A kind of multifunctional composite filter material, preparation method, filter device and filter method

A composite filter material and composite filtration technology, which is applied in the direction of filtration separation, membrane filter, separation method, etc., can solve the problems of large footprint and low filtration efficiency of the filtration device, and achieve reduced footprint, high filtration efficiency, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

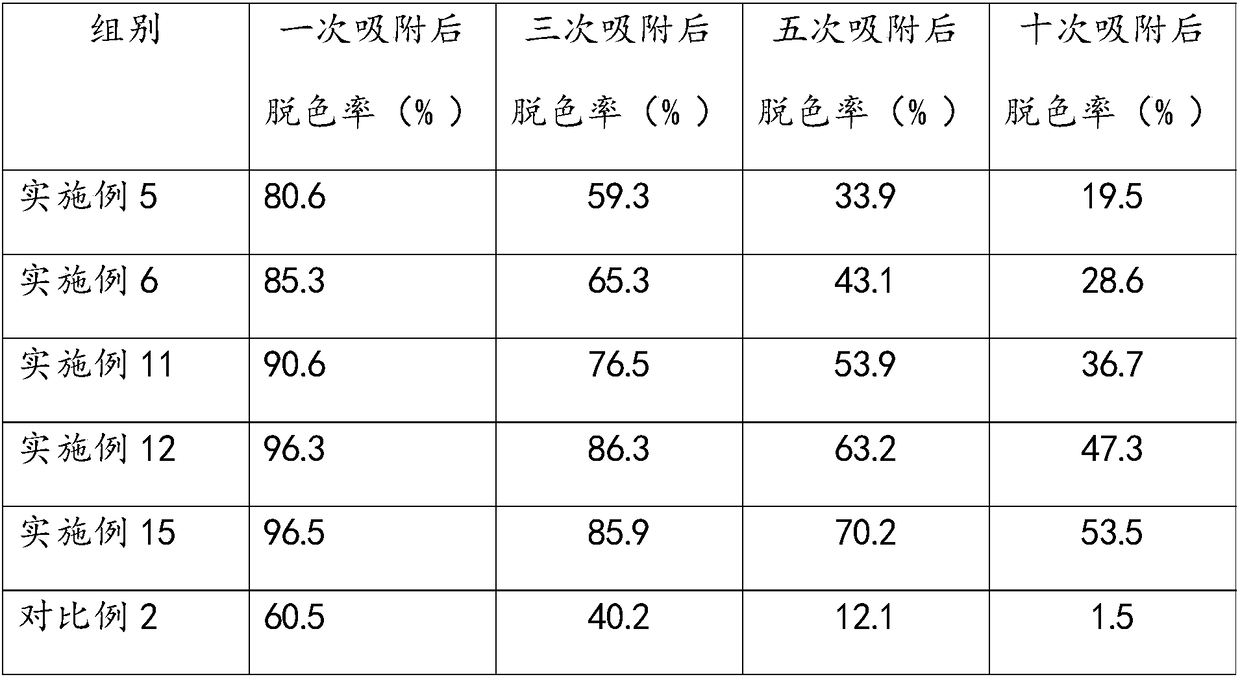

Examples

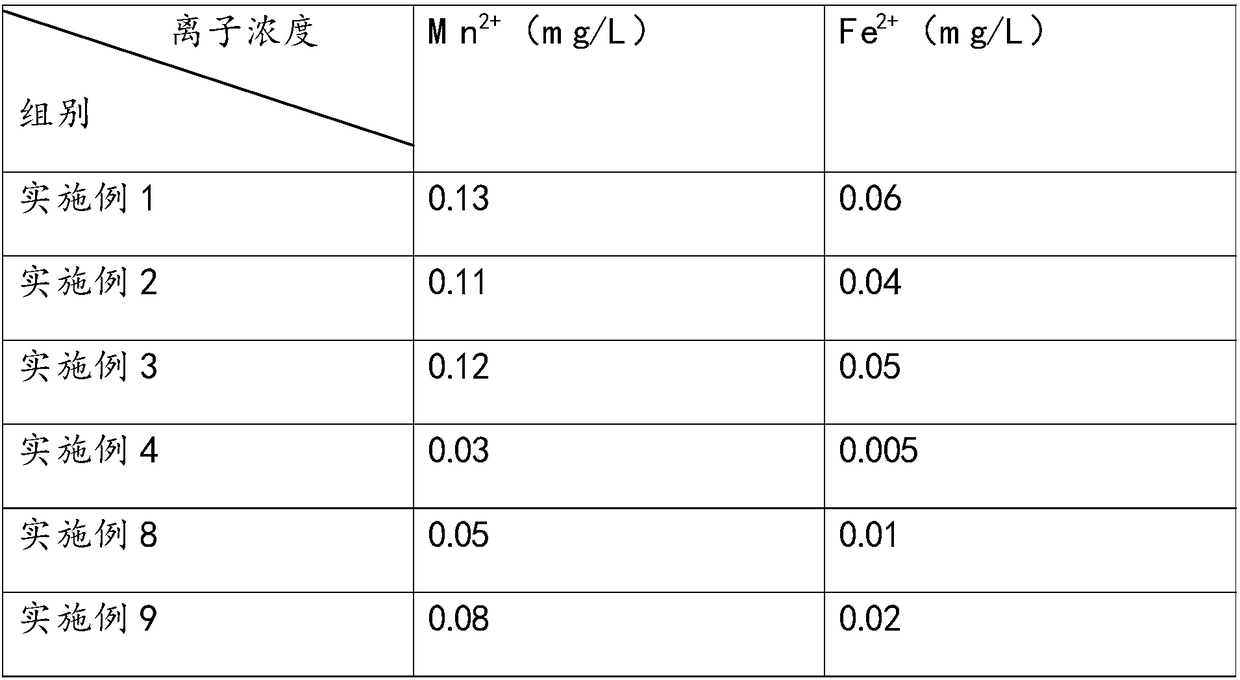

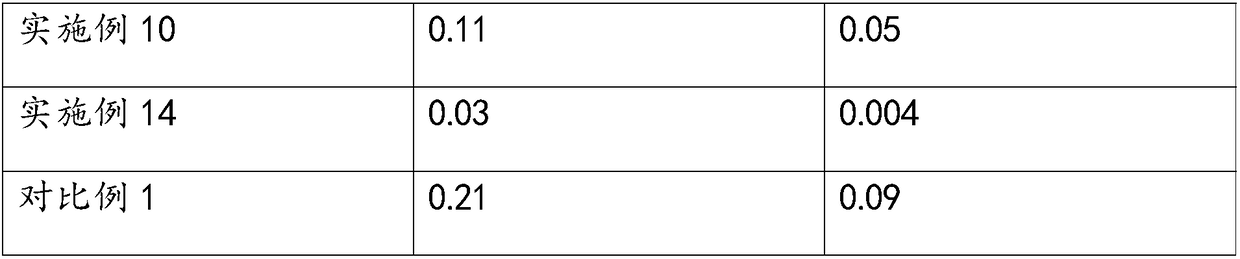

Embodiment 1

[0045] According to the mixing mass ratio of 30% and 70%, appropriate amount of porous volcanic particles with an average particle size of 0.6 mm and manganese sand with an average particle size of 2 mm were weighed respectively. Wherein, the compressive strength of the volcanic rock particles is not less than 5.5Mpa, the shear strength is not less than 3.5Mpa, the porosity is not less than 75%, and the specific gravity is 1.4g / cm 3 , bulk density 0.7g / cm 3 .

[0046] Then the two materials were mixed and compacted naturally to obtain the mixed filter material of Example 1.

Embodiment 2

[0048] According to the mixing mass ratio of 10% and 90%, appropriate amount of porous volcanic particles with an average particle size of 2.6 mm and manganese sand with an average particle size of 2 mm were weighed respectively. Wherein, the compressive strength of the volcanic rock particles is not less than 5.5Mpa, the shear strength is not less than 3.5Mpa, the porosity is not less than 75%, and the specific gravity is 1.1g / cm 3 , bulk density 0.6g / cm 3 .

[0049] Then the two materials were mixed and compacted naturally to obtain the mixed filter material of Example 2.

Embodiment 3

[0051] According to the mixing mass ratio of 70% and 30%, appropriate amount of porous volcanic particles with an average particle size of 3 mm and manganese sand with an average particle size of 2 mm were weighed respectively. Wherein, the compressive strength of the volcanic rock particles is not less than 5.5Mpa, the shear strength is not less than 3.5Mpa, the porosity is not less than 75%, and the specific gravity is 1.3g / cm 3 , bulk density 0.6 / cm 3 .

[0052] Then the two materials were mixed and compacted naturally to obtain the mixed filter material of Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com