Degasser

A degassing device and mud technology, applied in liquid degassing, wellbore/well components, earthwork drilling and production, etc., can solve problems affecting degassing efficiency, affecting operating efficiency, unstable mud flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] Below in conjunction with preferred embodiments, the specific implementation, features and effects provided by the present invention are described in detail as follows; for the purpose of simplicity and clarity, the description of known technologies is appropriately omitted below to avoid unnecessary details Affect the description of this technical solution.

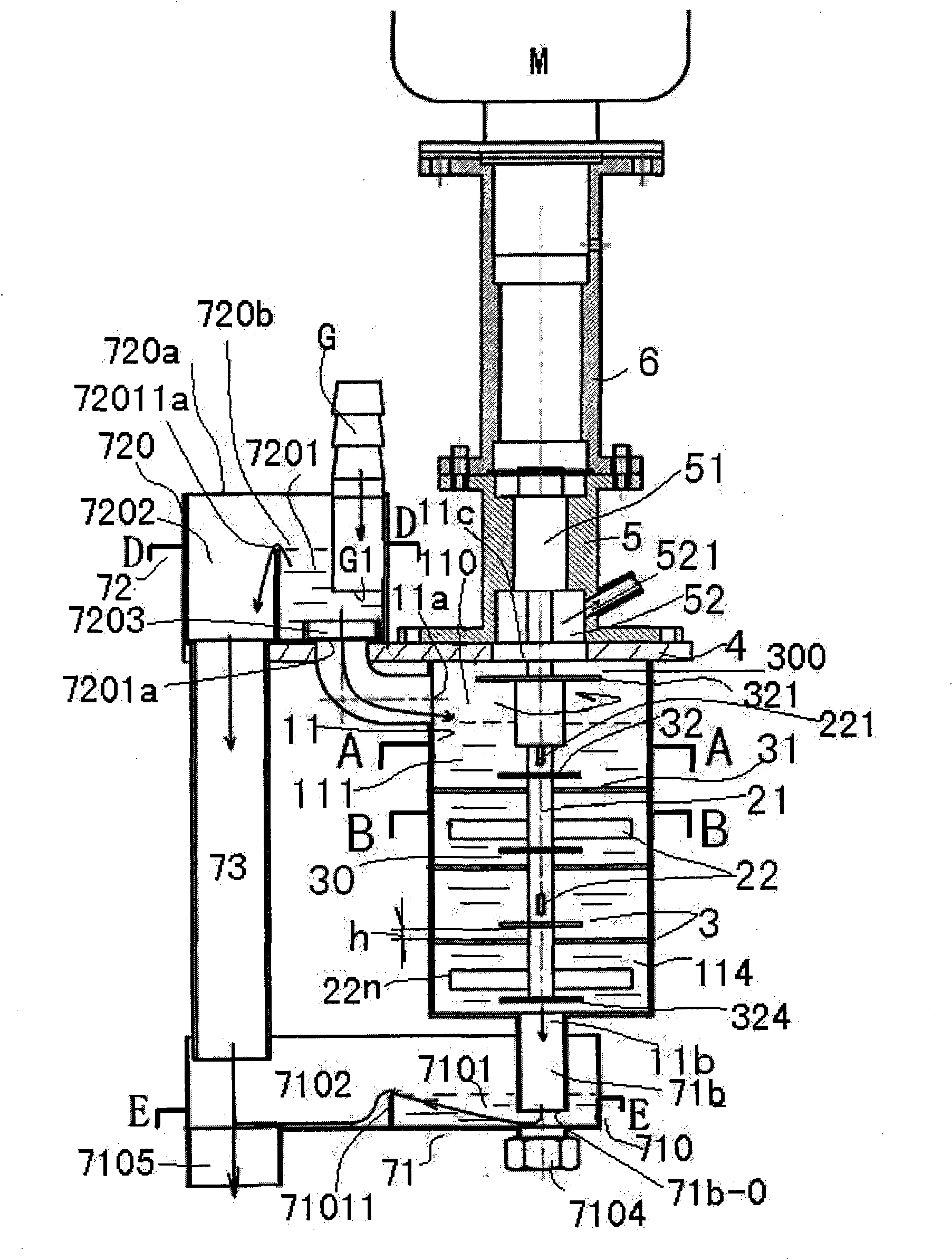

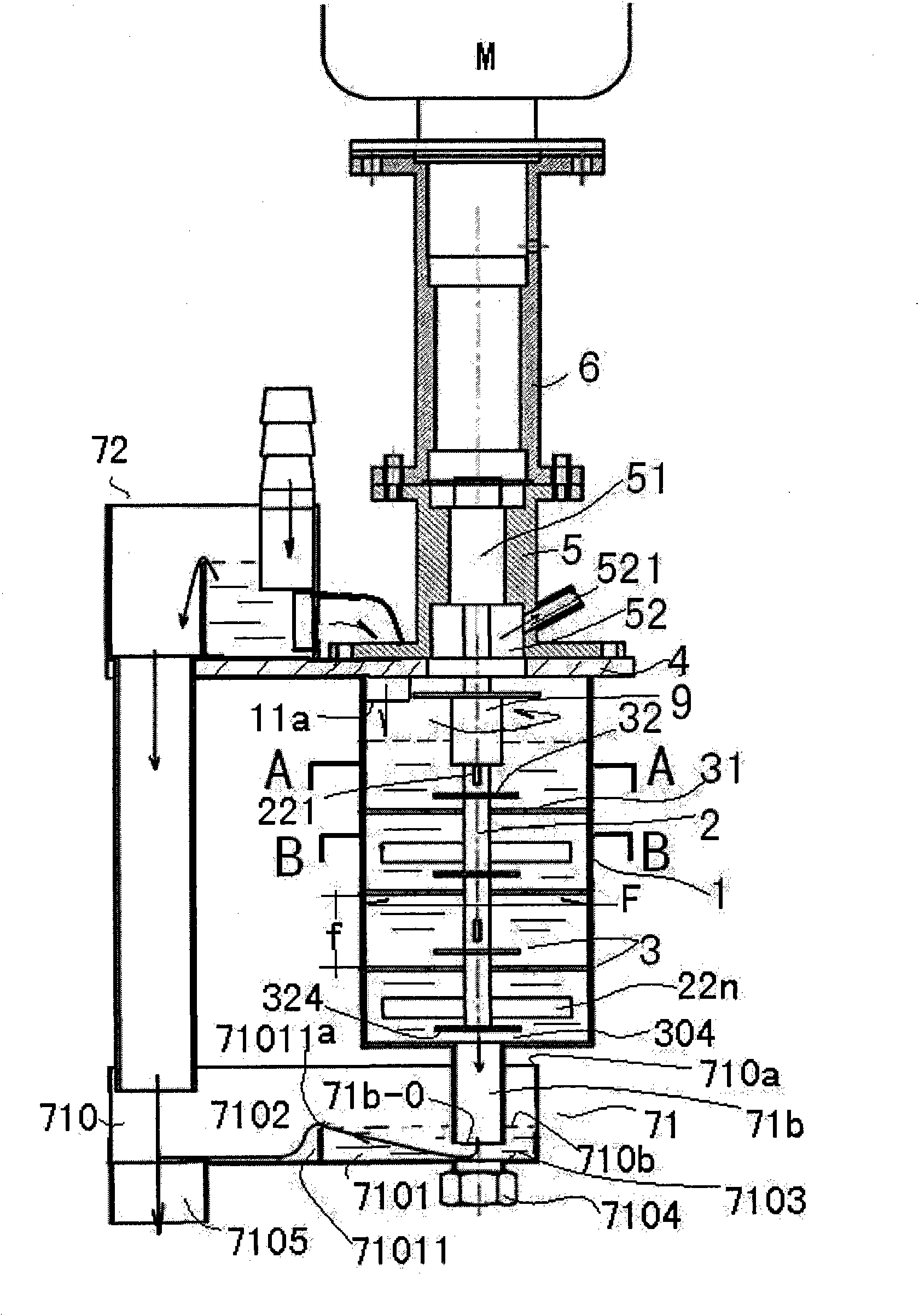

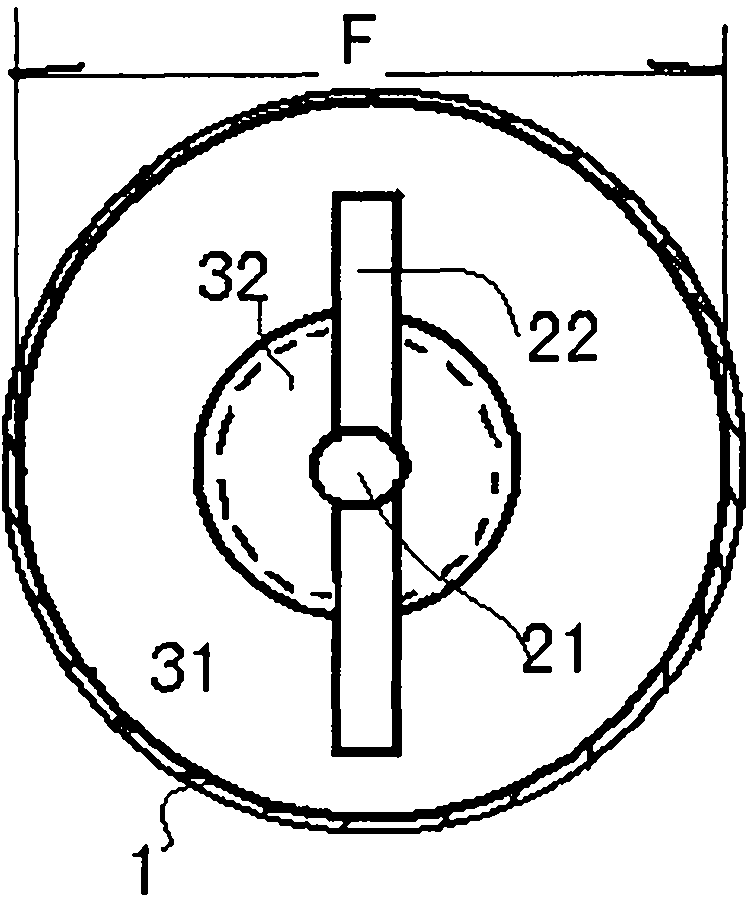

[0081] see Figure 1-7 As shown, a degassing device has a tank body 1 containing mud and a stirring body 2 that can extend into the tank body and be driven by a power source M. The power source includes but is not limited to a motor, and the stirring body is used for Extend into the tank body to stir the mud; the tank body has a mud inlet and a mud outlet, wherein,

[0082] see figure 1 , the tank body is fixed by the mounting plate 4, the motor M is installed above the mounting plate 4, the motor drive shaft transmits the power to the central shaft 21 of the stirring body through the coupling 6, and the couplin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com