Waterproof heat insulating decorative imitating ceramic composite board

A technology imitating ceramics and composite boards, which is applied in the direction of hydraulically coagulable layered products, building components, building insulation materials, etc., can solve the problems of affecting the use effect of products, poor composite effect, easy to fade, etc., and achieve enhanced waterproof and heat insulation Effect, water saving, smooth appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The embodiments of the present invention will be described in detail with reference to the accompanying drawings.

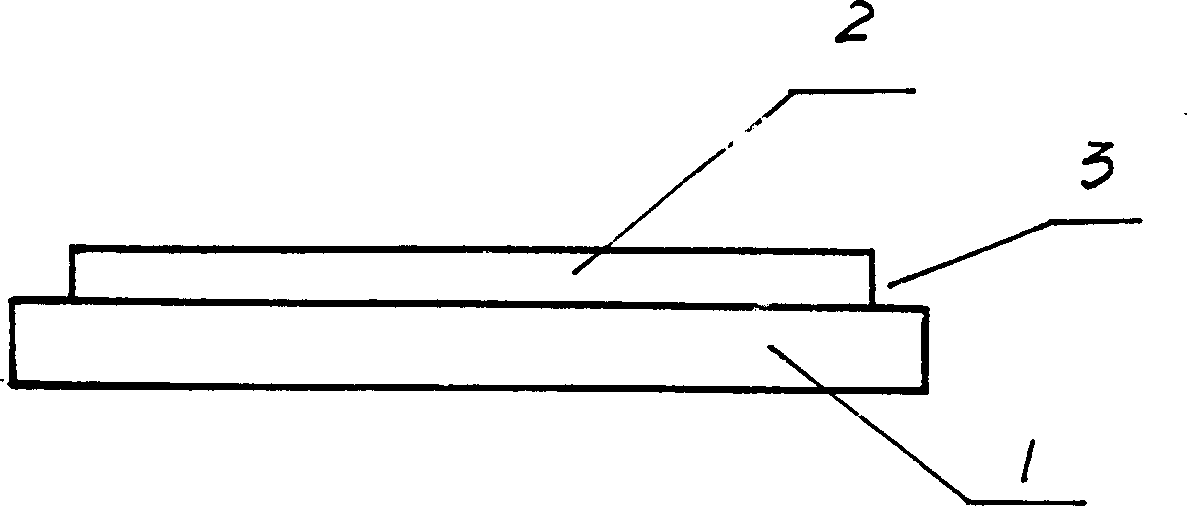

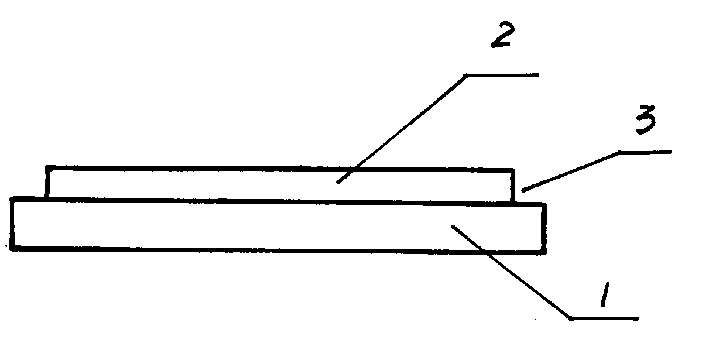

[0012] The waterproof and heat-insulating decorative ceramic imitation composite board of the present invention is made by compounding the substrate [1] and the waterproof and heat-insulation layer [2], with gaps [3] left around.

[0013] The substrate is made by mixing cement, fine sand, 1-2 crushed sand and water agent 1:1, and its formula (weight percentage) is:

[0014] Recipe 1: cement 35 fine sand 30 1-2 crushed sand 35

[0015] Recipe 2: cement 40 fine sand 30 1-2 crushed sand 30

[0016] Formula 3: cement 40 fine sand 25 1-2 crushed sand 35 water can be added 2% early strength superplasticizer and 8% polyethylene glue.

[0017] The waterproof and heat-insulating decorative layer is made by mixing white jade sand, white cement, light imitation ceramic additive powder and polyethylene glue 1:1, and its formula is: (weight percentage)

[0018] Form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com