Method for removing hydrogen sulfide of food-grade phosphoric acid

A hydrogen sulfide, food-grade technology, applied in the field of phosphorus chemical technology and environmental protection, to achieve the effect of improving degassing efficiency, production continuity and shortening cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

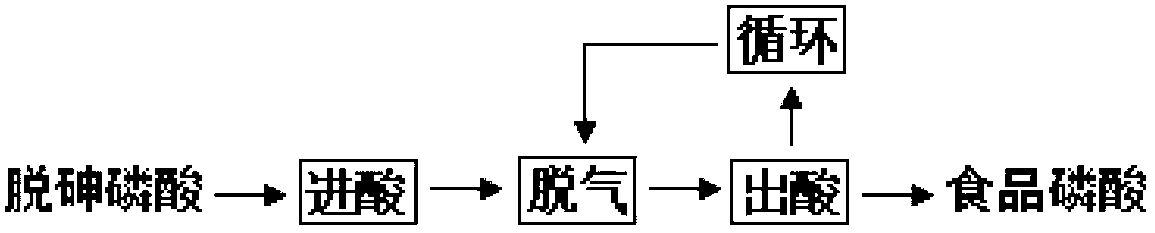

Image

Examples

Embodiment 1

[0028] First pump the top of the hydrogen sulfide removal tower to form a negative pressure, then inject the phosphoric acid after dearsenization into the acid collection tank from the acid inlet to the liquid level of 1 / 2 of the volume of the acid collection tank, heat and maintain the temperature at 80°C , turn on the circulating pump to transport the dearsenized phosphoric acid to the top of the hydrogen sulfide removal tower, spray evenly through the spray head, flow through the packing layer, and fully contact with the clean air rising from the bottom of the tower, the hydrogen sulfide in the phosphoric acid It is blown off from the top of the tower and enters the arsenic removal reactor. Phosphoric acid for hydrogen sulfide removal enters the acid collection tank from the bottom of the tower, and is transported to the top of the tower by a circulating pump to continue removing hydrogen sulfide or to the finished product tank to obtain food-grade phosphoric acid, depending...

Embodiment 2

[0030] First pump the top of the hydrogen sulfide removal tower to form a negative pressure, then inject the phosphoric acid after dearsenization into the acid collection tank from the acid inlet to the liquid level of 2 / 3 of the volume of the acid collection tank, heat and maintain the temperature at 90°C , turn on the circulating pump to transport the dearsenized phosphoric acid to the top of the hydrogen sulfide removal tower, spray evenly through the spray head, flow through the packing layer, and fully contact with the clean air rising from the bottom of the tower, the hydrogen sulfide in the phosphoric acid It is blown off from the top of the tower and enters the arsenic removal reactor. Phosphoric acid for hydrogen sulfide removal enters the acid collection tank from the bottom of the tower, and is transported to the top of the tower by a circulating pump to continue removing hydrogen sulfide or to the finished product tank to obtain food-grade phosphoric acid, depending...

Embodiment 3

[0032] First pump the top of the hydrogen sulfide removal tower to form a negative pressure, then inject the phosphoric acid after dearsenization into the acid collection tank from the acid inlet to the liquid level of 3 / 5 of the volume of the acid collection tank, heat and maintain the temperature at 70°C , turn on the circulating pump to transport the dearsenized phosphoric acid to the top of the hydrogen sulfide removal tower, spray evenly through the spray head, flow through the packing layer, and fully contact with the clean air rising from the bottom of the tower, the hydrogen sulfide in the phosphoric acid It is blown off from the top of the tower and enters the arsenic removal reactor. Phosphoric acid for hydrogen sulfide removal enters the acid collection tank from the bottom of the tower, and is transported to the top of the tower by a circulating pump to continue removing hydrogen sulfide or to the finished product tank to obtain food-grade phosphoric acid, depending...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com