Carbon steel and stainless steel clad steel plate with toughness performance and production method

A clad steel plate and stainless steel technology, which is applied to carbon steel and stainless steel clad steel plates and production fields, can solve the problems of poor corrosion resistance and strength, and achieve excellent resistance to hydrogen-induced cracking, excellent strength and toughness. The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

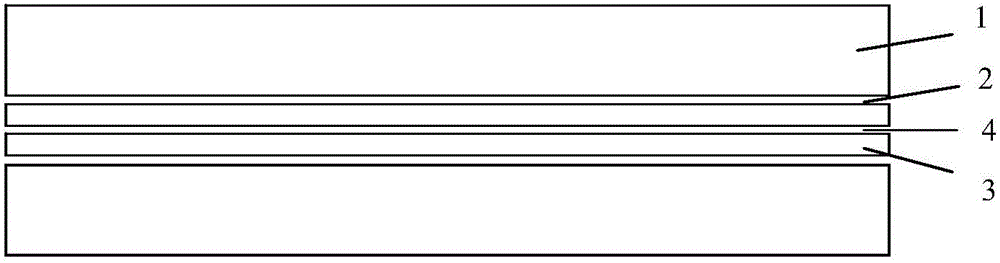

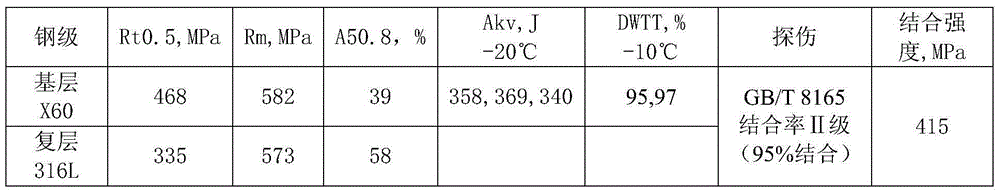

[0017] In this experiment, carbon steel 1 is used as the base material, base material X60 chemical composition C: 0.03~0.10%, Si: 0.01~0.40%, Mn: 1.00~1.70%, P: ≤0.015%, S: ≤0.003%, Alt: 0.01 ~0.06%, N: ≤0.006%, H: ≤0.0002%, the balance is Fe and unavoidable impurity elements, and Nb, V, Ti, Cu, Ni, Cr microalloy strengthening elements are also added, Nb+V+Ti≤ 0.15%, Cu: 0.00 to 0.30%, Ni: 0.00 to 0.30%, and Cr: 0.00 to 0.30%, 1 to 3 kinds selected. The rest are Fe and unavoidable impurity elements.

[0018] Actual chemical composition (wt%) is as shown in table 1:

[0019] Table 1 The actual chemical composition of Example 1

[0020] C Si MN P S Alt NB V Ti NI Cr Cu CEQ 0.085 0.26 1.45 0.012 0.0019 0.035 0.05 0.035 0.014 0.239 0.2 0.115 0.42

[0021] The 3 components of the clad 316L stainless steel meet the requirements of the ASTM A240M-05 standard "Standard Specification for Chromium and Chromium-Nickel Stainless Steel Pl...

Embodiment 2

[0032] Actual chemical composition (wt%) is as shown in table 3:

[0033] Table 3 Example 2 actual chemical composition

[0034] C Si MN P S Alt NB V Ti NI Cr Cu CEQ 0.082 0.22 1.5 0.01 0.0016 0.033 0.04 0.037 0.014 0.245 0.21 0.143 0.42

[0035] The 3 components of the clad 316L stainless steel meet the requirements of the ASTM A240M-05 standard "Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plates, Sheets and Strips for Pressure Vessels and General Purposes", and the weight percentage is C≤0.03%, Mn ≤2.0%, Si≤0.75%, in addition, it also contains Cr, Ni, Mo and other alloying elements to increase corrosion resistance. The specification of the steel plate is: (20+3.5)×1800×12000mm (thickness×width×length), wherein the thickness of carbon steel 1 is 20mm, and the thickness of 316L stainless steel 3 is 3.5mm.

[0036] The production process includes billet assembly, heating, rough rolling, finish rollin...

example 3

[0047] Example 3 actual chemical composition (wt%) is as shown in table 5:

[0048] Table 5 Example 3 actual chemical composition

[0049] C Si MN P S Alt NB V Ti NI Cr Cu CEQ 0.082 0.22 1.5 0.01 0.0016 0.033 0.04 0.037 0.014 0.245 0.21 0.143 0.42

[0050] The 3 components of the clad 316L stainless steel meet the requirements of the ASTM A240M-05 standard "Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plates, Sheets and Strips for Pressure Vessels and General Purposes", and the weight percentage is C≤0.03%, Mn ≤2.0%, Si≤0.75%, in addition, it also contains Cr, Ni, Mo and other alloying elements to increase corrosion resistance. The specification of the steel plate is: (16+3)×1800×12000mm (thickness×width×length), wherein the thickness of carbon steel 1 is 16mm, and the thickness of 316L stainless steel 3 is 3mm.

[0051] The production process includes billet assembly, heating, rough rolling, finish ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com