Surface quenching structure and quenching process of large-diameter cylindrical workpieces

A technology of surface quenching and large diameter, applied in the field of workpiece quenching, can solve the problems of poor hardness uniformity, difficulty in control, and many factors affecting the hardening depth, and achieve the effect of controlling the hardening depth and good hardness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

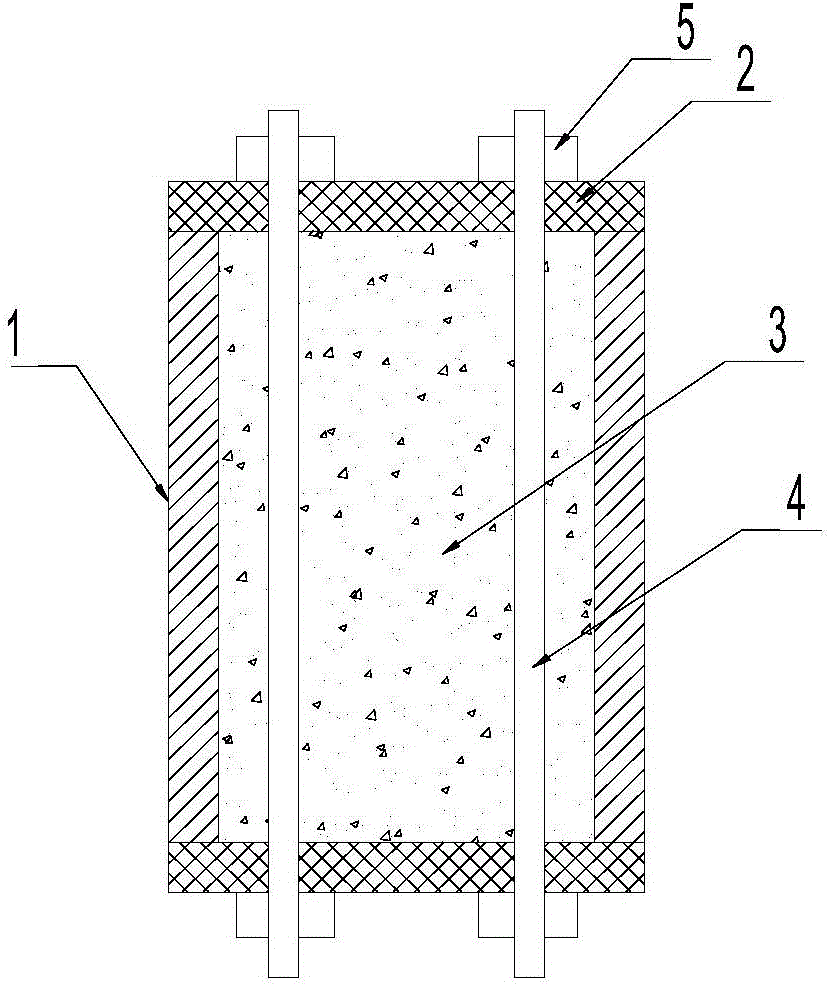

[0015] Such as figure 1 As shown, a surface quenching structure of a large-diameter cylindrical workpiece includes a cylindrical workpiece 1, a cover 2, and an insulating material 3. The insulating material 3 fills the interior of the cylindrical workpiece 1, and the cylindrical workpiece 1 The end is closed by a cover 2, and the cover 2 is fixed on the end of the cylindrical workpiece 1 by a mounting mechanism.

[0016] The installation mechanism includes a pull rod 4 and a lock nut 5. The two ends of the pull rod 4 have threads matched with the lock nut 5. The two ends of the pull rod 4 pass through the cover 2 respectively, and the lock nuts 5 are respectively installed on both ends of the pull rod 4. , apply pressure to the cover 2, and fix the cover 2 to the end of the cylindrical workpiece 1 by pressing.

[0017] The thermal insulation material 3 is yellow sand or asbestos.

[0018] A surface quenching process for large-diameter cylindrical workpieces is characterized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com