Degassing and dehydrating miniature device for transformer oil

A technology for transformer oil and small devices, applied in measuring devices, instruments, measuring electrical variables, etc., can solve problems such as poor circulation of transformer oil, difficulty in sampling work, affecting the degassing and dehydration effect of transformer oil, etc., and shorten the working time , fast degassing speed, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

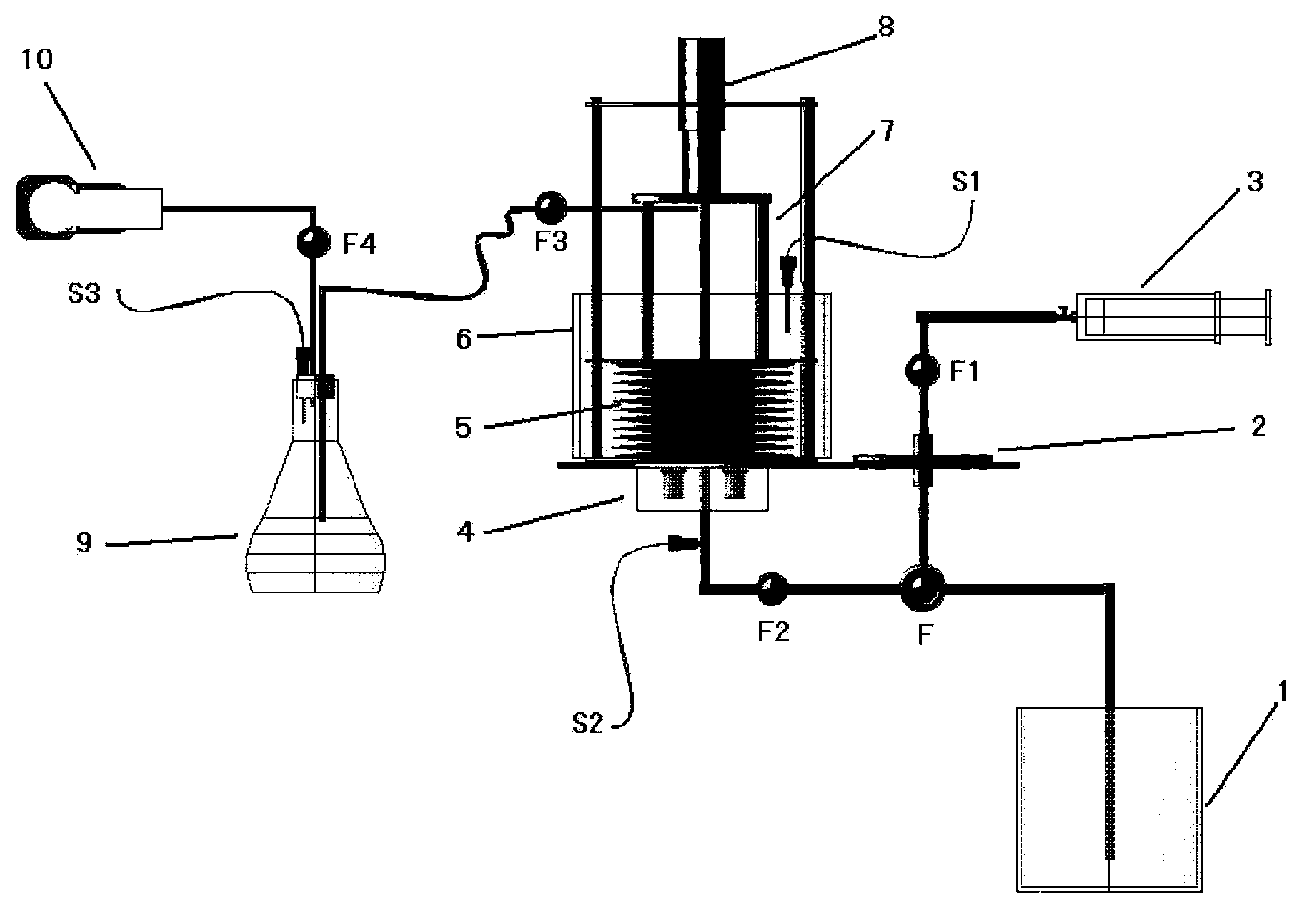

[0014] The small-sized device for degassing and dehydrating transformer oil according to the present invention includes an oil storage tank 1, a membrane filter 2, a sampler 3, an ultrasonic vibrator 4, a telescopic degassing tank 5, an air bath 6, a connecting rod 7, Electric reciprocating thruster 8, vacuum buffer tank 9, vacuum pump 10, temperature sensor S1, pressure sensor S2, vacuum pressure sensor S3, three-way solenoid valve F, single-way solenoid valve AF1, single-way solenoid valve BF2, and single-way solenoid valve CF3 , single-way solenoid valve DF4; oil storage tank 1 is connected to telescopic degassing tank 5 through three-way solenoid valve F and single-way solenoid valve BF2, and telescopic degassing tank 5 is connected to vacuum buffer tank 9 through single-way solenoid valve CF3 , the vacuum buffer tank 9 is connected to the vacuum pump 10 through the one-way electromagnetic valve DF4, the sampler 3 is connected to the three-way electromagnetic valve F throug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com