Patents

Literature

35results about How to "Reduced oxidative weight gain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite ceramic material and inner container of electric cooker prepared from composite ceramic material

ActiveCN105084905AExcellent thermal diffusivityImprove heat transfer efficiencyCooking-vessel materialsPtru catalystComposite ceramic

The invention discloses a composite ceramic material and an inner container of an electric cooker prepared from the composite ceramic material. The composite ceramic material is prepared from the following components in parts by weight: 3-8 parts of barium carbonate, 20-35 parts of calcite, 5-10 parts of kaolin, 35-55 parts of silica powder, 3-8 parts of potassium nitrate, 10-15 parts of paraffin, 3-8 parts of sodium carbonate, 7-8 parts of boric acid, 11-15 parts of quartz, 50-75 parts of aluminum nitride powder, 2-3 parts of yttrium oxide and 3-5 parts of lanthanum oxide, wherein the aluminum nitride powder is generated by reacting aluminum oxide powder serving as an aluminum source and carbon black powder in the flowing nitrogen atmosphere at the temperature of 1500-1700 DEG C; calcium oxide is added as a catalyst in the reaction process, and decarbonization is carried out in dry air with the temperature of 700-800 DEG C after the reaction is finished; the mass content of cation impurities in the aluminum oxide powder is lower than or equal to 0.02%, and the mass contents of silicon and iron impurities are respectively lower than 0.001%; and the average particle size of the carbon black powder is 35-40nm, and the specific surface area is smaller than or equal to 90m<2> / g.

Owner:GUANGDONG ENAITER ELECTRICAL APPLIANCES CO LTD

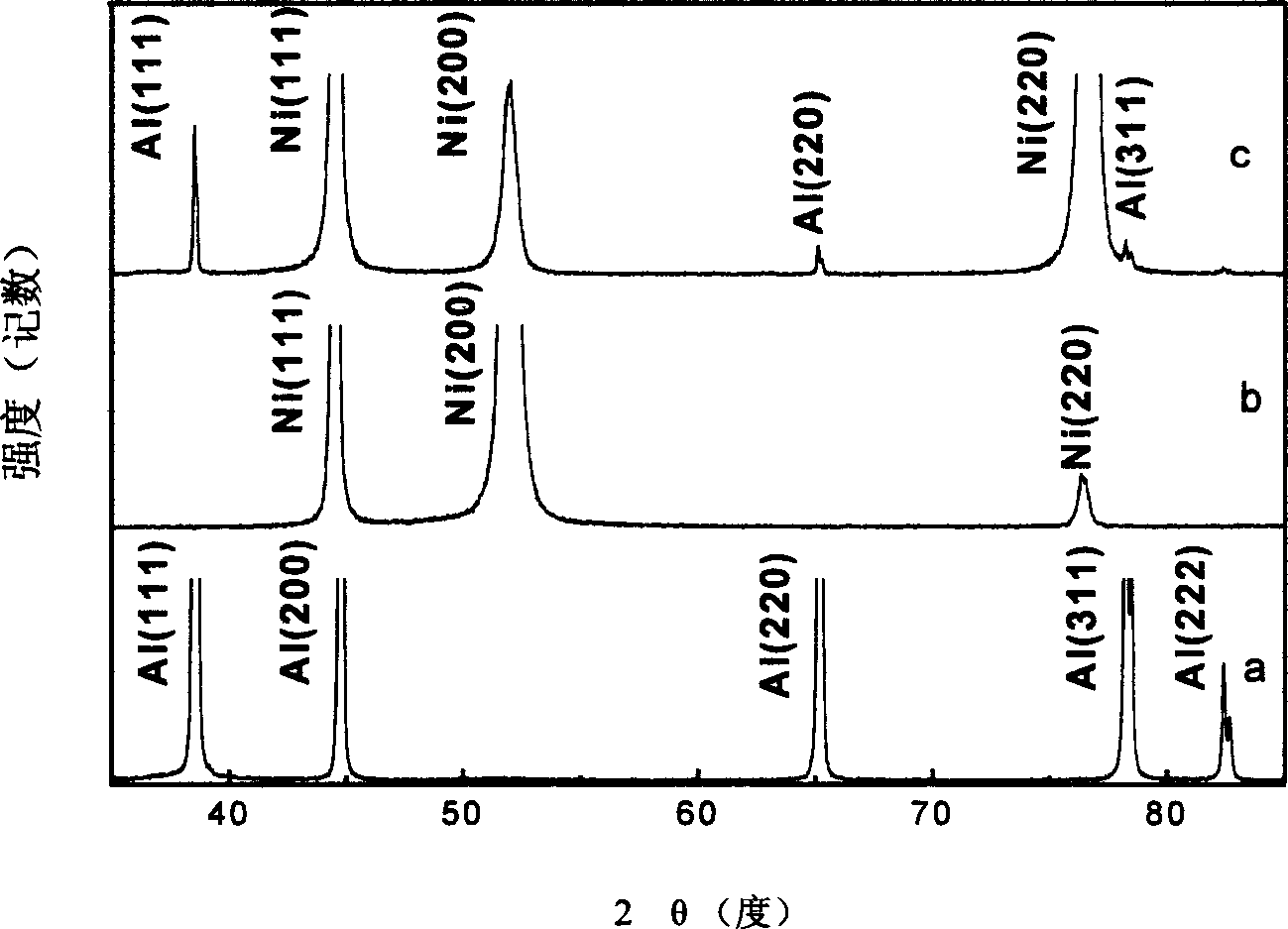

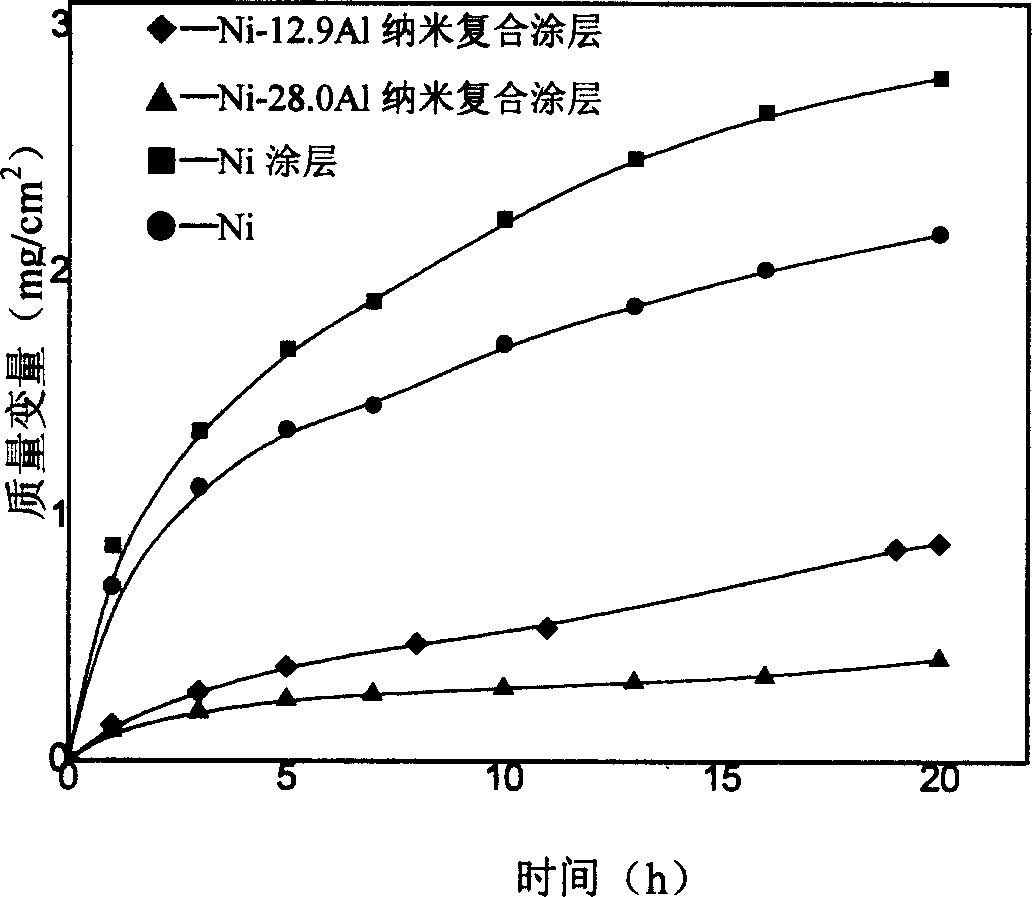

Thermal growth AL2O3 film type M A1 nano composite plating and producing process and application

InactiveCN1576398AIncrease the number of nucleiDiffusion fastElectrolytic coatingsGrown filmNanoparticle

The thermally grown Al2O3 film type M-Al nano composite coating consists of nano crystal M coating and nano metal Al grains dispersed in the coating, where M is Ni, Fe or Co. The Al content is 9.8-35 wt%, and M is the rest. The nano composite Ni-Al, Fe-Al or Co-Al coating is prepared through composite electroplating process to deposit metal M and Al coating on to the base material of Ni, Fe or Co, carbon steel or alloy steel. The present invention has the features of simple technological process, low cost, high and controllable compounded amount, compact coating, no need of vacuum diffusion treatment of the nano composite coating, direct thermally growth of protecting Al2O3 film, etc.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

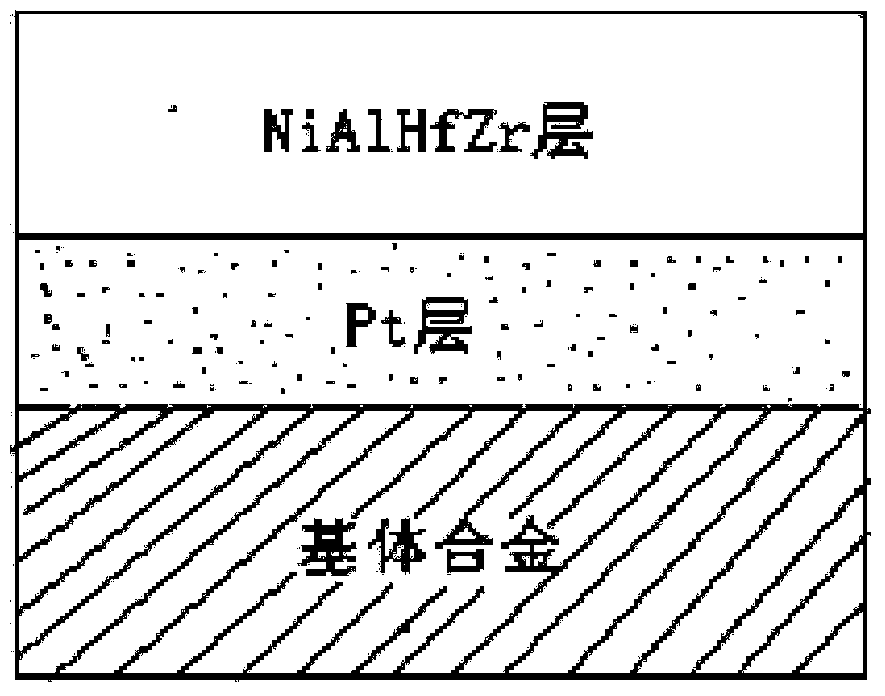

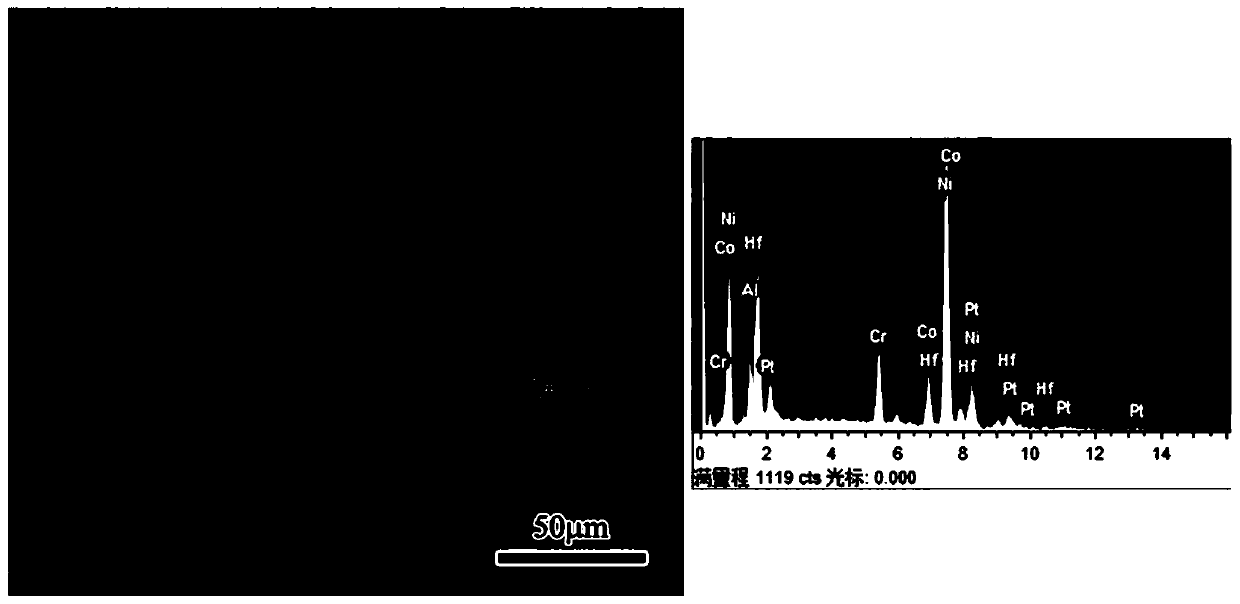

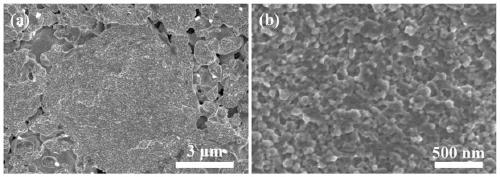

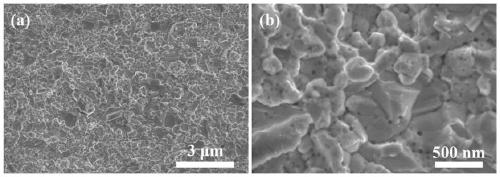

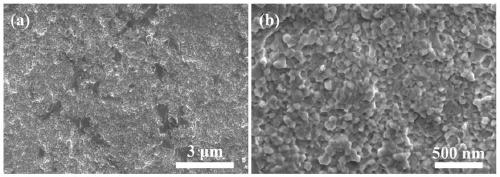

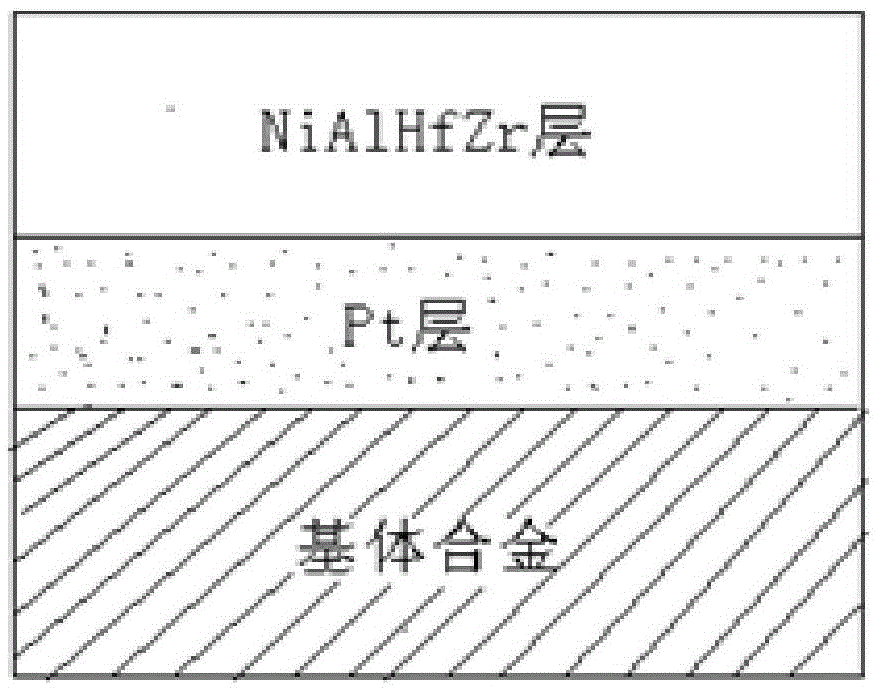

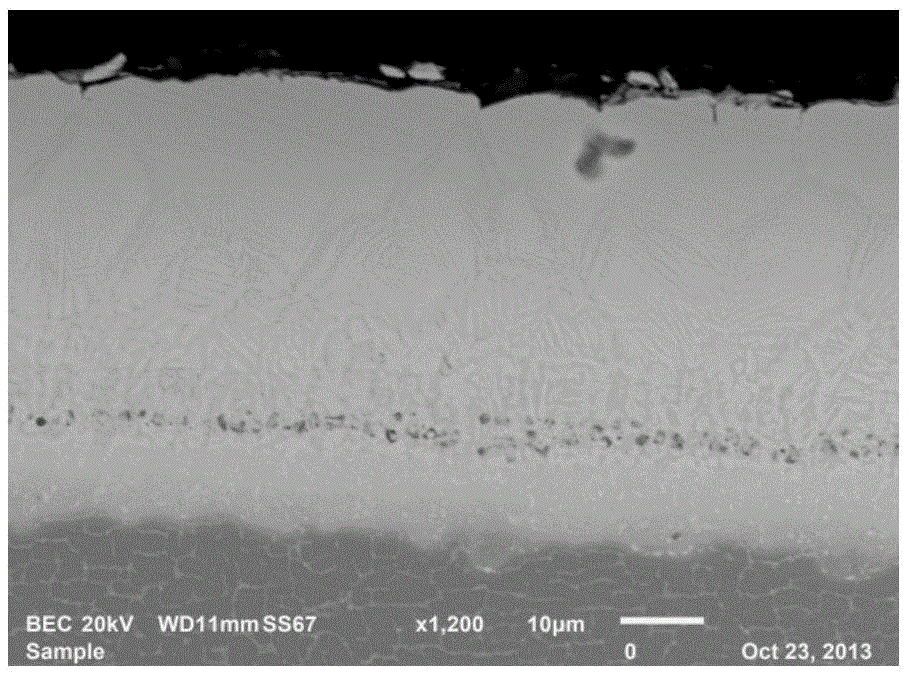

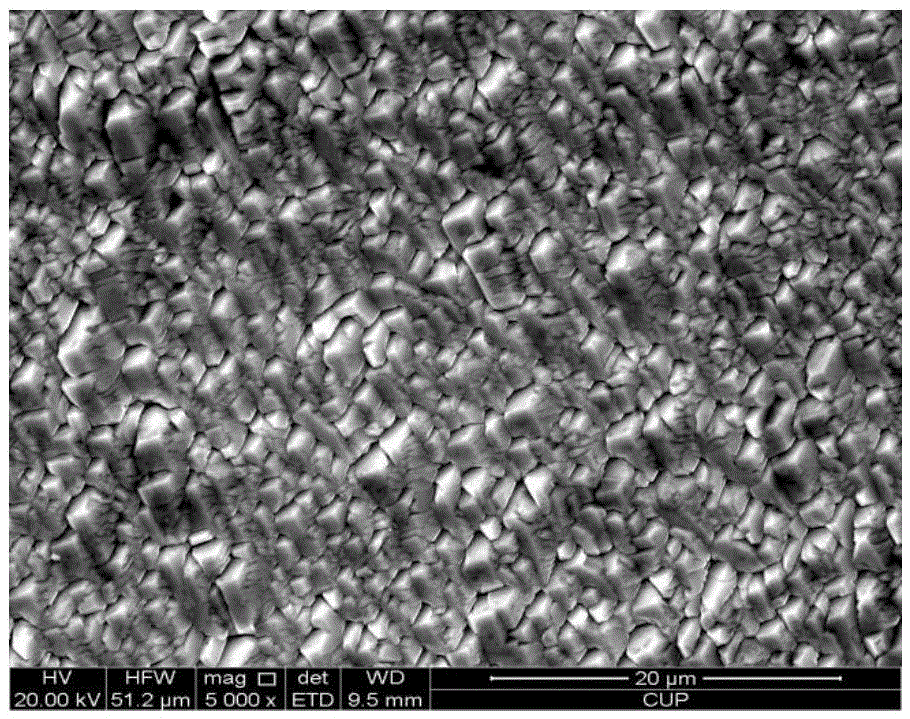

Pt Ni Al bonding layer doped with binary trace active elements and capable of being completely oxidation resisting at 1200 DEG C and preparation method thereof

ActiveCN103966615AImprove high temperature oxidation resistanceImprove adhesionVacuum evaporation coatingSputtering coatingOxidation resistantThermal barrier coating

The present invention discloses a Pt Ni Al bonding layer doped with binary trace active elements and capable of being completely oxidation resisting at 1200 DEG C and a preparation method thereof and belongs to the field of novel thermal barrier coatings and the preparation technologies. According to the invention, firstly, a Pt layer with the thickness of 5-10 microns is prepared on a nickel base monocrystal high temperature alloy matrix through the plating or the electron beam physical vapor deposition method, and then a NiAlHfZr coating with the thickness of 20-60 microns is deposited on the Pt layer through the electron beam physical vapor deposition method. The Pt layer reduces the interfacial holes and effectively improves the adhesion of an oxidation film; binary doping of Hf, Zr enables the NiAl coating surface to be smoother and denser and enables the oxidation film generated during the oxidation process on the coating surface to be straighter, especially with little oxidation increase, and greatly improves the oxidation resistance of the coating. The Pt Ni Al bonding layer is completely oxidation resisting at 1200 DEG C. The service life of the coating is prolonged to certain degree through doping of binary elements namely Hf and Zr and Pt modification.

Owner:BEIHANG UNIV

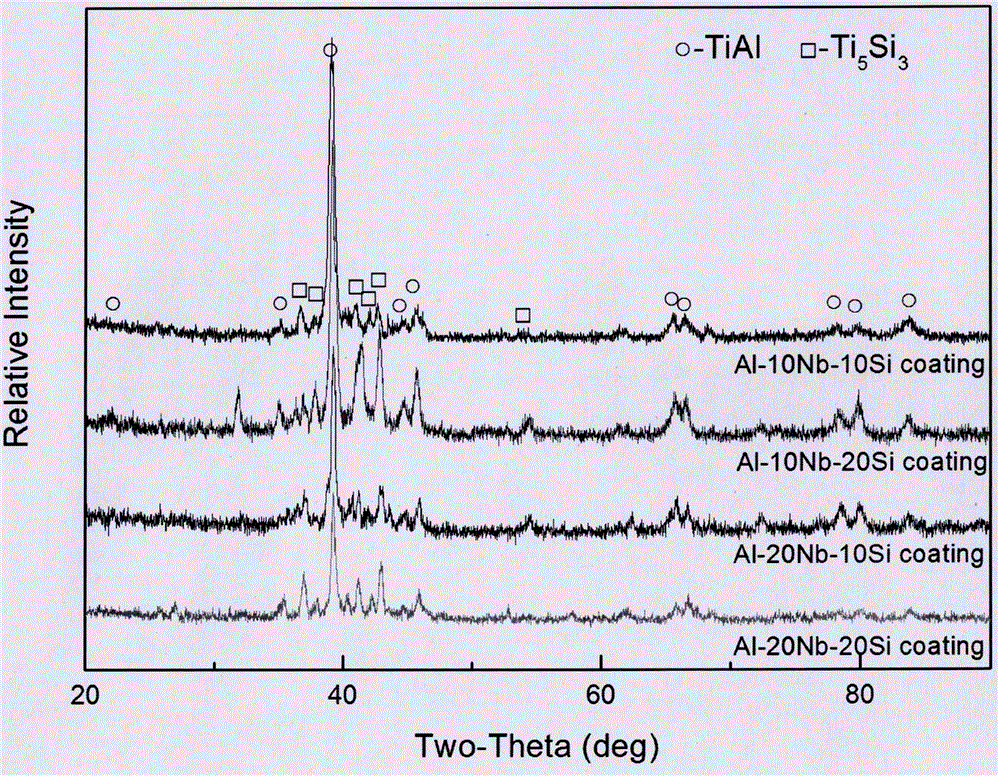

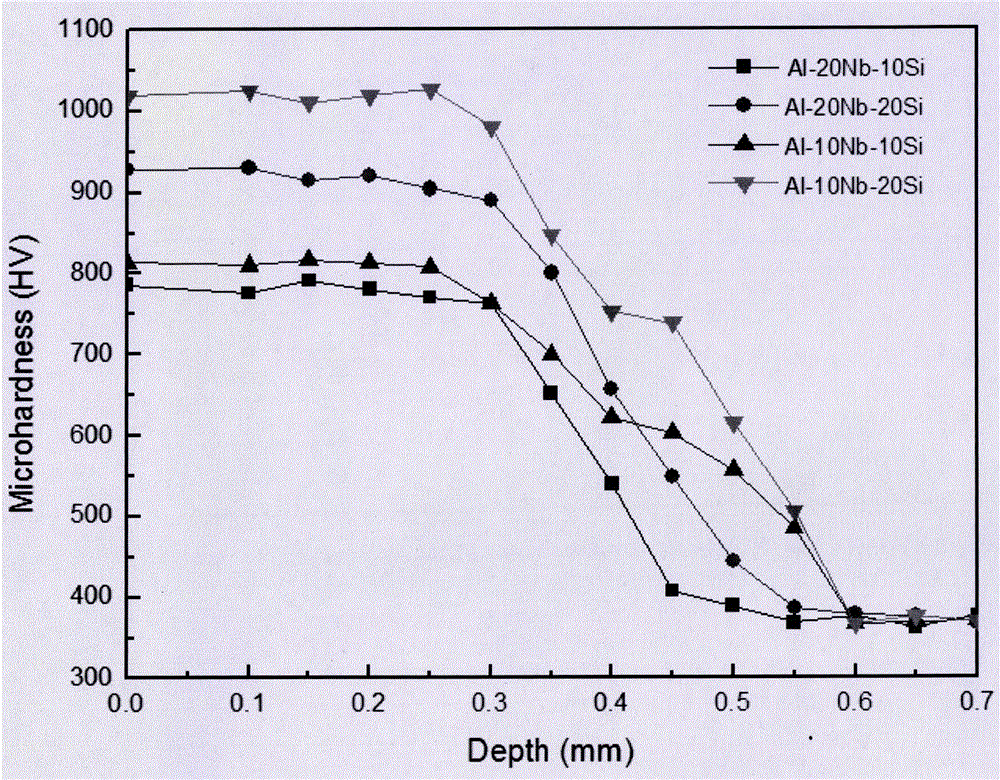

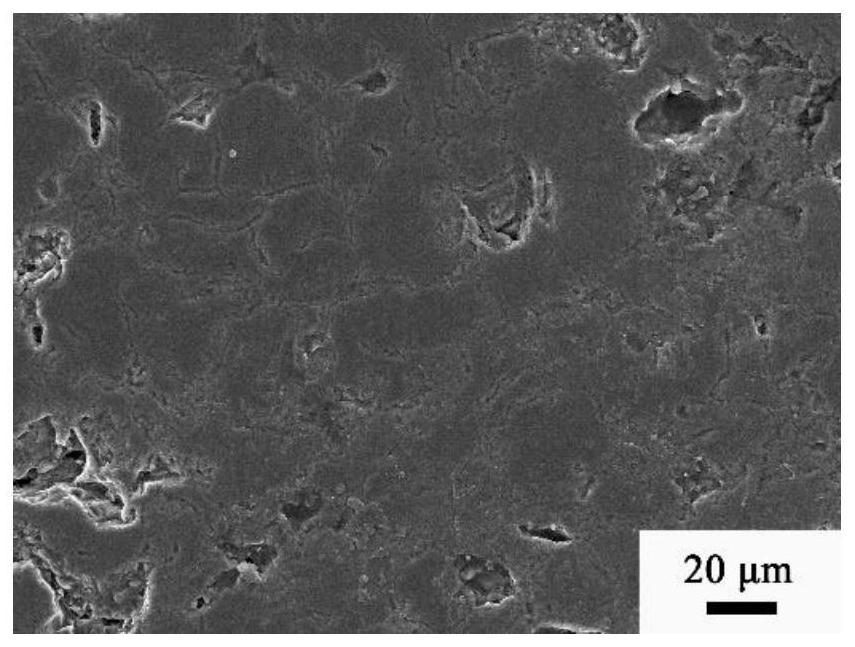

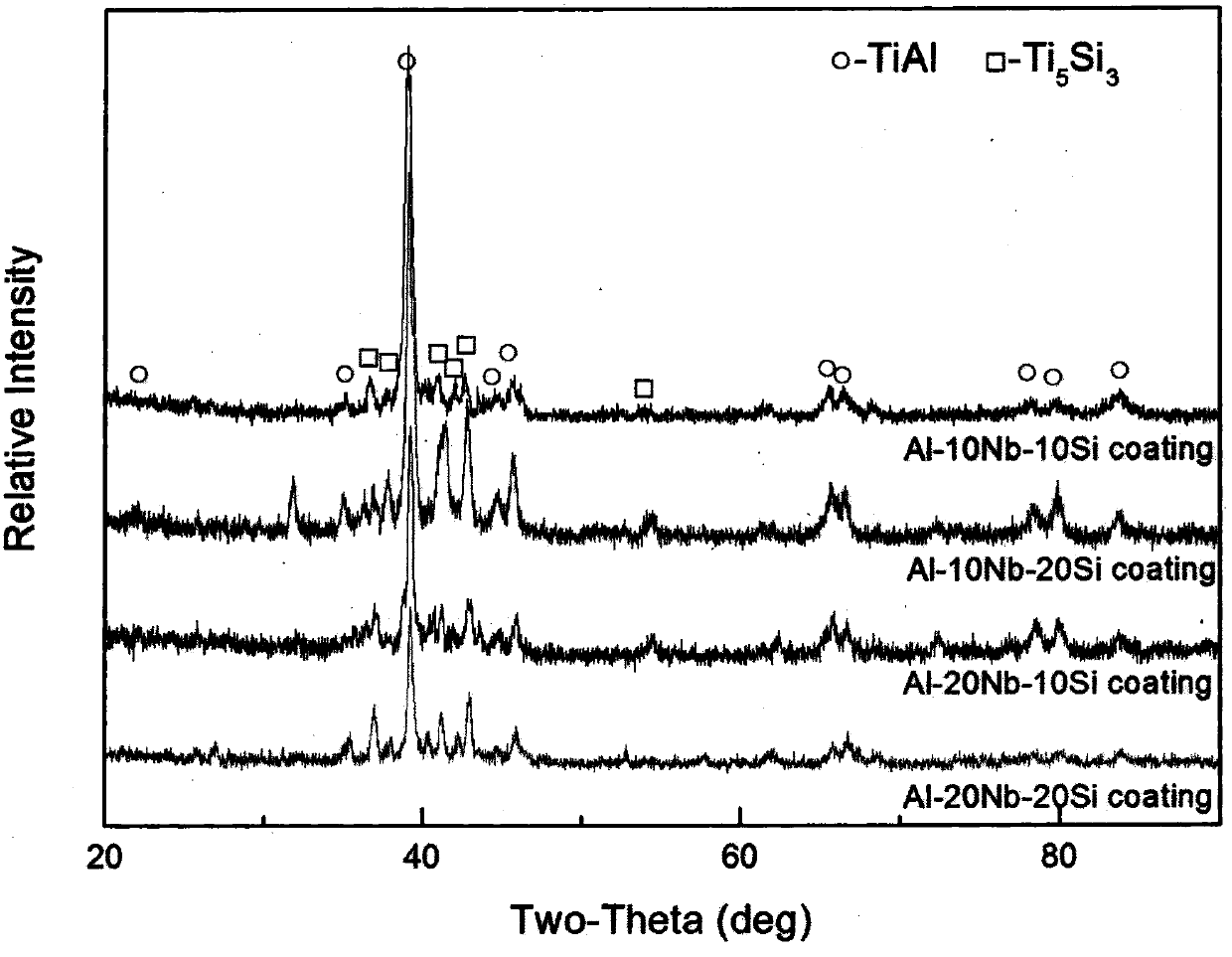

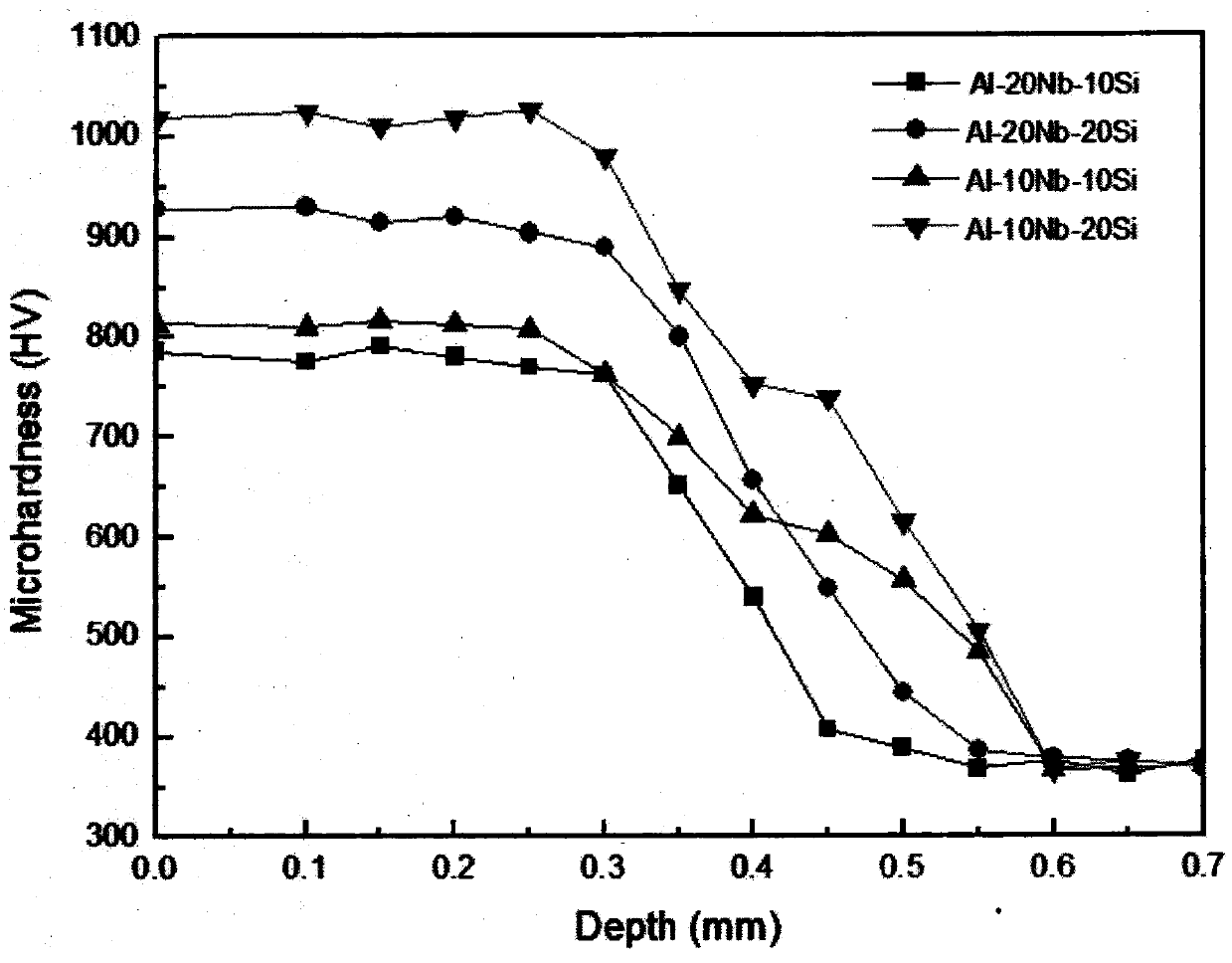

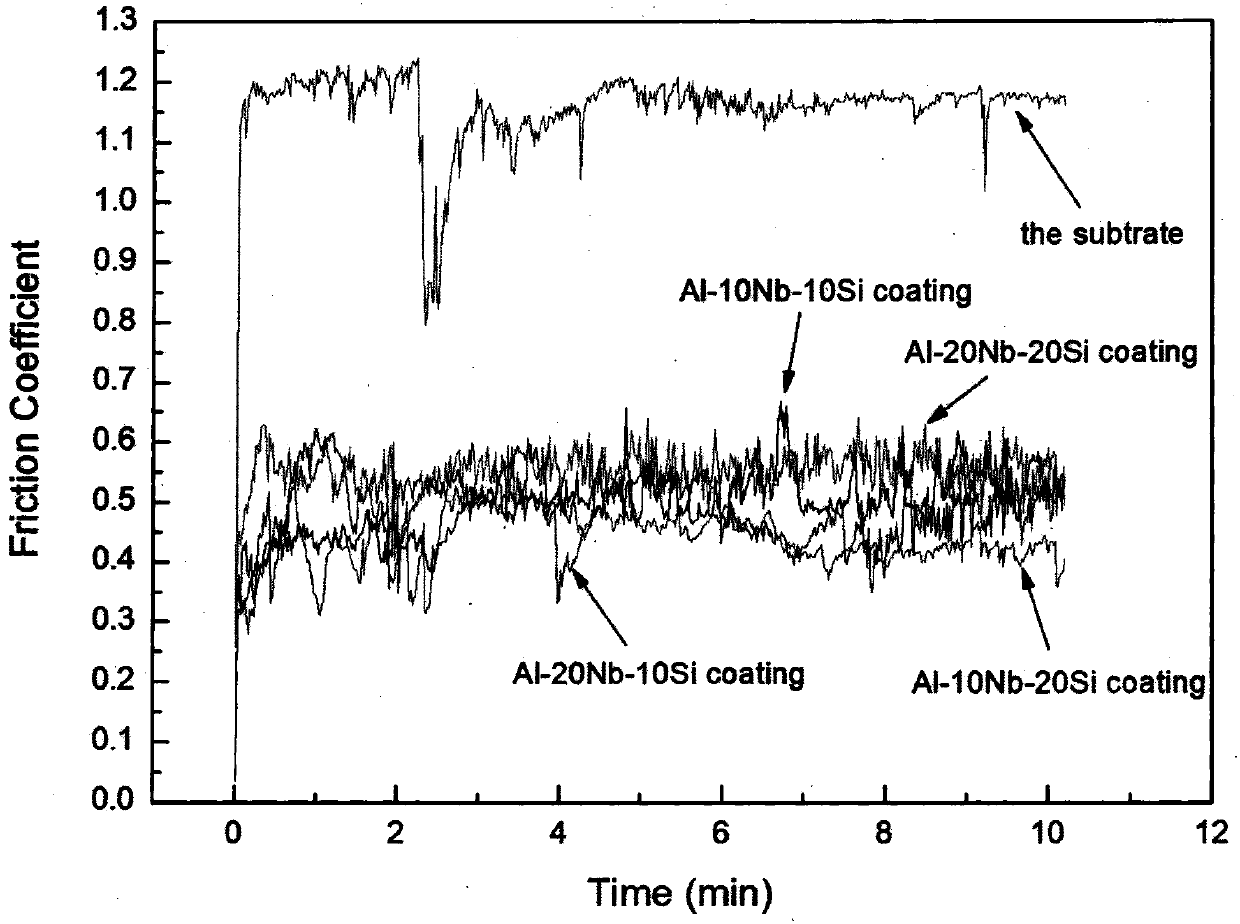

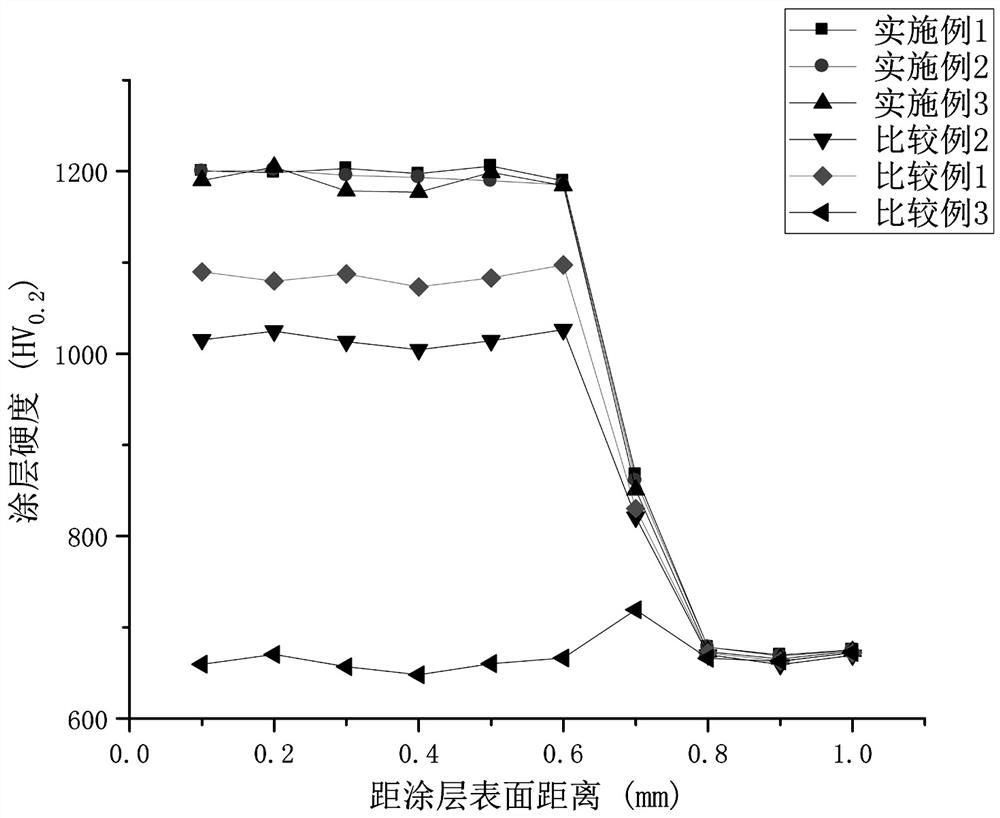

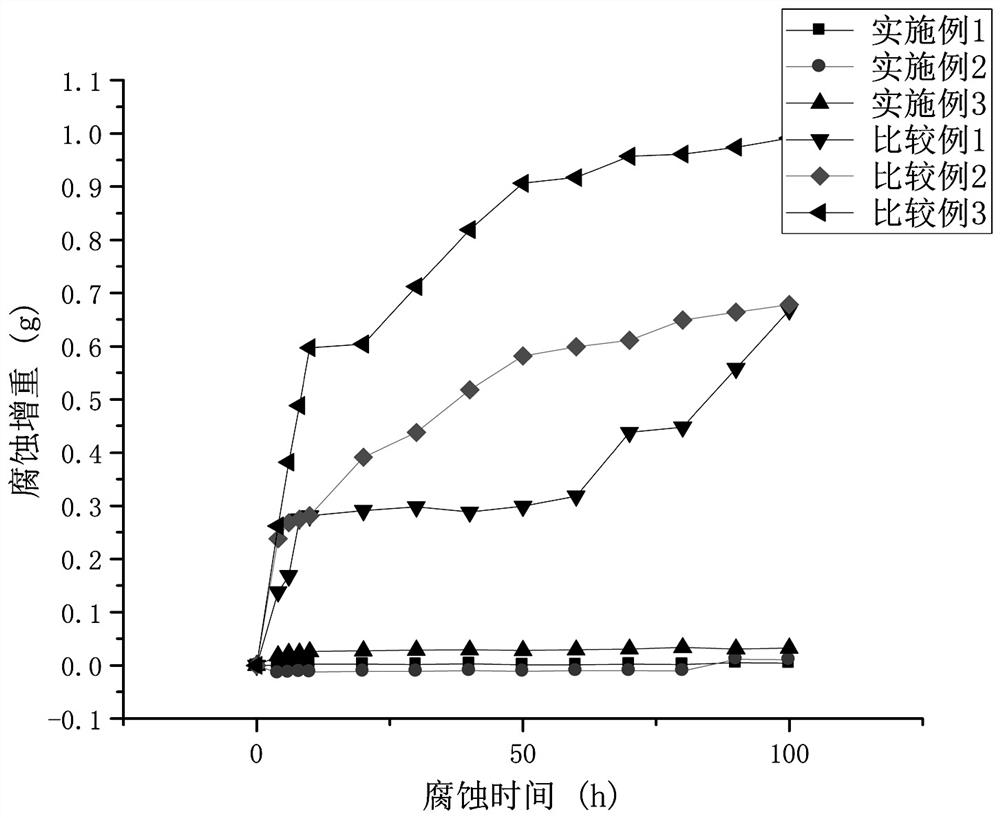

Titanium alloy laser surface silicide enhanced multielement high-temperature alloying layer and preparing method thereof

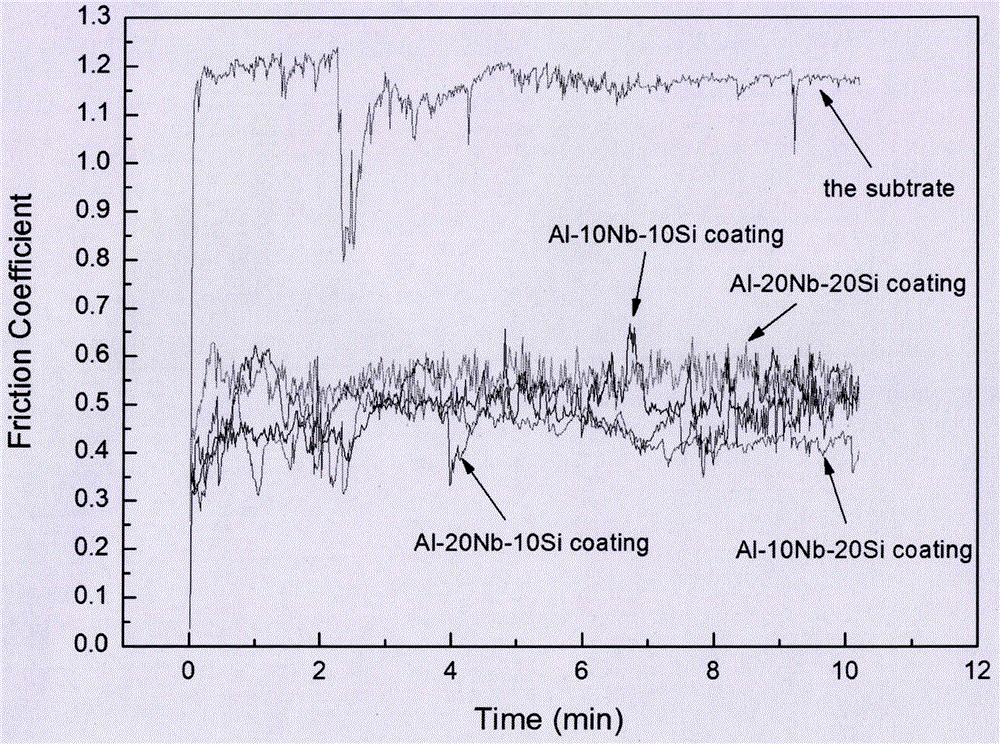

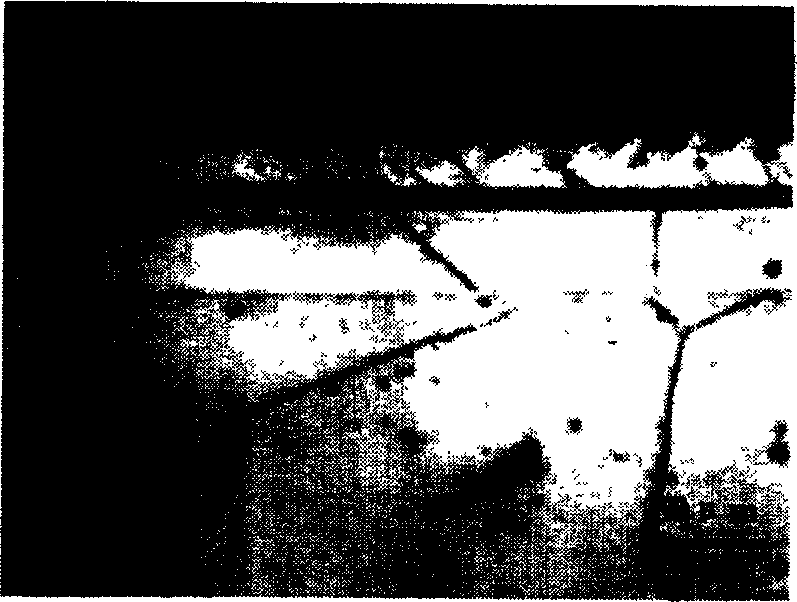

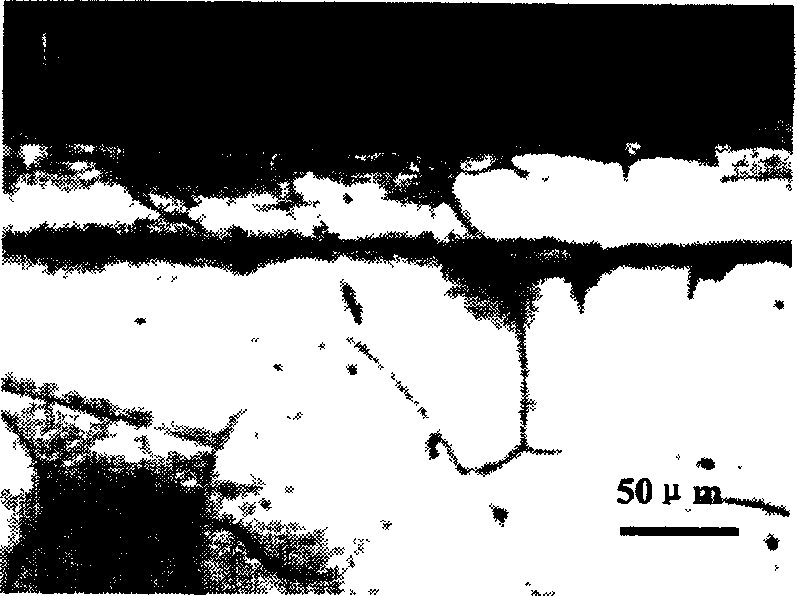

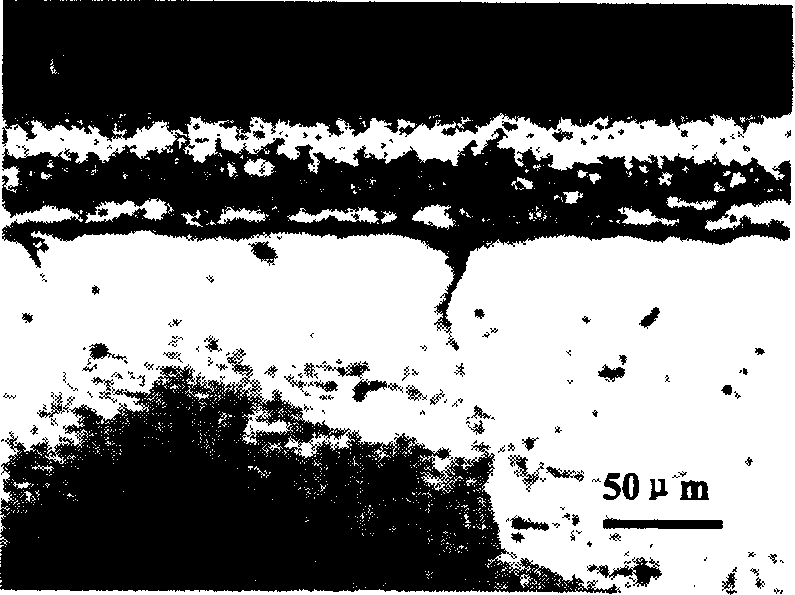

ActiveCN106757013AHigh hardnessStable fluctuationMetallic material coating processesNiobiumTi 6al 4v

The invention provides a titanium alloy laser surface silicide enhanced multielement high-temperature alloying layer. A titanium alloy Ti-6Al-4V serves as a base material, mixed powder composed of aluminite powder, niobium powder and silica powder serves as an alloying powder material to be arranged in the surface of the titanium alloy Ti-6Al-4V base material in advance, and a laser surface alloying technology is adopted for preparation, wherein the purity of the aluminite powder is higher than or equal to 99.0%, the grain diameter of the aluminite powder ranges from 50 microns to 100 microns, the purity of the niobium powder is higher than or equal to 99.5%, the grain diameter of the niobium powder ranges from 50 microns to 100 microns, the purity of the silica powder is higher than or equal to 99.5%, the grain diameter of the silica powder ranges from 50 microns to 100 microns; and the alloying powder material is prepared from, by weight, 100 parts of the aluminite powder, 10-20 parts of the niobium powder and 10-20 parts of the silica powder. The alloying layer is simple in composition proportion, the extremely-high hardness and the good high temperature frictional wear resistance are shown, and the excellent long-term high temperature oxidation resistance is achieved.

Owner:QINGDAO BINHAI UNIV

Chromizing coating modified by rare earth oxide and preparation method and application thereof

The invention discloses a rare-earth oxide modified chromizing coating and its preparation method and uses. Modified chromizing coating constituent is made up of infiltrated chrome, composite deposit metal M and minim rare-earth oxide rare-earth oxide Re#-[x]O#-[y]is Re=Ce, Y, La etc. According to mass percent, chrome content of chromizing coating surface layer is 35-55 portion, and others are M and minim rare-earth oxide, in which M coming from M-Re#-[x]O#-[y] composite deposit. The process is as follows: using metal Ni, Fe , Co, carbon steel or low-alloy steel as base material, making M-Re#-[x]O#-[y] composite deposit on base material using composite electric plating method, diffusing for chromizing, getting rare-earth oxide modified chromizing coating. The invention has a simple and mature process. and coating can physically grow protective compact Cr#-[2]O#-[3]oxidation film under high temperature, which is intensively adhesive to coating base body. Coating have good oxidation and corrosion resistance.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Low temperature chromizing coating, its preparation method and application

InactiveCN1948554AFacilitated DiffusionAvoid damageSolid state diffusion coatingSuperimposed coating processRare earthOxidation resistant

The invention disclosed a technology of coating preparation, which was a two-step process of low temperature chromized coating with its preparation method and application. Chromized coating was composed of inspersed chrome, M, derived from composite deposite, and small quantity of rare earth oxide. Rare earth oxide was RexOy representing Re=Ce,Y,La etc. Calculating by quality quota, the content of chrome in superficial coat was 50 to 90, the rest was M and rare earth oxide, in which M was derived from M-RexOy composite deposite. The preparation process were as follows: Taking Ni, Fe or Co, carbon steel or lean alloy steel as backings, M-RexOy composite deposite of nanocrystal was got with complex electric plating. Then, modified chromized coating was achieved by diffusing chromizing under 600deg.C-800deg.C. The temperature of traditional chromizing craft was debased from over 1000 deg.C to 600deg.C-800deg.C. The craft was simple to generalizing. The coat could get thermally grown and compact oxide film with good non-oxidizability.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Titanium alloy composite capable of resisting high temperature oxidation and hot salt corrosion and preparation method thereof

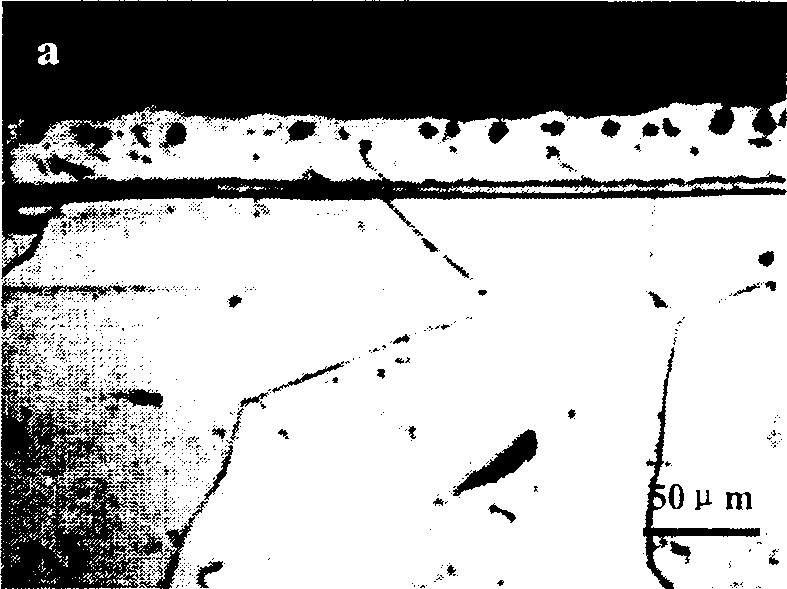

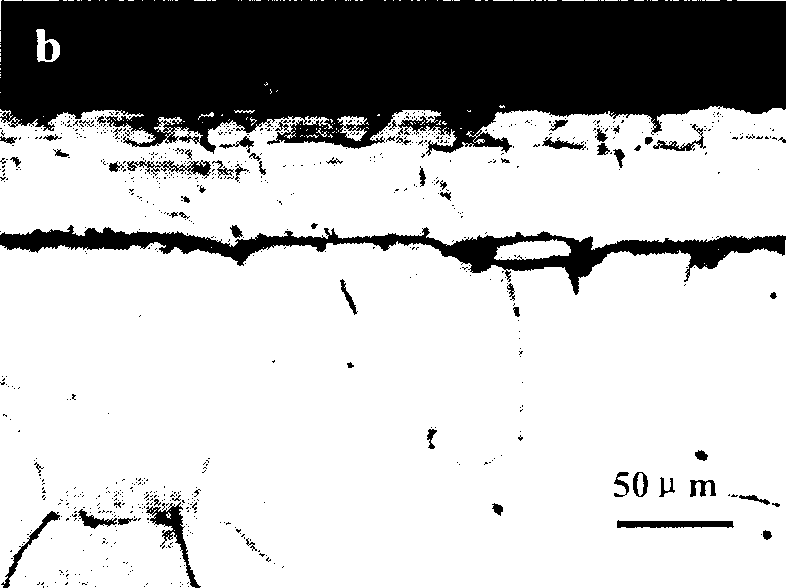

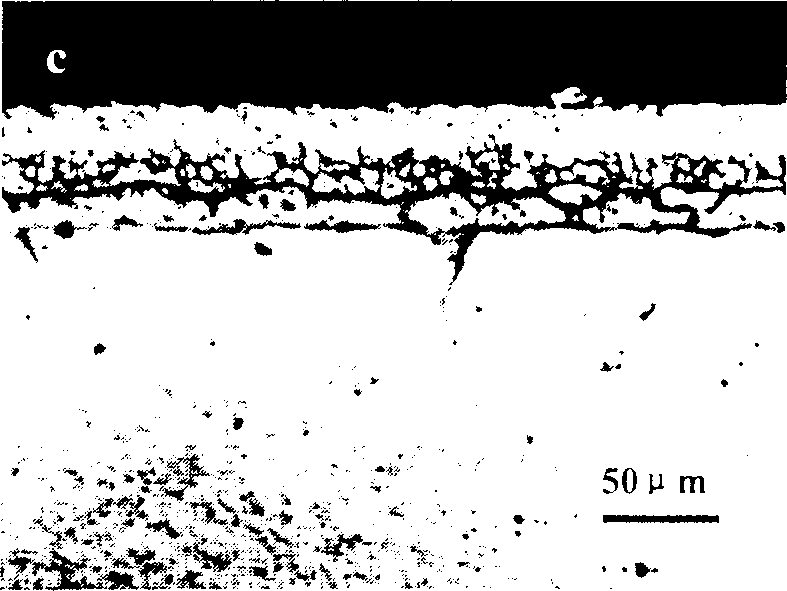

InactiveCN109023479AReduce internal stressGood chemical stabilitySurface reaction electrolytic coatingMicro arc oxidationAlloy substrate

The invention discloses a titanium alloy composite capable of resisting high temperature oxidation and hot salt corrosion and a preparation method thereof. The titanium alloy composite comprises a titanium alloy substrate; a ceramic transition layer and an enamel coating are arranged on the surface of the titanium alloy substrate; the ceramic transition layer is located between the titanium alloysubstrate and the enamel coating; the ceramic transition layer is a micro-arc oxidation ceramic layer; and the enamel coating and the ceramic transition layer form a high-temperature protection gradient composite coating on the titanium alloy substrate. The titanium alloy composite is excellent in resistance to high temperature oxidation and high temperature hot salt corrosion and the gradient composite coating is good in chemical stability.

Owner:SICHUAN ENG TECHN COLLEGE

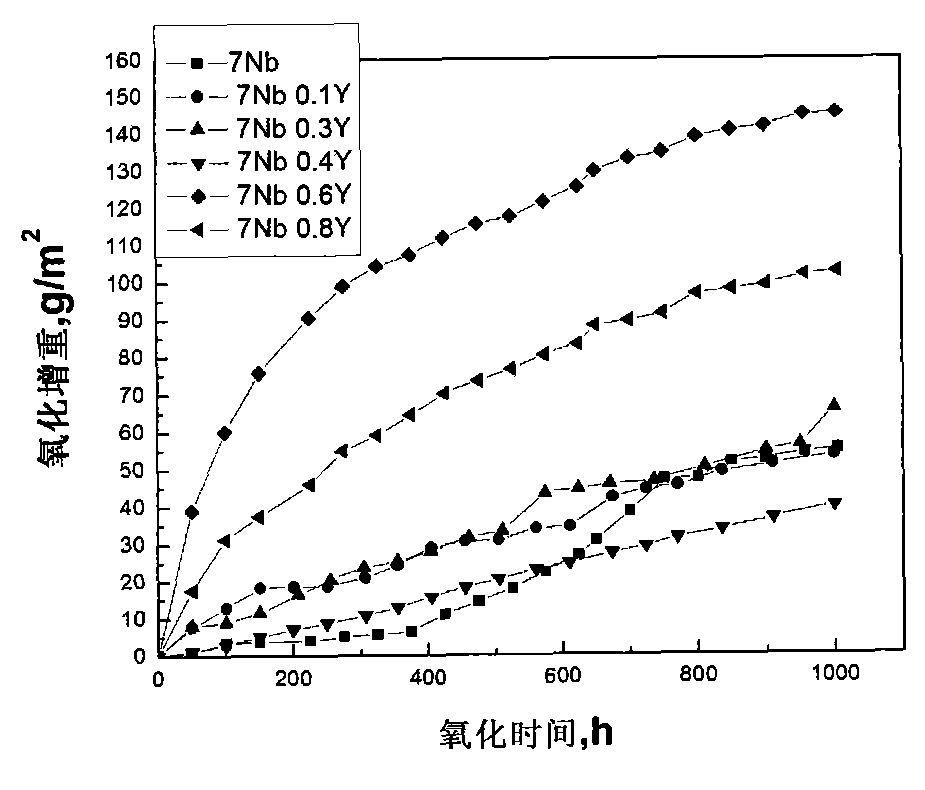

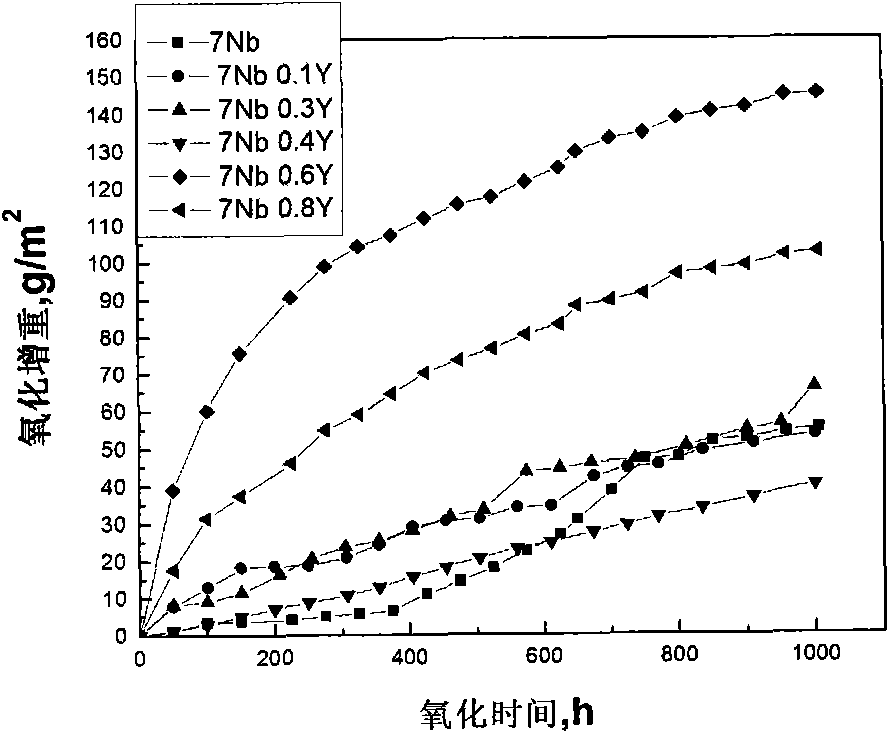

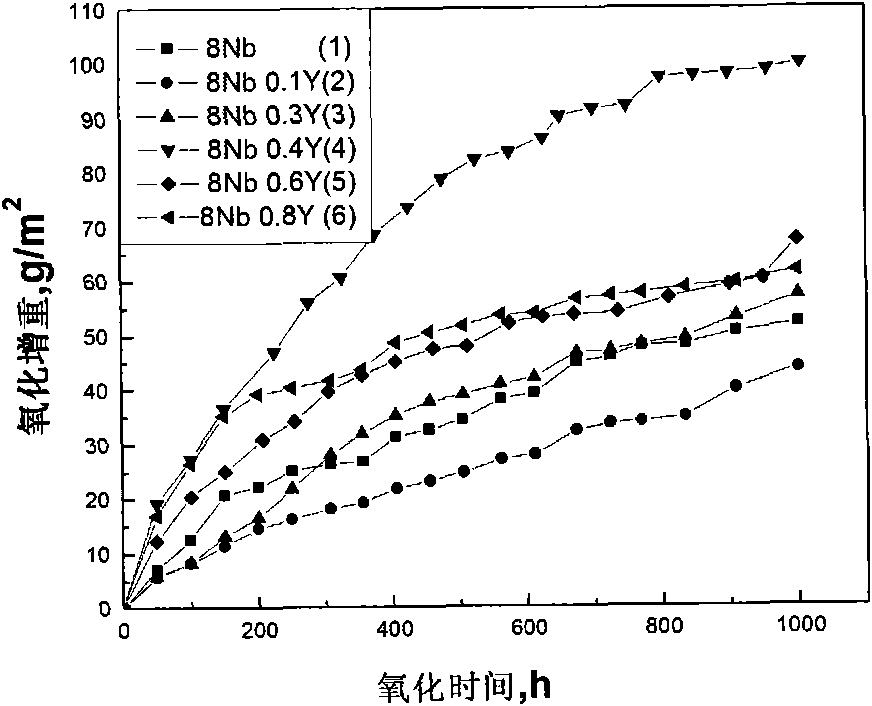

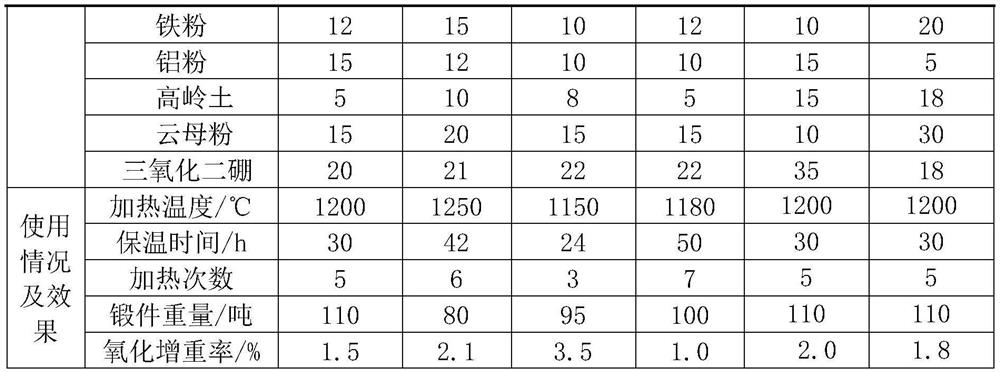

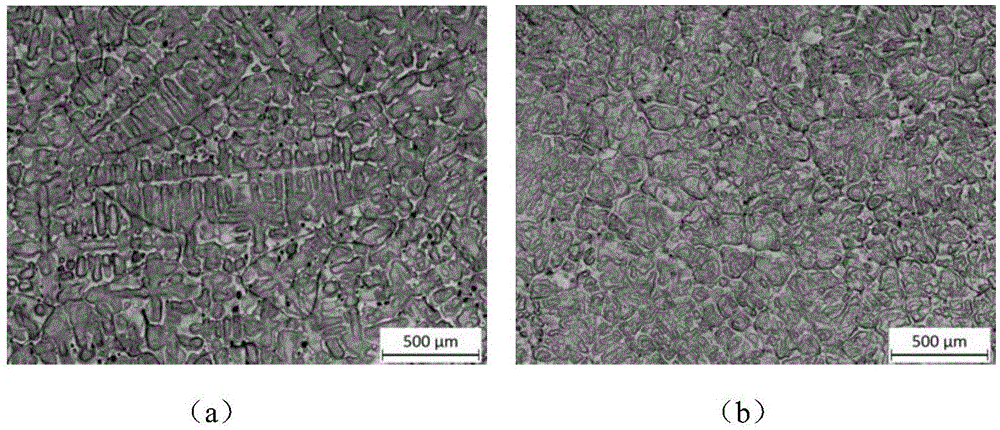

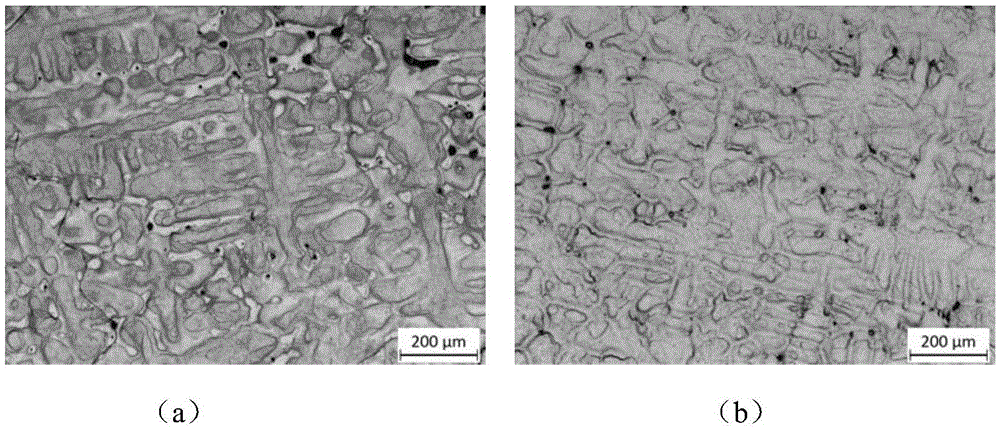

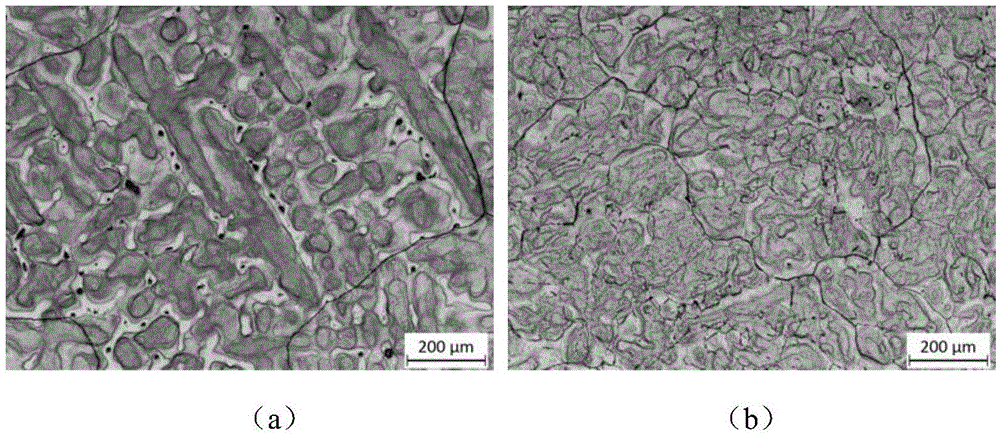

Method for improving long-term oxidation resistance of high-niobium titanium-aluminum alloy through adding yttrium at high temperature

InactiveCN101812604AEnhanced resistance to peelingImprove high temperature long-term oxidation resistanceMetallic materialsYttrium

The invention discloses a method for improving long-term oxidation resistance of a high-niobium titanium-aluminum alloy through adding yttrium at high temperature, belonging to the high temperature oxidization field of the metal material. The invention is characterized in that Y is added in a Ti 45Aa17Nb alloy or a Ti 45Al 8Nb alloy, a tiny yttrium doping high-niobium titanium-aluminum alloy complete lamellar structure is obtained after using vacuum melting and homogenization treatments; the alloy comprises the following components by atomic percent: 46.4-47.9% of Ti, 45% of Al, 7-8% of Nb and 0.1-0.8% of Y; and the homogenization treatment process comprises the following steps: heat insulation is carried out at a temperature of 1320 DEG C for 12h, a converter is insulated for 30 minutes at a temperature of 900 DEG C and then taken out for air cooling. The invention has the advantages that adding proper amount of Y increases the proportion of Al2O3 in an oxide film, reduces the thickness of the oxide film, refines particles producing the oxide, facilitates plastic deformation of the oxide film and reduces cracking of the film; and by epoxidation experiments, after all alloys containing Y go through 1000 cycle periods, no obvious shedding phenomenon occurs in the oxide film, and addition of Y improves the adhesion of the alloy oxide film and raises the use temperature of the high-niobium titanium-aluminum alloy to the temperature of more than 900 DEG C.

Owner:UNIV OF SCI & TECH BEIJING

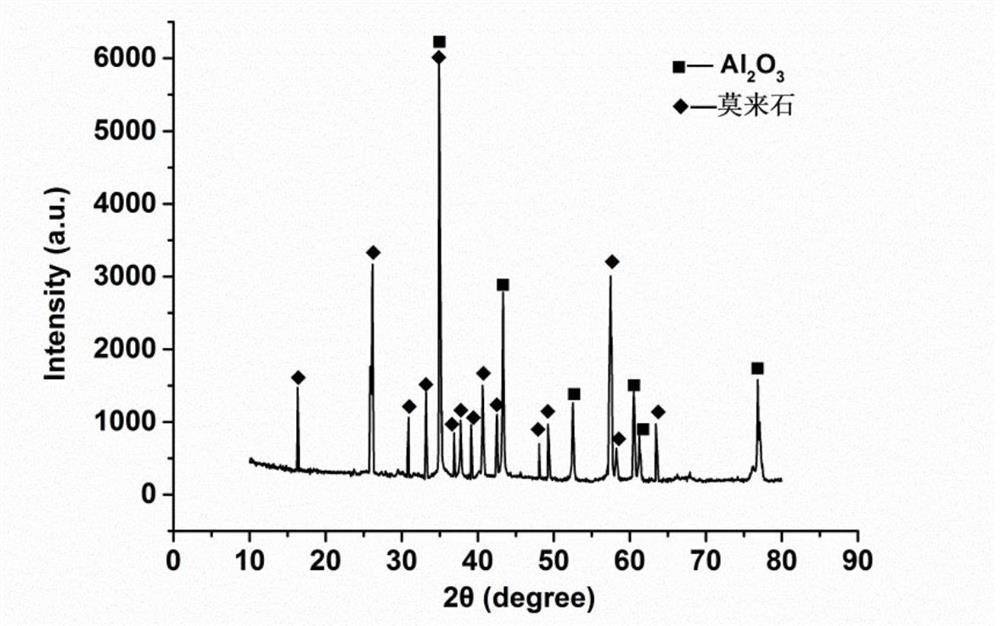

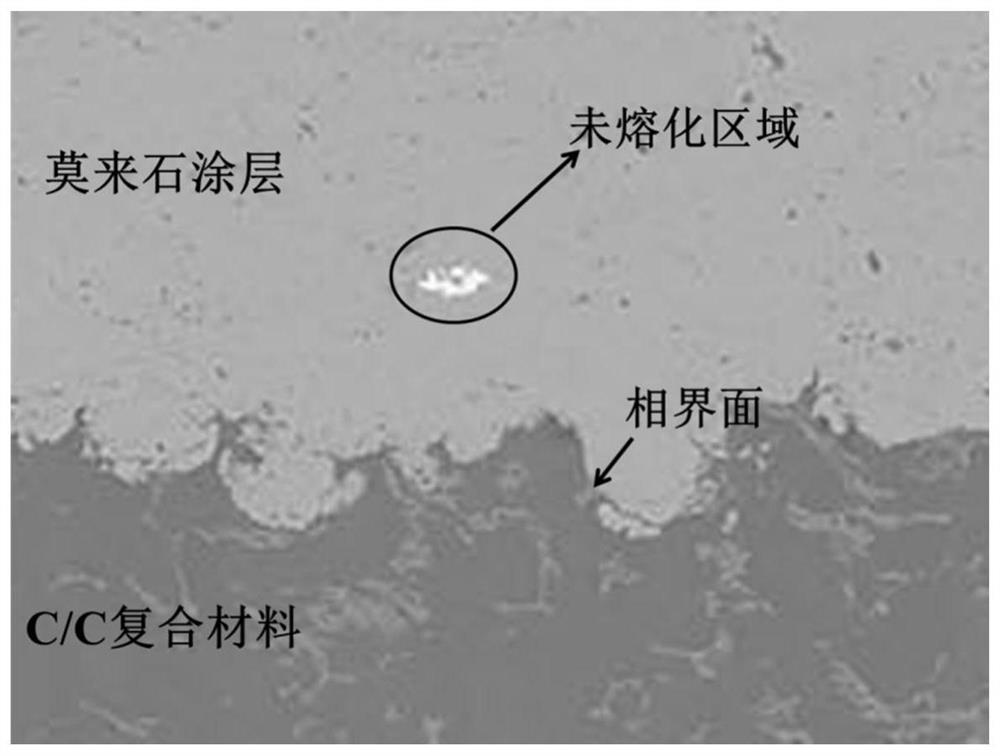

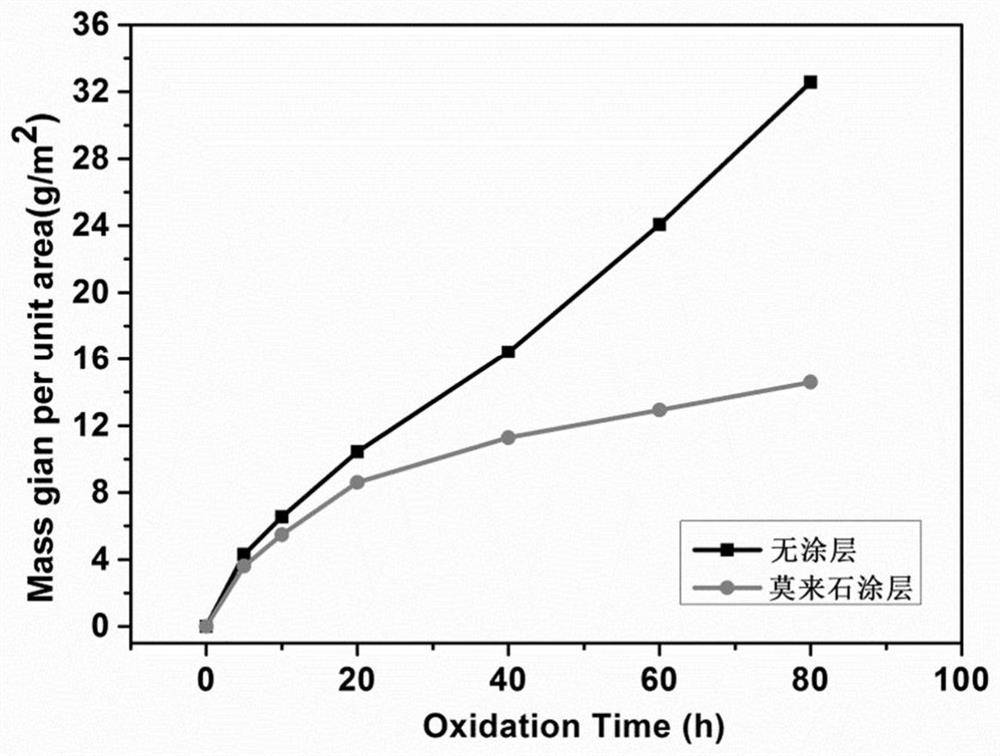

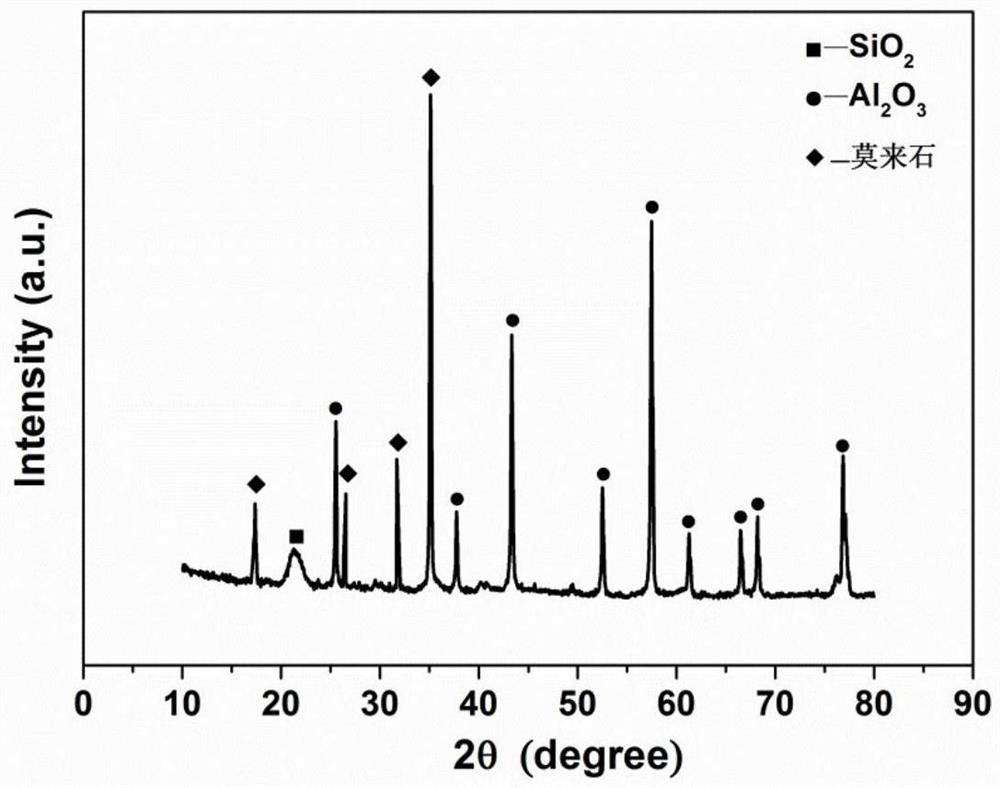

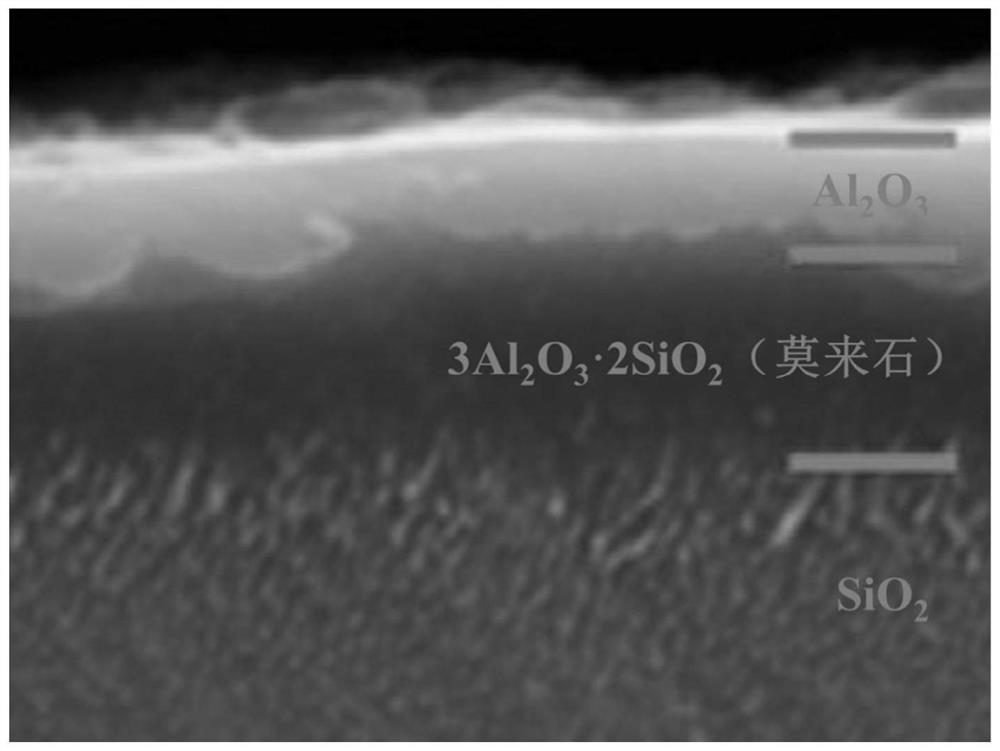

Mullite high-temperature anti-oxidation coating on surface of composite material and preparation method of mullite high-temperature anti-oxidation coating

The invention discloses a mullite high-temperature anti-oxidation coating on the surface of a composite material and a preparation method of the mullite high-temperature anti-oxidation coating. The preparation method comprises the following steps of: preparing an Al (NO3) 3.9 H2O solution with a set concentration; dropwise adding excessive ammonia water into the solution obtained in the previous step, and continuously stirring until white precipitate is generated; adding transparent silica sol into the white precipitate; placing the mixed suspension in the previous step on a roller type ball mill for ball milling; placing a C / C composite material plate and the mixed suspension on liquid-phase plasma spraying equipment, and preparing Al (OH) 3 and SiO2 coatings on the composite material plate by using suspension plasma spraying equipment; and carrying out vacuum heat treatment on the prepared coatings at high temperature to make the coatings react to generate a mullite coating. According to the invention, Al2O3 and SiO2 are compounded to generate a mullite phase with good high-temperature stability, so that the oxidation resistance of the composite material is improved.

Owner:XIAN THERMAL POWER RES INST CO LTD

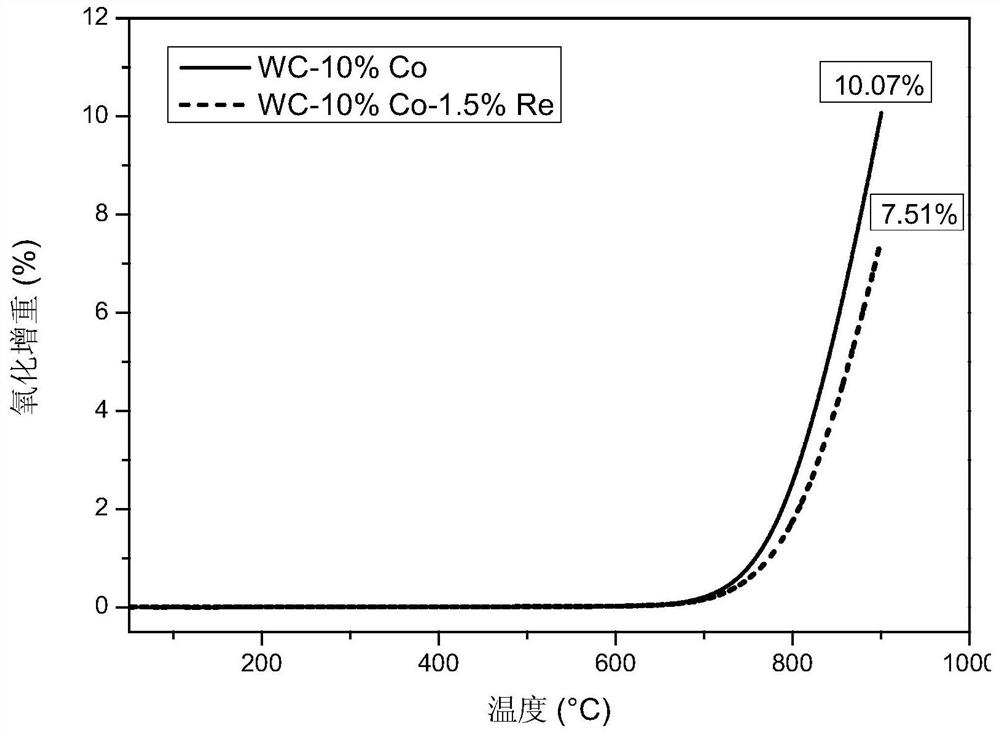

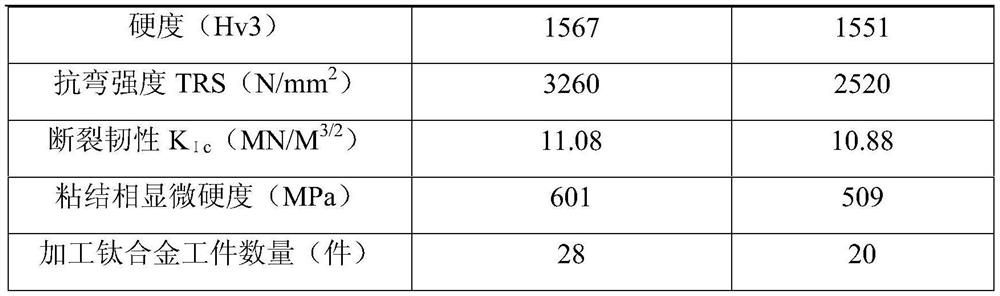

Rhenium-containing hard alloy and preparation method and application thereof

The invention discloses a rhenium-containing hard alloy and a preparation method and application thereof. The rhenium-containing hard alloy is mainly prepared by mixing binder phase powder, Re powderand hard phase powder as raw materials, the mass fraction of the binder phase powder is 3-15%, the mass fraction of the Re powder is 5-30% of the mass fraction of the binder phase powder, the rest isthe hard phase powder, and Re in the rhenium-containing hard alloy is dissolved in the binder phase. The preparation method comprises the steps of proportioning, ball milling, drying granulation, molding and sintering of the raw materials according to a powder metallurgy method to obtain the rhenium-containing hard alloy, and the rhenium-containing hard alloy can be applied to preparation of hardalloy tools, especially milling and turning tools. The rhenium-containing hard alloy has high hardness, strength and fracture toughness, has good high-temperature oxidation resistance, and remarkablyprolongs the service life of a cutter.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Grid section used for sintering acid mine

The invention relates to a grid section used for sintering acid mine. The grid section comprises the following components in percentage by weight: 1.1-1.3% of C, 26.0-28.0% of Cr, 0.3-0.5% of Mo, 1.0-1.5% of Ni, 1.0-1.5% of Si, 0.5-1.0% of Mn, 0.10% of Ti, 0.05-0.15% of Re, 1.0-2.0% of Al and the balance of Fe. The grid section disclosed by the invention is totally suitable for acid mine sintering working conditions and satisfies use requirements, the service life of the grid section is prolonged to more than 12 months from less than 3 months, and therefore the use cost of the grid section isgreatly lowered. Meanwhile, replacement frequency of the grid section can be reduced, the labor intensity of operators is lowered, downtime for replacing the grid section is shortened, and productionefficiency is improved.

Owner:JINAN JIGANG IRON ALLOY FACTORY

Ceramic material, ceramic liner and electric cooker prepared from same

ActiveCN105084906AExcellent thermal diffusivityImprove heat transfer efficiencyCooking-vessel materialsPtru catalystKaolin clay

The invention discloses a ceramic material, a ceramic liner and an electric cooker prepared from the same. The ceramic material is prepared from 3-8 parts of barium carbonate, 20-35 parts of calcite, 5-10 parts of kaolin, 35-55 parts of silicon micropowder, 3-8 parts of potassium nitrate, 10-15 parts of paraffin, 3-8 parts of soda ash, 7-8 parts of boric acid, 11-15 parts of quartz, 50-75 parts of aluminum nitride powder, 2-3 parts of samarium oxide and 3-5 parts of erbium oxide. The aluminum nitride powder is prepared by reacting an aluminum source aluminum oxide powder with carbon black powder in a flowing nitrogen atmosphere at 1500-1700 DEG C. In the reaction process, calcium fluoride or yttrium oxide is added as a catalyst; and after the reaction finishes, decarbonization treatment is performed in 700-800-DEG C dry air. The mass percent of the cation impurities in the aluminum oxide powder is less than or equal to 0.02%, and the mass percents of the silicon and iron impurities are respectively less than 0.001%. The average particle size of the carbon black powder is 35-40nm, and the specific area is less than or equal to 90 m<3> / g.

Owner:GUANGDONG ENAITER ELECTRICAL APPLIANCES CO LTD

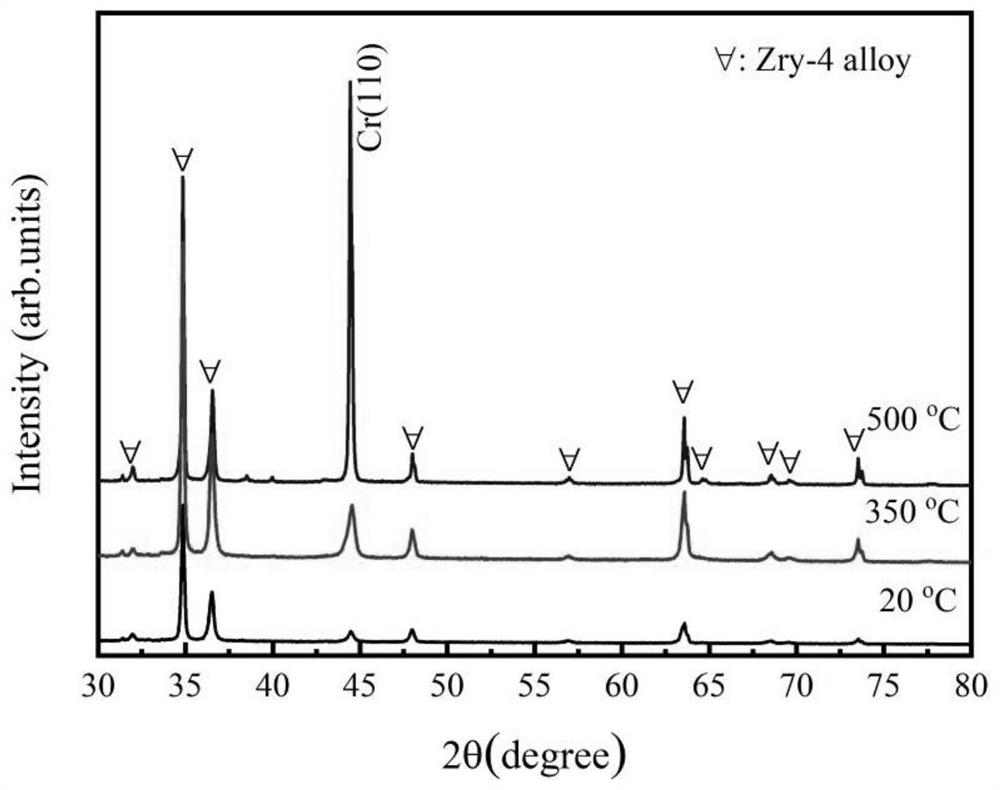

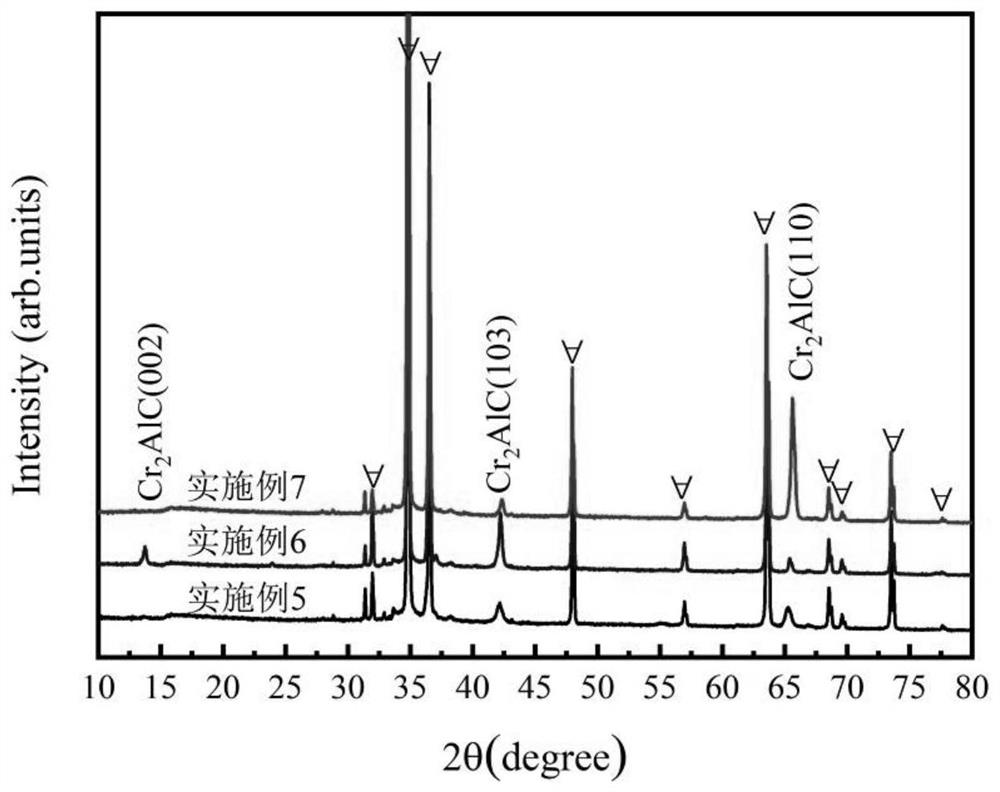

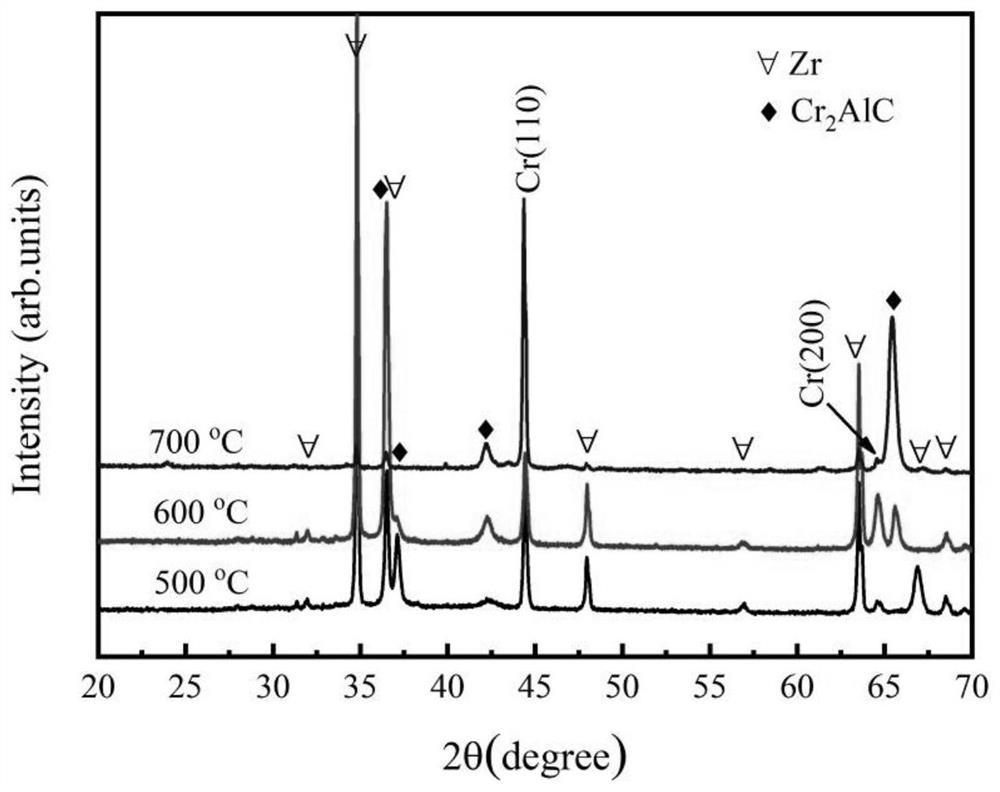

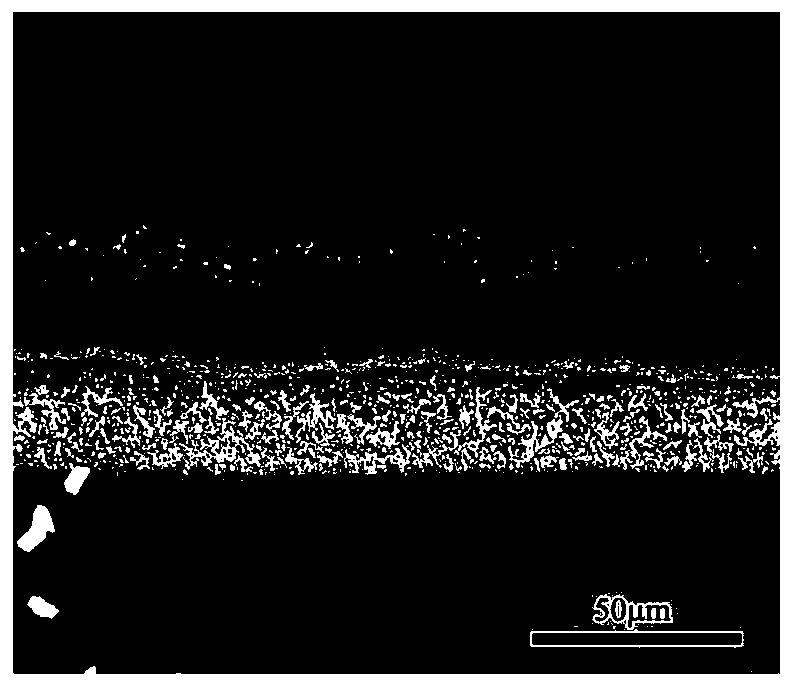

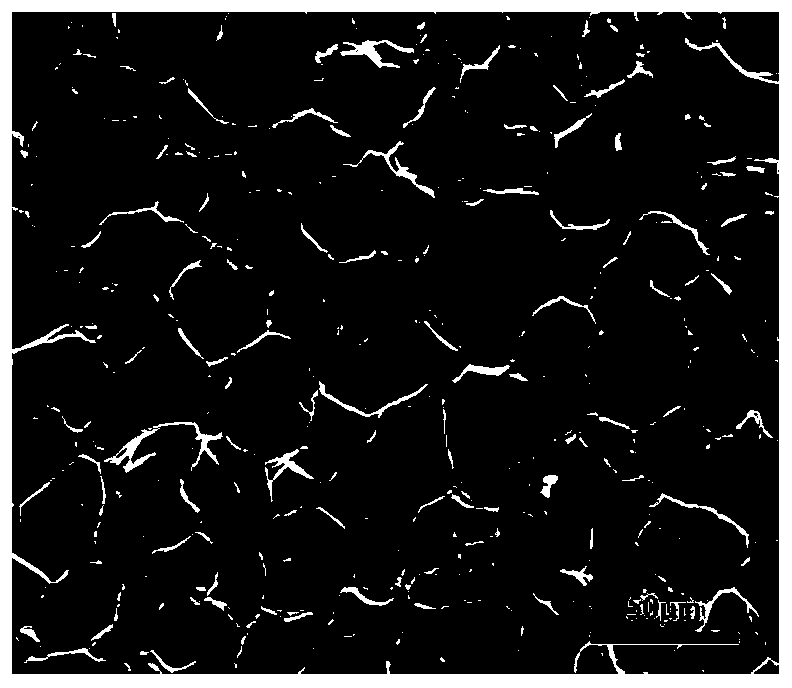

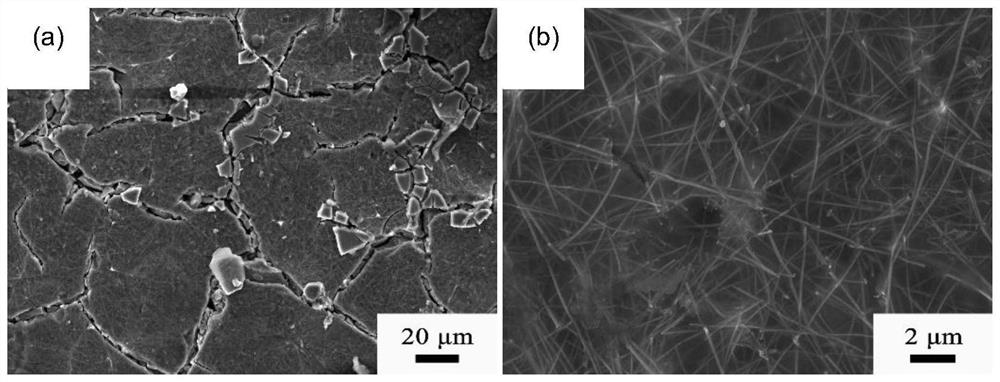

Double-layer Cr/Cr2AlC coating for accident fault-tolerant fuel cladding and preparation method of double-layer Cr/Cr2AlC coating

ActiveCN113388811AImprove antioxidant capacityImprove the protective effectOptical rangefindersNuclear energy generationAqueous corrosionSputtering

The invention relates to a double-layer Cr / Cr2AlC coating for an accident fault-tolerant fuel cladding and a preparation method of the double-layer Cr / Cr2AlC coating. The protection capacity of the zirconium alloy cladding under the normal operation working condition and the accident working condition can be effectively improved by coating the surface of zirconium alloy with the double-layer coating. The double-layer Cr / Cr2AlC coating is deposited on the surface of the zirconium alloy by adopting a multi-target magnetron sputtering technology, the bonding between the coating layers and between the coating layers and a matrix is good, the total thickness is 4-10 microns, and the thickness range of the Cr2AlC coating is 3-8 microns. The double-layer coating integrates the advantages of the two coatings, and the Cr coating not only effectively relieves thermal stress between the coating and a zirconium alloy matrix, but also has the accident fault tolerance capability; the Cr2AlC coating not only has good oxidation resistance in a high-temperature water vapor environment, but also shows excellent fretting wear resistance in a high-temperature and high-pressure water environment under a normal operation condition of a reactor, and protects the zirconium alloy matrix from being oxidized in a high-temperature and high-pressure water corrosion process, and reliability and safety of operation of a nuclear fuel system can be obviously improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Hf modified PtAl coating and preparation method and application thereof

InactiveCN110735162AThe content is easy to controlEvenly distributedBlade accessoriesSolid state diffusion coatingPlatinumHafnium

The invention provides an Hf modified PtAl coating and a preparation method and application thereof. The preparation method comprises the steps that a nickel layer is pre-plated on the surface of a nickel-based high-temperature alloy matrix through an electroplating method, then a platinum layer is electroplated on the surface of the nickel layer through the electroplating method, and aluminizingand hafnium plating are conducted through a chemical vapor deposition method after annealing treatment. The coating prepared through the preparation method has excellent high-temperature oxidation resistance and thermal corrosion resistance, and meanwhile the binding force of the coating and the matrix is higher.

Owner:QILU UNIV OF TECH

High-density nano W alloy with good self-passivation behavior and preparation method thereof

The invention discloses a high-density nano W alloy with good self-passivation behavior and a preparation method thereof. The nano W alloy is prepared from the components in percentage by weight: a basic component W, a passivation element Cr and activation elements Y and Zr, wherein Cr is greater than or equal to 10wt.% and less than or equal to 13wt.%, the total amount of the activation elementsis greater than 0wt.% and less than or equal to 2wt.%, and the balance is W. By controlling process parameters such as the sintering temperature and pressure, the heating rate and the heat preservation time during sintering, the high-density nano W alloy is obtained. The W alloy with the relative density being higher than 98.5% and the grain size being less than 100 nm is obtained under the conditions that the sintering temperature is 1150 DEG C and the applied load is 90 MPa. The nano W-alloy shows the good self-passivation behavior, and the oxidation weight gain of the nano W-alloy is only 7.8 mg / cm<2> after 165 h of heat-shock oxidation under the air atmosphere of 1000 DEG C.

Owner:HEFEI UNIV OF TECH

Chromizing coating modified by rare earth oxide and preparation method and application thereof

InactiveCN1296512CStable growthSlow growth rateSolid state diffusion coatingRare-earth elementOxidation resistant

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

A kind of heat-resistant wear-resistant alloy steel and preparation method thereof

ActiveCN105803339BImprove heat resistanceHigh hardnessProcess efficiency improvementWear resistantCerium

The invention provides heat-resisting and wear-resisting alloy steel. The heat-resisting and wear-resisting alloy steel is prepared from, by weight, 0.25%-0.35% of C, 17%-19% of Cr, 17%-19% of Mn, 0.6%-1.2% of Si, 0.6%-1.0% of Ti, 1.2%-2.0% of W, 0-0.02% of P, 0-0.02% of S, 0.05%-0.25% of Y, 0.05%-0.25% of Ce, 0.025%-0.05% of Al and the balance Fe. A preparation method of the heat-resisting and wear-resisting alloy steel comprises the steps that scrap steel, low-carbon ferrochromium and electrolytic manganese are placed in a furnace to be molten; oxygen blowing is conducted when the temperature of molten steel is higher than 1580 DEG C; 70% of aluminum, 20% of silicon and 10% of calcium wires are inserted into per ton of molten steel, composite powder containing 1% of carbon, 50% of silicon and 49% of calcium is added onto the liquid surface, slagging is conducted, ferrotitanium and ferrotungsten are added, yttrium-cerium-based mixture rare earth is added to the bottom of a steel ladle, and the tapping temperature is 1620-1640 DEG C; a casting is cast at the temperature of 1530-1580 DEG C; and heat treatment is conducted at the temperature of 1050-1100 DEG C, the casting is placed in water after being discharged out of the furnace, and the water temperature is not higher than 38 DEG C. According to the heat-resisting and wear-resisting alloy steel and the preparation method thereof, through the optimal design of the elements, melt purification and optimization of the heat treatment technique, the steel which is high in heat strength, abrasion resistance and heat resistance is obtained.

Owner:GUANGDONG INST OF NEW MATERIALS

A kind of composite ceramic material and the electric cooker liner prepared thereof

ActiveCN105084905BExcellent thermal diffusivityImprove heat transfer efficiencyCooking-vessel materialsComposite ceramicCalcite

The invention discloses a composite ceramic material and an inner container of an electric cooker prepared from the composite ceramic material. The composite ceramic material is prepared from the following components in parts by weight: 3-8 parts of barium carbonate, 20-35 parts of calcite, 5-10 parts of kaolin, 35-55 parts of silica powder, 3-8 parts of potassium nitrate, 10-15 parts of paraffin, 3-8 parts of sodium carbonate, 7-8 parts of boric acid, 11-15 parts of quartz, 50-75 parts of aluminum nitride powder, 2-3 parts of yttrium oxide and 3-5 parts of lanthanum oxide, wherein the aluminum nitride powder is generated by reacting aluminum oxide powder serving as an aluminum source and carbon black powder in the flowing nitrogen atmosphere at the temperature of 1500-1700 DEG C; calcium oxide is added as a catalyst in the reaction process, and decarbonization is carried out in dry air with the temperature of 700-800 DEG C after the reaction is finished; the mass content of cation impurities in the aluminum oxide powder is lower than or equal to 0.02%, and the mass contents of silicon and iron impurities are respectively lower than 0.001%; and the average particle size of the carbon black powder is 35-40nm, and the specific surface area is smaller than or equal to 90m<2> / g.

Owner:GUANGDONG ENAITER ELECTRICAL APPLIANCES CO LTD

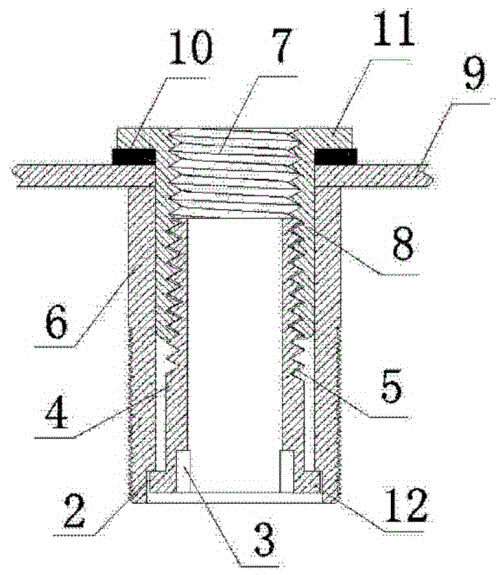

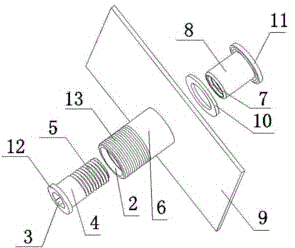

Healthy electric water heater

ActiveCN104197519BReduced oxidative weight gainImprove oxidation resistanceFluid heatersOxidation resistantShock resistance

Owner:GUANGDONG WELL BORN ELECTRIC APPLIANCES

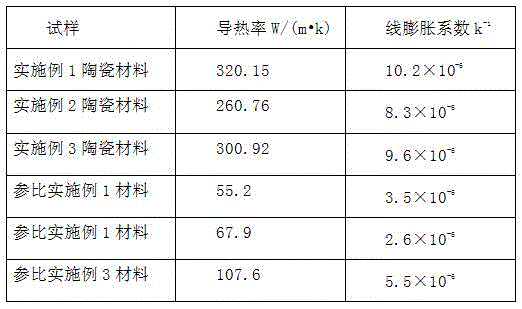

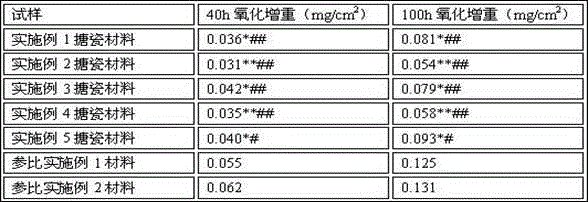

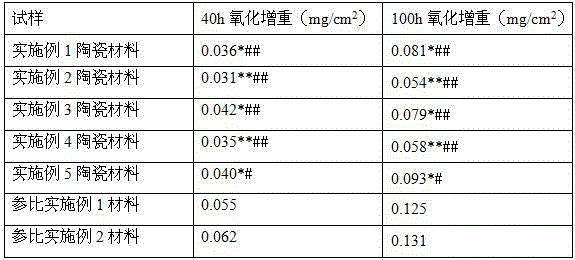

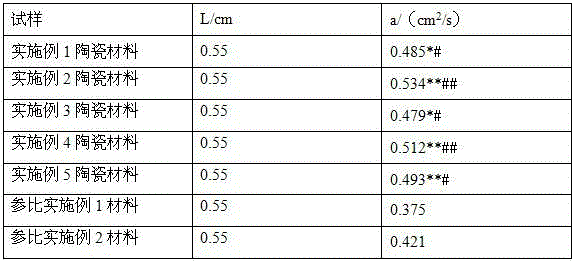

Composite ceramic for inner container of rice cooker, and produced ceramic inner container and rice cooker

ActiveCN103922711BExcellent thermal diffusivityImprove heat transfer efficiencyComposite ceramicHeat transfer efficiency

The invention belongs to the field of a ceramic material, and relates to a composite ceramic for the inner container of a rice cooker, and a ceramic inner container. The current rice cooker with the ceramic inner container has the problems of being slow to heat, uneven in heat transfer, frequently cannot boil rice and the like, and the ceramic inner container with better heat transfer property has bad anti-oxidization capability to seriously influence the service life and safety property of the ceramic inner container. In order to overcome the deficiencies of the prior art, the invention provides a ceramic material for manufacturing the inner container, and the ceramic container thereof. The heat diffusion property test and the anti-oxidization property test show that the ceramic material has the advantages of being fast in heat transfer efficiency and strong in anti-oxidization capability, as well as the advantages of being good in safety performance, low in energy consumption, and long in service life when being used for manufacturing the inner container of an electric rice cooker, thus being suitably applied in the field of manufacturing the inner container of the electric rice cooker.

Owner:GUANGDONG ENAITER ELECTRICAL APPLIANCES CO LTD

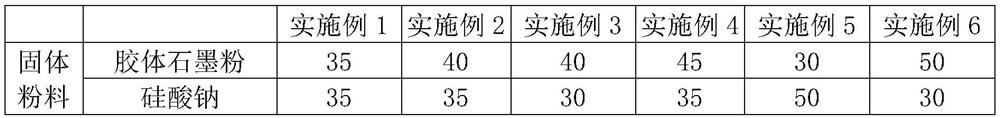

Anti-oxidation coating and its preparation method and application

ActiveCN110330819BAvoid pollutionReduce the preparation processLiquid surface applicatorsAlkali metal silicate coatingsIron powderNuclear power

The invention relates to an antioxidant coating as well as a preparation method and application thereof and belongs to the technical fields of metal fabricating and coatings for the metal fabricating.The antioxidant coating is prepared from the following materials in parts by weight: 30 to 50 parts of colloidal graphite powder, 30 to 50 parts of sodium silicate, 10 to 20 parts of iron powder, 5 to 15 parts of aluminum powder, 5 to 18 parts of kaolin, 10 to 30 parts of mica powder and 18 to 35 parts of boron trioxide. The coating is all prepared from solid powder, is applied to the surface ofa nuclear power forging by a spraying method, and can provide convenient antioxidant protection for the nuclear power forging forged and heated at the temperature of 1200 DEG C or above; oxidation weight increase caused by long-time heating process is reduced by 95 percent or above.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

A kind of wear-resistant heat-resistant alloy material and preparation method thereof

The invention discloses a wear-resistant heat-resistant alloy material and a preparation method thereof, and in the material, high wear-resistant hard phase is uniformly distributed on a high temperature oxidation resistant fine-grain austenite matrix. The austenite matrix is obtained by adding Cr and Ni, the Y-based rare earth is added to closely combine with the matrix while oxide compactness is formed, the W is added to form W to displace Fe and Cr elements in (Cr, Fe)7C3 and (Cr, Fe)23C6 and to solid-dissolve in the (Cr, Fe)7C3 and (Cr, Fe)23C6 and improve the (Cr, Fe)7C3 and (Cr, Fe)23C6 hardness; the Nb is added to form a hard spot compound; and meanwhile, the Nb is used as a crystal core to refine the grain, the vibration solidification method is combined to eliminate the dendrite and improve the carbide form so as to further refine the grain. The heat-resistant steel performance can be obviously improved by adopting the invention, wherein the hardness can be improved by 10-15%, the strength can be improved by 10-18%, the oxidation increase is reduced by 18-20%, and the service life is improved by 20-25% at 1000 DEG.C.

Owner:GUANGDONG INST OF MATERIALS & PROCESSING +1

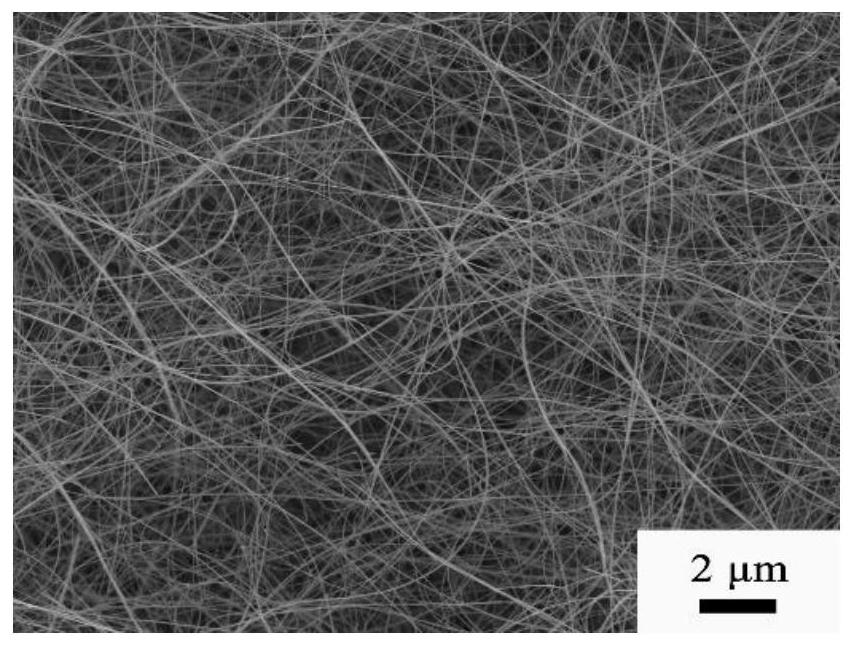

A kind of preparation method of silicon carbide nanowire toughened silicon carbide ceramics in situ

ActiveCN111848196BEvenly distributedThe preparation process is simple and controllableCarbide siliconNanowire

The invention discloses a preparation method of in-situ silicon carbide nanowire toughened silicon carbide ceramics, which utilizes the pyrolysis reaction of polycarbosilane to in-situ grow silicon carbide inside and on the surface while synthesizing silicon carbide bulk ceramics Nanowires, through further precursor impregnation and pyrolysis (PIP) densification process, prepare high-density silicon carbide nanowire toughened silicon carbide ceramics, with the help of the toughening effect of nanowires, reduce the cracking tendency of silicon carbide ceramics and improve its Thermal shock resistance.

Owner:BEIHANG UNIV

A kind of titanium alloy laser surface silicide enhanced multi-element superalloying layer and its preparation method

The invention provides a titanium alloy laser surface silicide enhanced multielement high-temperature alloying layer. A titanium alloy Ti-6Al-4V serves as a base material, mixed powder composed of aluminite powder, niobium powder and silica powder serves as an alloying powder material to be arranged in the surface of the titanium alloy Ti-6Al-4V base material in advance, and a laser surface alloying technology is adopted for preparation, wherein the purity of the aluminite powder is higher than or equal to 99.0%, the grain diameter of the aluminite powder ranges from 50 microns to 100 microns, the purity of the niobium powder is higher than or equal to 99.5%, the grain diameter of the niobium powder ranges from 50 microns to 100 microns, the purity of the silica powder is higher than or equal to 99.5%, the grain diameter of the silica powder ranges from 50 microns to 100 microns; and the alloying powder material is prepared from, by weight, 100 parts of the aluminite powder, 10-20 parts of the niobium powder and 10-20 parts of the silica powder. The alloying layer is simple in composition proportion, the extremely-high hardness and the good high temperature frictional wear resistance are shown, and the excellent long-term high temperature oxidation resistance is achieved.

Owner:QINGDAO BINHAI UNIV

A 1200°C complete anti-oxidation binary trace active element-doped ptnial bonding layer and its preparation method

ActiveCN103966615BImproved high temperature oxidation resistanceImprove high temperature oxidation resistanceVacuum evaporation coatingSputtering coatingElectron beam physical vapor depositionGas phase

The present invention discloses a Pt Ni Al bonding layer doped with binary trace active elements and capable of being completely oxidation resisting at 1200 DEG C and a preparation method thereof and belongs to the field of novel thermal barrier coatings and the preparation technologies. According to the invention, firstly, a Pt layer with the thickness of 5-10 microns is prepared on a nickel base monocrystal high temperature alloy matrix through the plating or the electron beam physical vapor deposition method, and then a NiAlHfZr coating with the thickness of 20-60 microns is deposited on the Pt layer through the electron beam physical vapor deposition method. The Pt layer reduces the interfacial holes and effectively improves the adhesion of an oxidation film; binary doping of Hf, Zr enables the NiAl coating surface to be smoother and denser and enables the oxidation film generated during the oxidation process on the coating surface to be straighter, especially with little oxidation increase, and greatly improves the oxidation resistance of the coating. The Pt Ni Al bonding layer is completely oxidation resisting at 1200 DEG C. The service life of the coating is prolonged to certain degree through doping of binary elements namely Hf and Zr and Pt modification.

Owner:BEIHANG UNIV

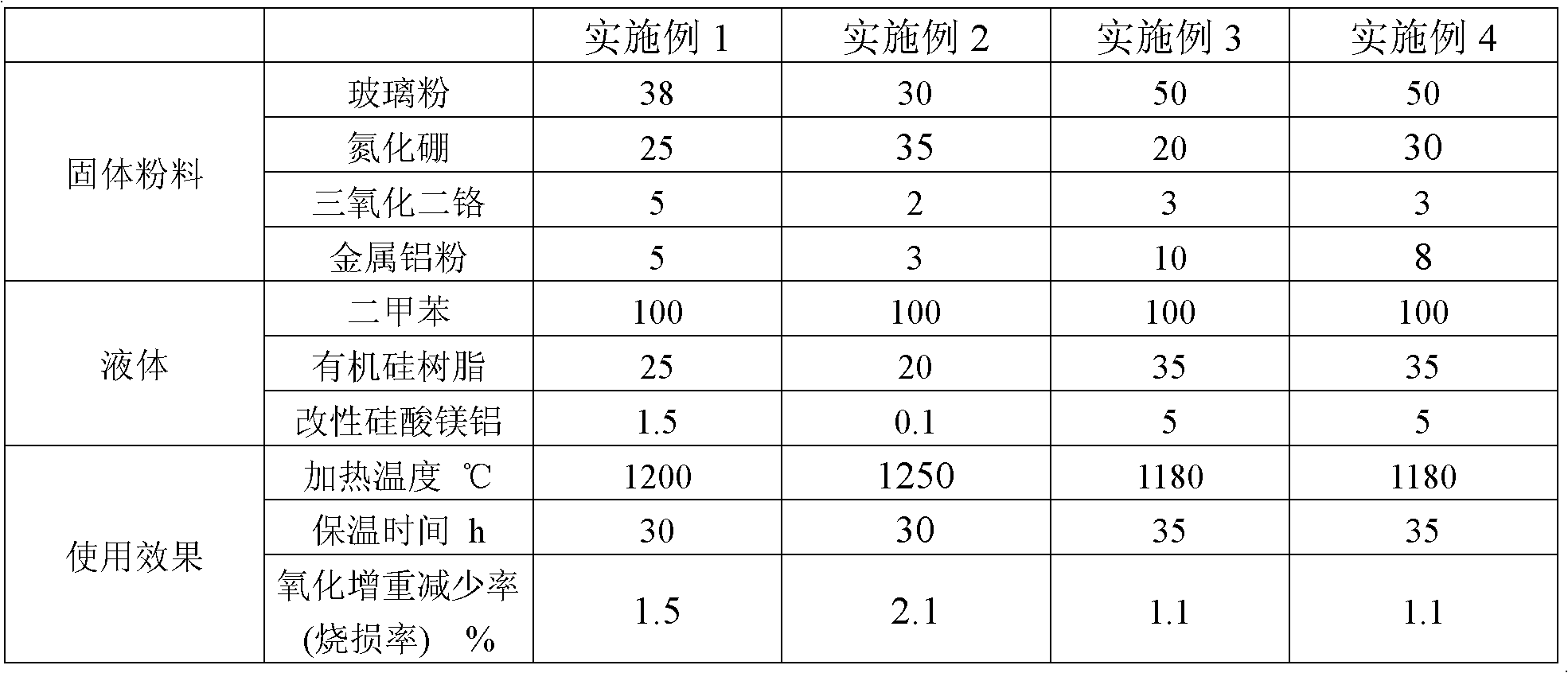

Anti-oxidation coating for heat treatment of iron and preparation method thereof

ActiveCN102585568BImprove performanceWide variety of sourcesSpecial surfacesCoatingsXylyleneMetallic aluminum

The invention belongs to the technical field of the preparation of high-temperature anti-oxidation coatings, in particular to an anti-oxidation coating used in a long-time heat treatment process of iron, and the like at high temperature. The coating comprises solid powder and liquid, and is characterized in that the solid powder comprises following components by weight part: 30 to 50 parts of glass powder, 10 to 50 parts of boron nitride, 2 to 5 parts of chromic oxide and 3 to 10 parts of metal aluminum powder; and the liquid comprises following components by weight part: 0.1 to 5 parts of modified magnesium aluminosilicate, 20 to 35 parts of organic silicone resin and 100 parts of xylene. Through the adoption of the coating, oxydic weight gain of carbon steel or alloy steel can be guaranteed to be reduced by more than 80 percent in the heat treatment process for a long time (larger than 30 hours) at temperature of 1200 DEG C and above.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

AlON ceramic composite material and preparation method thereof

InactiveCN113277855AImprove mechanical propertiesImprove high temperature oxidation resistanceCeramic compositeComposite ceramic

The invention belongs to the technical field of inorganic non-metallic materials, and particularly relates to an AlON ceramic composite material and a preparation method thereof. According to the invention, AlON, SiC and B4C powder are used as raw materials, and the AlON composite ceramic material is prepared by a hot pressed sintering method by adjusting the mass ratio of SiC to B4C. After the obtained product is statically oxidized for 40 hours in air at 1500 DEG C, the oxidation weight gain rate is reduced by 78.8%-85.7% compared with that of pure AlON ceramic, the bending strength at room temperature is 301-324 MPa, the fracture toughness is 1.40-1.51 MPa.m<1 / 2>, the oxidation resistance of the AlON material is greatly improved, and a reference is provided for further application of the AlON ceramic in the high-temperature field.

Owner:CENT SOUTH UNIV

Grid section used for sintering acid mine

The invention relates to a grid section used for sintering acid mine. The grid section comprises the following components in percentage by weight: 1.1-1.3% of C, 26.0-28.0% of Cr, 0.3-0.5% of Mo, 1.0-1.5% of Ni, 1.0-1.5% of Si, 0.5-1.0% of Mn, 0.10% of Ti, 0.05-0.15% of Re, 1.0-2.0% of Al and the balance of Fe. The grid section disclosed by the invention is totally suitable for acid mine sintering working conditions and satisfies use requirements, the service life of the grid section is prolonged to more than 12 months from less than 3 months, and therefore the use cost of the grid section is greatly lowered. Meanwhile, replacement frequency of the grid section can be reduced, the labor intensity of operators is lowered, downtime for replacing the grid section is shortened, and production efficiency is improved.

Owner:JINAN JIGANG IRON ALLOY FACTORY

Preparation method of niobium alloy surface high-temperature oxidation resistant coating

PendingCN114672805AImprove mechanical propertiesGood adhesionMetallic material coating processesAl powderOxidation resistant

The invention relates to a preparation method of a high-temperature oxidation resistant coating on a niobium alloy surface, which comprises the following steps: preparing composite powder for coating cladding by using 55-60 wt% of MoSi2 powder, 35-45 wt% of Al powder and 5-10 wt% of Ce powder, paving the composite powder for coating cladding on the surface of a niobium alloy matrix material, and forming a cladding coating on the surface of the niobium alloy matrix material by using a laser cladding technology. The niobium alloy surface high-temperature oxidation resistant coating prepared through the method is metallurgically bonded with a niobium alloy matrix, the hardness can reach nearly three times that of the niobium alloy matrix, and the oxidation resistance of the niobium alloy surface high-temperature oxidation resistant coating under the high-temperature environment of 1200 DEG C is also remarkably improved.

Owner:ZHONGBEI UNIV

SiO2-mullite-Al2O3 multi-component gradient anti-oxidation coating and preparation method thereof

PendingCN114395750AFlat surfaceDense surfaceVacuum evaporation coatingSputtering coatingMulliteOxidation resistant

The invention relates to a SiO2-mullite-Al2O3 multi-component gradient anti-oxidation coating and a preparation method thereof. The preparation method comprises the following steps: firstly, mechanically grinding a titanium alloy matrix, and then carrying out polishing treatment and ultrasonic cleaning; the cleaned titanium alloy matrix is dried in an air dry oven; plating a Si elementary substance layer on the surface of the titanium alloy by adopting a direct current sputtering mode on the dried substrate; carrying out oxidation treatment on the Si-plated substrate at a high temperature; taking out the titanium alloy substrate, and uniformly laying a layer of aluminum foil on the surface; placing the titanium alloy substrate in a vacuum furnace, preserving heat at high temperature to completely melt the titanium alloy substrate, and uniformly coating the titanium alloy substrate on the surface of the titanium alloy substrate; a titanium alloy substrate is subjected to oxidation treatment in air to obtain SiO2 and Al2O3, a mullite phase is generated through the reaction between the SiO2 and the Al2O3, and the SiO2-mullite-Al2O3 multi-component gradient anti-oxidation coating is obtained. According to the method, the oxidation resistance of the titanium alloy matrix can be improved.

Owner:XIAN THERMAL POWER RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com