Composite powder coated by ultramicro or Nano metal powder, and preparation method

A technology of nanometer metal powder and composite powder, which is applied in coating and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] 1. Preparation of ultrafine or nanometer metal powder

[0028] Use known methods (including chemical crystallization or physical methods) to prepare ultrafine or nanometer metal powders or use commercially available products.

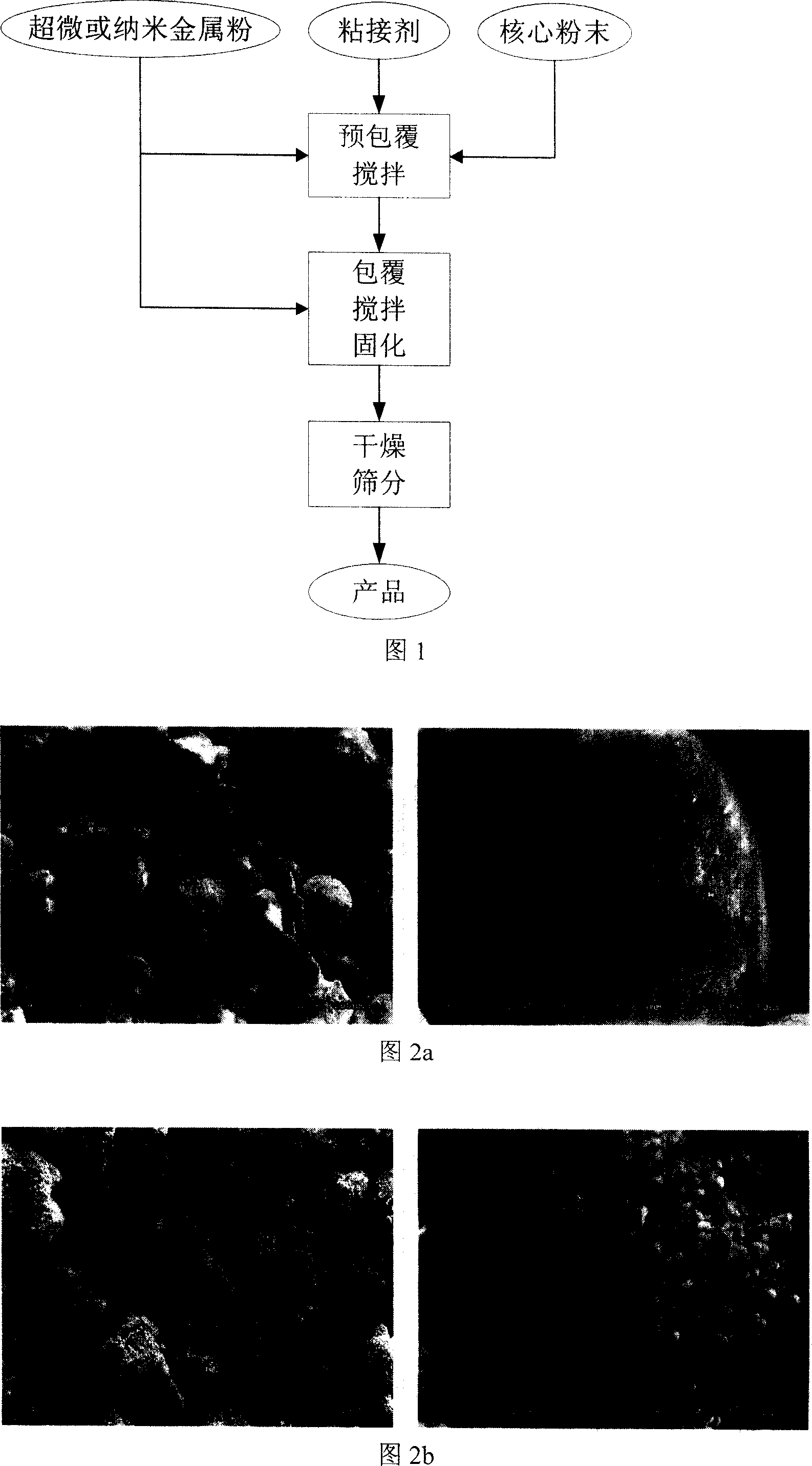

[0029] 2. Reunion coating process

[0030] The steps of the agglomeration coating process actually include: loading the core powder, adding a binder, adding a part of ultrafine or nanometer metal powder, pre-coating, stirring, adding the remaining ultrafine or nanometer metal powder, coating and stirring, Curing and drying, unloading. The coating process is carried out on a stirring device.

[0031] The particle size distribution of the core powder is controlled to be slightly finer than the final particle size requirement, while the average particle size of the ultrafine or nanometer metal powder can usually be adjusted in the range of 20-850nm.

[0032] In order to ensure the effect of coating and stirring, the charging amount should be cont...

Embodiment 1

[0035] Preparation of nano-aluminum clad nickel-chromium alloy composite powder. Prepare nano-aluminum powder according to a conventional method, and its average particle size is 50-150nm; and select nickel-chromium alloy powder with an average particle size of 20-120 μm: and weigh according to the following proportions, nano-aluminum powder 4wt%, bonding The agent is 5wt%, and the balance is nickel-chromium alloy. Use a stirring device to coat and stir, and proceed according to the following steps. First, put the above-mentioned weight of nickel-chromium alloy powder and 20% of nano-aluminum powder into the stirring device, then add the above-mentioned weight of binder, and start the stirring device Pre-coating and stirring are carried out, and then the remaining 80% of nano-aluminum powder is added for coating and stirring. Wherein, the total volume of the nickel-chromium alloy, the binder, and the nano-aluminum powder accounts for 50% of the volume of the stirring device. ...

Embodiment 2

[0046] Preparation of nano-aluminum coated tungsten carbide-iron chromium borosilicate composite powder. Prepare nano-aluminum powder according to the conventional method, and its average particle size is 50-150nm; and select tungsten carbide and iron-chromium-borosilicate powder with an average particle size of 45-200 μm: and weigh according to the following ratio, nano-aluminum powder 8wt %, the binder is 6wt%, and the balance is a 1:1 mixed powder of tungsten carbide and iron chromium borosilicate. Use a stirring device for coating and stirring, and proceed according to the following steps. First, put the core powder of the above weight and 30% of nano-aluminum powder into the stirring device, then add the binder of the above weight, and start the stirring device for pre-packing Cover and stir, and then add the remaining 70% of nano-aluminum powder for coating and stirring. Wherein, the total volume of the core powder, the binder, and the nano-aluminum powder accounts for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com