Launder-type on-line degassing device

The technology of flow trough and column is applied in the field of flow trough type on-line degassing device, which can solve the problems of unsatisfactory degassing effect, low degassing rate of purified gas, poor structure of aluminum liquid flow, etc., achieving simple structure and improving efficiency. , good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

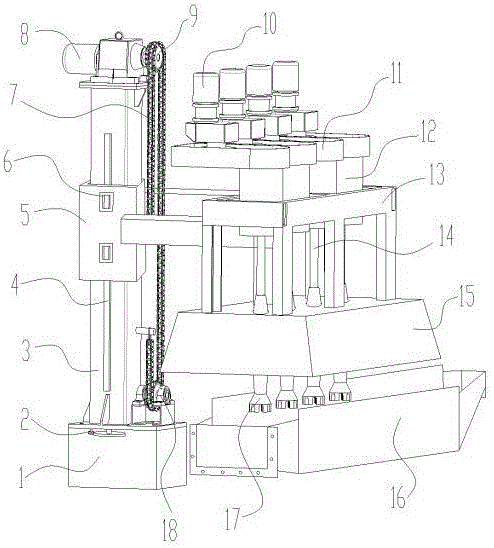

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] The present invention provides a specific embodiment of a trough-type online degassing device, which includes a base 1, a rotary drive device 2, a column 3, a guide rail 4, a guide sleeve 5, a roller 6, a chain 7, and a lifting motor 8. Double row sprocket 9, rotating motor 10, transition connection plate 11, bearing sleeve 12, steel frame 13, hollow shaft 14, launder cover 15, launder 16, rotor part 17, lower bearing seat 18.

[0024] Described launder cover 15 is a heat preservation cover that has 4 round holes, after being strengthened with rib plate inside the 5mm steel shell, make with the ceramic fiber plate of 1200 ℃ of high temperature resistance. A circle of No. 5 channel steel is arranged in the launder cover 15, and 5 circles of graphite packing are filled in the channel steel, so as to achieve sealing with the launder 16 when closed.

[0025] No. 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com