Wood cutting tool material of Ti(CN) cermet and preparation method thereof

A cutting tool material and cermet technology, which is applied in the field of powder metallurgy manufacturing, can solve problems such as high brittleness and poor toughness, and achieve the effects of reduced cutting processing costs, improved durability, and increased service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

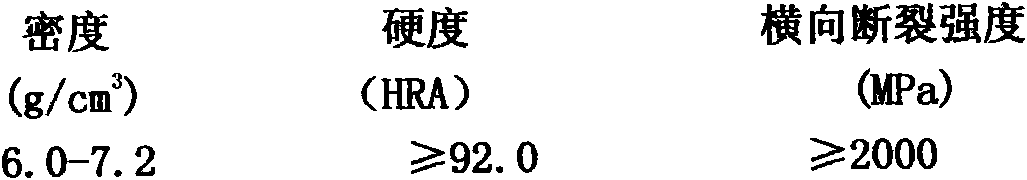

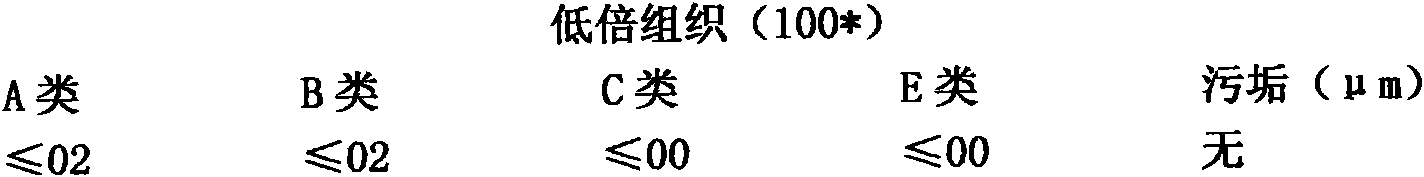

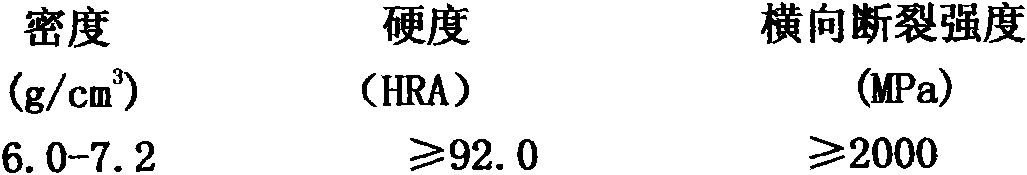

[0022] Add the mass percentage according to the ratio of Ti(CN) powder: 55%; cobalt powder: 6%; nickel powder: 6%; molybdenum powder: 8%; tungsten carbide powder: 20%; Rolling ball mill with cemented carbide as the grinding body (the purity of the raw materials is greater than 99.5%, and the average particle size is less than 2.0 μm). Water ethanol, add molding agent of 4.1% of the total mass of raw materials and 0.3% of oleic acid, 0.4% of stearic acid at the same time, the cumulative ball milling time is: 96 hours, the slurry after ball milling to the point is atomized and dried by spray drying , Drying outlet temperature: 90°C, drying time: 120 minutes, bulk density of the obtained spray-dried mixed pellets: 2.95g / cm 3 , the fluidity is: 37 seconds / 50g, the sprayed pellets that meet this requirement are molded by a precision press and sintered in a pressure sintering furnace. The carrier gas flow rate is 40 liters / min; the sintering temperature is 1440°C, the carrier gas p...

Embodiment 2

[0026] The mass percentage is according to Ti (CN) powder: 60%; Cobalt powder: 7%; Nickel powder: 7%; Molybdenum powder: 10%; Tungsten carbide powder: 10.2%; Tantalum carbide powder: 5%; %; vanadium carbide powder: after 0.4% of the ratio of ingredients, add the rolling ball mill (the purity of the raw material is greater than 99.5%, and the average particle size is less than 2.0 μm) with cemented carbide as the grinding body. The rotating speed of the ball mill is: 35 rev / min, The ball-to-material ratio is: 10:1, the ball milling medium is absolute ethanol, and 4.2% molding agent, 0.3% oleic acid, and 0.3% stearic acid of the total mass of raw materials are added at the same time, and the cumulative ball milling time is: 100 hours, The slurry after ball milling to the point is atomized and dried by spray drying, the drying outlet temperature is 90°C, the drying time is 120 minutes, and the bulk density of the obtained spray-dried mixed pellets is: 3.10g / cm 3 , the fluidity is...

Embodiment 3

[0030]The mass percentage is according to Ti(CN) powder: 54%; cobalt powder: 9%; nickel powder: 11%; molybdenum powder: 10%; tungsten carbide powder: 10.2%; tantalum carbide powder: 5%; After the ratio of % is added to the rolling ball mill with cemented carbide as the grinding body (the purity of the raw materials is greater than 99.5%, and the average particle size is less than 2.0 μm), the rotating speed of the ball mill is: 35 rpm, and the ball-to-material ratio of the ball mill is: 10 : 1, the ball milling medium is absolute ethanol, and simultaneously add 4.1% molding agent of raw material gross mass and 0.3% oleic acid, 0.4% stearic acid, the accumulated ball milling time is: 110 hours, the slurry after ball milling to the point Spray drying is used for atomization drying, drying outlet temperature: 90°C, drying time: 130 minutes, and the bulk density of the obtained spray-drying mixed pellets is: 3.00g / cm 3 , the fluidity is: 35 seconds / 50g, the sprayed pellets that me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bulk density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com