Inner lining anti-corrosion metallic composite pipeline with easy welded joint structure

A metal composite pipe, corrosion-resistant metal technology, applied in the direction of pipes/pipe joints/fittings, pipeline protection, pipeline anti-corrosion/rust protection, etc., can solve the problems of difficult on-site welding, insufficient corrosion resistance, preferential corrosion, etc. Complete anti-corrosion performance, good corrosion resistance, the effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

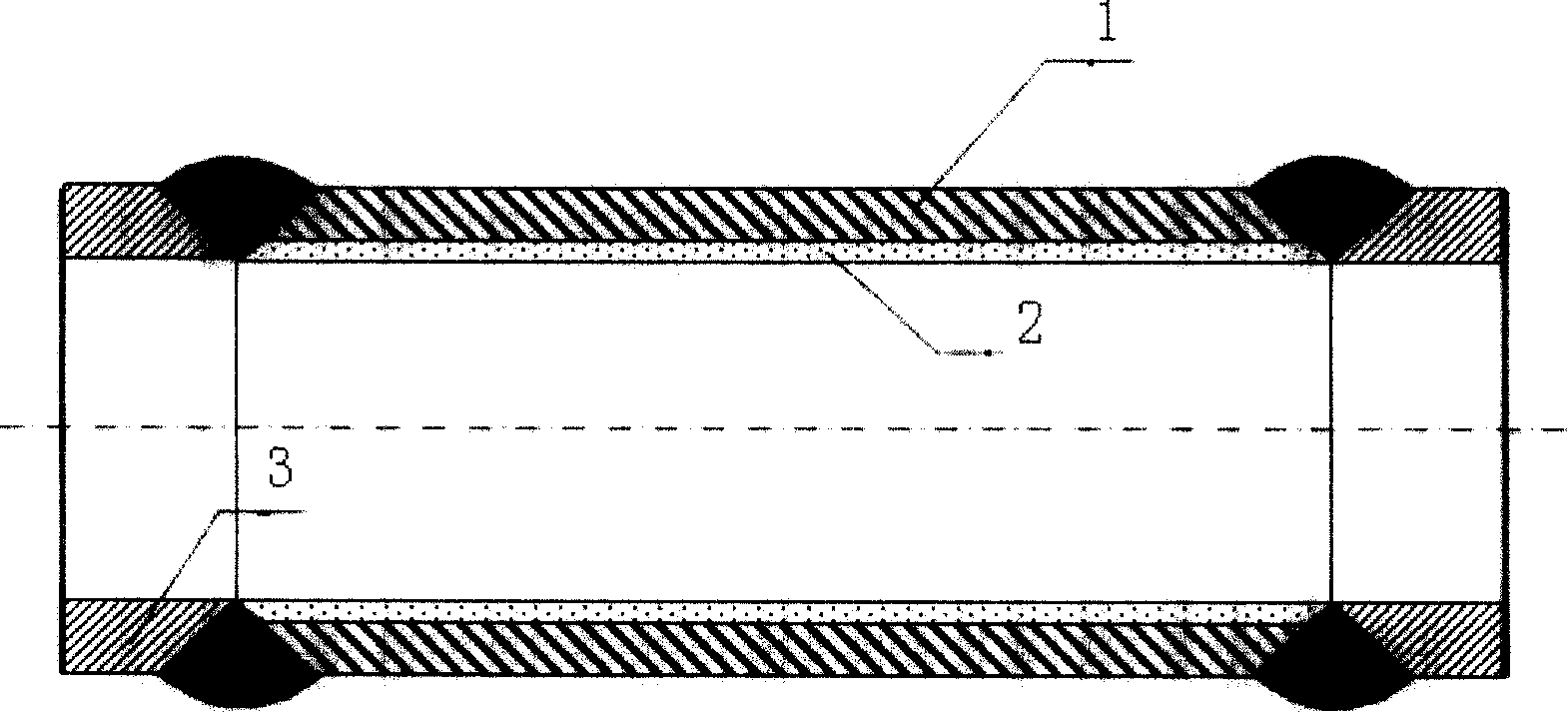

[0040] Embodiment 1 (structure one):

[0041](1) A seamless carbon steel pipe with a length of 2 meters and a specification of Φ325×7 mm is prepared. Use mechanical sandblasting equipment to sandblast the inside of the base tube, and then clean it with alcohol

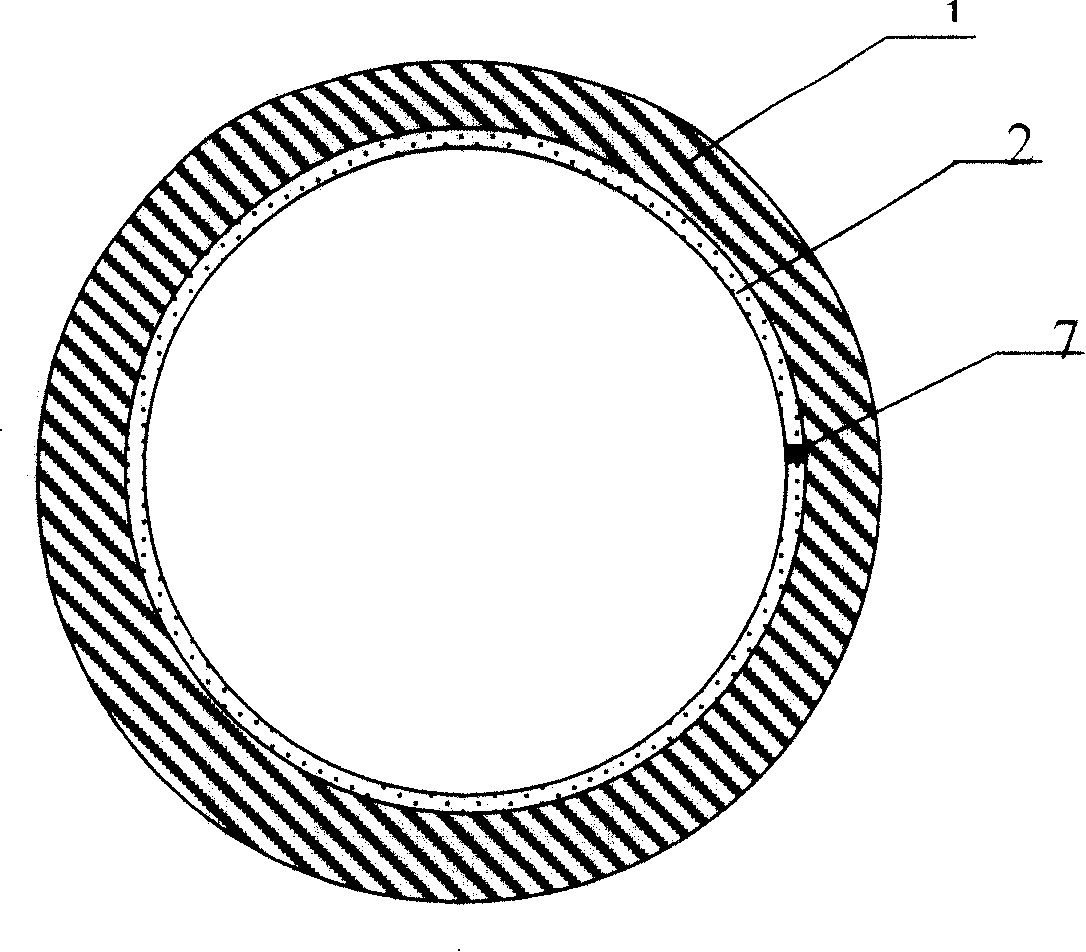

[0042] (2) Use a stainless steel plate with a thickness of 1mm to make a stainless steel welded pipe with a length of 2 meters and an outer diameter of Φ315mm on a pipe making machine. It is welded by argon tungsten arc welding, and the outer height of the weld is ground and smoothed.

[0043] (3) Put the lining pipe into the carbon steel pipe, and connect the inner stainless steel pipe and the outer carbon steel pipe as a whole by hydrostatic extrusion. After the connection is completed, use a cutting tool to cut the two ends of the composite pipe flat and polish the bevel, that is, the preparation of the intermediate pipe body of the composite pipe is completed.

[0044] (4) Two seamless stainless steel pipes with ...

Embodiment 2

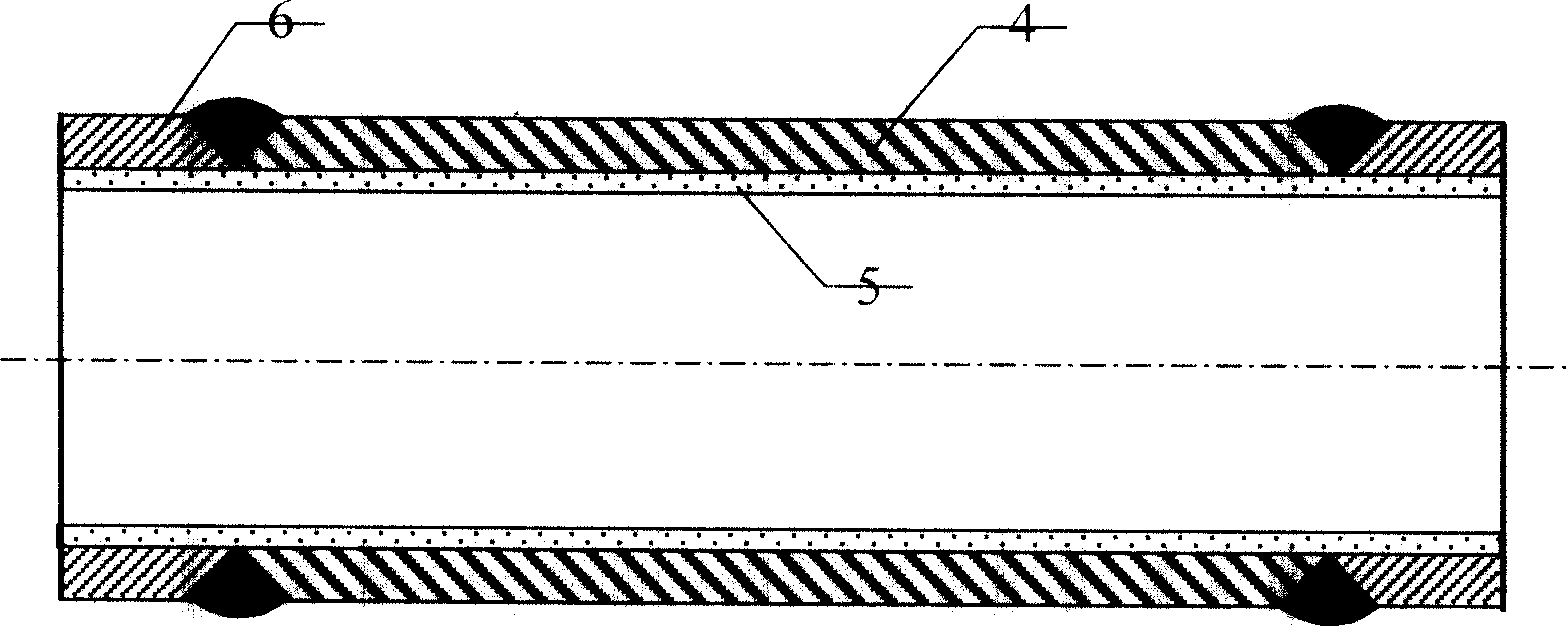

[0045] Embodiment 2 (structure two):

[0046] (1) Prepare a seamless carbon steel pipe with a length of 2 meters and a specification of Φ325×7mm, and prepare grooves at both ends of the pipe.

[0047] (2) Two seamless stainless steel pipes with a length of 0.2 meters and a specification of Φ325×7 mm were prepared, and their ends were beveled. Using a dissimilar metal welding method, respectively weld two sections of stainless steel pipes to both ends of the carbon steel pipe described in (1) to obtain a base pipe.

[0048] (3) Sandblasting equipment performs sandblasting treatment on the inside of the base tube, and after the treatment is completed, clean the inside of the tube with alcohol.

[0049] (4) Use a stainless steel plate with a thickness of 1mm to make a stainless steel welded pipe with a length of 2.4 meters and an outer diameter of Φ315mm on a pipe making machine. It is welded by argon tungsten arc welding, and the outer reinforcement of the weld is polished and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com