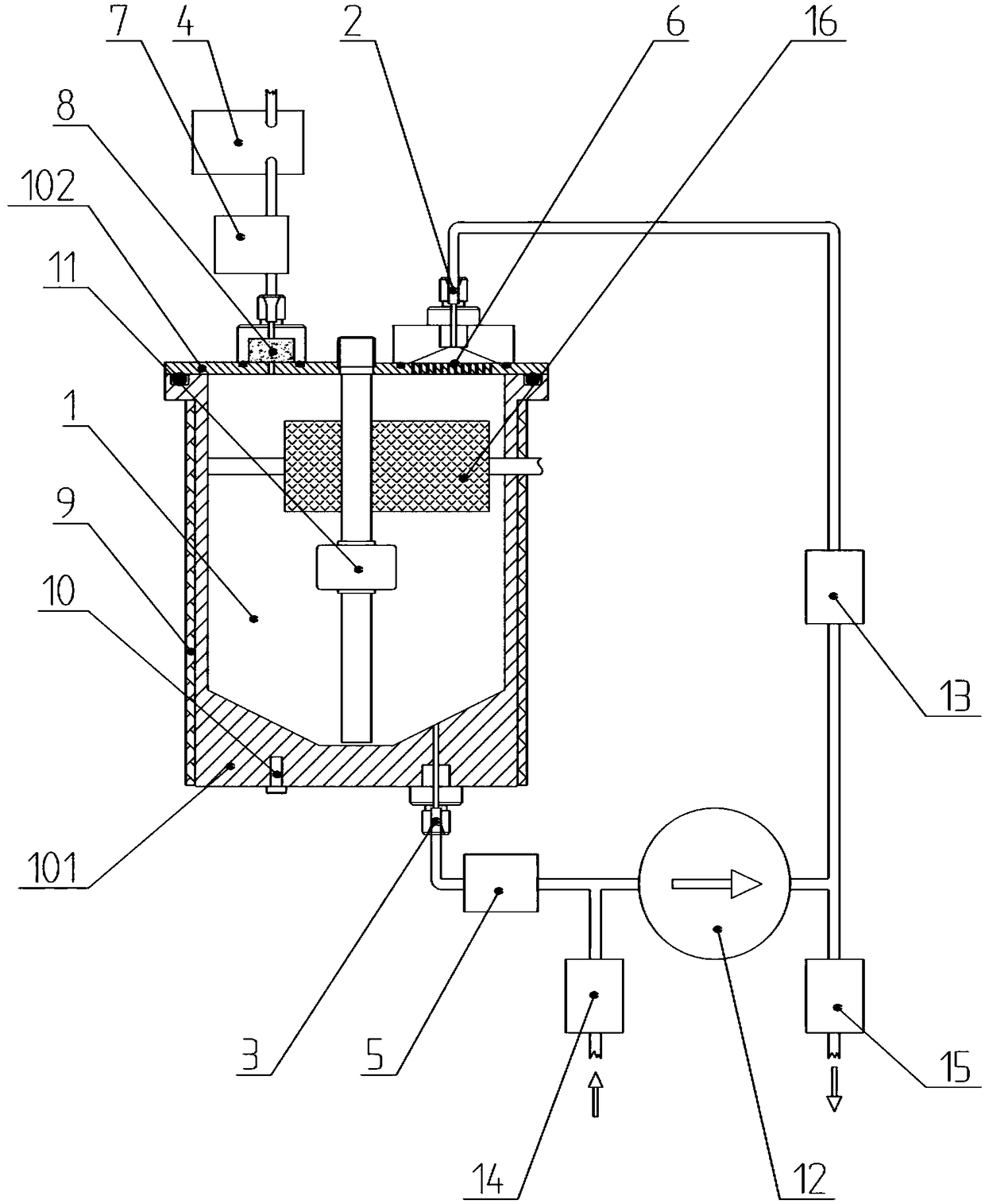

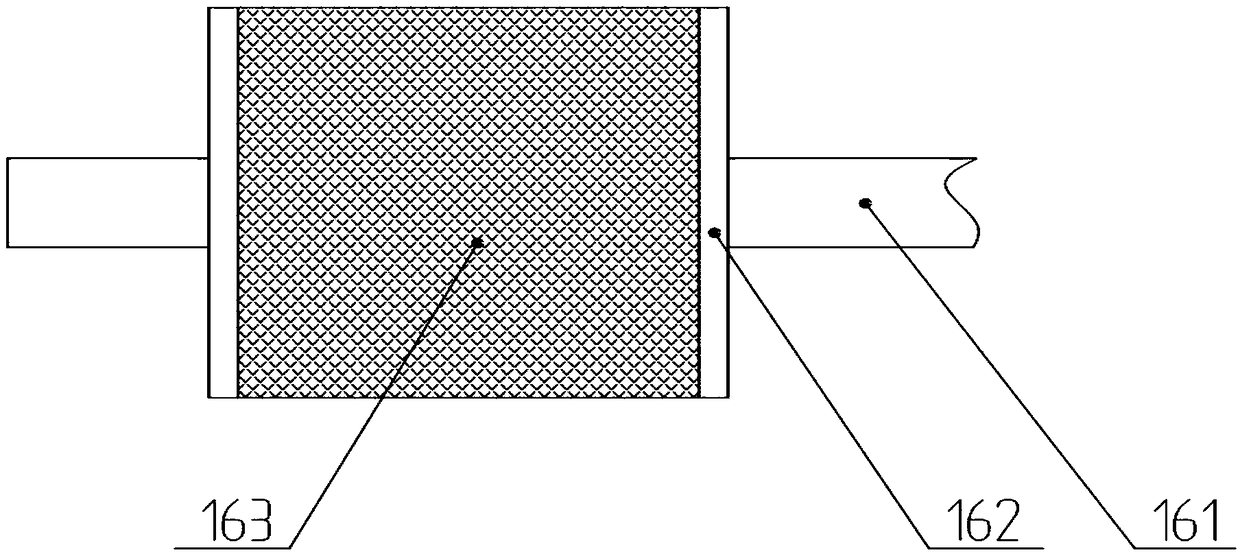

[0026] In order to further elaborate the technical means and effects that the present invention adopts for reaching the intended invention purpose, below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, features and effects of the present invention are described in detail as follows:

[0027] The principle of this application is that the essence of removing dissolved gas from transformer oil is a process in which dissolved gas diffuses from transformer oil to the vacuum area and tends to balance. Under the same volume, temperature, and pressure conditions, the larger the contact area, the faster the diffusion rate of dissolved gas, and the shorter the time required to reach the diffusion equilibrium. Therefore, the degassing time can be shortened and the degassing efficiency can be improved by increasing the contact area between the transformer oil and the vacuum area.

[0028] An oil spray vacuum degassing device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com