A fully automatic online cold welding repair roll press technology

A roller press, fully automatic technology, applied in the direction of welding medium, manufacturing tools, welding equipment, etc., can solve the problems of hidden dangers in welding quality, sealing of vulnerable equipment, transmission system, low construction efficiency, etc., and achieve the reduction of quality control links, Achieve automatic welding and save repair costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

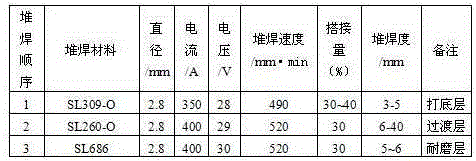

[0027] The specific steps of extrusion roller repair and remanufacturing process are:

[0028] (1) Carry out pretreatment on the surface of the cement extrusion roller to remove the fatigue layer, and weld retaining rings on both ends of the roller surface, and the retaining ring and the roller surface are on the same curved surface.

[0029] Among them, the specific process of pretreatment is: after the extrusion roller is installed with a slow motion device, the roller surface is processed by electric melting blasting to remove the fatigue layer; and then the roller surface is polished to remove sticky particles and cracks.

[0030] The electromelting explosion processing technology used in pretreatment is a non-contact strong electric processing. In the process of processing, special devices are used to make low voltage and high current generate special electric action between the electrode of the charged tool and the surface of the workpiece, and emit electrons to the surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com