Aluminum melt vacuum treatment system and method

A technology for vacuum treatment and aluminum melt, applied in the field of aluminum melt vacuum treatment system, can solve problems such as weak stirring effect, and achieve the effect of enhancing overall movement, uniform stirring, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following describes several preferred embodiments of the present invention with reference to the accompanying drawings, so as to make the technical content clearer and easier to understand. The present invention can be embodied in many different forms of embodiments, and the protection scope of the present invention is not limited to the embodiments mentioned herein.

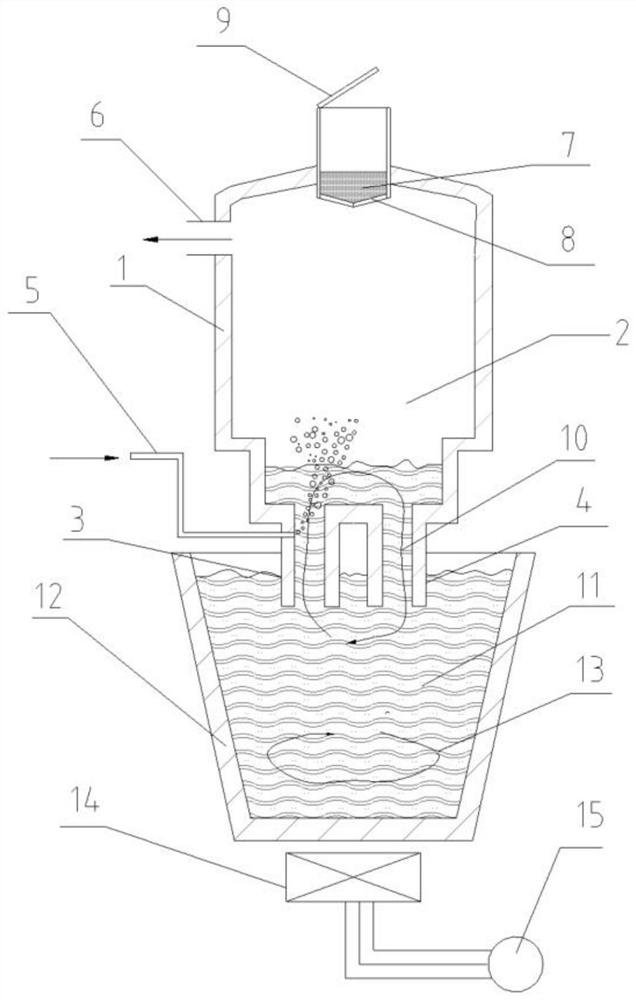

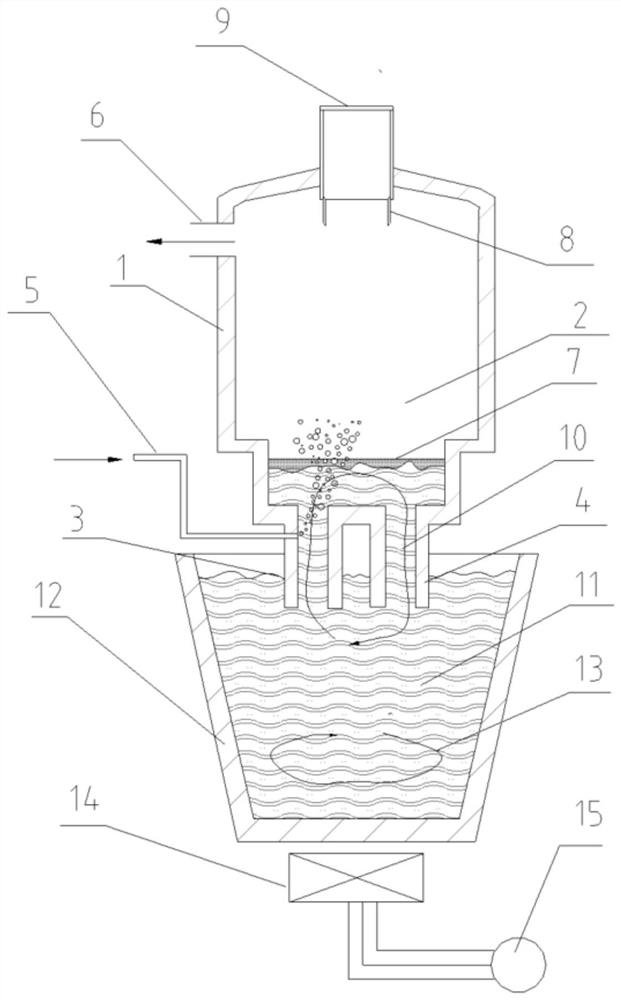

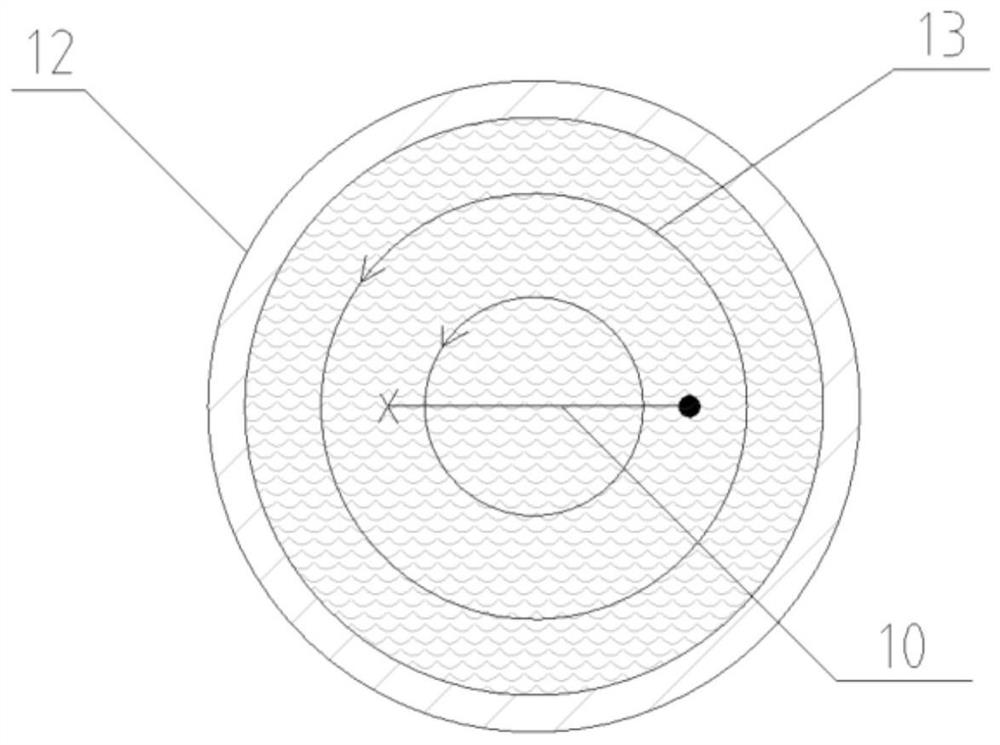

[0025] In some embodiments, the present invention provides a vacuum processing system for molten aluminum, including an aluminum melting furnace, a vacuum circulation degassing device, a permanent magnetic stirring device, and a raw material adding device (or a feeding device), wherein:

[0026] The vacuum cycle degassing device includes a vacuum chamber, the side wall of the vacuum chamber is provided with a suction port, the bottom of the vacuum chamber is provided with an ascending pipe (or a first passage) and a descending pipe (or a second passage), and the pipe wall of the ascending pipe There i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com