Environment-friendly flue gas desulfurizing system

A desulfurization system, an environmentally friendly technology, applied in gas treatment, dispersed particle filtration, membrane technology, etc., can solve the problems of incomplete removal of sulfur, short flue gas reaction time, short flue gas residence time, etc. Longer, faster response time, better effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

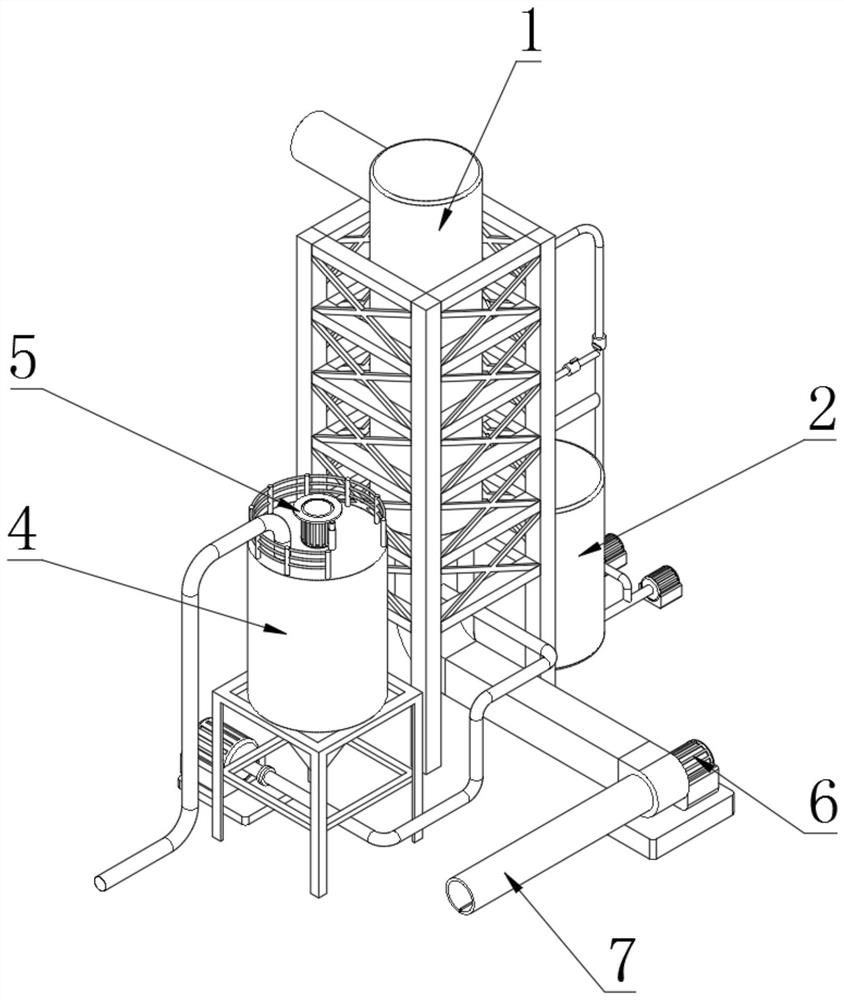

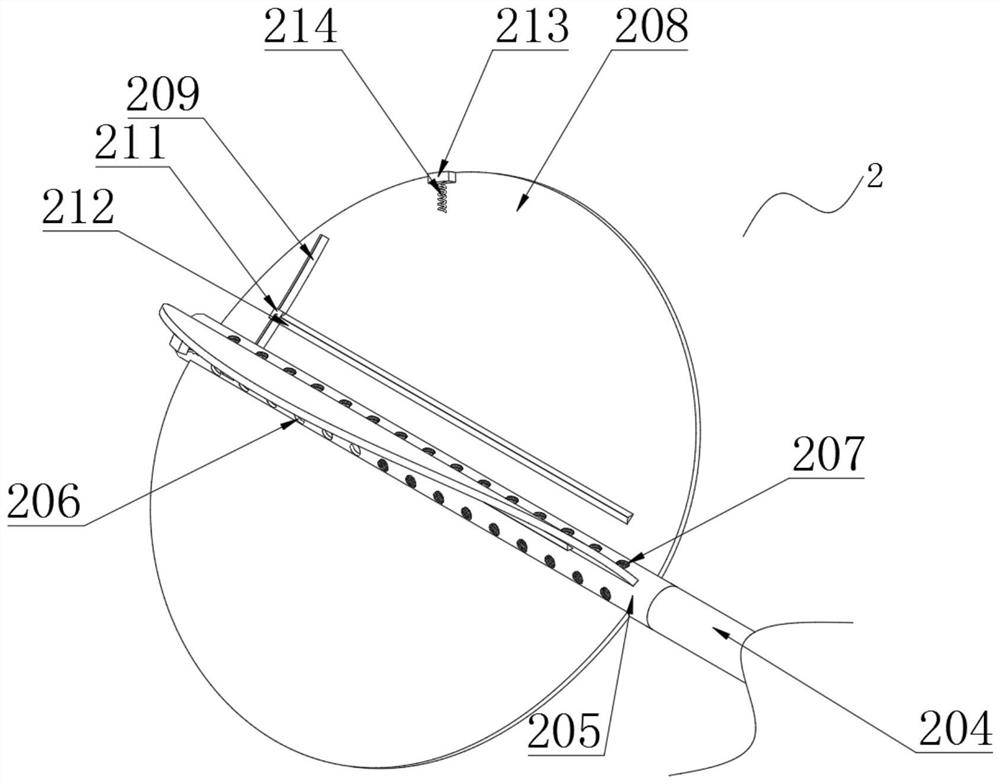

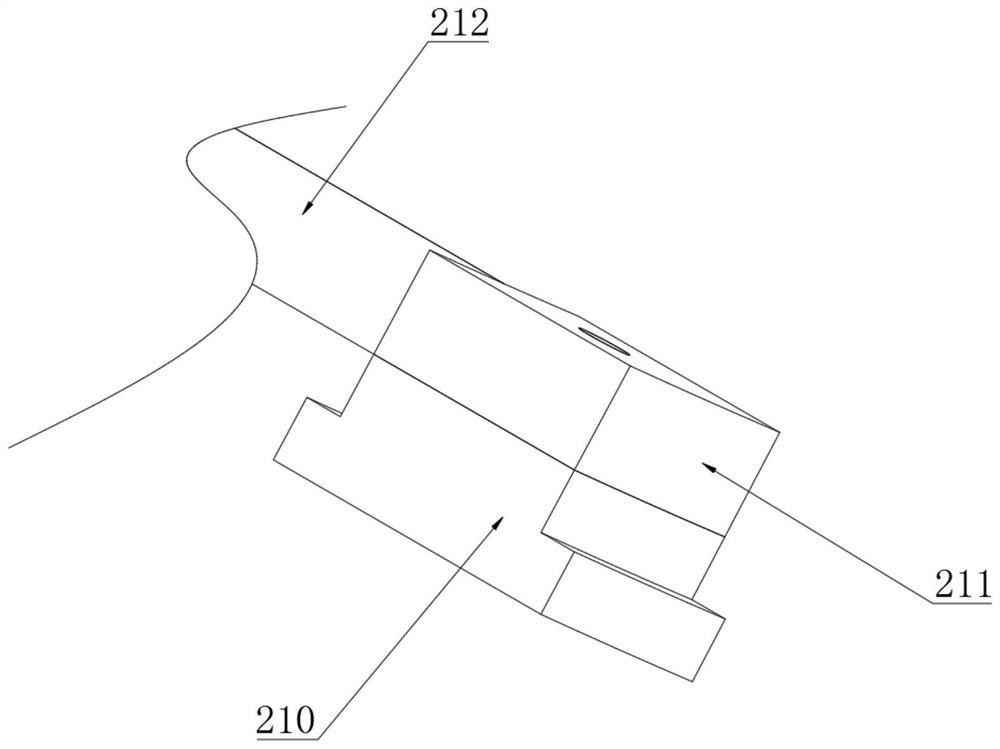

[0055] Example: such as Figure 1-10 As shown, the present invention provides a technical solution, an environment-friendly flue gas desulfurization system, including a desulfurization tower 1, a high-efficiency and energy-saving cleaning component 2 is installed inside the desulfurization tower 1, and the high-efficiency and energy-saving cleaning component 2 includes a water tank 201, a booster pump 202, a connecting Pipeline 203, pass into pipeline 204, water spray pipe 205, water spray hole 206, stop filter screen 207, rotating plate 208, sliding groove 209, slide block 210, installation block 211, cleaning bar 212, fixed block 213 and limit spring 214;

[0056] One side of the desulfurization tower 1 is connected to a water tank 201, and both ends of one side of the water tank 201 are installed with a booster pump 202, and both ends of one side of the water tank 201 are connected to a booster pump 202 through an outlet pipe, and the two outlet pipes are welded through Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com