Ventilating air-eliminating refining method of 3104 aluminum alloy flat ingot in casting furnace

A casting furnace and aluminum alloy technology, which is applied in the field of smelting degassing and slag removal, can solve the problems of long blowing time, high labor intensity, and many casting defects, and achieve the goals of reducing the formation of residues, increasing labor intensity, and reducing labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

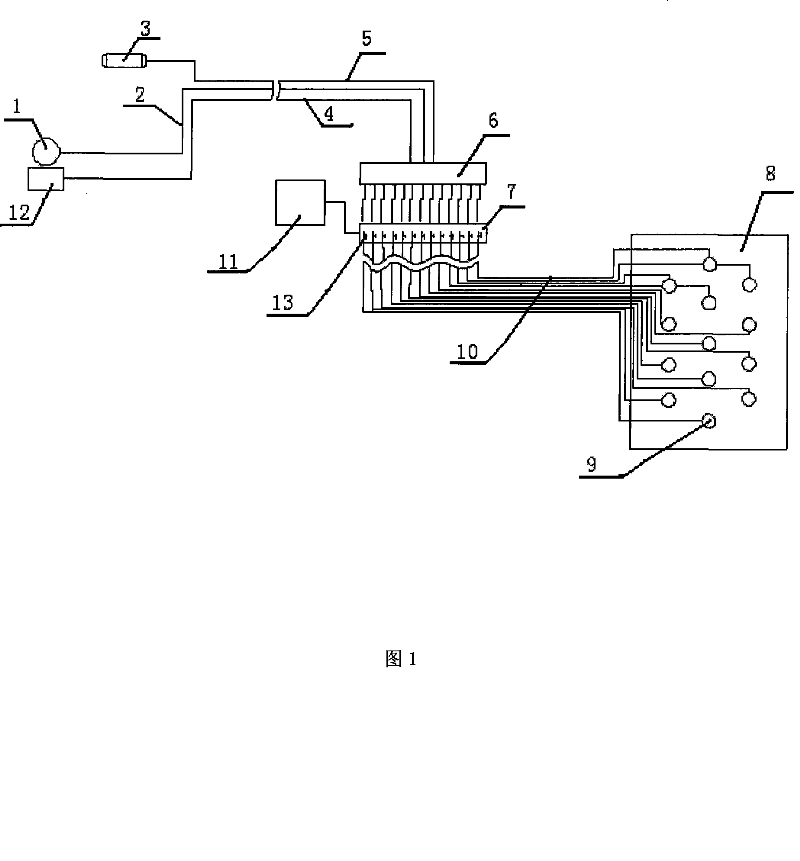

[0016] The method for refining 3104 aluminum alloy flat ingot casting furnace by ventilation, degassing and slag removal comprises a tiltable holding furnace 8, 13 ventilation bricks built on the furnace bottom refractory material structure 9, and 13 ventilation pipes are arranged at the furnace bottom Road 10 constitutes, and the distribution of the 13 ventilation bricks at the bottom of the tilting holding furnace 8 is shown in Figure 1, which is divided into 3 rows and distributed in a staggered manner; the 13 ventilation pipes at the outlet of the gas flow control cabinet 7 have 10 ends Parts are respectively provided with manual regulating valves 13; the described refining method of ventilating degassing and slag removal is through the ventilation pipeline 10 provided under 13 ventilating bricks 9 at the bottom of the furnace, which is controlled by the SIEMENS PLC system through the gas flow control cabinet 7 to the holding furnace 8 Nitrogen was passed through for degass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com