Automatic volume displaced type vacuum degasser for transformer oil

A vacuum degassing device, transformer oil technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of long time-consuming, time-consuming, low efficiency, etc., to improve work efficiency, shorten work time, and improve service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

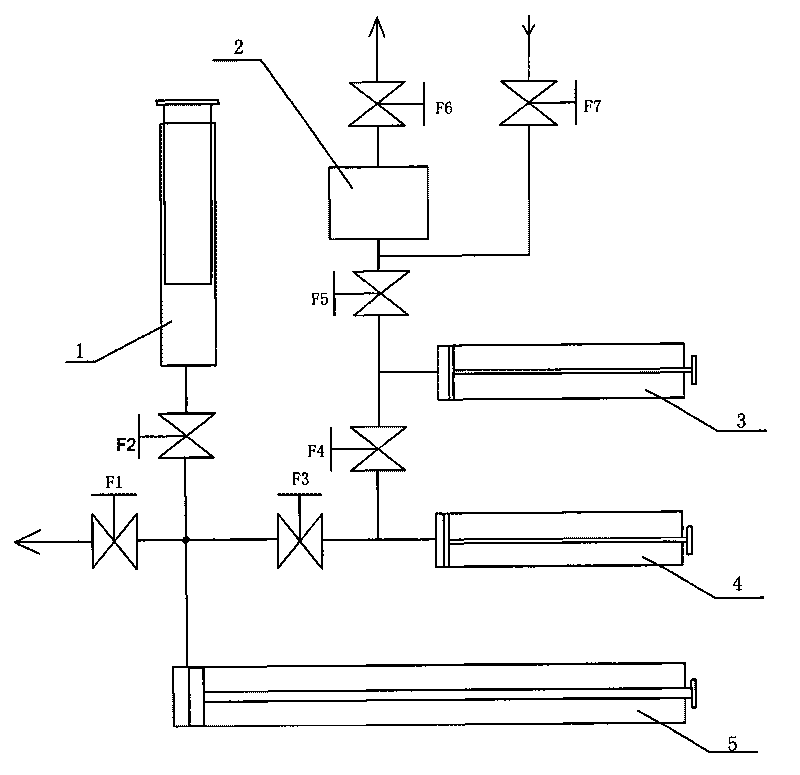

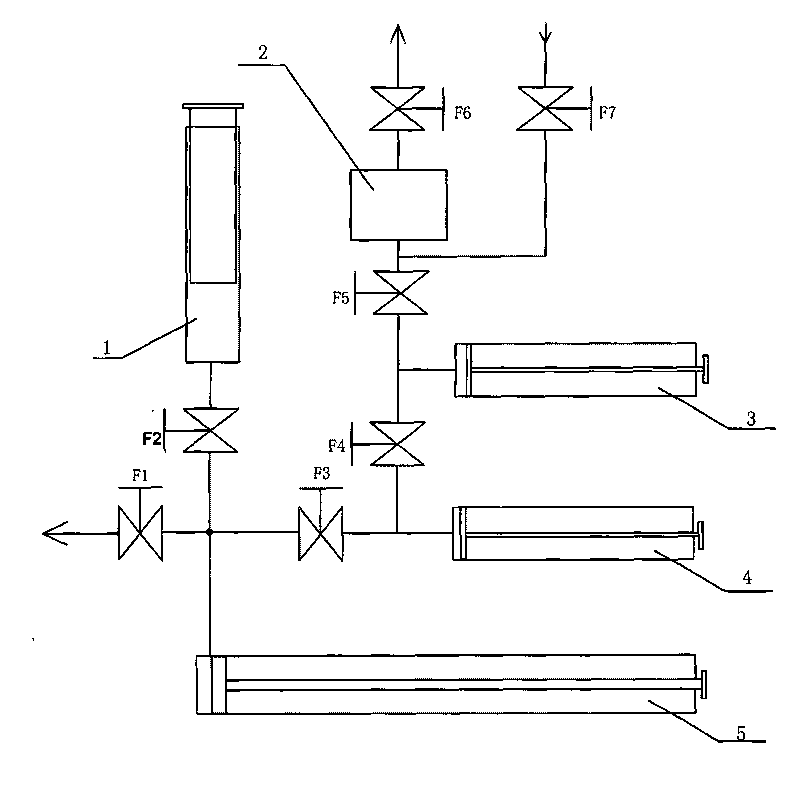

[0010] exist figure 1 In the embodiment, the outlet of the sample oil sampler 1 is respectively connected to the oil sample degassing cylinder 5, the oil discharge valve F1 and the third solenoid valve F3 through the pipeline provided with the second solenoid valve F2, and the other part of the third solenoid valve F3 One end is respectively connected to the gas exchange cylinder 4 and the fourth solenoid valve F4, the other end of the fourth solenoid valve F4 is respectively connected to the gas transfer cylinder 3 and the fifth solenoid valve F5, and the other end of the fifth solenoid valve F5 is respectively connected to the sample gas metering tube 2 And the seventh solenoid valve F7, the other end of the seventh solenoid valve F7 communicates with the carrier gas, and the outlet of the sample gas measuring tube 2 is provided with a sixth solenoid valve F6. The outlet port 2 of the oil discharge valve F1 can be connected to a container for holding waste oil. After the sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com