Wear-resistant MoSiCu laser clad layer material and preparation method thereof

A laser cladding and coating material technology, applied in the field of material surface strengthening, to achieve the effects of stable friction coefficient, good wear resistance, fine and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The composition of the first cladding powder material is calculated by atomic percentage: 27% Mo, 33% Si, 40% Cu. A single-element powder with a particle size of 200 mesh was used for powder mixing in a ball mill for 1.5 hours according to the above alloy ratio, and a uniform powder was obtained after mixing. Then clean and polish the surface of the substrate, wipe it clean, and blow dry; use diacetone alcohol solution to adjust the powder to a viscous state, pre-set it on the surface of the substrate and dry it naturally, then dry it in a drying box for 2 hours at a drying temperature of 180 °C. The thickness is 1.5mm. Then use the laser beam to carry out laser cladding on the substrate surface of the preset Mo, Si, Cu alloy powder to prepare the ternary alloy coating. The flow rate is 20L / min, the laser power is 2500W, the scanning speed is 900mm / min, and the defocus is 25mm.

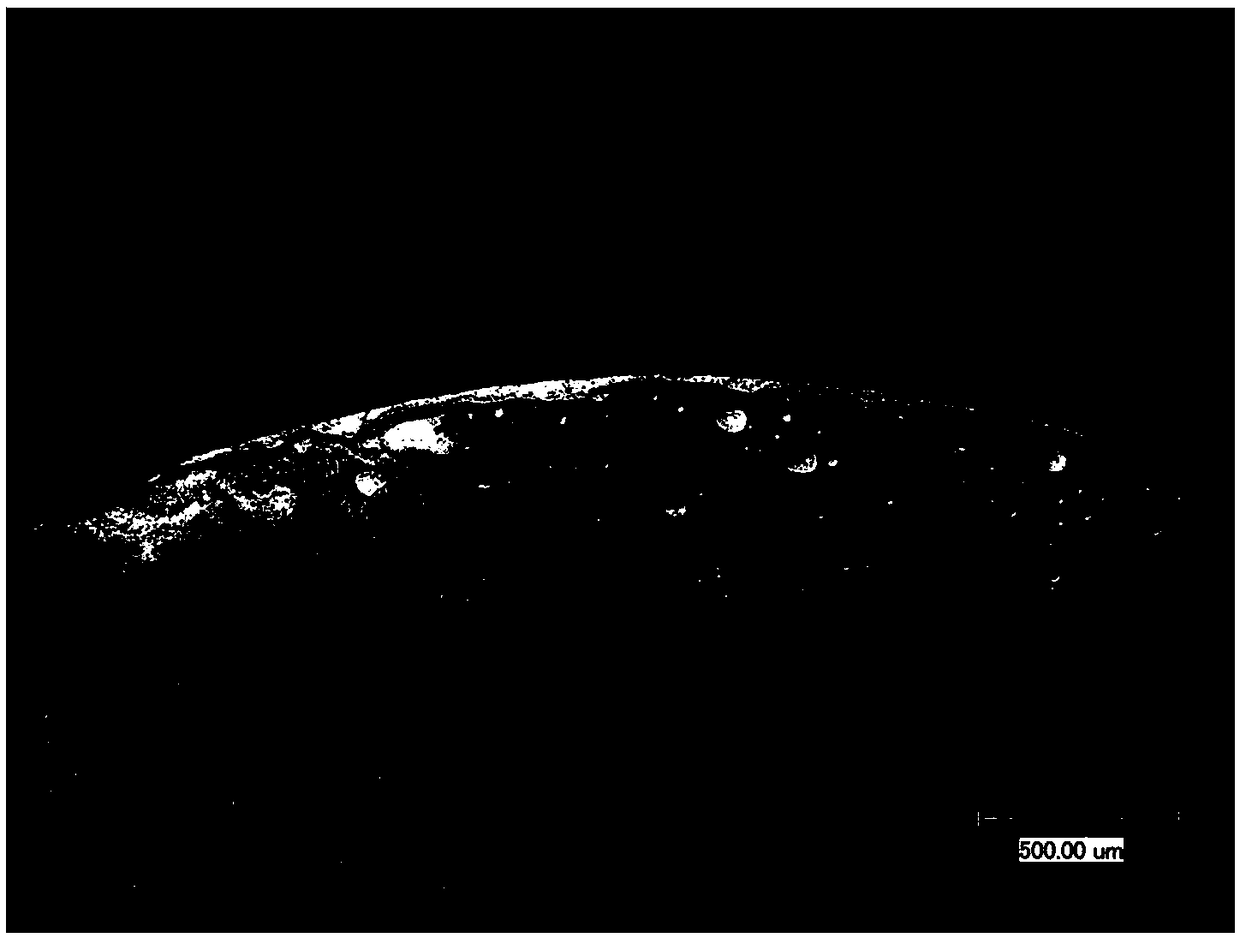

[0025] See attached figure 1 , 2 As shown in , 4 and 5, the structure of the obtained c...

Embodiment 2

[0027] The composition of the first cladding powder material is calculated by atomic percentage: 37% Mo, 22% Si, 40% Cu. A single-element powder with a particle size of 150 mesh was used for powder mixing in a ball mill for 1 hour according to the above alloy ratio, and a uniform powder was obtained after mixing. Then clean and polish the surface of the substrate, wipe it clean, and blow dry; use diacetone alcohol solution to adjust the powder to a viscous state, pre-set it on the surface of the substrate and let it dry naturally, then dry it in a drying box for 1.5 hours at a drying temperature of 150 °C. The thickness is 1.2mm. Then use the laser beam to carry out laser cladding on the substrate surface of the preset Mo, Si, Cu alloy powder to form a ternary alloy coating. The flow rate is 20L / min, the laser power is 3000W, the scanning speed is 1500mm / min, and the defocus is 25mm.

[0028] see image 3 As shown, the feathery material in the obtained cladding layer is mai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com