Use of a non-corrosive, martensitically hardening steel

a martensitic hardening, non-corrosive technology, applied in the field of stainless steels and precipitation hardenable, can solve the problems of inability to apply tools, difficult to apply to rotary tools with complicated geometry, and tools are sensitive to the bending loads applied in practical use, and achieve high corrosion resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

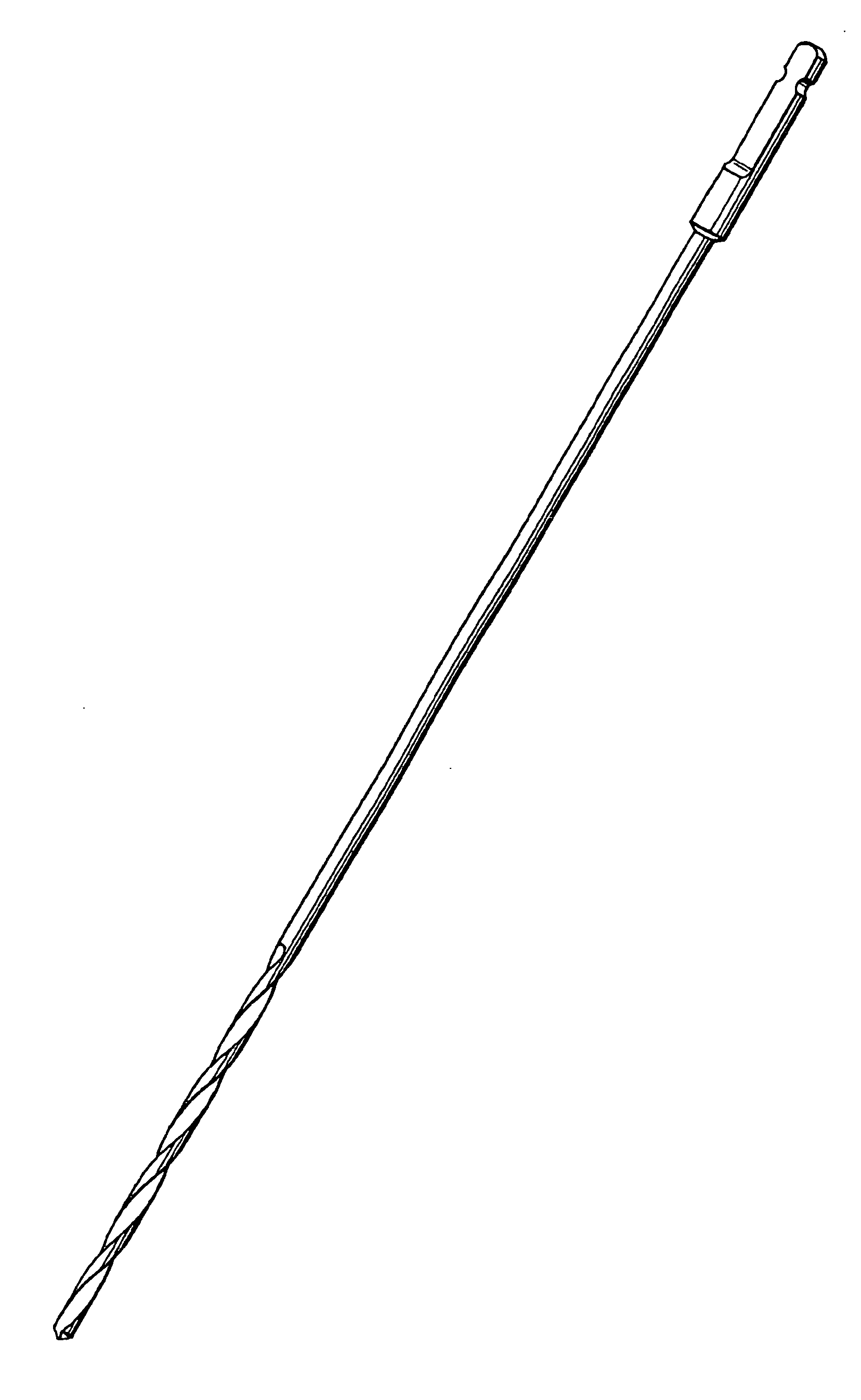

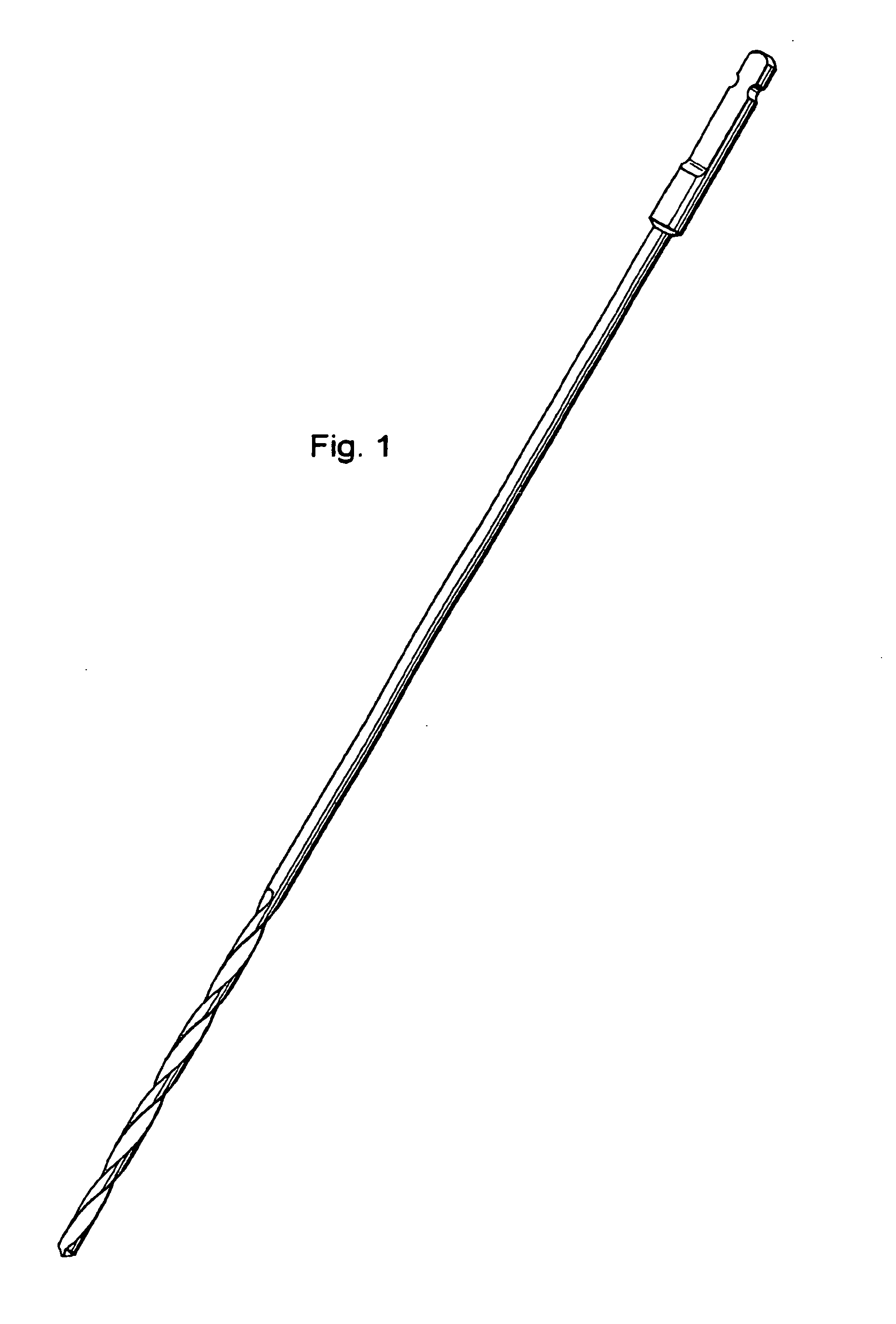

Image

Examples

Embodiment Construction

[0011] The object of the present invention is to overcome the aforementioned problems and disadvantages of the state of the art.

[0012] This object is achieved according to the invention through the use of a precipitation-hardenable, martensitic, rustless chrome nickel steel with the following composition (in wt.-%):

Chromium10 to 14Nickel7 to 11Molybdenum0.5 to 6Copper0.5 to 4Aluminium0.05 to 0.55Titanium0.4 to 1.4Carbon + nitrogenup to 0.3Sulphurless than 0.05Phosphorusless than 0.05Manganeseup to 0.5Siliconup to 0.5Tantalum, niobium, vanadium andeach up to 0.2tungstenCobaltwhere appropriate up to 9.0Boronwhere appropriate 0.0001 to 0.1[0013] the remainder comprising iron and customary impurities, for the manufacture of machine-operated rotary tools. This object according to the invention is further achieved by the provision of machine-operated rotary tools which are made from precipitation-hardenable, martensitic, rustless chrome nickel steel with the aforementioned composition....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com