Method and device for pulsed eddy current testing weld seam

A pulsed eddy current and sensor technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as difficult implementation, threats to the human body, and reduced reliability, and achieve simple and easy operation of equipment, high detection efficiency, and high detection efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

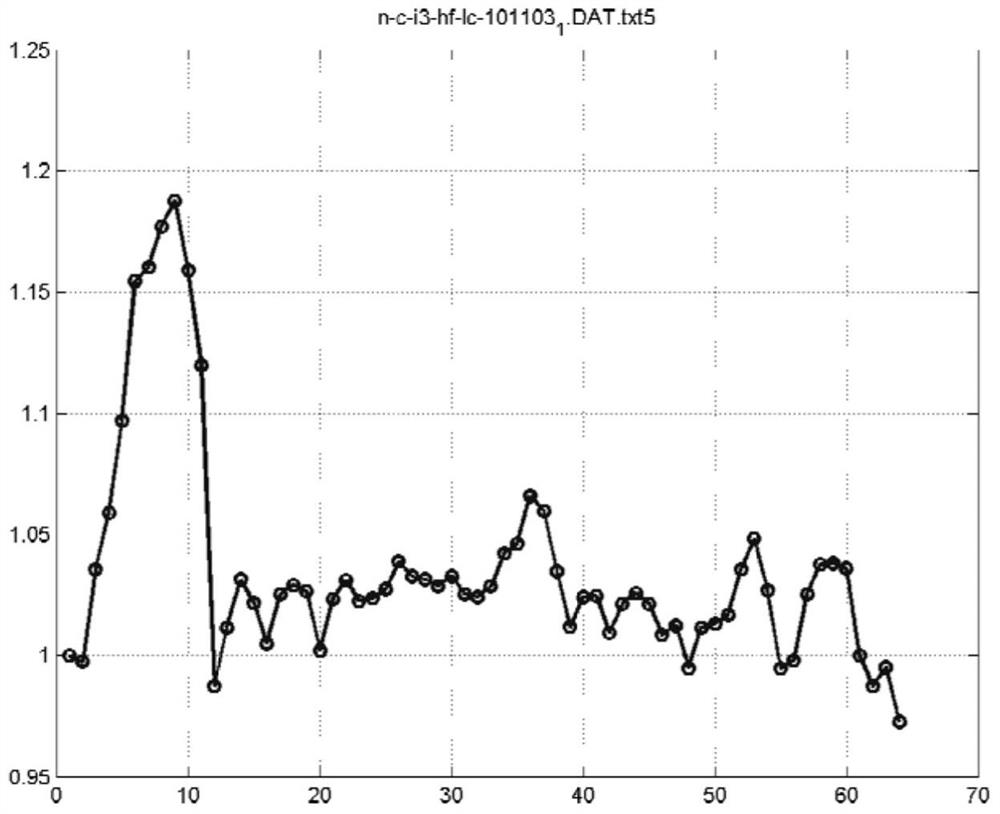

[0035] Ultrasonic test block with weld defects, weld width 2cm, the wall thickness of 11.0mm, 20 # steel, formed with cracks, incomplete penetration, porosity defects in three positions. Temperature room temperature detection section 0.80m, along the weld inspection. Detecting the following steps:

[0036] 1) selection of a diameter of 20mm, the number of turns of the sensor 200 × 500.

[0037] 2) The region directly above the sensor line is set by the test apparatus transmitting and receiving a control pulse eddy PDA, 1Hz square wave to select a transmission signal detection.

[0038] 3) Select an arbitrary position of the line segment, ultrasonic thickness measurement, the thickness values detected record. To take the sensor detecting the position of the pulsed eddy current, the ultrasonic wave value input PAD value, the calibration factor is obtained.

[0039] 4) start the detection mode, the sensor will move slowly along the line region to be diagnosed until the end of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com