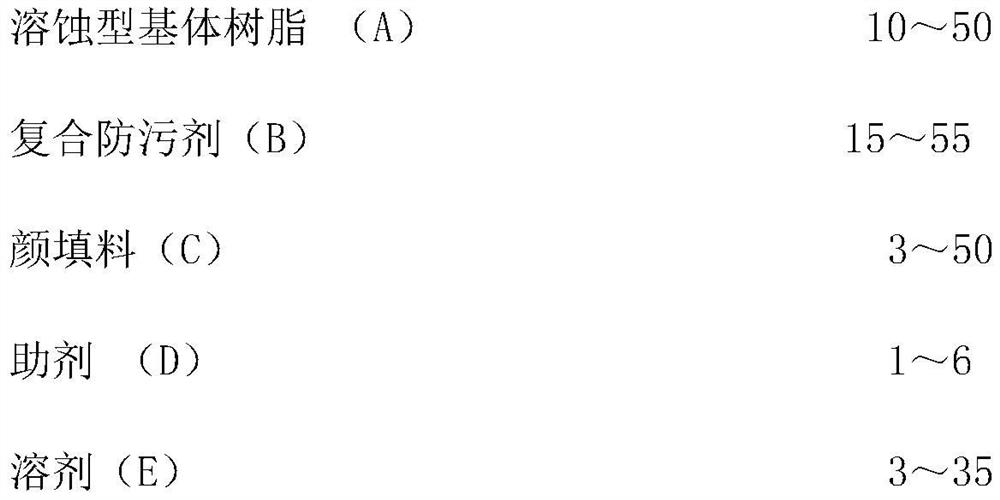

Corrosion type marine anti-fouling paint, corrosion type matrix resin and preparation method

A marine antifouling and matrix resin technology, applied in the field of erosion-type matrix resin and its preparation, and erosion-type marine antifouling coatings, can solve the problems of high cost and inappropriateness, and achieve low cost, easy maintenance, and simple and easy synthesis process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

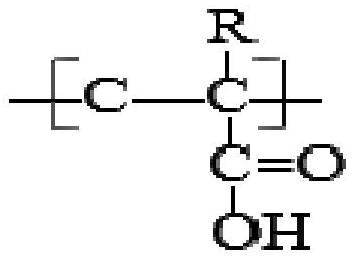

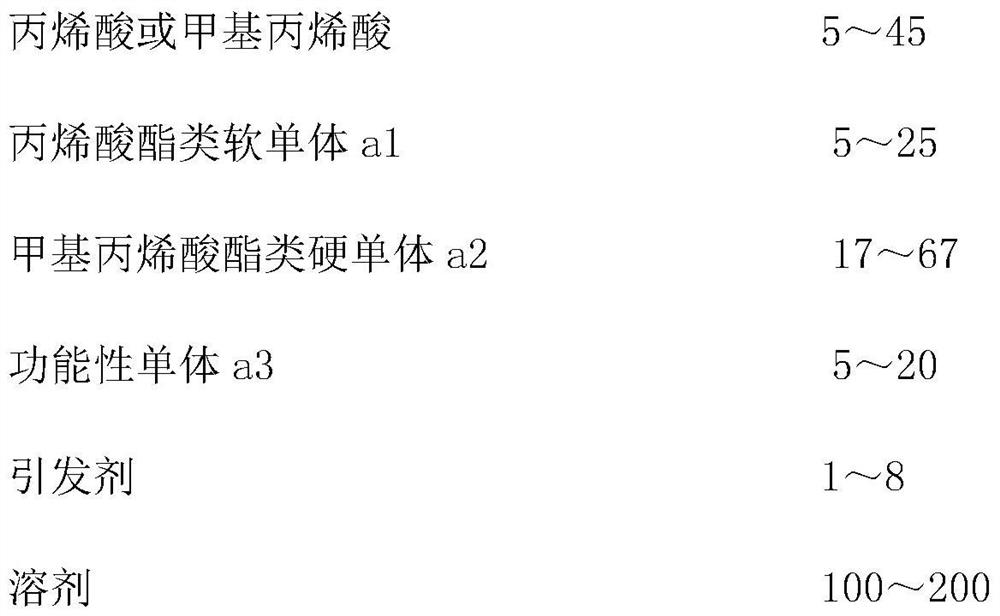

[0060] (1) Preparation process of erosion type matrix resin A

[0061] Add part of the solvent and part of the monomer a1 according to the formula amount into a four-necked bottle equipped with a stirring device, a condenser, a dropping funnel, and a thermometer, raise the temperature to 90-115°C, and mix acrylic acid or methacrylic acid and the remaining mono Mix monomer a1, monomer a2, monomer a3 and part of the initiator according to the formula ratio, and add them all dropwise into the four-necked bottle, add dropwise for 3.0-3.5 hours, keep warm for 1.0-1.5 hours, and then add the remaining initiator and After adding the solvent, keep it warm for 2.0 to 2.5 hours, cool down and discharge the material, and prepare the erosion-type matrix resin A.

[0062] In the process of preparing the erosion-type matrix resin A, the weight ratio of monomer a1 added twice is 1:1-10.

[0063] In the process of preparing the erosion-type matrix resin A, the weight ratio of the initiator a...

Embodiment 1

[0068] Example 1: Erosion-type matrix resin A1

[0069] Add 25 parts of propylene glycol methyl ether, 85 parts of xylene and 5 parts of ethyl acrylate into a four-necked flask equipped with a stirring device, a condenser, a dropping funnel, and a thermometer, and stir and heat to 105°C. From the dropping funnel, add 15 parts of acrylic acid, 15 parts of ethyl acrylate, 40 parts of methyl methacrylate, 15 parts of ethyl methacrylate, 10 parts of methoxyethyl acrylate, 2.5 parts of azobisisobutyl The mixed liquid composed of nitrile was 3 hours. After adding all the mixed liquid dropwise, keep it warm for 1.0 hour, then add 0.5 parts of azobisisobutyronitrile and 10 parts of xylene, keep it for another 2.5 hours, cool down and discharge the material to obtain the erosion matrix resin A1.

Embodiment 2

[0070] Embodiment 2: erosion type matrix resin A2

[0071] Add 25 parts of n-butanol, 85 parts of xylene and 5 parts of butyl acrylate into a four-neck flask equipped with a stirring device, a condenser, a dropping funnel, and a thermometer, and stir and heat to 105°C. 25 parts of acrylic acid, 10 parts of ethyl acrylate, 40 parts of trifluoroethyl methacrylate, 10 parts of butyl methacrylate, 10 parts of ethoxyethyl acrylate, 2.5 parts of azobis The mixed liquid composed of isobutyronitrile was kept for 3 hours. After adding all the mixed liquid dropwise, keep it warm for 1.0 hour, then add 0.5 parts of azobisisobutyronitrile and 10 parts of xylene, keep it warm for another 2.5 hours, cool down and discharge the material to obtain the erosion matrix resin A2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com