High-strength zinc-aluminum-magnesium-coated steel sheet with good surface quality and manufacturing method thereof

A technology for surface quality and coated steel sheets, which is applied in the manufacture of high-strength zinc-aluminum-magnesium coated steel sheets and the field of high-strength zinc-aluminum-magnesium coated steel sheets. Good toughness and high coating hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

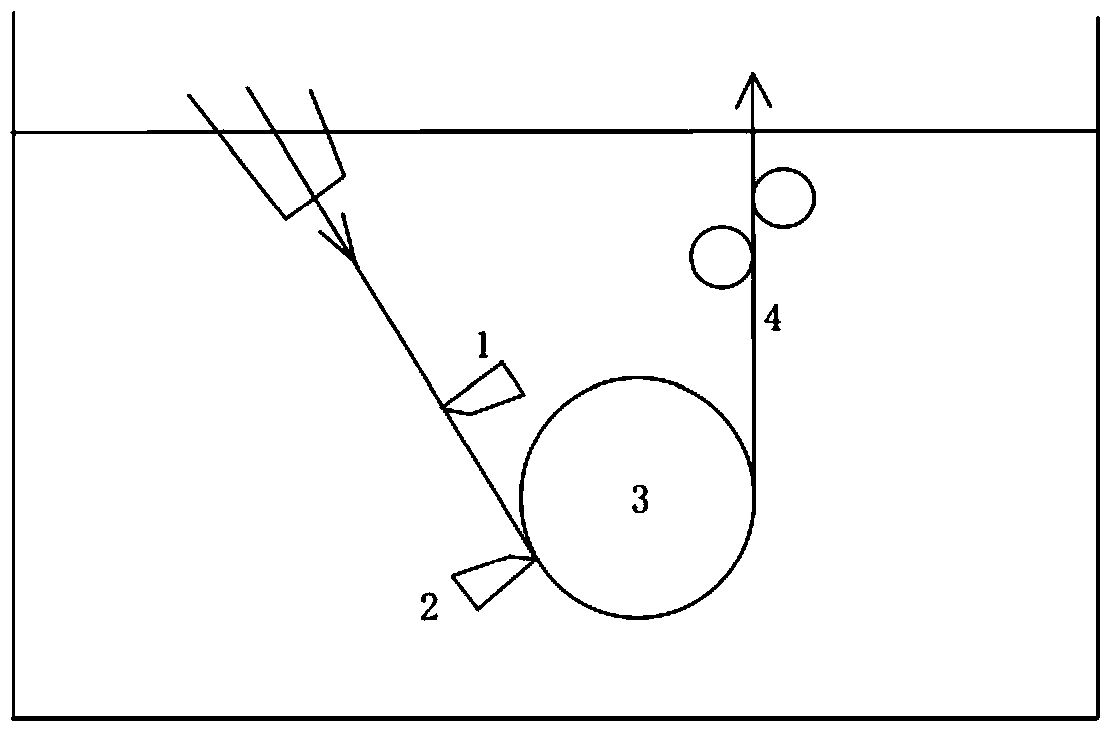

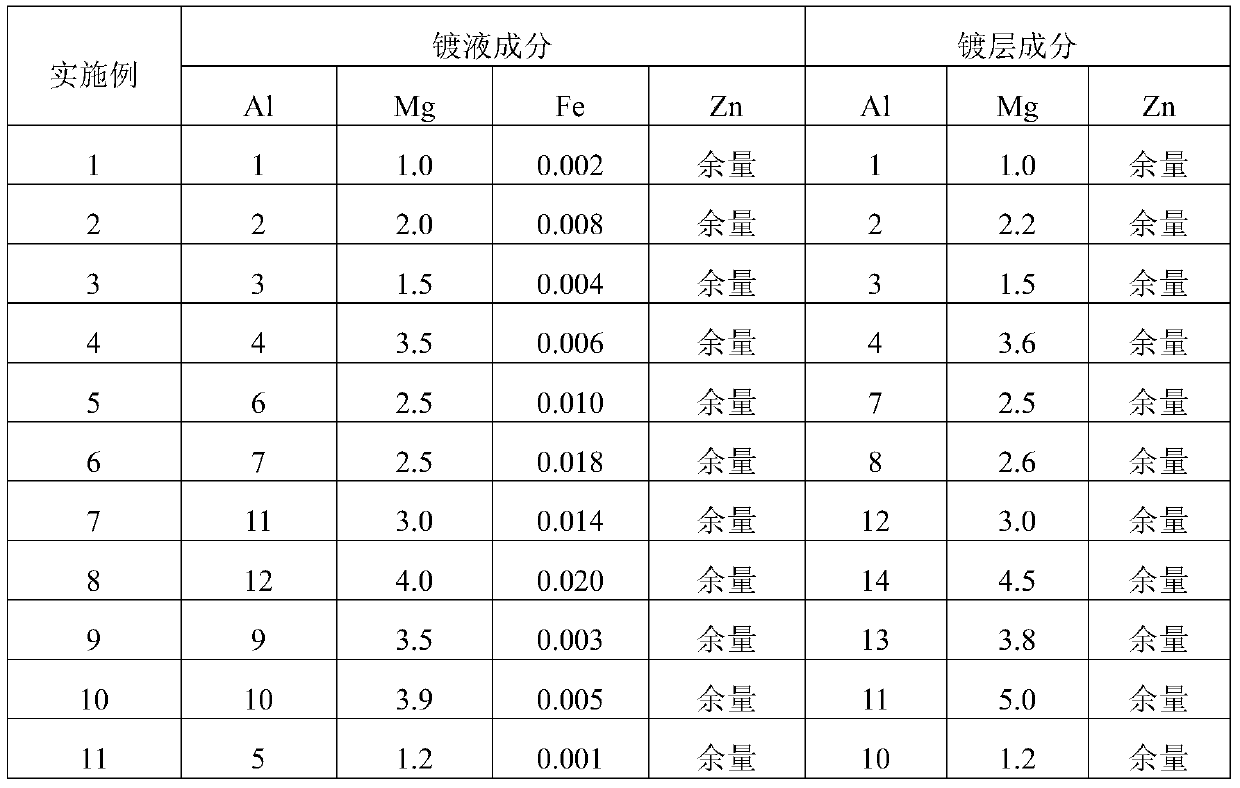

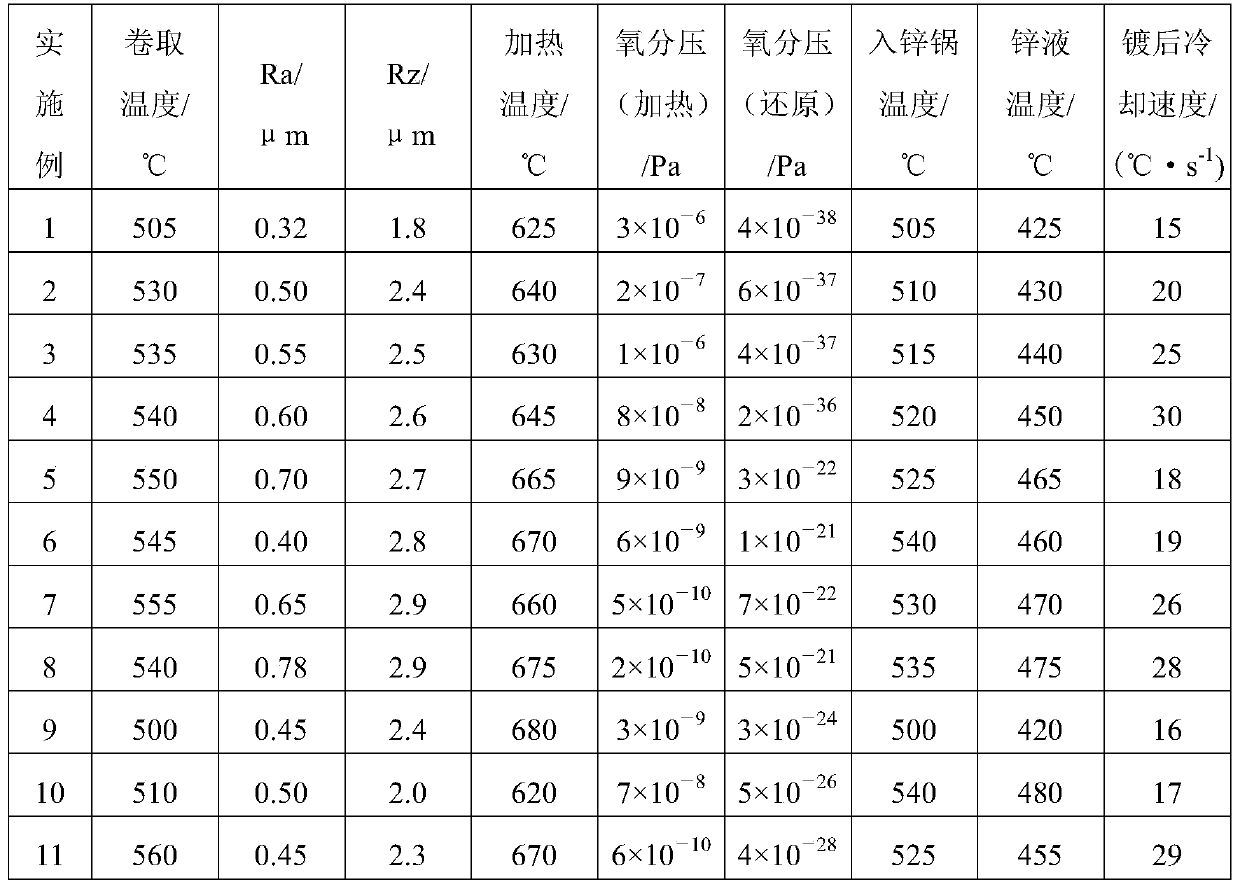

[0039] The invention discloses a high-strength zinc-aluminum-magnesium coated steel plate with good surface quality and a manufacturing method thereof. 0.008%, Cr 0.01%~0.60% and / or Mo 0.01%~0.30% can also be added, the chemical composition of the plating solution is Al 1%~12%, Mg1.0%~4.0%, Fe 0.002%~0.020%. The hot-rolling coiling temperature is 500-560°C, the surface roughness of the steel plate after cold-rolling is Ra 0.3-0.8μm, Rz≤3μm, the heating temperature is 620-680°C, and the oxygen partial pressure in the furnace is 2×10 -10 ~3×10 -6 Pa, the partial pressure of oxygen in the furnace during the subsequent heating and cooling process is 4×10 -38 ~5×10 -21 Pa, the temperature of the strip steel entering the zinc pot is 500-540°C, the temperature of the zinc-aluminum-magnesium alloy melt is 420-480°C, after plating, it is cooled at a cooling rate of 15-30°C / s, and the temperature of the strip steel is reduced to below 280°C before turning . When the strip steel ente...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com