Nichrome and carbon steel composite board as well as production method thereof

A technology of nickel-chromium alloy and production method, which is applied in the field of manufacturing and transporting corrosion-resistant oil and natural gas steel pipes, can solve the problems that carbon steel cannot meet the corrosion resistance requirements, and achieve the effect of improving the safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

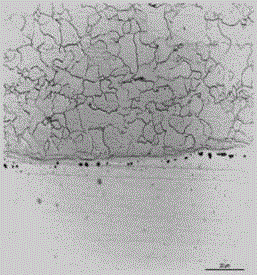

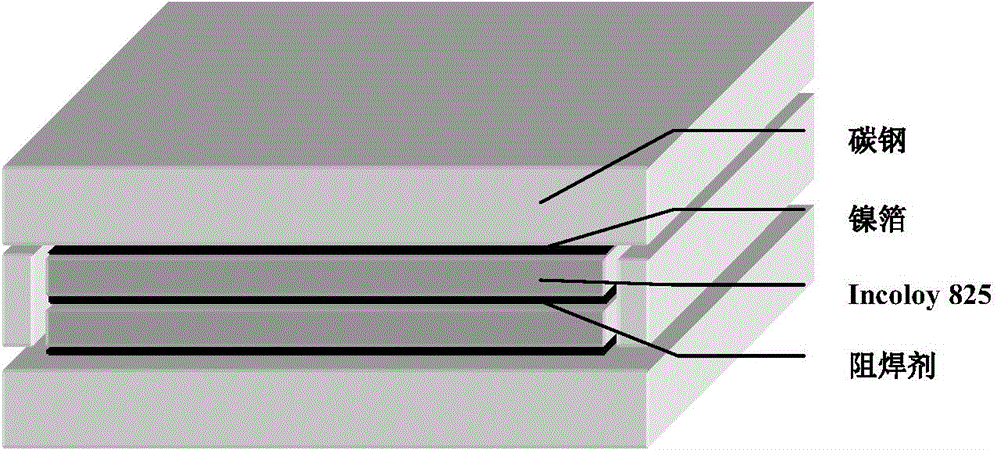

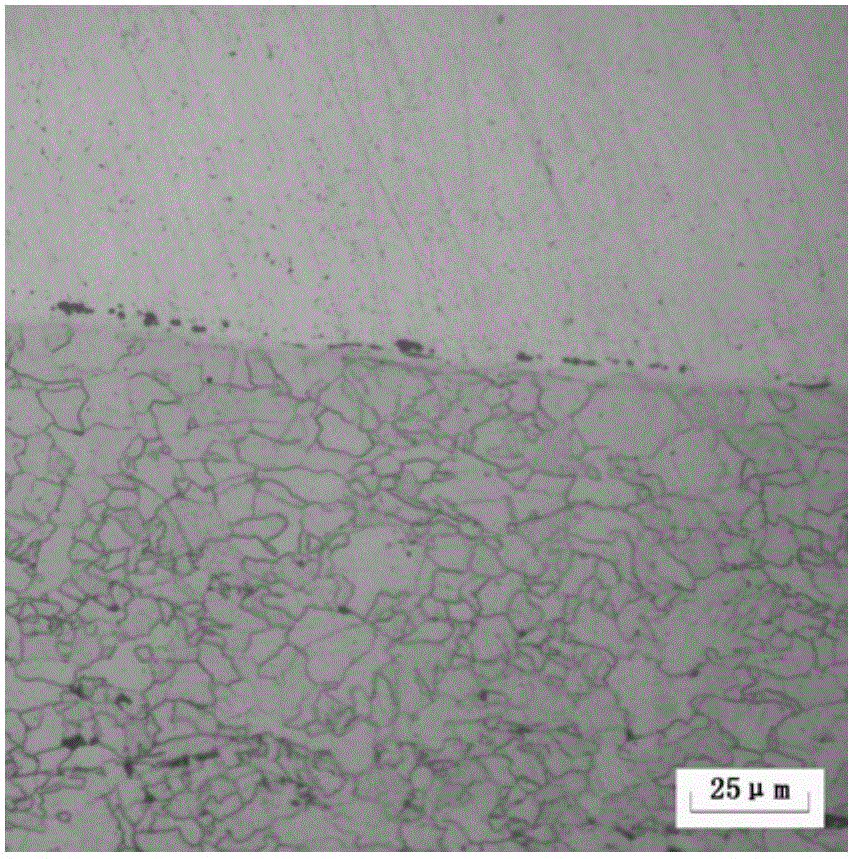

Image

Examples

Embodiment 1

[0018] The steel plate composition of the present invention: the base material X60MS meets the requirements of API5L "American Petroleum Pipeline Technical Specifications", and the weight percentages of the present invention are: C: 0.03-0.07%, Si: 0.01-0.40%, Mn: 1.00-1.40%, P : ≤0.015%, S: ≤0.003%, Alt: 0.01~0.06%, N: ≤0.006%, H: ≤0.0002%, the balance is Fe and unavoidable impurity elements, the metallographic structure is composed of acicular ferrite composition. Nb, V, Ti, Cu, Ni, Cr microalloy strengthening elements can also be added, Nb+V+Ti≤0.15%; Cu: 0.00-0.30%, Ni: 0.00-0.20%, Cr: 0.00-0.30% 1 to 3 species. The rest are Fe and inevitable impurity elements, and the metallographic structure is composed of acicular ferrite. Multilayer Incoloy 825 nickel-chromium alloy composition C≤0.05%, 19.5≤Cr≤23.5%, 38.0≤Ni≤46.0%, Si≤0.50%, Mn≤1.0%, 0.60≤Ni≤1.20%, and also contains Cu, Mo , Fe and other alloying elements to increase corrosion resistance.

[0019] The steel plate ...

Embodiment 2

[0028] The steel plate composition of the present invention: the base material X60MS meets the requirements of API5L "American Petroleum Pipeline Technical Specifications", and the weight percentages of the present invention are: C: 0.03-0.07%, Si: 0.01-0.40%, Mn: 1.00-1.40%, P : ≤0.015%, S: ≤0.003%, Alt: 0.01~0.06%, N: ≤0.006%, H: ≤0.0002%, the balance is Fe and unavoidable impurity elements, the metallographic structure is composed of acicular ferrite composition. Nb, V, Ti, Cu, Ni, Cr microalloy strengthening elements can also be added, Nb+V+Ti≤0.15%; Cu: 0.00-0.30%, Ni: 0.00-0.20%, Cr: 0.00-0.30% 1 to 3 species. The rest are Fe and inevitable impurity elements, and the metallographic structure is composed of acicular ferrite. Multilayer Incoloy 825 nickel-chromium alloy composition C≤0.05%, 19.5≤Cr≤23.5%, 38.0≤Ni≤46.0%, Si≤0.50%, Mn≤1.0%, 0.60≤Ni≤1.20%, and also contains Cu, Mo , Fe and other alloying elements to increase corrosion resistance.

[0029] The steel plate ...

Embodiment 3

[0038] The steel plate composition of the present invention: the base material X60MS meets the requirements of API5L "American Petroleum Pipeline Technical Specifications", and the weight percentages of the present invention are: C: 0.03-0.07%, Si: 0.01-0.40%, Mn: 1.00-1.40%, P : ≤0.015%, S: ≤0.003%, Alt: 0.01~0.06%, N: ≤0.006%, H: ≤0.0002%, the balance is Fe and unavoidable impurity elements, the metallographic structure is composed of acicular ferrite composition. Nb, V, Ti, Cu, Ni, Cr microalloy strengthening elements can also be added, Nb+V+Ti≤0.15%; Cu: 0.00-0.30%, Ni: 0.00-0.20%, Cr: 0.00-0.30% 1 to 3 species. The rest are Fe and inevitable impurity elements, and the metallographic structure is composed of acicular ferrite. Multilayer Incoloy 825 nickel-chromium alloy composition C≤0.05%, 19.5≤Cr≤23.5%, 38.0≤Ni≤46.0%, Si≤0.50%, Mn≤1.0%, 0.60≤Ni≤1.20%, and also contains Cu, Mo , Fe and other alloying elements to increase corrosion resistance.

[0039] The steel plate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com