Tech. for spraying corrosion resistant coating on dry screw compressor rotor

A dry screw compressor, spraying anti-corrosion coating technology, applied in mechanical equipment, machines/engines, rotary piston pumps, etc., can solve the problems of uneven thickness, weak adhesion, poor coating quality, etc., to achieve meshing Reasonable gap, excellent adhesion, uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

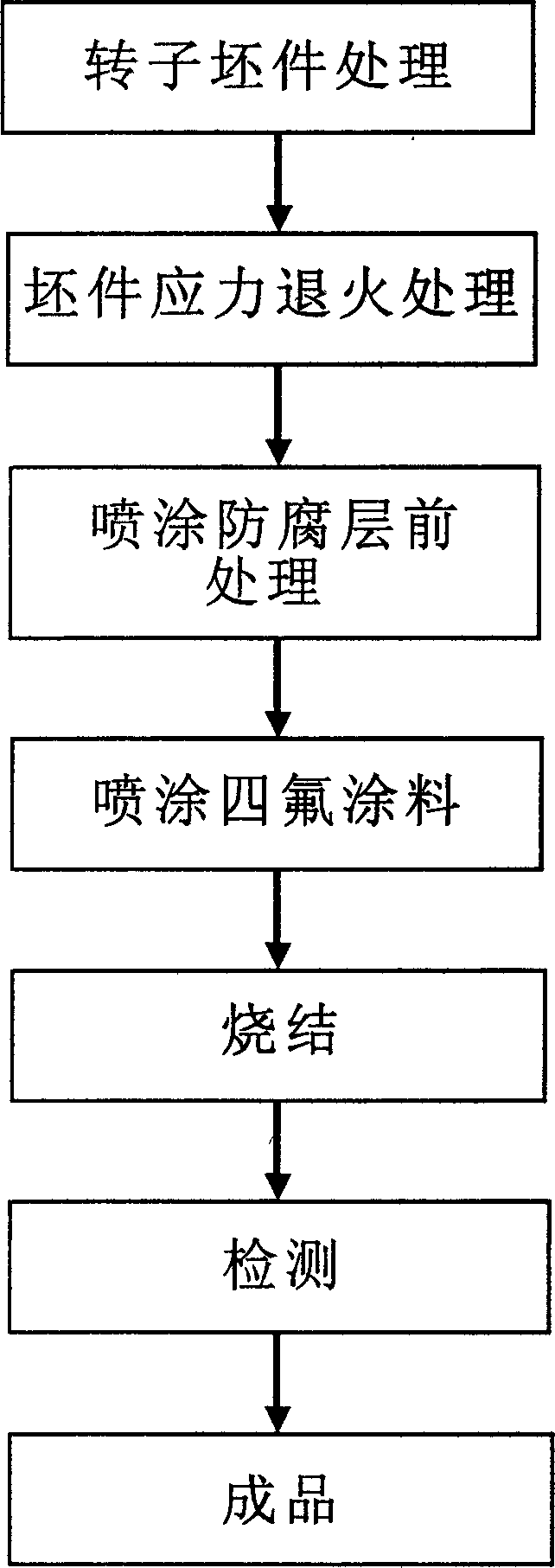

Method used

Image

Examples

Embodiment 1

[0034] 1. The material of the rotor body is forged steel 35#, and the pretreatment is carried out first:

[0035] The first condition for the coating not to be damaged is to pre-treat the base material to be sprayed.

[0036] (1) Cut the rotor matrix material into the required rotor blank when calculating the profile of the rotor tool. The spiral surface of the rotor blank should be given a coating value, and the coating value is: 0.02mm;

[0037] (2) After the rotor blank is processed, the test run is carried out, and the feasible meshing clearance of the rotor profile is tested; 0.28mm;

[0038] (3) The rotor blank is forged from the blank, and after rough machining, it must be treated with stress relief annealing, so as to avoid peeling off of the coating due to stress release due to temperature rise during sintering.

[0039] 2. Stress relief annealing heat treatment of rotor blank:

[0040] (1) Put the rotor blank into the furnace below 220°C;

[0041] (2) Afterwards, ...

Embodiment 2

[0059] 1. Pretreatment of the rotor matrix material:

[0060] The coating value is: 0.03mm; the meshing gap of the rotor profile is; 0.3mm;

[0061] 2. Stress relief annealing heat treatment of rotor blank:

[0062] (1) Put the rotor blank into the furnace below 220°C;

[0063] (2) Afterwards, heat up to 600°C at a rate below 80°C / hour;

[0064] (3), when the temperature is: 580 ℃, heat preservation for 3 hours;

[0065] (4) Cool in the furnace to below 300°C;

[0066] (5) When the temperature in the furnace reaches below 300°C, take out the rotor blank from the furnace;

[0067] (6), then placed in the atmosphere to cool.

[0068] 3. Pre-treatment of spraying anti-corrosion layer:

[0069] (1) The surface of the rotor blank to be sprayed is cleaned with acetone or trichlorethylene;

[0070] (2) Sinter in an electric furnace after cleaning, and sinter at a temperature of 300°C for 3 hours;

[0071] (3) After sintering and cooling, the rotor blank is subjected to sandblas...

Embodiment 3

[0081] Using the process steps and process conditions in Embodiment 1 and Embodiment 2, the rotor coated with an anti-corrosion layer can also obtain the above effects. The thickness of the rotor spiral surface coating is 0.03mm, and it only needs to be sprayed once to reach the desired thickness, and then dried; the thickness of the rotor spiral end surface coating is 0.06mm, and the thickness of the outer circle coating of the rotor shaft seal is: 0.06mm (thickness above 0.03mm); therefore, when using a spray gun to spray on the rotor helical end face and the outer circle of the rotor shaft seal, it must be sprayed more than two times, and a pre-drying treatment should be carried out every time it is sprayed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com