Coating wastewater treatment technology

A technology for treating process and coating wastewater, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. improvement and other problems, to achieve the effect of stable treatment effect, convenient operation and maintenance, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

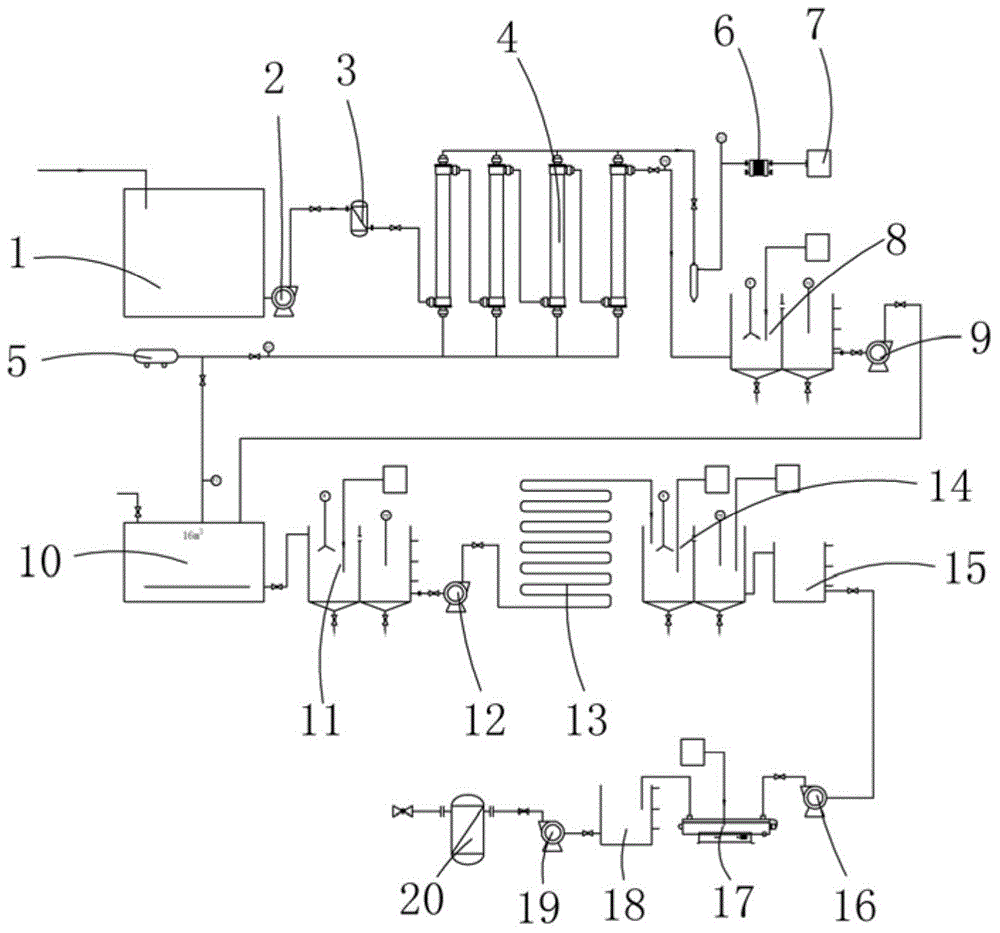

[0024] Examples, see attached figure 1 , a paint wastewater treatment process, it includes the following process:

[0025] (1) Raw water enters the regulating tank: the raw water enters the regulating tank 1 through the pump, the water inflow rate is 3.5t / h, and the volume of the regulating tank is 24m 3 , the system starts to operate normally after the water volume in the adjustment pool reaches a certain level.

[0026] (2) The water in the adjustment pool enters the pre-filter 3 through the lifting pump 2 and enters the degassing carbonization linkage system 4 after being filtered: the degassing carbonization linkage system is provided with a carbonized membrane module, and the carbonized membrane module is made of 30 hollow fibers Tubes and membranes are connected in series. The hollow fiber tubes are equipped with an air inlet, an air outlet, a water inlet and a water outlet. The water distributor makes the tube membrane fill evenly inside the carbonized membrane module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com