Melting technique for producing QT450-18 nodular cast iron through silicon solid solution reinforced ferrite

A technology of solid solution strengthening and nodular cast iron, which is applied in the field of nodular cast iron production, can solve the problems of large fluctuation range of casting hardness, difficult elongation to meet higher toughness requirements, and lower processing performance of castings, so as to reduce machining cost and hardness. Good uniformity and the effect of improving processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

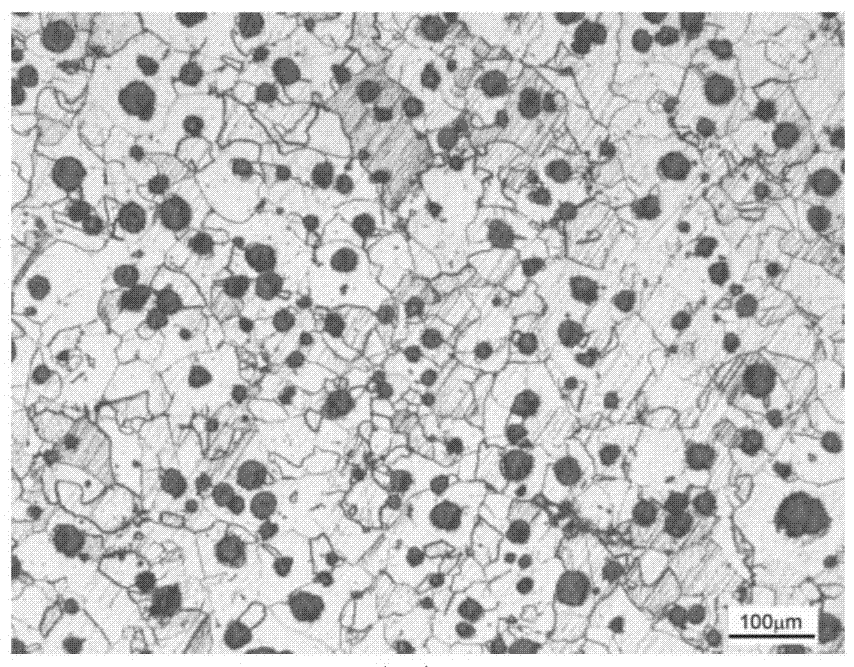

Embodiment 1

[0026] A smelting process for producing QT450-18 ductile iron by adopting silicon solid-solution strengthened ferrite, comprising the following steps:

[0027] 1) Alternative raw materials are nodular iron pig iron, high-quality carbon steel scrap and recycled material for batching. The weight percentage content of each raw material is: nodular iron pig iron: 67%, carbon steel scrap: 8%, and recycled material: 25%;

[0028] 2) Optional auxiliary materials: yttrium-based heavy rare earth nodulizer, high-calcium barium inoculant, ferromanganese, antimony ingot;

[0029] 3) For smelting, first add nodular iron pig iron, then add recycled material, and finally add carbon scrap steel, and control the temperature of the melting process at 1330°C;

[0030] 4) Sampling and analysis after the charge is melted, adjust the composition according to the analysis results, the adjusted mass percentage of the chemical composition in the molten iron furnace is: C: 3.62% C, Si: 1.32%, Mn: 0.18%...

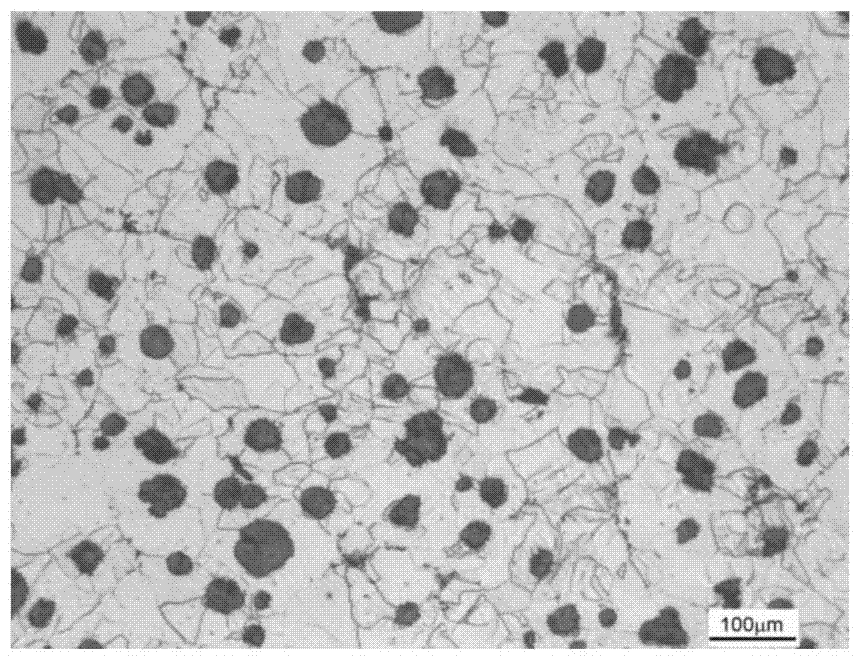

Embodiment 2

[0035] 1) Alternative raw materials are nodular iron pig iron, high-quality carbon steel scrap and recycled material for batching. The weight percentage content of each raw material is: nodular iron pig iron: 65%, carbon steel scrap: 15%, and recycled material: 20%;

[0036] 2) Optional auxiliary materials: yttrium-based heavy rare earth nodulizer, high-calcium barium inoculant, ferromanganese, antimony ingot;

[0037] 3) Carry out smelting, first add nodular iron pig iron, then add recycled materials, and finally add carbon scrap steel, and control the temperature of the melting process at 1350°C;

[0038] 4) Sampling and analysis after melting the charge, and adjusting the composition according to the analysis results. The adjusted mass percentages of the chemical composition in the molten iron furnace are: C: 3.58% C, Si: 1.61%, Mn: 0.21%;

[0039] 5) Carry out spheroidizing inoculation treatment; use the flushing method to carry out spheroidizing treatment, weigh the auxil...

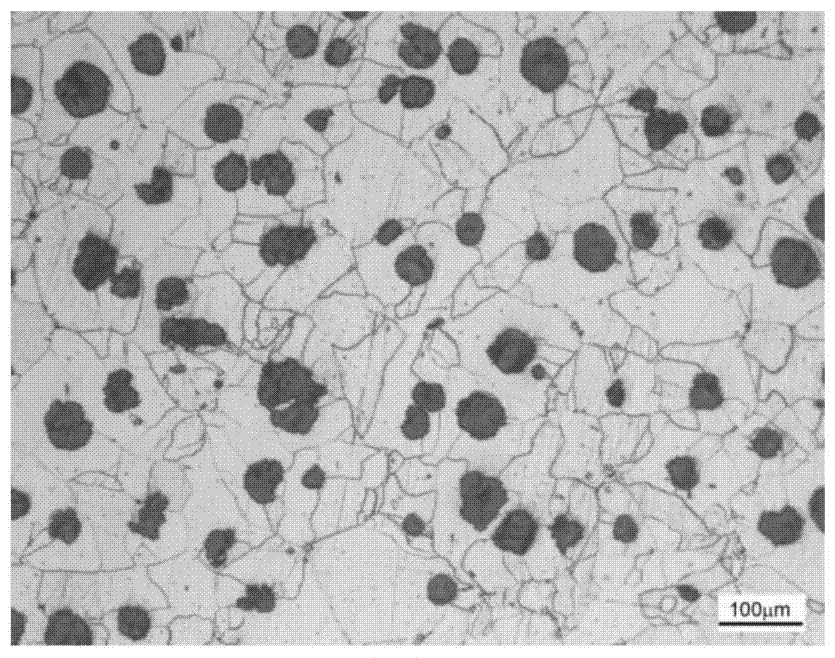

Embodiment 3

[0043] 1) Alternative raw materials are nodular iron pig iron, high-quality carbon steel scrap and recycled material for batching. The weight percentage content of each raw material is: nodular iron pig iron: 65%, carbon steel scrap: 20%, and recycled material: 15%;

[0044] 2) Optional auxiliary materials: yttrium-based heavy rare earth nodulizer, high-calcium barium inoculant, ferromanganese, antimony ingot;

[0045] 3) Carry out smelting, first add nodular iron pig iron, then add recycled materials, and finally add carbon scrap steel, and control the temperature of the melting process at 1350°C;

[0046] 4) Sampling and analysis after the charge is melted, adjust the composition according to the analysis results, the adjusted mass percentage of the chemical composition in the molten iron furnace is: C: 3.76% C, Si: 1.85%, Mn: 0.29%;

[0047] 5) Carry out spheroidizing inoculation treatment; use the flushing method to carry out spheroidizing treatment, weigh the auxiliary ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com