Wear resistance rolling roll for strip steel cold rolling and manufacturing method of wear resistance rolling roll

A strip steel and roll technology is applied to the wear-resistant roll and its preparation for cold-rolled strip, and the wear-resistant roll and its preparation field. , Low production cost, high roller strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

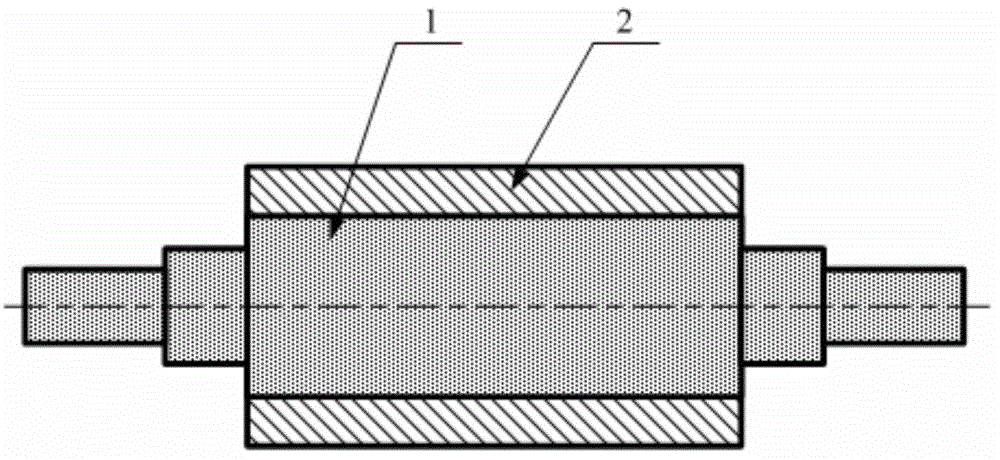

Image

Examples

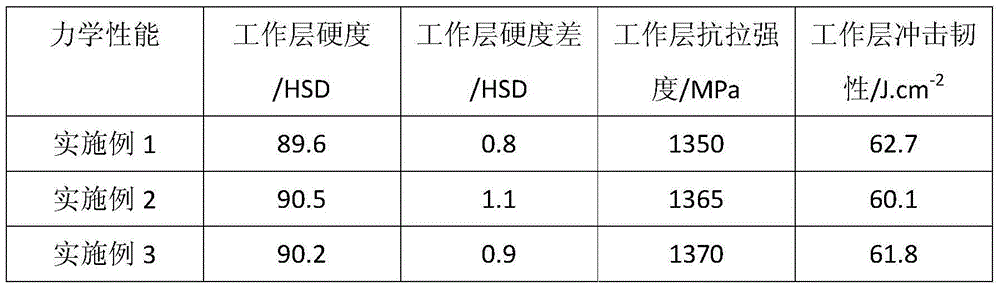

Embodiment 1

[0033] Adopt 750 kilograms of medium-frequency induction electric furnaces to smelt the material of the present invention, at first adopt GGr15 steel scrap, Q235 low-carbon steel scrap, low-carbon ferrochromium, ferromolybdenum, ferro-niobium, ferromanganese nitride, metal aluminum and ferroboron as ingredients, then adopt electric furnace smelting, and Carry out micro-alloying treatment on the molten steel, pour wear-resistant roll sleeves on the centrifugal casting machine, and perform hot-packing compounding with the processed roll shafts to obtain wear-resistant rolls for cold rolling of strip steel. The specific preparation method is as follows:

[0034] ① Melt the wear-resistant roll sleeve 2 of the working layer of the wear-resistant roll used for strip steel cold rolling in a 750 kg medium-frequency induction furnace. Wear-resistant roller sleeve 2 adopts GGr15 scrap steel with a mass fraction of 79% (the chemical composition and mass fraction of GCr15 scrap steel are: ...

Embodiment 2

[0039] Adopt 500 kilograms of medium-frequency induction electric furnaces to smelt the material of the present invention, first adopt GGr15 steel scrap, Q235 low-carbon steel scrap, low-carbon ferrochromium, ferromolybdenum, ferro-niobium, ferromanganese nitride, metal aluminum and ferroboron as ingredients, then adopt electric furnace smelting, and Carry out micro-alloying treatment on the molten steel, pour wear-resistant roll sleeves on the centrifugal casting machine, and perform hot-packing compounding with the processed roll shafts to obtain wear-resistant rolls for cold rolling of strip steel. The specific preparation method is as follows:

[0040]① First melt the wear-resistant roll sleeve 2 of the working layer of the wear-resistant roll used for strip cold rolling in a 500 kg medium-frequency induction furnace. Wear-resistant roller sleeve 2 adopts GGr15 scrap steel with a mass fraction of 80.8% (the chemical composition and mass fraction of GCr15 scrap steel are: 1....

Embodiment 3

[0045] Adopt 1500 kilograms of medium-frequency induction furnaces to smelt the material of the present invention, first adopt GGr15 steel scrap, Q235 low-carbon steel scrap, low-carbon ferrochromium, ferromolybdenum, ferro-niobium, ferromanganese nitride, metal aluminum and ferroboron as ingredients, then adopt electric furnace to smelt, and Carry out micro-alloying treatment on the molten steel, pour wear-resistant roll sleeves on the centrifugal casting machine, and perform hot-packing compounding with the processed roll shafts to obtain wear-resistant rolls for cold rolling of strip steel. The specific preparation method is as follows:

[0046] ① First melt the wear-resistant roll sleeve 2 of the working layer of the wear-resistant roll used for strip cold rolling in a 1500 kg medium-frequency induction furnace. Wear-resistant roller sleeve 2 adopts GGr15 scrap steel with a mass fraction of 80% (the chemical composition and mass fraction of GCr15 scrap steel are: 0.99%C, 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com