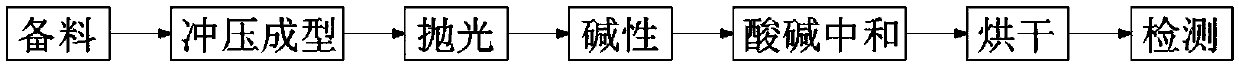

Production technology of lead frame with locating function

A lead frame and production technology technology, applied in the field of lead frame production technology, can solve the problems of poor corrosion resistance of the lead frame, poor surface cleanliness of the lead frame, unreasonable production process, etc., and achieve corrosion prevention, convenient positioning, and improved anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] S1. Material preparation: Select copper sheets with moderate thickness, softness and hardness according to requirements. The tensile strength of copper sheets is 411N / mm2, the elongation rate is 16%, the hardness is 130HV, the conductivity is 70S, the burr is 0.01, and the side bending is 0.5;

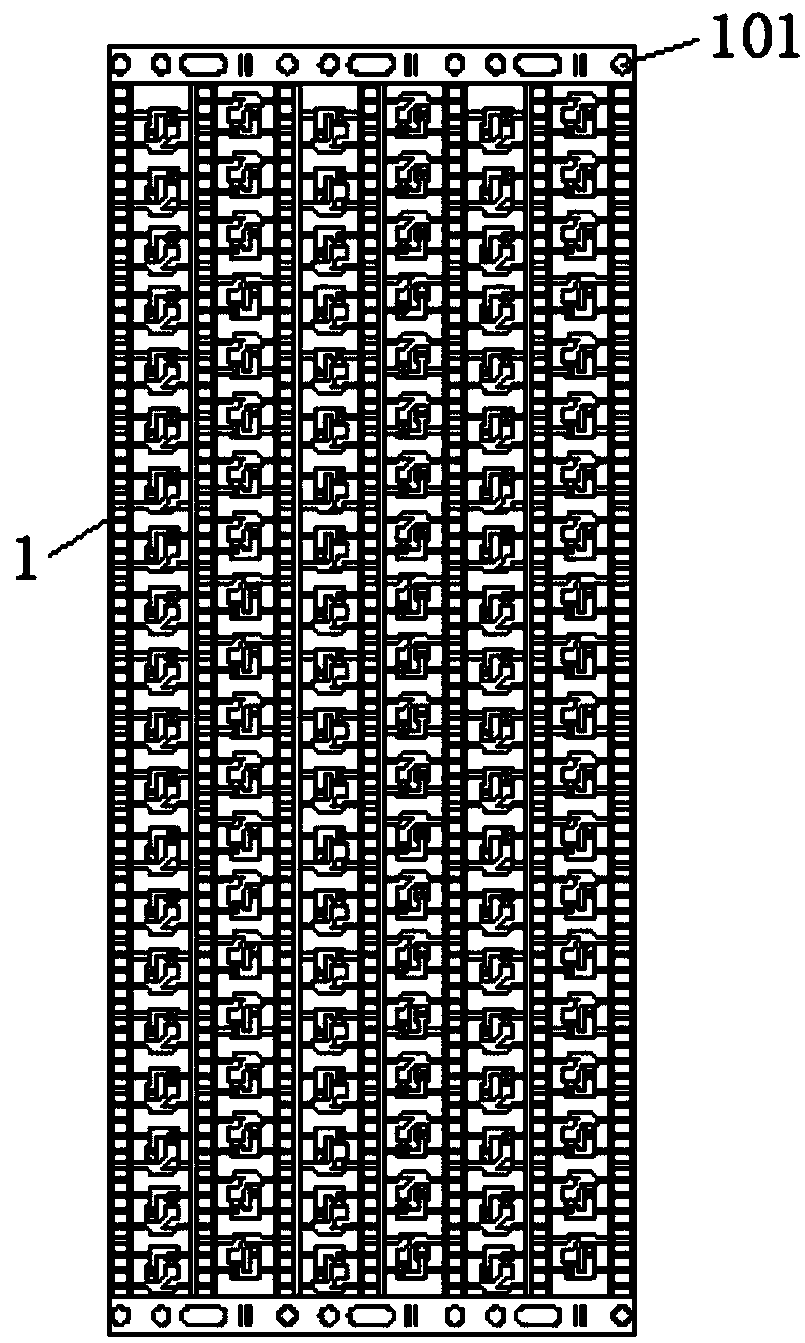

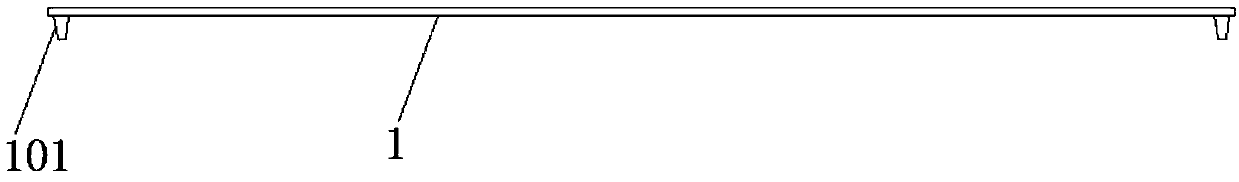

[0048] S2. Stamping and forming: put the copper sheet into the stamping die for stamping and forming to make a lead frame 1, which is the same as the traditional one, the difference is that four support tubes 101 are added to the four corners of the lead frame 1 to support The diameter of the tube 101 decreases gradually from top to bottom, and the bottom of the support tube 101 is provided with an annular seal;

[0049] S3. Polishing: grinding the surface of the lead frame 1 and each pin with sandpaper and a file to remove burrs;

[0050] S4. Alkali cleaning: put the polished lead frame 1 into an alkaline solution to remove oil, the alkaline solution is 30g / L sodium carbonate s...

Embodiment 2

[0055] A production process of a lead frame 1 with a positioning function, specifically comprising the following steps:

[0056] S1. Material preparation: Select copper sheets with moderate thickness, softness and hardness according to requirements. The tensile strength of copper sheets is 413N / mm2, the elongation rate is 16%, the hardness is 120HV, the conductivity is 70S, the burr is 0.01, and the side bending is 0.5;

[0057] S2. Stamping and forming: put the copper sheet into the stamping die for stamping and forming to make a lead frame 1, which is the same as the traditional one, the difference is that four support tubes 101 are added to the four corners of the lead frame 1 to support The diameter of the tube 101 decreases gradually from top to bottom, and the bottom of the support tube 101 is provided with an annular seal;

[0058] S3. Polishing: grinding the surface of the lead frame 1 and each pin with sandpaper and a file to remove burrs;

[0059] S4. Alkali cleaning:...

Embodiment 3

[0064] The difference from Example 1 is that the lead frame 1 must be sprayed with a corrosion-resistant layer, and the wear-resistant layer is prepared by the following method:

[0065] A production process of a lead frame 1 with a positioning function, specifically comprising the following steps:

[0066] Take the following raw materials and weigh them by weight: 6 parts of titanium dioxide, 4 parts of quartz powder, 2 parts of white pearl powder, 12 parts of talcum powder, 8 parts of polyvinyl alcohol, 10 parts of polyvinyl butyral, 6 parts of polyisocyanate, 8 parts of thickener, 14 parts of binder, 6 parts of defoamer, 80 parts of distilled water;

[0067] A, material preparation: first weigh the above-mentioned raw materials;

[0068] B. Alcohol mixing: first pour distilled water into the blender, then pour polyvinyl alcohol, polyvinyl butyral, polyisocyanate into the blender, stir and mix, control the speed of the blender at 60r / min , the temperature is at 45 degrees ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com