Non-molybdenum non-nickel middle chrome wear resistant steel casting and heat treatment method thereof

A heat treatment method and steel casting technology are applied in the field of metal wear-resistant materials, which can solve the problem of high production cost and achieve the effects of good hardness uniformity, high hardness and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

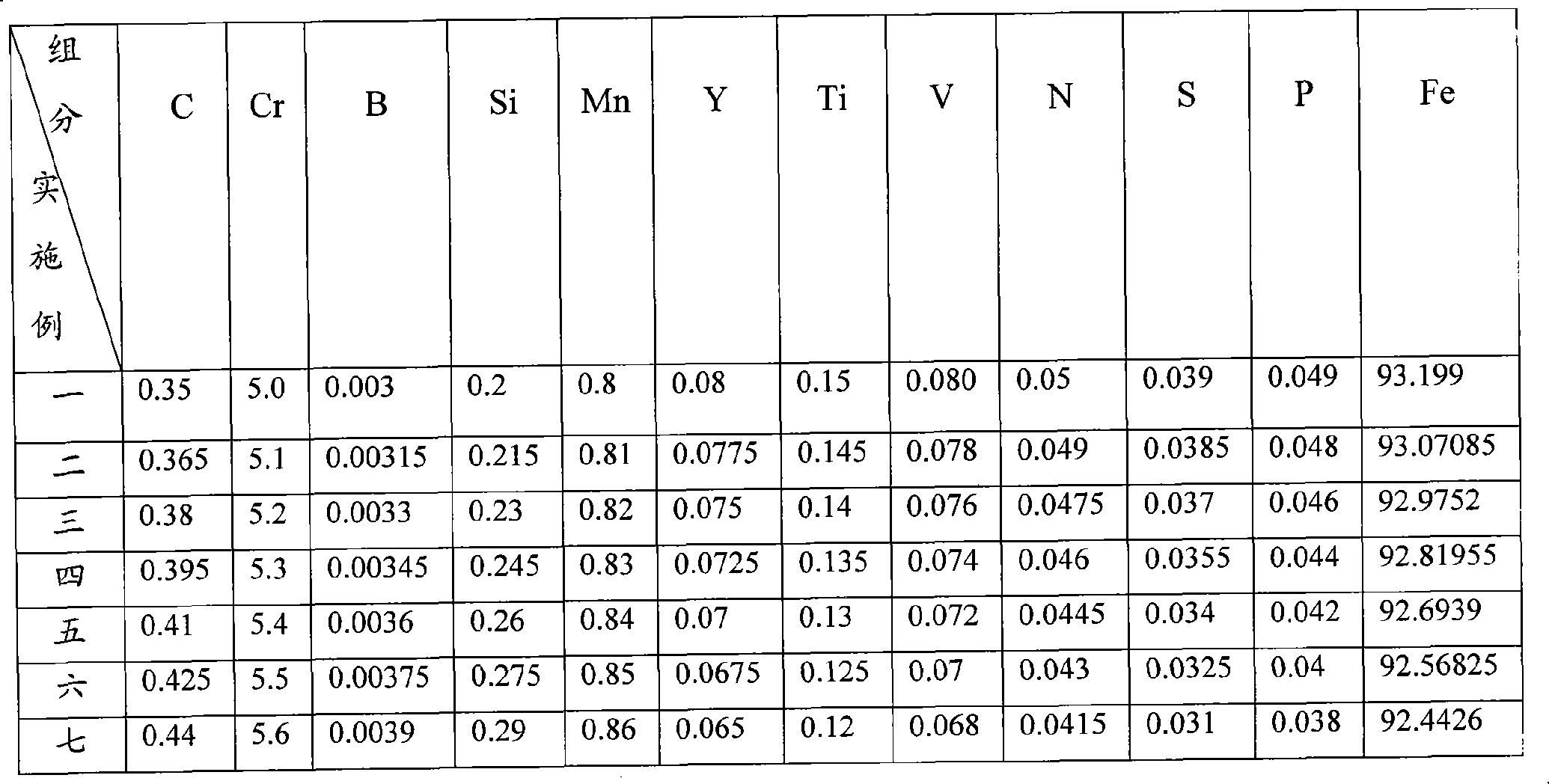

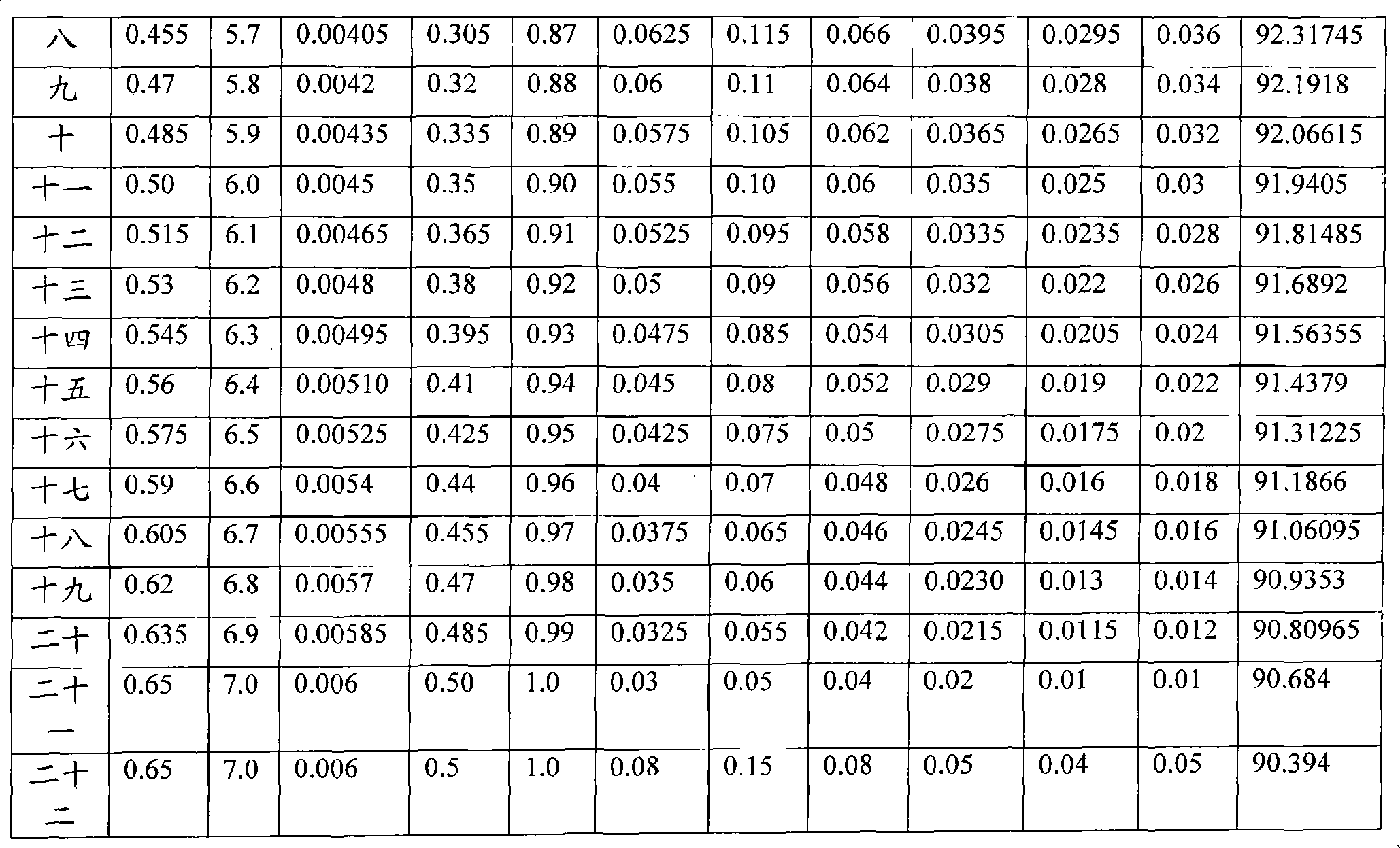

Examples

Embodiment 1

[0059] The steps of the heat treatment method for smelting the non-molybdenum-nickel medium-chromium wear-resistant steel castings provided by the present invention with a 500 kg intermediate frequency induction electric furnace are:

[0060] ① Heat and melt scrap steel, pig iron, ferrochrome, ferrosilicon and ferromanganese;

[0061] ②After adjusting the composition in front of the furnace, the temperature is raised to 1592℃, pre-deoxidized with silicon-calcium alloy, and finally deoxidized with aluminum, and then out of the furnace. The percentage of silicon-calcium alloy added to the mass of molten steel is 0.28%, and the amount of aluminum added to molten steel is 0.28%. The mass percentage is 0.11%;

[0062] ③Crush the yttrium-based rare earth, titanium-iron, boron-iron, and vanadium-nitrogen alloys into small pieces with a particle size of less than 12mm, dry them below 220 ℃, place them at the bottom of the ladle, and use the ladle flushing method to perform compound modifi...

Embodiment 2

[0071] The steps of the heat treatment method for smelting the molybdenum-nickel-free medium-chromium wear-resistant cast steel provided by the present invention in a 1000 kg intermediate frequency induction electric furnace are:

[0072] ① Heat and melt scrap steel, pig iron, ferrochrome, ferrosilicon and ferromanganese;

[0073] ② Adjust the composition in front of the furnace and raise the temperature to 1619℃, pre-deoxidize with silicon-calcium alloy, and finally deoxidize with aluminum, and then out of the furnace. The percentage of silicon-calcium alloy added to molten steel mass is 0.18%. The mass percentage is 0.15%;

[0074] ③Crush the yttrium-based rare earth, titanium-iron, boron-iron, and vanadium-nitrogen alloys into small pieces with a particle size of less than 12mm, dry them below 220 ℃, place them at the bottom of the ladle, and use the ladle flushing method to perform compound modification treatment on the molten steel ;

[0075] ④The casting is made of sand cast...

Embodiment 3

[0084] The 750 kg intermediate frequency induction electric furnace is used to melt the molybdenum-nickel-free medium-chromium wear-resistant steel castings provided by the present invention, and the heat treatment steps are as follows:

[0085] ① Heating and melting scrap steel, pig iron, ferrochrome, ferrosilicon and ferromanganese;

[0086] ② Adjust the composition in front of the furnace and raise the temperature to 1604℃, pre-deoxidize with silicon-calcium alloy, and finally deoxidize with aluminum, and then come out of the furnace. The percentage of silicon-calcium alloy added to the mass of molten steel is 0.22%, and the added amount of aluminum is compared with molten steel. The mass percentage is 0.13%;

[0087] ③Crush the yttrium-based rare earth, titanium-iron, boron-iron, and vanadium-nitrogen alloys into small pieces with a particle size of less than 12mm, dry them below 220 ℃, place them at the bottom of the ladle, and use the ladle flushing method to perform compoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com