Wearable alloy profile steel bushing combined roller with groove and manufacturing method thereof

A technology of wear-resistant alloy and manufacturing method, which is applied in the direction of metal rolling, metal rolling, rolls, etc., can solve the problems of low slot hardness, short service life of rolls, poor wear resistance, etc., and achieve good hardness uniformity, roll The effect of high shaft strength and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

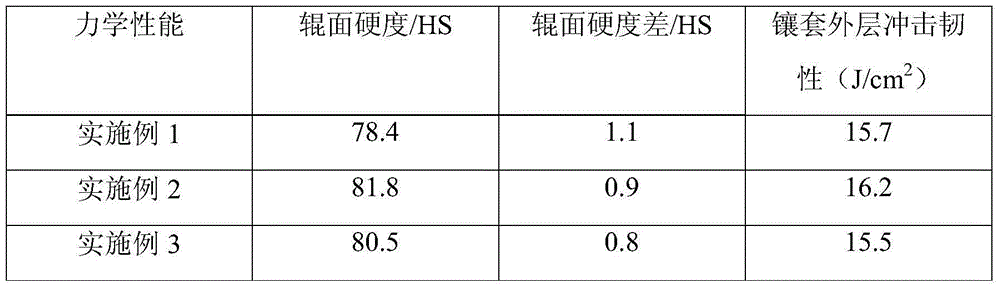

Embodiment 1

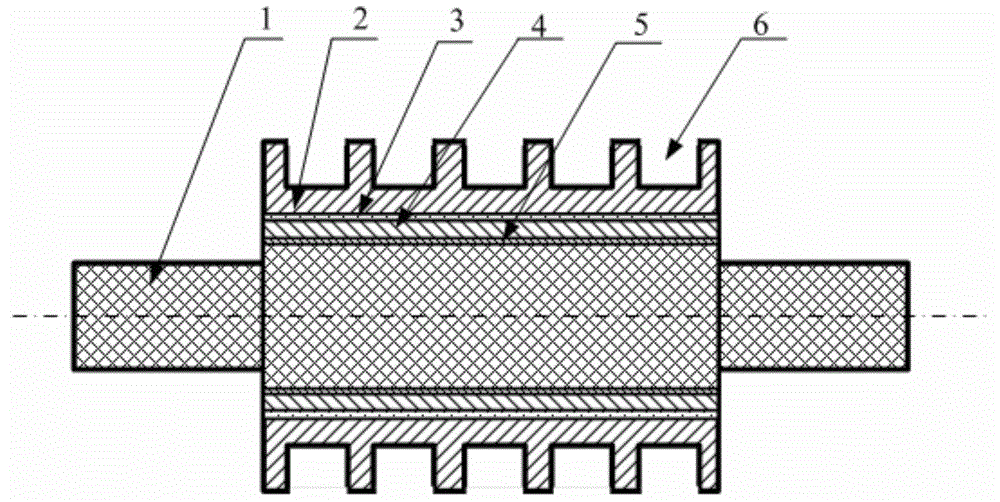

[0036] a roll diameter The manufacturing method of the wear-resistant alloy belt channel-shaped steel-inlaid combination roll with a roll body length of 900 mm is characterized in that the wear-resistant alloy belt-channel-shaped steel-inlaid combination roll is composed of the roll shaft 1 and the inlay by thermal fitting and bonding. In one piece, the outer layer of the sleeve is multi-component high-chromium wear-resistant alloy 2, the inner layer is low-alloy steel pipe 4, and the roller shaft 1 is placed in the low-alloy steel pipe 4 and runs through the low-alloy steel pipe 4 coaxially, specifically including the following steps:

[0037] ① Melt the outer multi-component high-chromium wear-resistant alloy melt in a 1000-kg medium-frequency induction furnace. The multi-component high-chromium wear-resistant alloy melt is composed of high-carbon ferrochrome with a mass fraction of 25% (chemical composition of high-carbon ferrochrome And the mass fraction is: 65.37% Cr, 7....

Embodiment 2

[0041] a roll diameter The manufacturing method of the wear-resistant alloy belt channel-shaped steel insert combined roll with a roll body length of 850mm is characterized in that the wear-resistant alloy belt channel-shaped steel insert combined roll is composed of the roll shaft 1 and the insert through thermal fitting and bonding compounding. In one piece, the outer layer of the sleeve is multi-component high-chromium wear-resistant alloy 2, the inner layer is low-alloy steel pipe 4, and the roller shaft 1 is placed in the low-alloy steel pipe 4 and runs through the low-alloy steel pipe 4 coaxially, specifically including the following steps:

[0042] ① Melt the outer multi-component high-chromium wear-resistant alloy melt in a 750-kg medium-frequency induction furnace. The multi-component high-chromium wear-resistant alloy melt is composed of high-carbon ferrochrome with a mass fraction of 25% (chemical composition of high-carbon ferrochrome And the mass fraction is: 62....

Embodiment 3

[0046] a roll diameter The manufacturing method of the wear-resistant alloy belt channel-shaped steel-inlaid combination roll with a roll body length of 950 mm is characterized in that the wear-resistant alloy belt-channel-shaped steel-inlaid combination roll is composed of the roller shaft 1 and the inlay by thermal fitting and bonding. In one piece, the outer layer of the sleeve is multi-component high-chromium wear-resistant alloy 2, the inner layer is low-alloy steel pipe 4, and the roller shaft 1 is placed in the low-alloy steel pipe 4 and runs through the low-alloy steel pipe 4 coaxially, specifically including the following steps:

[0047]① Melt the outer multi-component high-chromium wear-resistant alloy melt in a 1000-kg medium-frequency induction furnace. The multi-component high-chromium wear-resistant alloy melt is composed of high-carbon ferrochrome with a mass fraction of 26.5% (chemical composition of high-carbon ferrochrome And the mass fraction is: 66.44% Cr,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com