Build up welding method for repairing cold rolling and leveling supporting rollers

A support roller and leveling technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of waste of resources, poor weldability, difficulty in ensuring uniform hardness, etc., and achieve cost saving, low cost, and economical improvement Use the effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

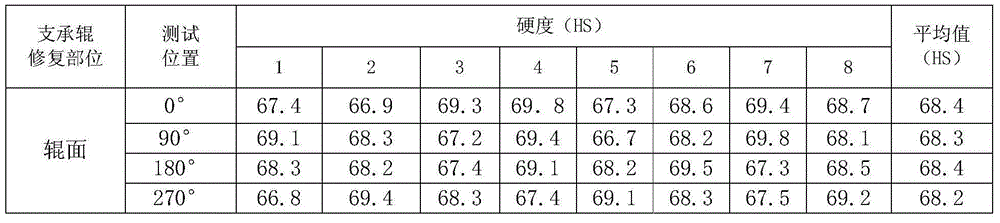

[0036] Select a failed roll, and use a CT-E magnetic particle flaw detector to conduct 100% coloring inspection on the roll surface. It is found that there are thermal cracks on the roll surface, no slag inclusion, no penetration, no fusion and other defects, and no ≥φ2.0mm is found single defect. After the back-up roll was repaired, the hardness of the roll surface and the roll neck were tested with a TH160 Li hardness tester. The results of the hardness test are shown in Table 3.

[0037] Table 3 surface hardness of back-up roll after surfacing

[0038]

[0039] It can be seen from the above table that after surfacing, the hardness of each point on the surface of the cold-rolled leveling backup roll is uniform, the hardness is HSD66.7-69.8, the hardness uniformity is ±HSD1.55, and the average hardness of the four directions is HSD68.2-68.4 Between, and the quality of the new roller is equivalent, fully qualified for use.

[0040] After surfacing the cold-rolled leveling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com