Train wheel cooling device and method and preparation method

A technology of cooling device and cooling method, which is applied in the direction of quenching device, manufacturing tools, heat treatment equipment, etc., can solve the problems of unresolved rim cooling uniformity, inability to fully cover, affect the uniformity of rim section hardness, etc., and achieve enhanced cooling uniformity performance, improve the cooling effect, improve the effect of cooling uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

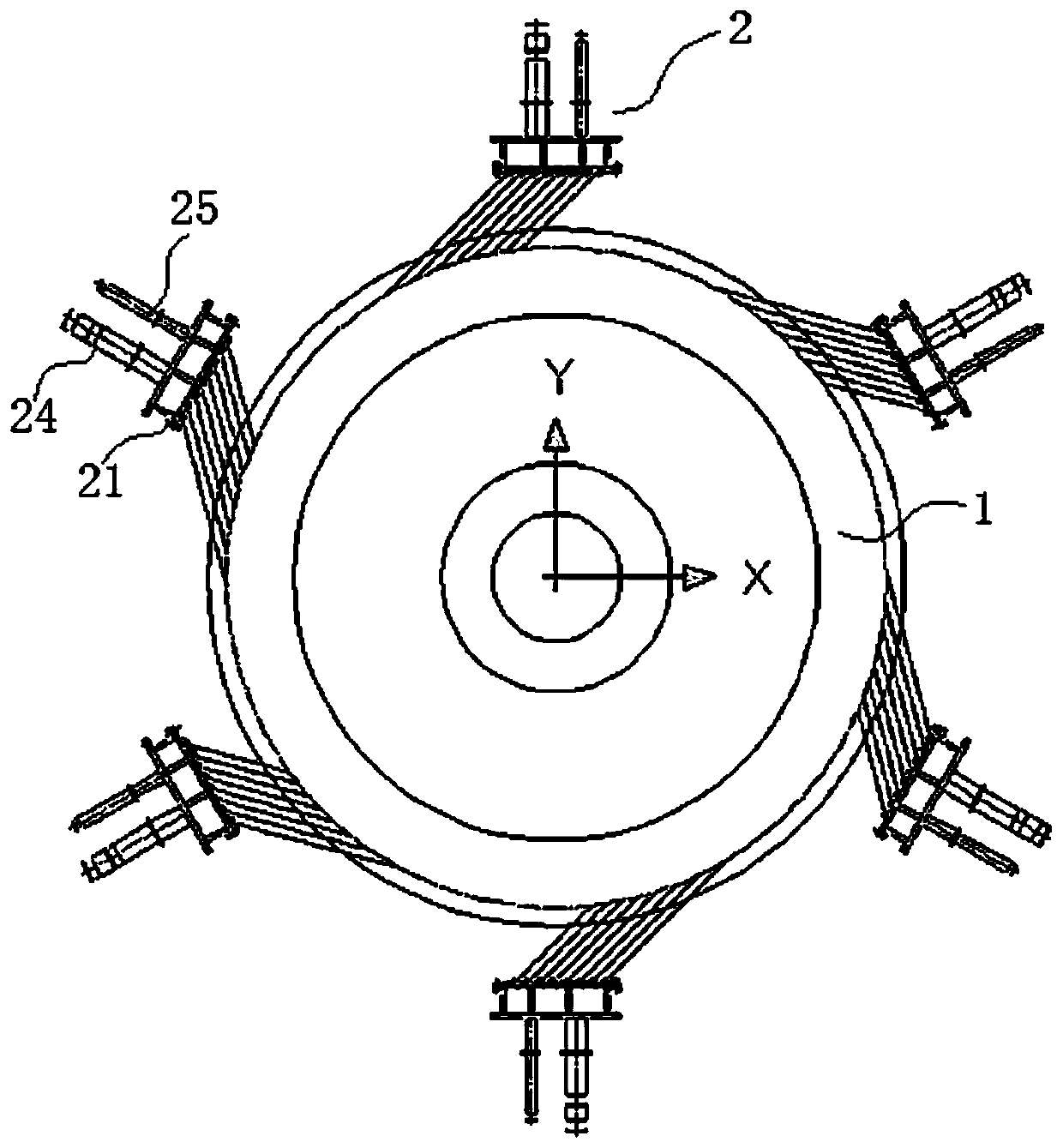

[0054] The utility model relates to a cooling device for railway wheels, which is used for cooling the wheels during the heat treatment stage during the preparation of the iron wheels. Such as figure 1 As shown, the device includes a quenching platform 1 and a spray gun 2. The quenching platform 1 is a wheel structure that can rotate by itself, and the rotation is controlled by a motor. There are multiple spray guns 2, which are evenly distributed along the circumference of the quenching platform 1. Depending on the size of the diameter, the present embodiment is 6 spray guns. When cooling the wheel, place the side of the wheel on the quenching platform 1, make the spraying direction of the spray gun 2 face the tread of the wheel, and carry out spray cooling to the tread of the wheel. The specific structure of the spray gun 2 will be described in detail below.

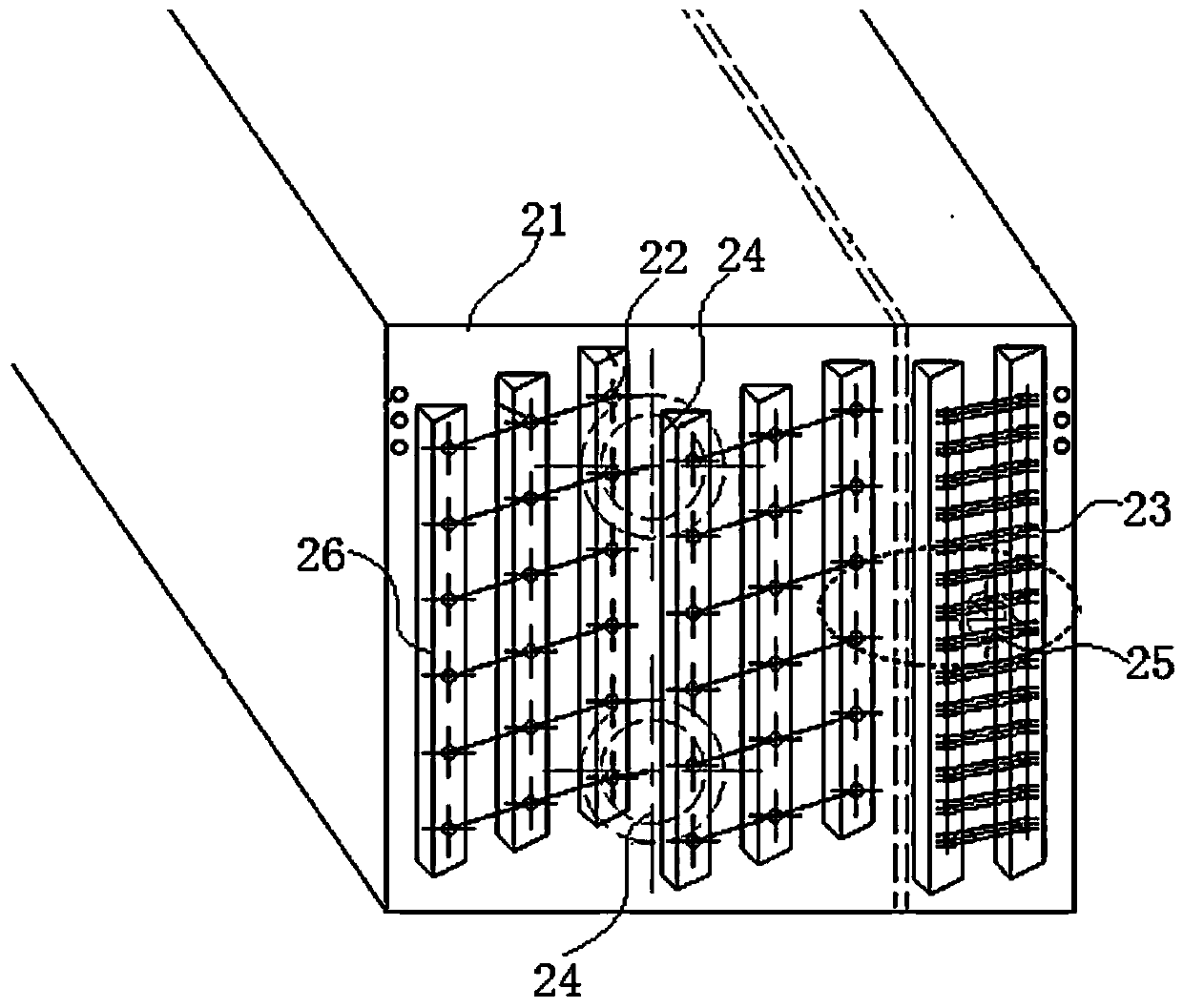

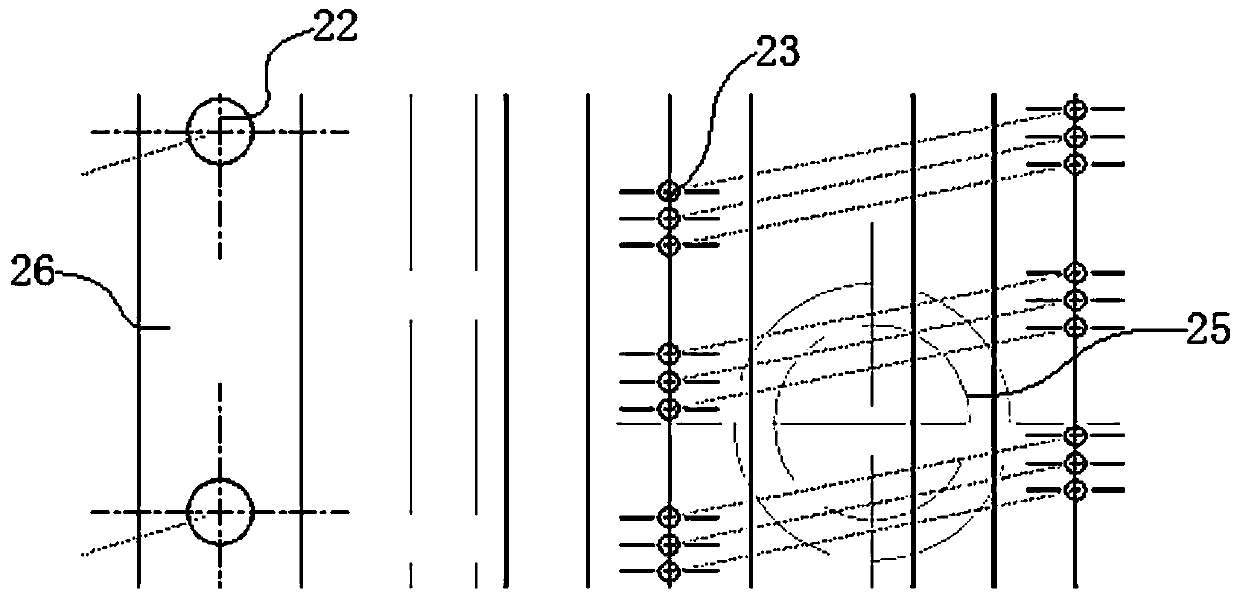

[0055] Such as Figure 1 to Figure 3 As shown, the spray gun 2 includes a water outlet panel 21 and a water inlet...

Embodiment 2

[0062] A method for cooling railway wheels, adopting a kind of railway wheel cooling device of embodiment 1 to cool the wheels to be cooled, comprising the following steps:

[0063] 1. Preparation stage

[0064] Transport the wheel to be cooled in the heat treatment stage to the quenching platform 1, make the side of the wheel face up, and the wheel tread is facing the water outlet panel 21 of the spray gun 2, and then start the quenching platform 1, so that the wheel is in a rotating state.

[0065] 2. Small flow injection stage

[0066] Start the small nozzle branch pipe 25 to spray the wheels, the spraying time is 60-210s, and the water pressure is P0. In this step, P0 is 0.05-0.15Mpa. The specific spraying time depends on the wheel diameter of the wheel and the chemical composition of the wheel steel. When the transformation of complete fine pearlite + a small amount of ferrite, that is, F-P structure, occurs within a certain depth near the surface of the tread, the spray...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com