Device for preparing composite absorption agent for semidry flue gas purification

A flue gas purification and preparation device technology, applied in mixers, separation methods, chemical instruments and methods, etc., can solve the problems of single slaked lime, poor mixing effect of materials, and high moisture content of materials, achieve good mixing and conveying effect, save energy Covering area and good stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

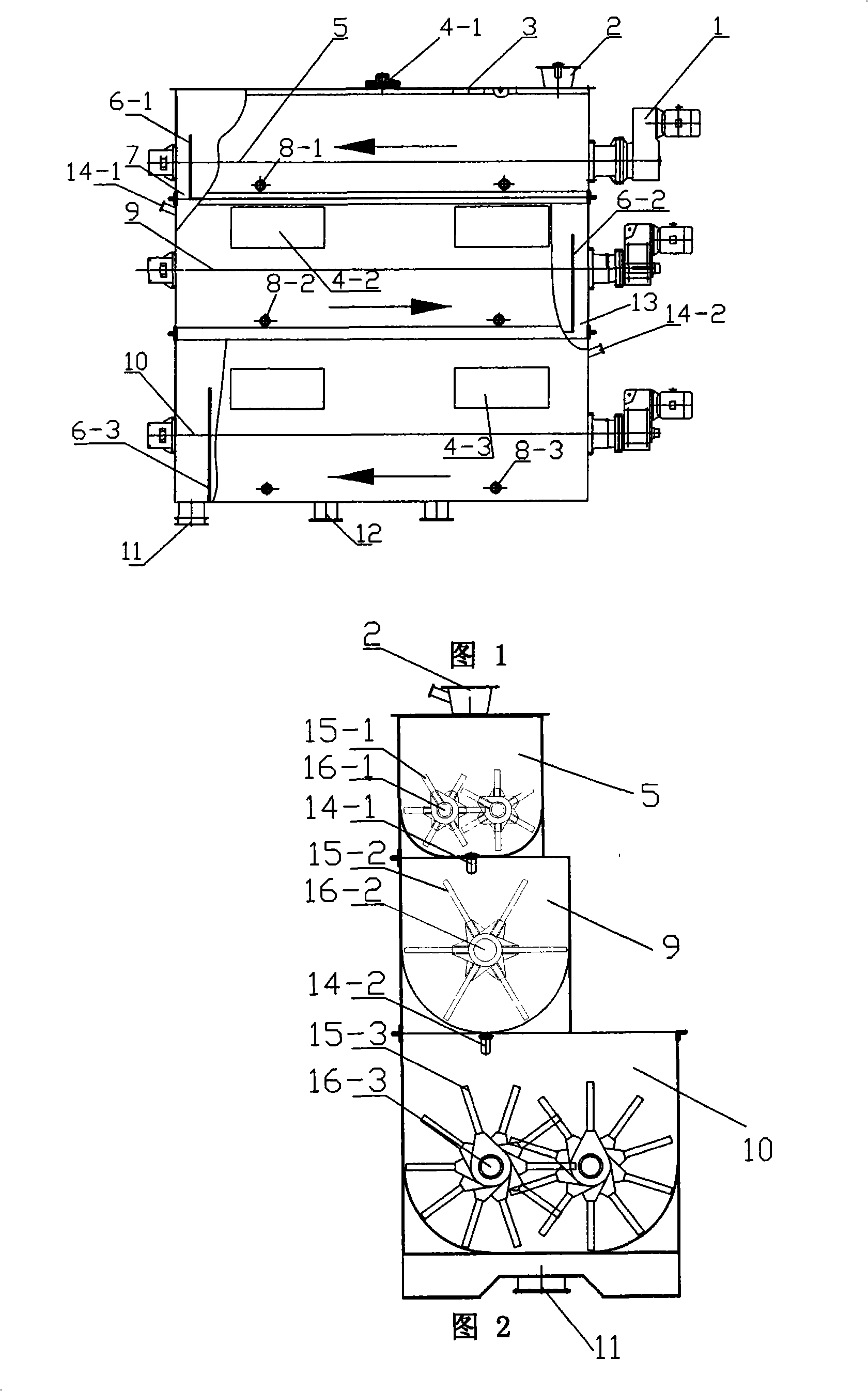

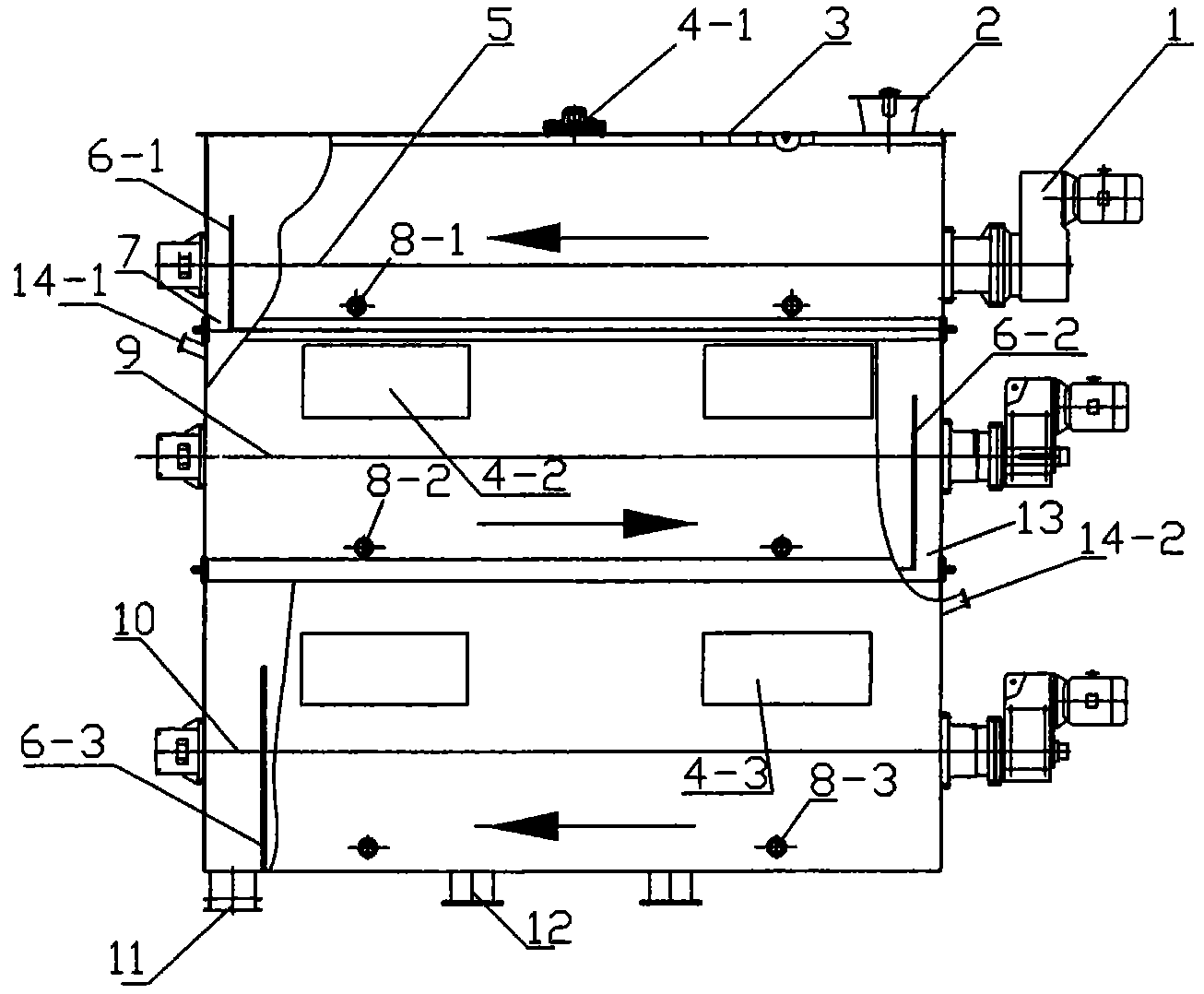

[0021] Such as figure 1 and figure 2 As shown, the arrow in the figure is the running direction of the material. The preparation device of the semi-dry flue gas purification composite absorbent includes a first-stage stirring box 5, a second-stage stirring box 9, and a third-stage stirring box 10. The three-stage stirring boxes are stacked, and the bottom of each stirring box is semi-cylindrical.

[0022] One end of the top of the primary mixing box 5 is provided with a primary material inlet 2 and an additive material inlet. The additive material inlet is used to add insoluble or water-insoluble additives. The raw materials and additives have a preset The process of mixing. There is a primary stirring inspection port 4-1 in the middle of the top of the primary stirring box 5, through which the working condition of the atomizing nozzle 3 and the stirring condition in the agitator can be observed. One end of the bottom of the primary mixing box 5 has a primary blanking open...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com