Two-step stainless steel smelting method

A smelting method and stainless steel technology, applied in furnace types, furnaces, electric furnaces, etc., can solve the problems of long smelting cycle and high smelting cost, and achieve the effects of reducing smelting cost, improving dephosphorization rate, and strong variety development ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

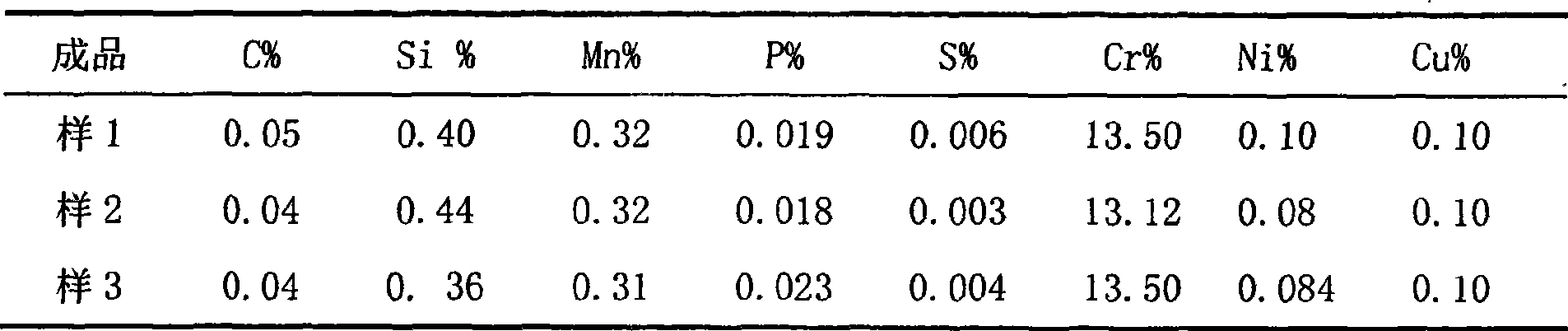

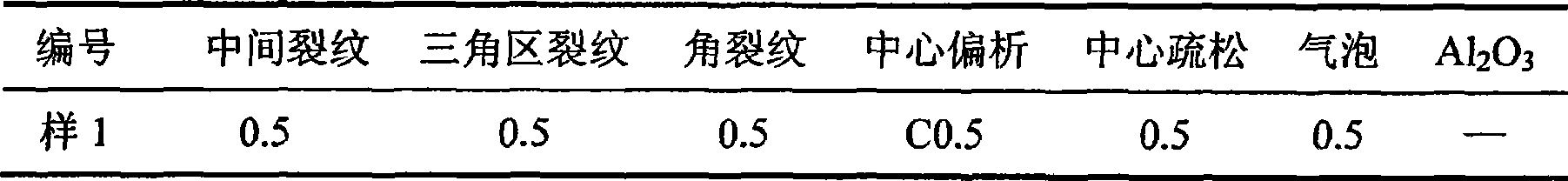

[0033] Implement this plan in our stainless steel factory to produce martensitic stainless steel (C≤0.05%, Si0.30-0.60%, Mn≤0.50%, P≤0.035%, S≤0.008%) of 06Cr13 (SUS410S), Cr13.0—13.5%, Ni≤0.20%, Cu0.08—0.1%) as an example, the process flow is dephosphorization molten iron → electric furnace → slag removal station → GOR → LF → continuous casting → finishing → qualified inspection → rolling . Include the following steps:

[0034] 1. Smelting of molten iron for dephosphorization: The molten iron for dephosphorization is smelted in a top-bottom combined blowing converter. During dephosphorization, the working oxygen pressure of top blowing is (0.70-0.85) MPa, and the basic gun position is 1000 mm. According to the furnace type and loading capacity, Properly adjust and carry out bottom blowing nitrogen throughout the whole process. Under the working pressure of 1.5MPa, the supply strength of bottom blowing will reach 0.12-0.2Nm 3 / t min, lime (60-70) kg / t, 1 / 2-2 / 3 of the total a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com