Electric resistor with lead wire and manufacturing method thereof

A manufacturing method and technology of resistors, applied in the direction of adding resistors at the lead-out end, manufacturing resistors, resistors, etc., can solve problems such as not being good enough, and achieve the effects of reducing the amount of gas generated and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

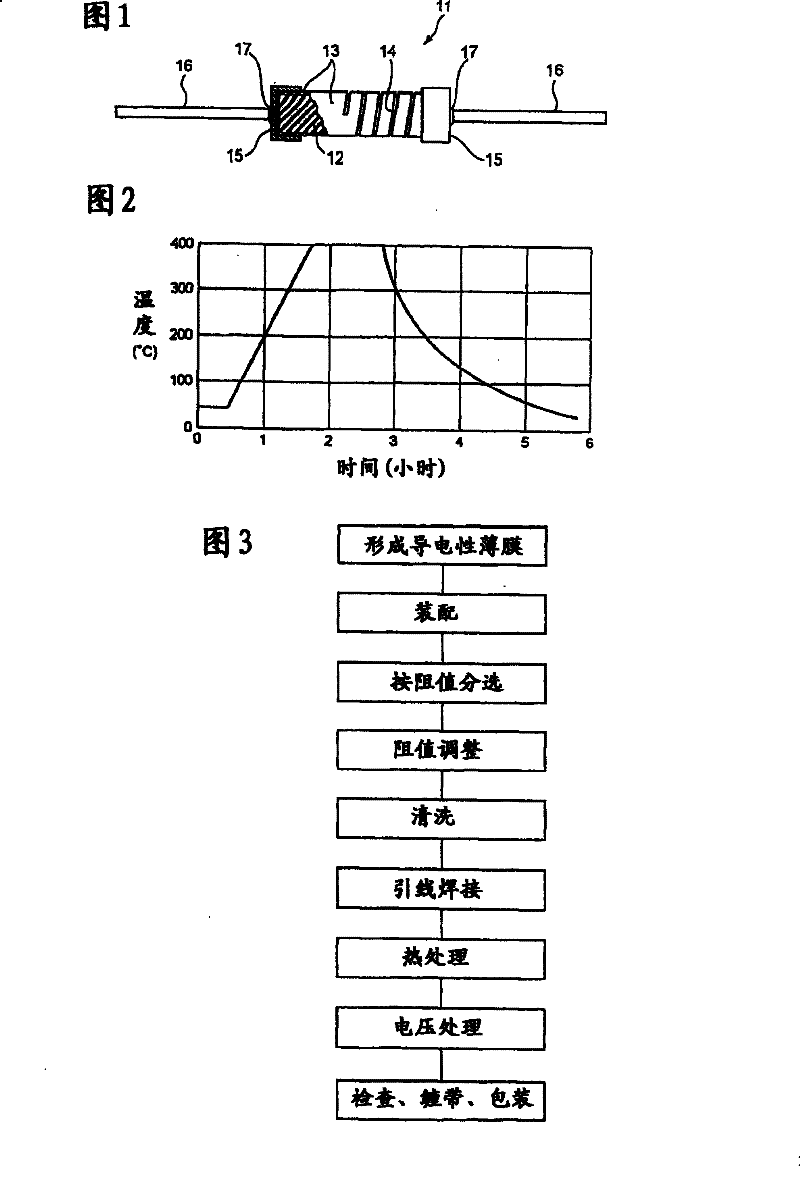

[0014] Embodiments of the present invention will be described in detail below with reference to the drawings. figure 1 One embodiment of the resistor with leads according to the present invention is shown.

[0015] In the resistor 11 with leads, a conductive thin film 13 made of carbon film is formed on the surface of a cylindrical ceramic base 12 . Cutting grooves 14 for finely adjusting the resistance value are provided on the conductive film 13 . Electrode caps 15 are embedded on both ends of the ceramic substrate 12 and are connected to the conductive film 13 . On the electrode cap 15 , a lead wire 16 is fixed by a welding portion 17 . Here, the electrode cap 15 is formed by forming a copper plating film and a nickel plating film on the surface of iron processed into a cap shape. In addition, the lead wire 16 has a copper plating film formed on the iron wire material.

[0016] As shown in the figure, the resistor 11 with leads does not have an overcoat insulating resin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com