Positioning mechanism of edge covering assembly detector

A technology of positioning mechanism and assembly, applied in the direction of using mechanical device, mechanical measuring device, mechanical counter/curvature measurement, etc., can solve the problem of inability to know the offset of the assembly, and inability to ensure whether the hemming assembly is qualified or not.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

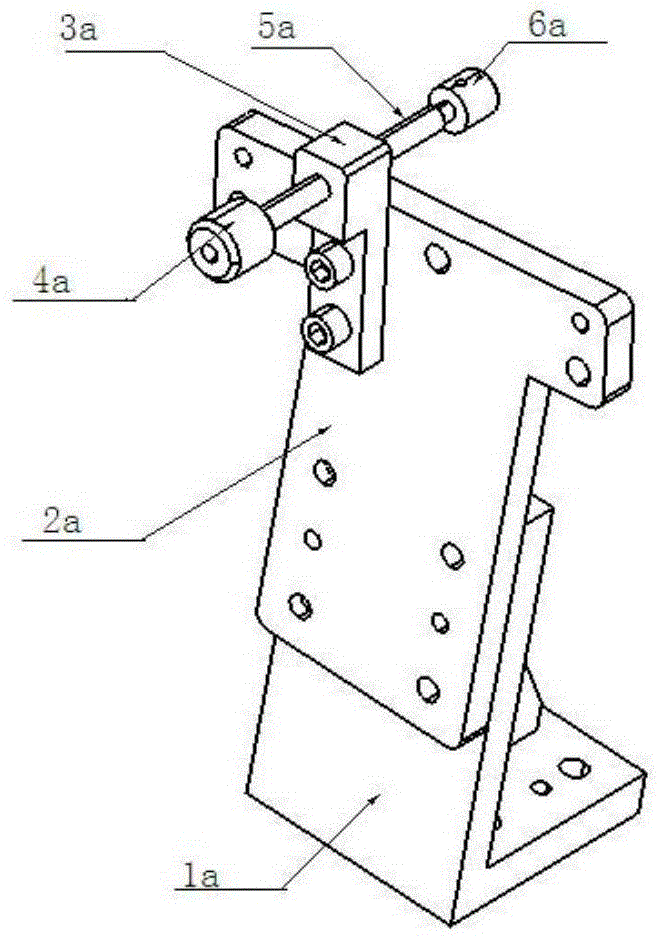

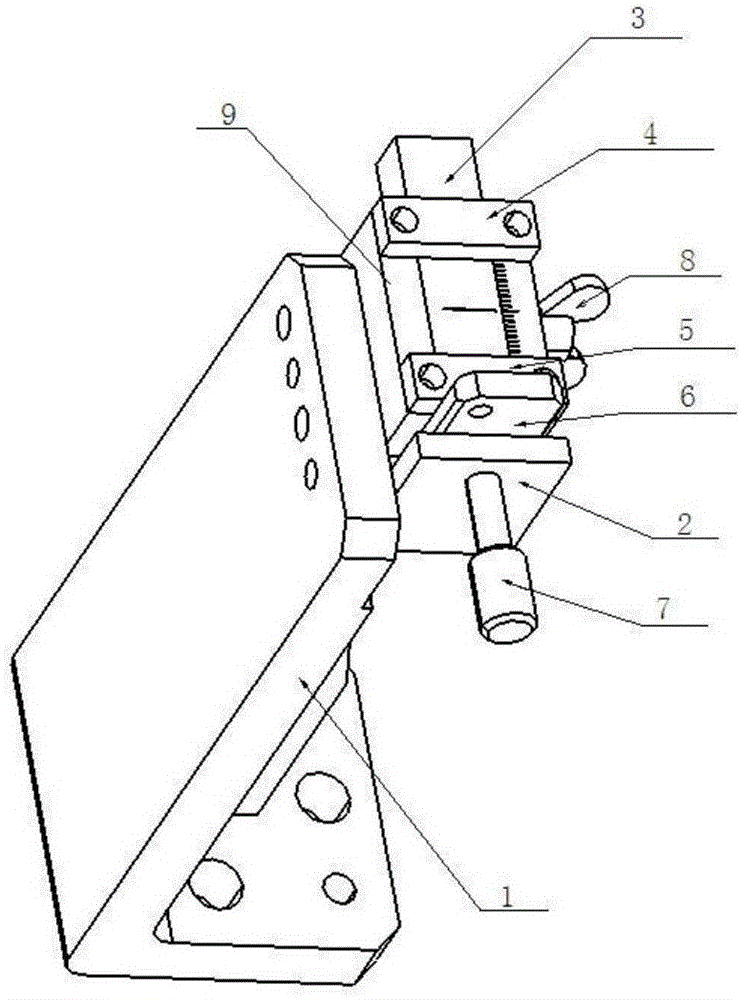

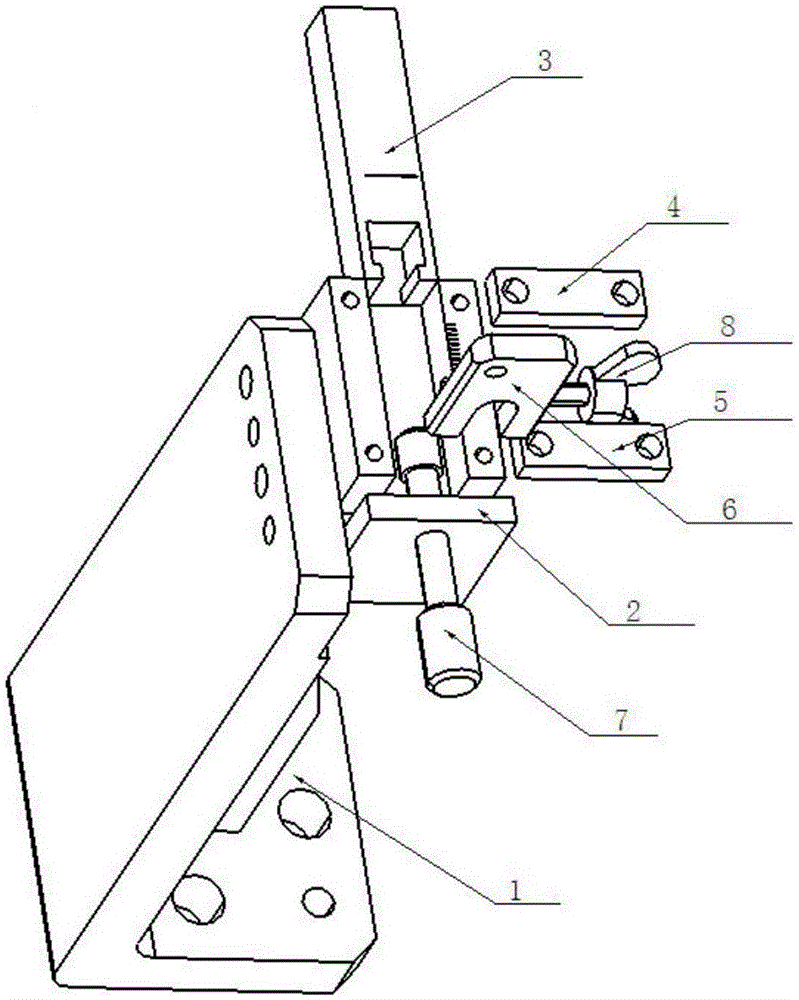

[0022] Such as Figure 2 to Figure 5 As shown, the positioning mechanism of a hemming assembly inspection tool provided by the present invention includes a support 1, a mounting block 9 disposed on the top side of the support 1, a positioning block 3 disposed in the mounting block 9 and a set A push rod 7 with a preset length at the front end of the positioning block 3; a U-shaped groove penetrating through the mounting block 9 is provided inside the mounting block 9, and a scale is provided on the top of the mounting block 9 along the edge of the U-shaped groove The positioning block is slidably installed in the U-shaped groove, and a scale line is provided at the preset position at the top of the positioning block; wherein, the front end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com