Method for analysis and on-line monitoring of vibration performance of band steel in continuous annealing unit furnace

A technology for continuous withdrawal of units and vibration characteristics, applied in vibration testing, furnaces, furnace types, etc., can solve problems such as inability to achieve timely monitoring, furnace rollers do not necessarily vibrate, and the effect is not good, to achieve a clear and clear method and principle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

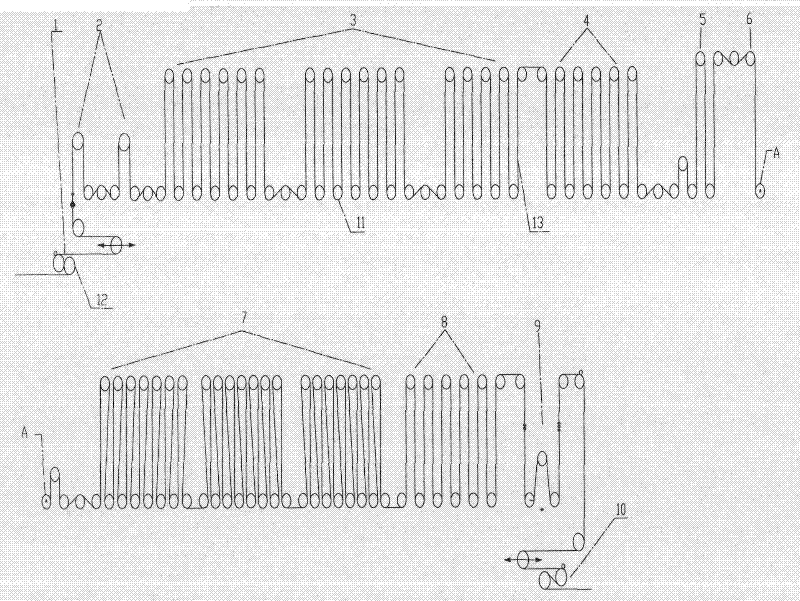

[0057] In order to illustrate the basic idea of the present invention, now take the quenching section as an example, and select the continuous annealing process of the strip steel whose incoming material grade is SPCC and whose specification is 0.8mm×1250mm as an example, by means of Figure 6 To describe the vibration characteristics analysis and on-line monitoring implementation process of the quenching section of the strip steel of a specific steel type and specification on a specific continuous annealing unit.

[0058] First, in step 1, the key equipment process parameters of the continuous annealing unit are collected, and the furnace roll diameters of each sub-process such as the preheating section, heating section, soaking section, slow cooling section, rapid cooling section, aging section, and final cooling section are obtained. 0.8m, the tension roller diameter of the entrance tension roller group and the exit tension roller group is 1.3m;

[0059] Subsequently, in ...

Embodiment 2

[0074] In order to further illustrate the basic idea of the present invention, taking the soaking section as an example, the continuous annealing process of strip steel whose incoming material grade is selected as DC04 and whose specification is 0.7mm×1000mm is taken as an example. Figure 10 To describe the vibration characteristics analysis and on-line monitoring implementation process of the soaking section of a strip steel of a specific steel type and specification on a specific continuous annealing unit.

[0075]First, in step 1, the key equipment process parameters of the continuous annealing unit are collected, and the furnace roll diameters of each sub-process such as the preheating section, heating section, soaking section, slow cooling section, rapid cooling section, aging section, and final cooling section are obtained. 0.8m, the tension roller diameter of the entrance tension roller group and the exit tension roller group is 1.3m;

[0076] Subsequently, in step 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com