Patents

Literature

68results about How to "Reduce the preparation process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

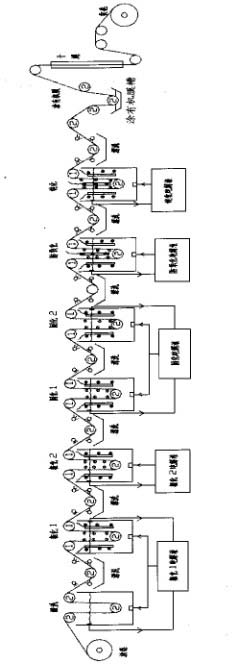

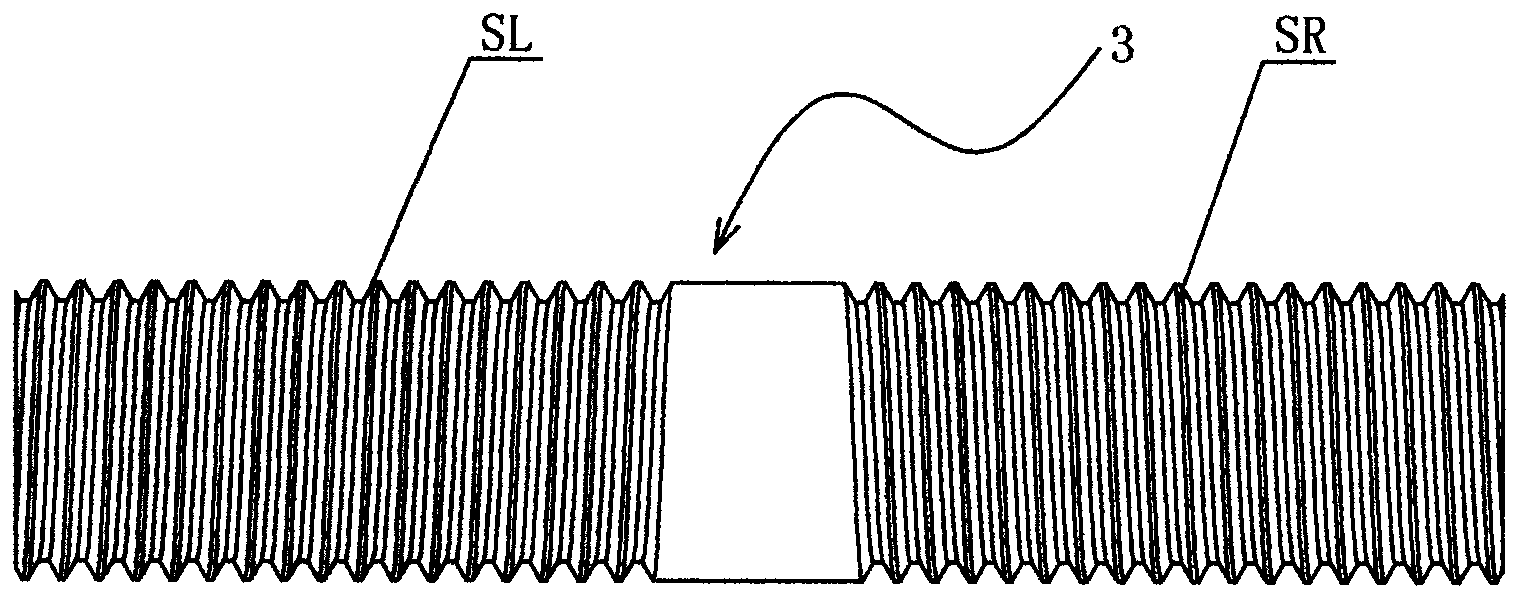

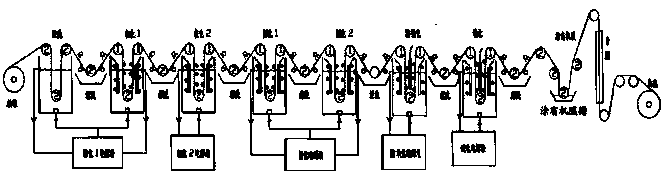

Manufacturing process of smooth roughened electrolytic copper foil

The invention relates to a process for manufacturing smooth surface roughened electrolytic copper foil, which comprises a step of pickling, a step of primary smooth surface roughening, a step of secondary smooth surface roughening, a step of primary smooth surface curing, a step of secondary smooth surface curing, a step of double-size anti-oxidization treatment, a step of double side passivation and a step of smooth surface coupling agent treatment, which are accomplished continuously on the same production line. Compared with the prior art, the smooth surface roughened electric copper foil manufactured by the process for manufacturing the smooth surface roughened electrolytic copper foil has the advantages of short copper teeth, easy etching, and high impedance controllability. When the copper foil is used in production of downstream products, the needs of blackening micro corrosion and toughening treatment are obviated, so the manufacturing process is shortened, and the short circuit rate and open circuit rate are lowered; meanwhile, the copper foil manufactured by the process has the same quality as the conventional high-precision or double-side toughened electrolytic copper foil, is produced at low cost and is more suitable for manufacturing the inner layers of high-precision multilayer plates and high-density fine line printed circuit boards (PCBs).

Owner:合肥铜冠电子铜箔有限公司

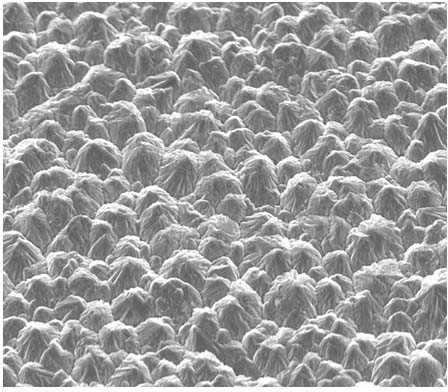

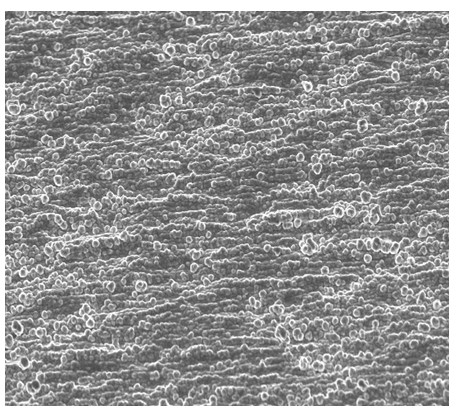

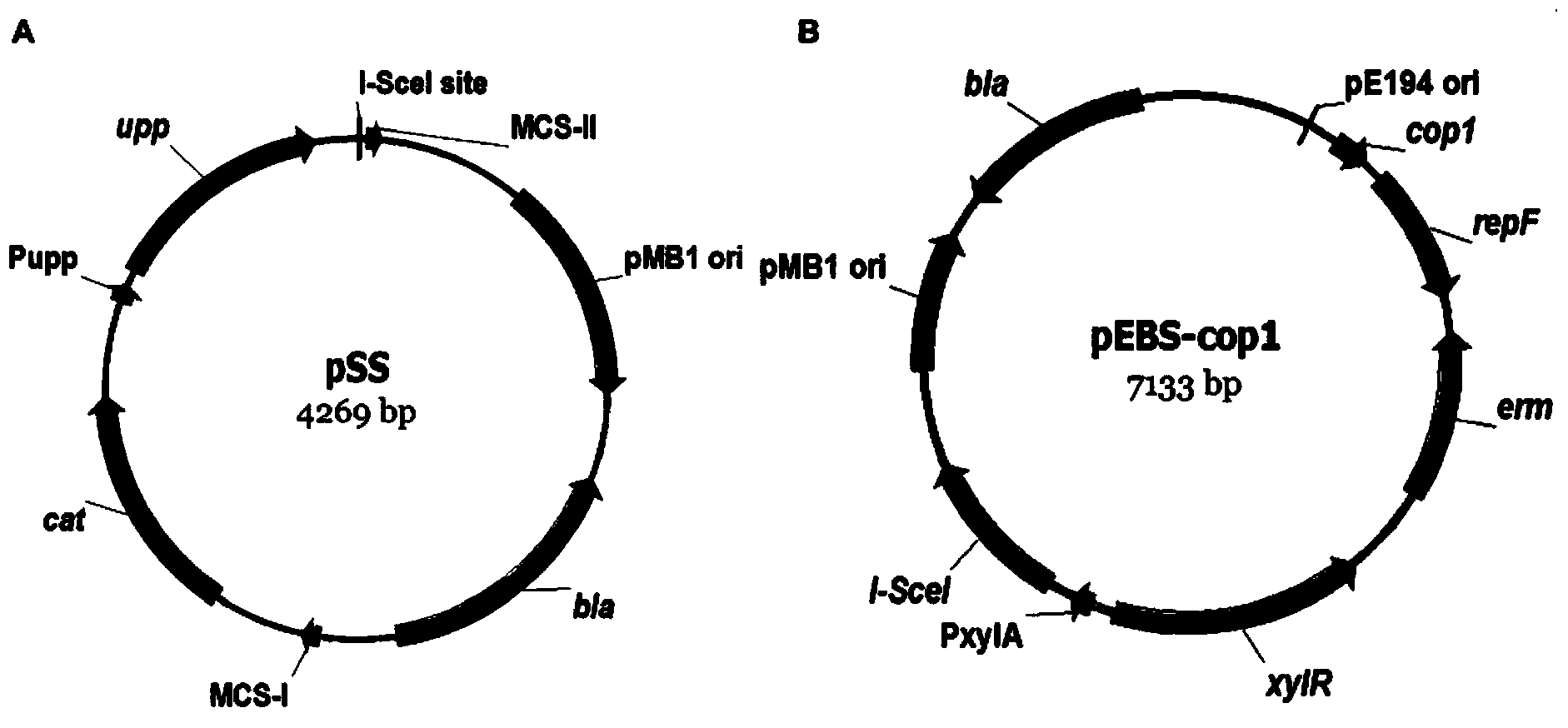

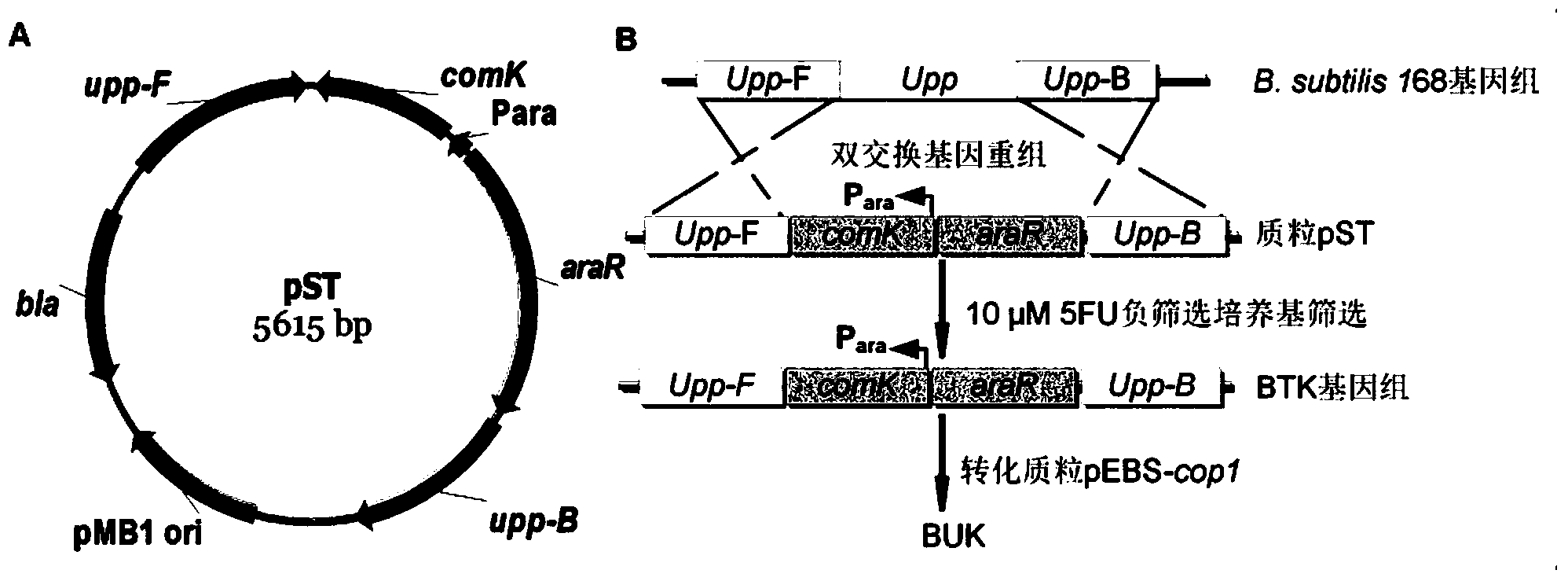

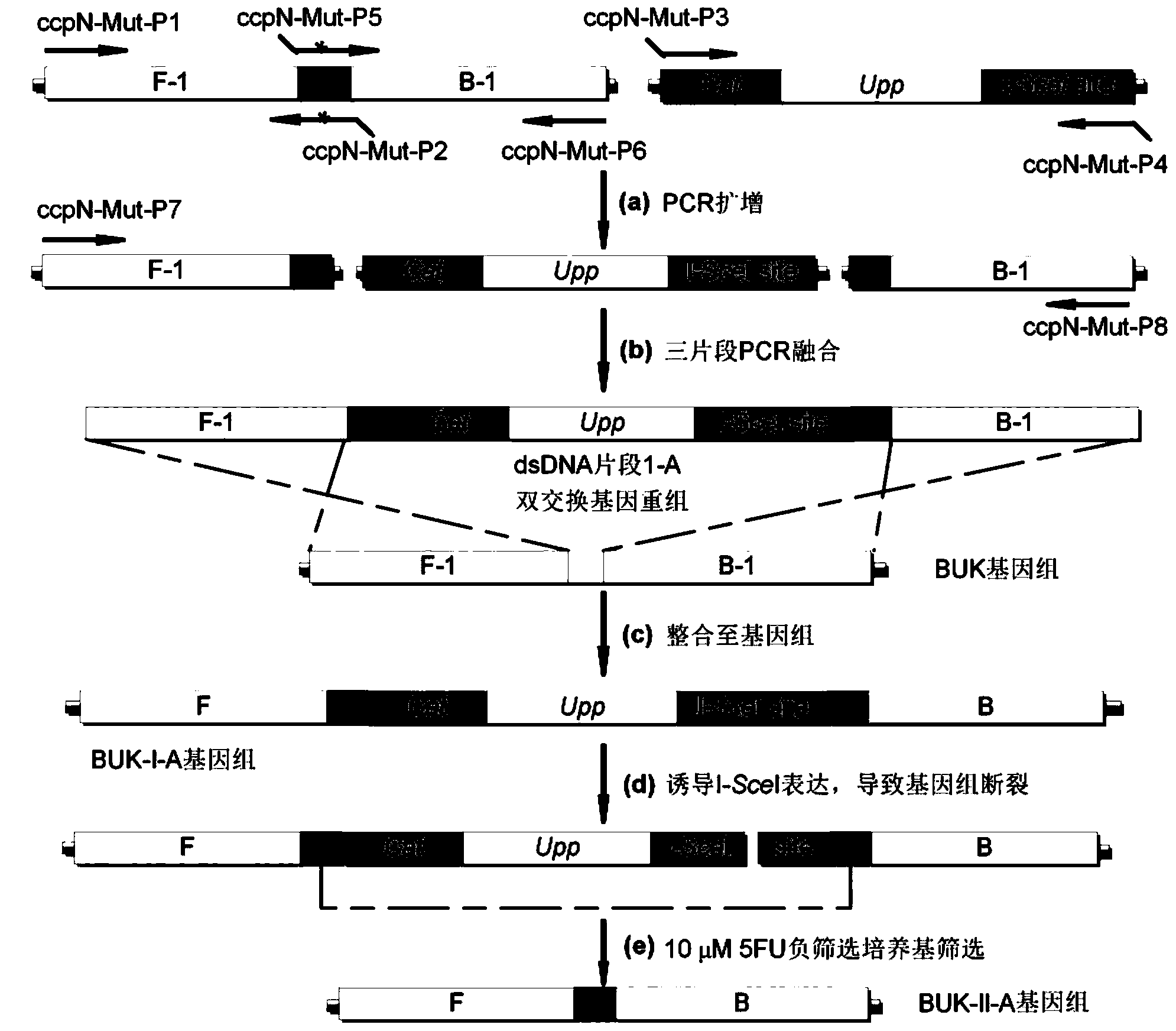

Traceless modification method of bacillus subtilis genome

ActiveCN103451224AReduce the preparation processImprove recombination efficiencyBacteriaMicroorganism based processesNucleotideLarge fragment

The invention discloses a traceless modification method of bacillus subtilis genome. The method disclosed by the invention is used for carrying out traceless modification on the bacillus subtilis genome by utilizing an upp positive-negative selection system. The method disclosed by the invention utilizes a ComK expression system, so that the bacillus subtilis has an excellent dsDNA (double-stranded deoxyribonucleic acid) conversion efficiency which can be up to 3-5*10<3>cfu / microgram dsDNA. Meanwhile, an exogenous endonuclease I-SceI expression system is utilized to bring double-stranded DNA breakage into the genome, so that the genetic recombination efficiency in negative selection molecules is obviously improved and can be up to 8*10<-4>. According to the method disclosed by the invention, iterative modification can be performed on a plurality of target nucleotide sequences in the bacillus subtilis genome, and the steps of introducing gene mutation to the genome, knocking out target gene sequences from the genome, deleting a large fragment of genomic sequences and the like are included.

Owner:TIANJIN UNIV

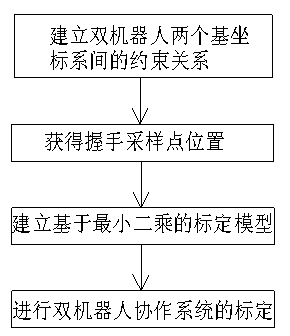

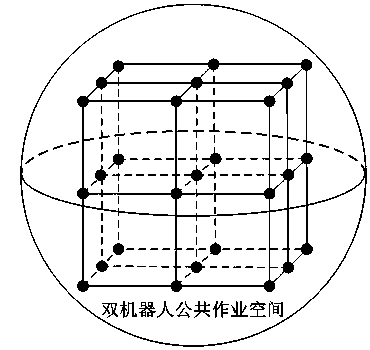

Base coordinate calibration method of two-robot collaboration system

ActiveCN104215206AReduce the preparation processHigh precisionMeasurement devicesSingular value decompositionHandshake

The invention discloses a base coordinate calibration method of a two-robot collaboration system. The base coordinate calibration method comprises the steps of firstly, establishing geometric constraint between the base coordinate systems of two robots according to a coordination transformation relation between the two robots in the collaboration system, secondly, performing a plurality of handshake action experiments of the two robots by use of a calibration finger mounted on the tail end of a tool hand to obtain the coordinates of the handshake sampling points of the two robots under the own coordinate systems, respectively, thirdly, building a calibration model according to the handshake sampling points and the robot base coordinate constraint, and finally, solving by use of a singular value decomposition algorithm to obtain a rotation matrix and a translation vector between the base coordinates of the two robots, and consequently, completing the calibration of the two-robot collaboration system. The base coordinate calibration method of the two-robot collaboration system does not rely on other external special measuring devices, and is simple and easy to implement; besides, the base coordinate calibration method is high in calibration accuracy by use of a numerical solution method, and also has excellent error fault-tolerant capability, and therefore, the processing level and the production quality of the two-robot collaboration system can be well improved.

Owner:SOUTHEAST UNIV

Process for spreading, spraying and positioning machine-processed parts surface hole position

InactiveCN101122788AFast hole positioningEasy hole positioningOther workshop equipmentNumerical controlNumerical controlThin slab

The invention discloses a technological process of expanding and spraying a position of a hole on surface of a machine-made part. The main procedures of the technological process are as following: surface data of the machines-made part is obtained from a digifax to set up a model; the data of various patterns of the machine-made part surface is calculated and the surface is made to be virtually expanded. According to expanding calculation, a graph plotter draws an expansion line; numerical control processing numerically processes a flexibly-expanding orifice mould on an elastic plate or a sheet which is less than 1mm; in the process, machine-made part is positioned by the shape and the structure. An expanding orifice module is used to spray positions of all connection holes on the surface of the part and then drills are made. The invention adopts the flexibly-expanding orifice mould to localize the shape of the part and holes, which is rapid, correct, time-saving and low labor intensity. The flexibly-expanding orifice mould, which can be expanded and curved without deformation, can make the connection hole localized as standardized, reduce drilling cycle of various connection holes of machine-made parts and solve the problem that the machine-made part can not be expanded to be positioned on the plane.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Preparation method of carbon material high-temperature oxidation-resistant coating by coating and sintering

ActiveCN104193421AReduce the preparation processShort preparation cycleOxidation resistantCoated surface

The invention provides a preparation method of a carbon material high-temperature oxidation-resistant coating by coating and sintering. The method comprises the following steps: (1) brushing a slurry I on a cleaned carbon material surface; (2) continuing brushing a slurry II on the carbon material surface brushed with the slurry I in the step (1); (3) carrying out high-temperature sintering on the carbon material brushed with the slurry I and slurry II at 1300-1800 DEG C for 2-3 hours, and naturally cooling to room temperature; (4) repeating the brushing and sintering in the step (1) to step (3) 1-3 times; (5) carrying out seal treatment on the coating surface of the carbon material obtained in the step (4) by using ethyl orthosilicate; and (6) repeating the ethyl orthosilicate brushing and drying in the step (5) 1-4 times to obtain a seal layer on the coating surface of the carbon material. The method is simple to operate, has the advantages of short preparation period and high material utilization ratio, and can obviously lower the coating preparation cost.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

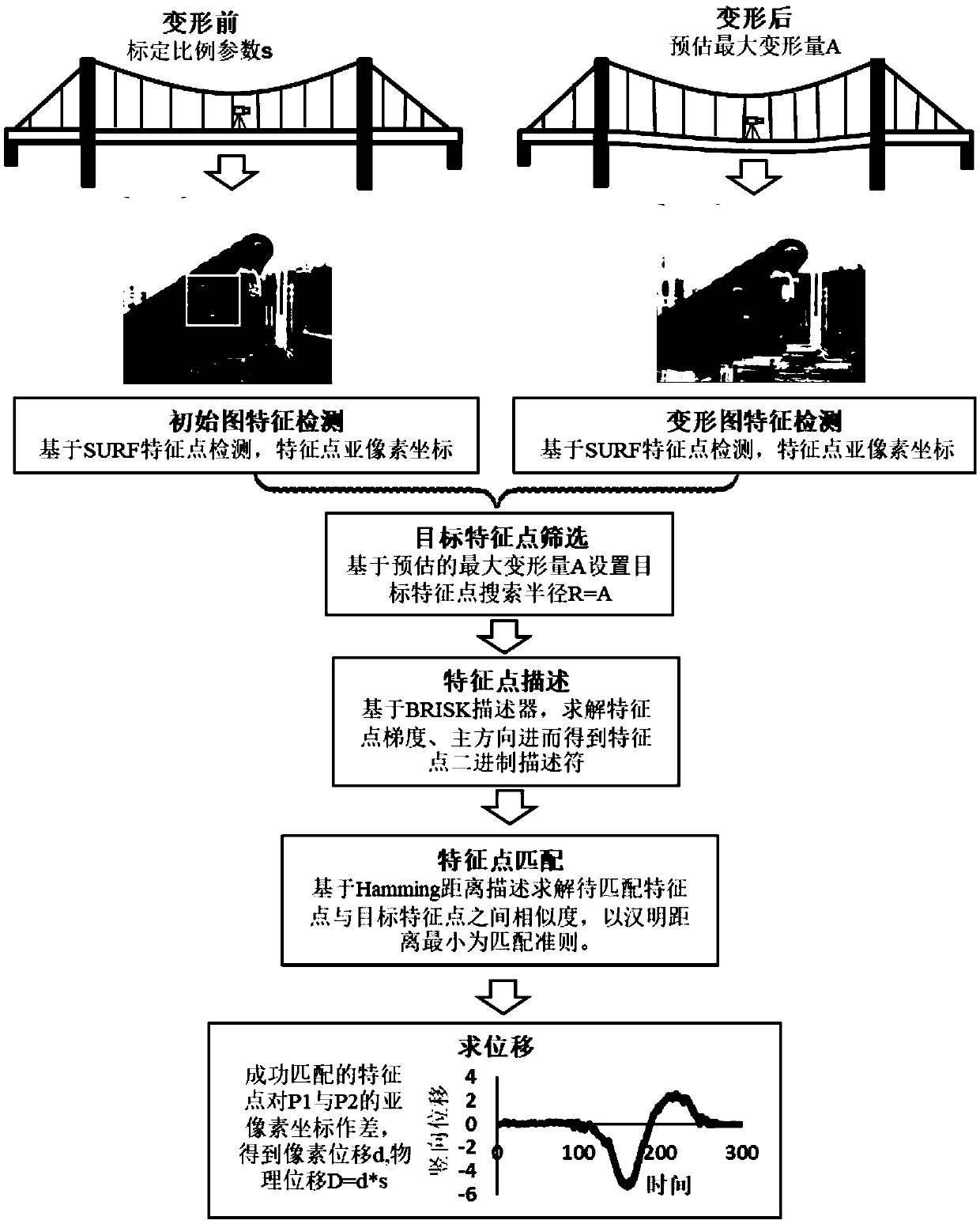

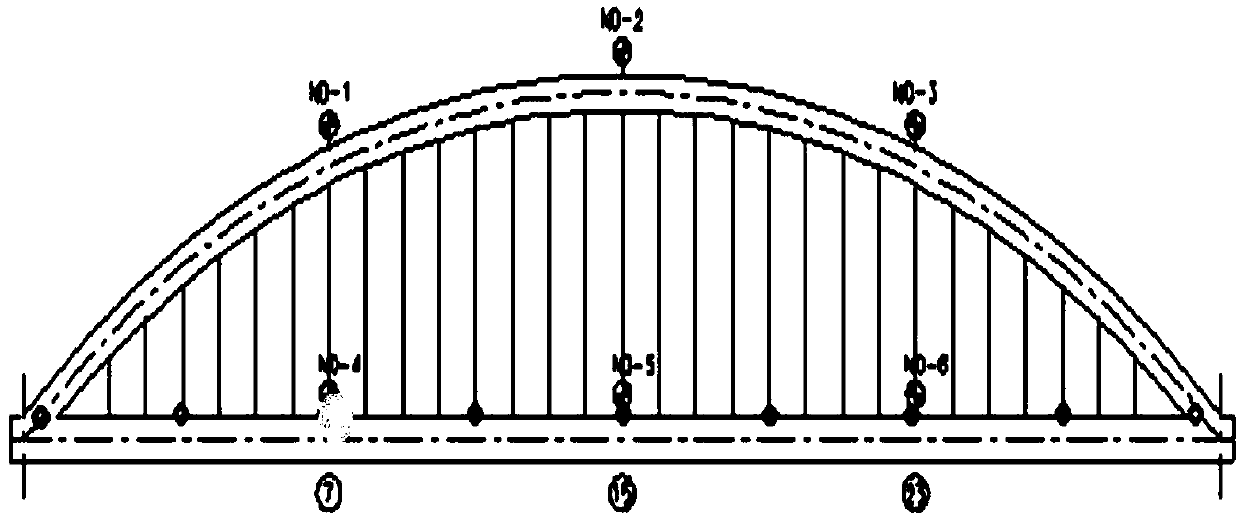

A bridge non-contact deformation measurement method based on feature point tracking

ActiveCN109559348AOvercome the arrangementOvercome the cumbersome defects of the acquisition systemImage analysisTarget surfaceComputer graphics (images)

The invention discloses a bridge non-contact deformation measurement method based on feature point tracking. According to the method, a camera erected on a bridge measuring point is focused on a fixedstructure with negligible far deformation, a series of images of the fixed structure are collected before and after bridge loading, and an improved feature point matching algorithm SURF-BRISK is utilized for tracking the sub-pixel coordinates of the feature points in the image so as to obtain the sub-pixel displacement at the bridge measuring point, and then the pixel displacement is converted into the actual physical displacement through the calibrated scaling coefficient. According to the method, the complex process of installation during contact of traditional displacement measurement means such as a displacement meter inclinometer and the like is overcome, the defect that a pre-designed special target surface needs to be pasted on the surface of a structure in a traditional image measurement method is also overcome, an existing screening strategy for feature point matching is improved, and the matching accuracy and the working efficiency are improved. The method has the characteristics of non-contact, few preparation processes and convenience in measuring point positioning, and has a wide application prospect.

Owner:SOUTHEAST UNIV

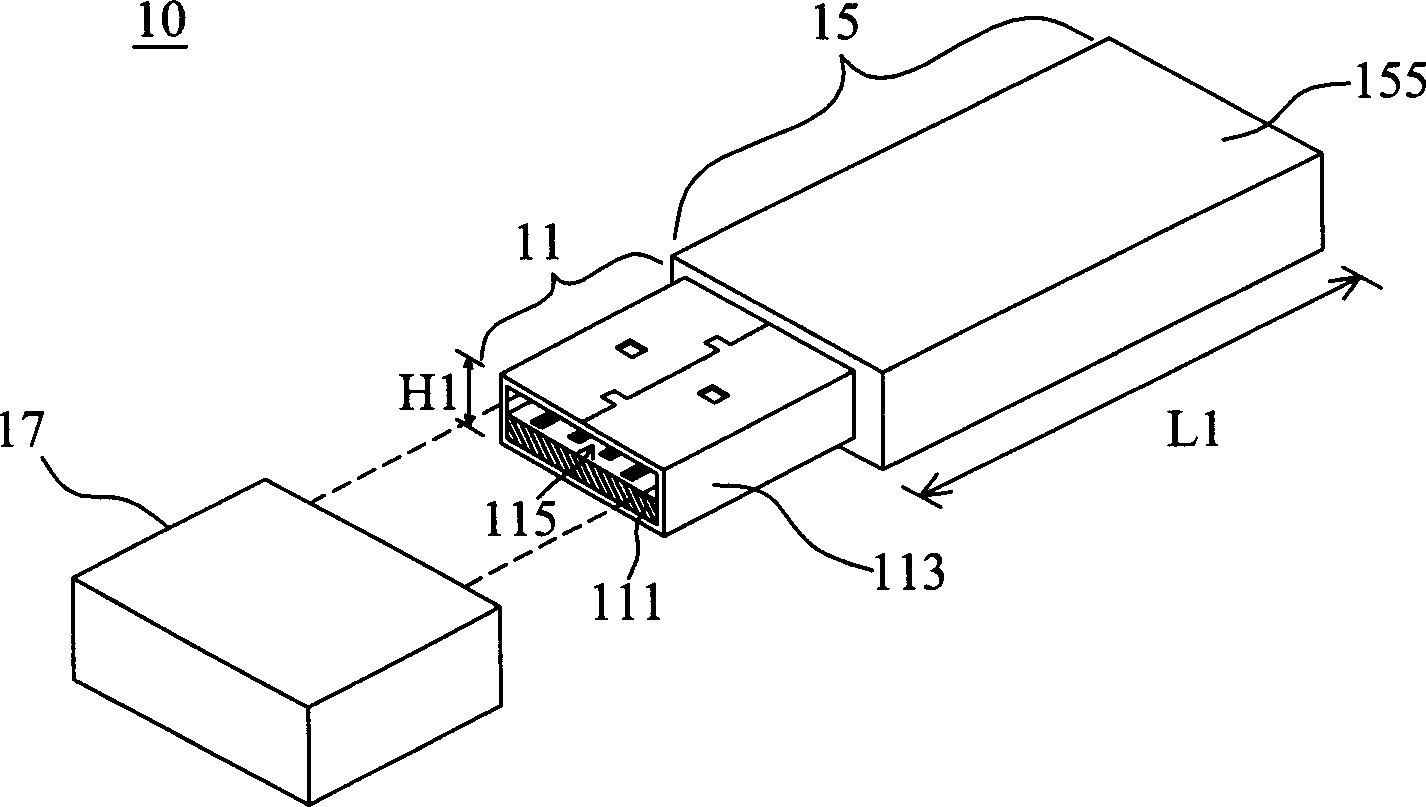

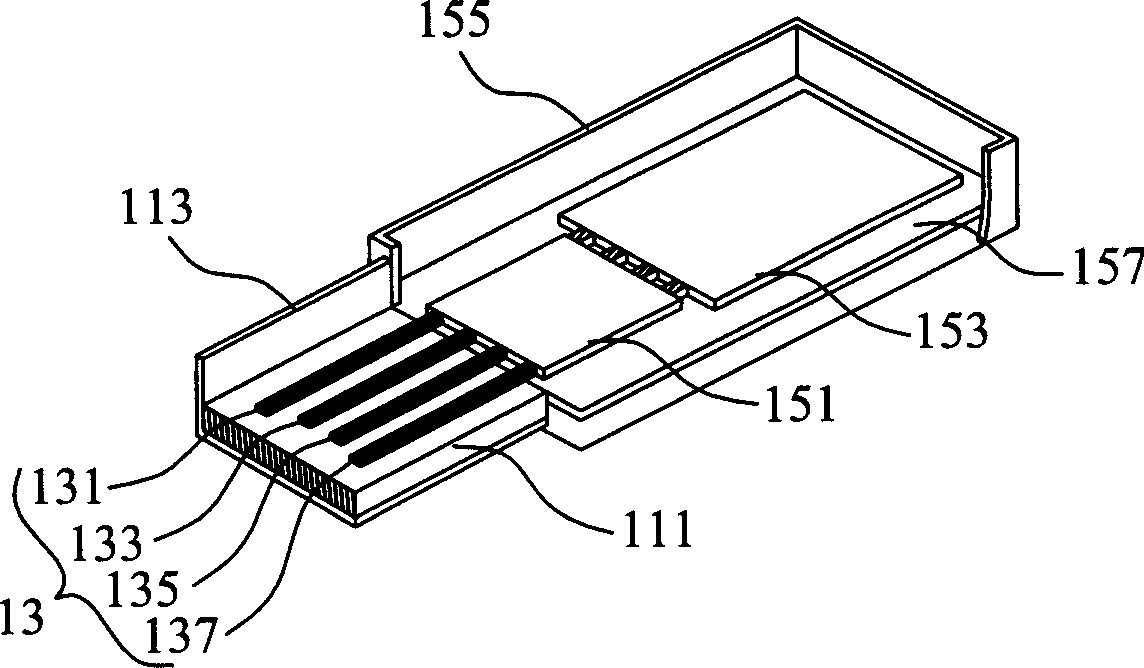

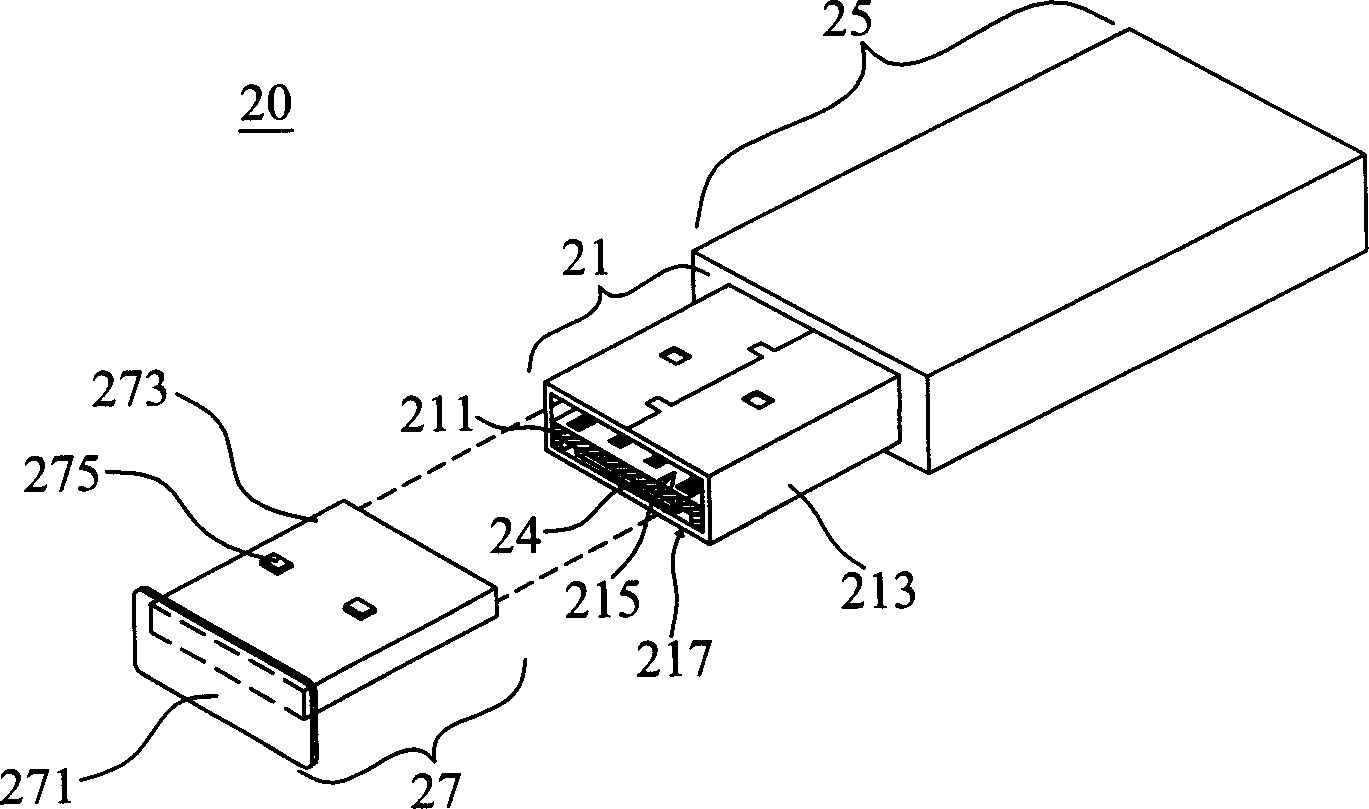

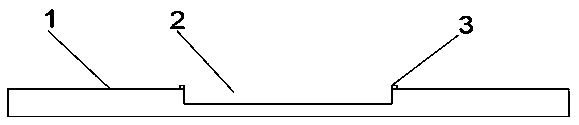

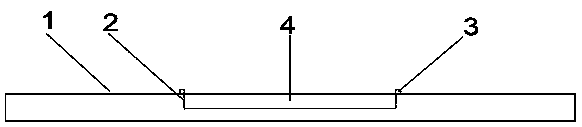

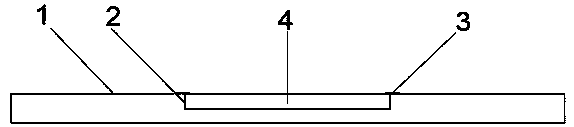

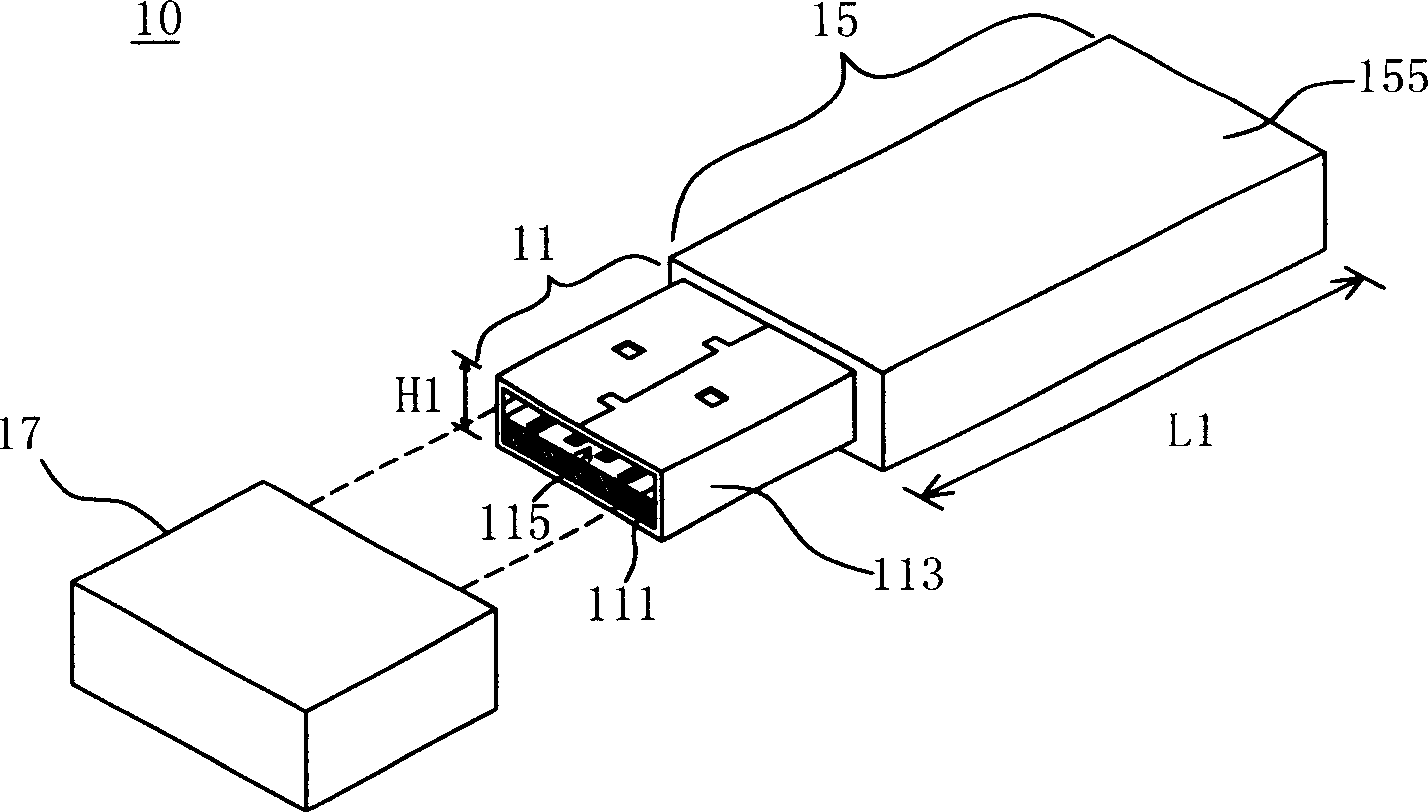

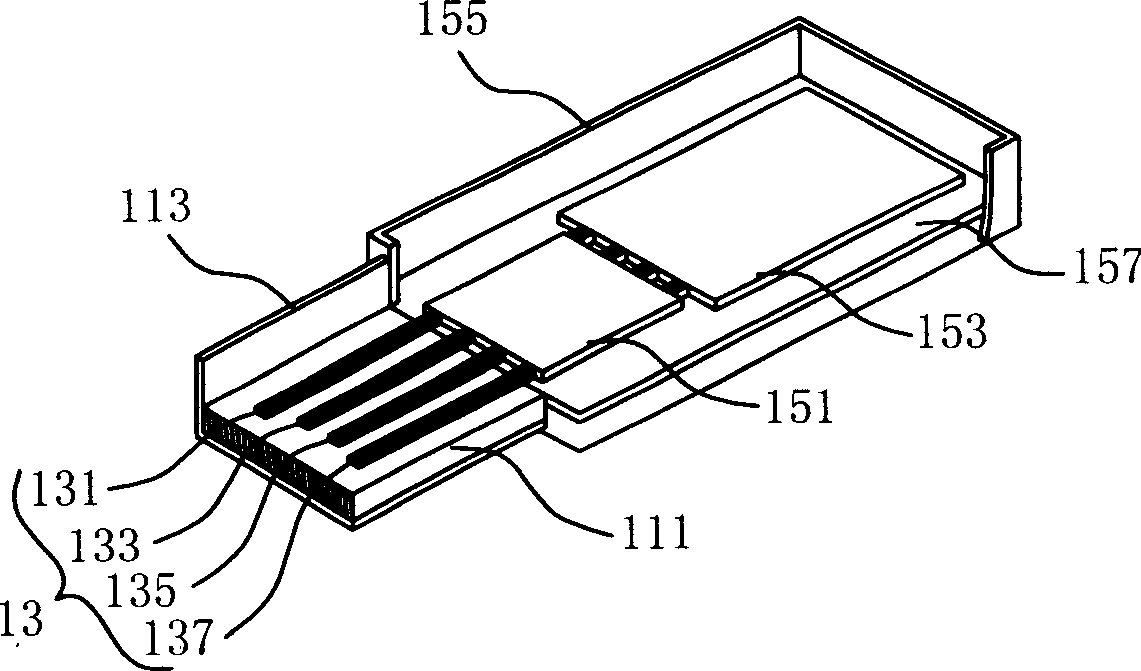

USB application apparatus

InactiveCN1632987AShorten the lengthImprove work efficiencyTwo-part coupling devicesEngineeringElectronic component

This invention discloses a USB applied device taking a PCB as the carrier board of a connector, the top surface of the carrier board can load multiple first connecting terminals and its bottom interlayer is formed between the bottom surface of PCB carrier board and the shell layer of the connector, for fixing an electronic component to reduce the length of the USB module or increase its working efficiency and function, besides, a data transmission circuit is set on part of the top surface without the first connection end on the PCB carrier board to increase its working efficiency and function.

Owner:INNODISK CORP

Process method for producing tool through caulking groove substrate

The invention discloses a process method for producing a tool through a caulking groove substrate. The process method comprises the following steps of (1) substrate preparing, (2) substrate cleaning,(3) high-speed steel bar embedding, (4) vacuum welding, (5) tempering, (6) straightening, (7) accurate grinding, (8) blade planing, (9) long blank cutting, (10) blade accurate grinding, (11) tool cutting, (12), perforating, (13), straightening and (14) cleaning, rust prevention and finished product packaging. By means of the process, the machining steps and process are shortened, the machining difficulty is reduced, the machining efficiency is improved, the machining cost is saved, and the machining yield and the stability of quality and performance are improved.

Owner:DONGE LIYUAN MACHINERY KNIFE

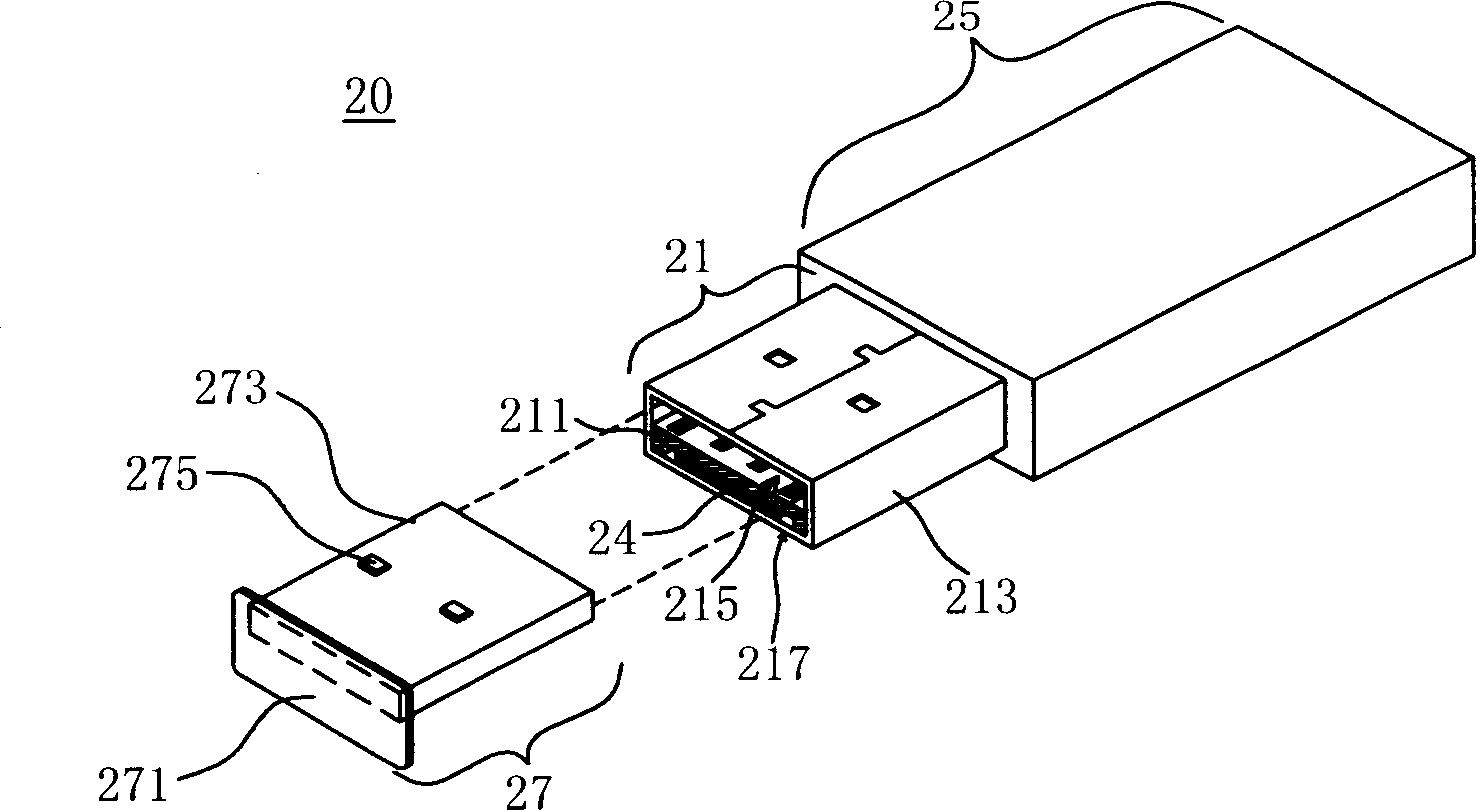

USB applier

InactiveCN1819365AShorten the lengthImprove work efficiencyCoupling device detailsTwo-part coupling devicesElectronic componentData transmission

A printed circuit board (PCB) is taken as USB port bearing board. On the surface of PCB bearing board, multi first connection ports can be mounted. A bottom interlayer is formed between the bottom surface of PCB bearing board and outer shell of connector, and is used to mount at least one electronic component by which the length of USB module can be shortened or working efficiency and functionality of USB module can be improved. And meanwhile, at part of the top surface not having first connection ports at least one board-top data transmission line can be installed.

Owner:INNODISK CORP

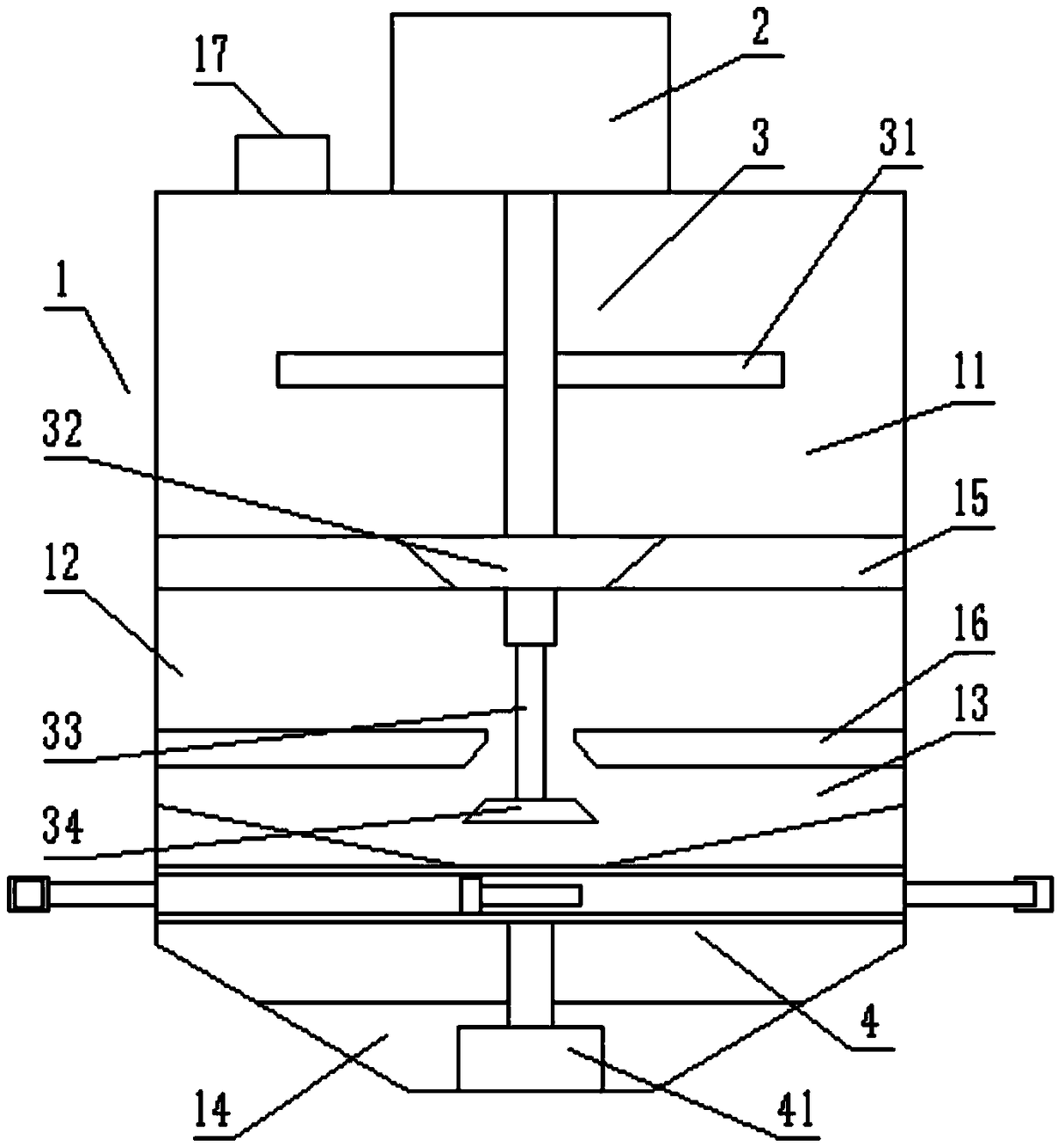

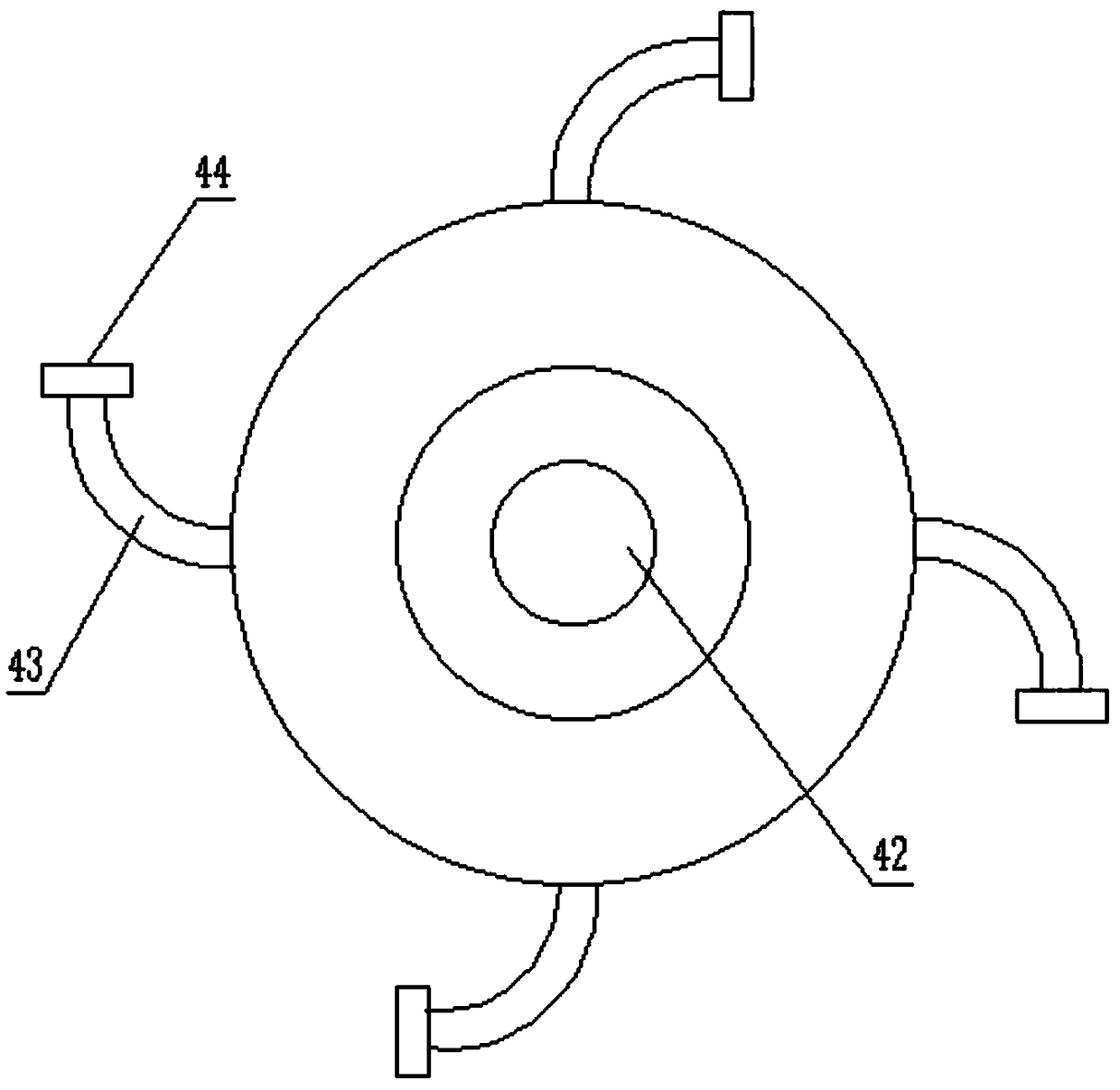

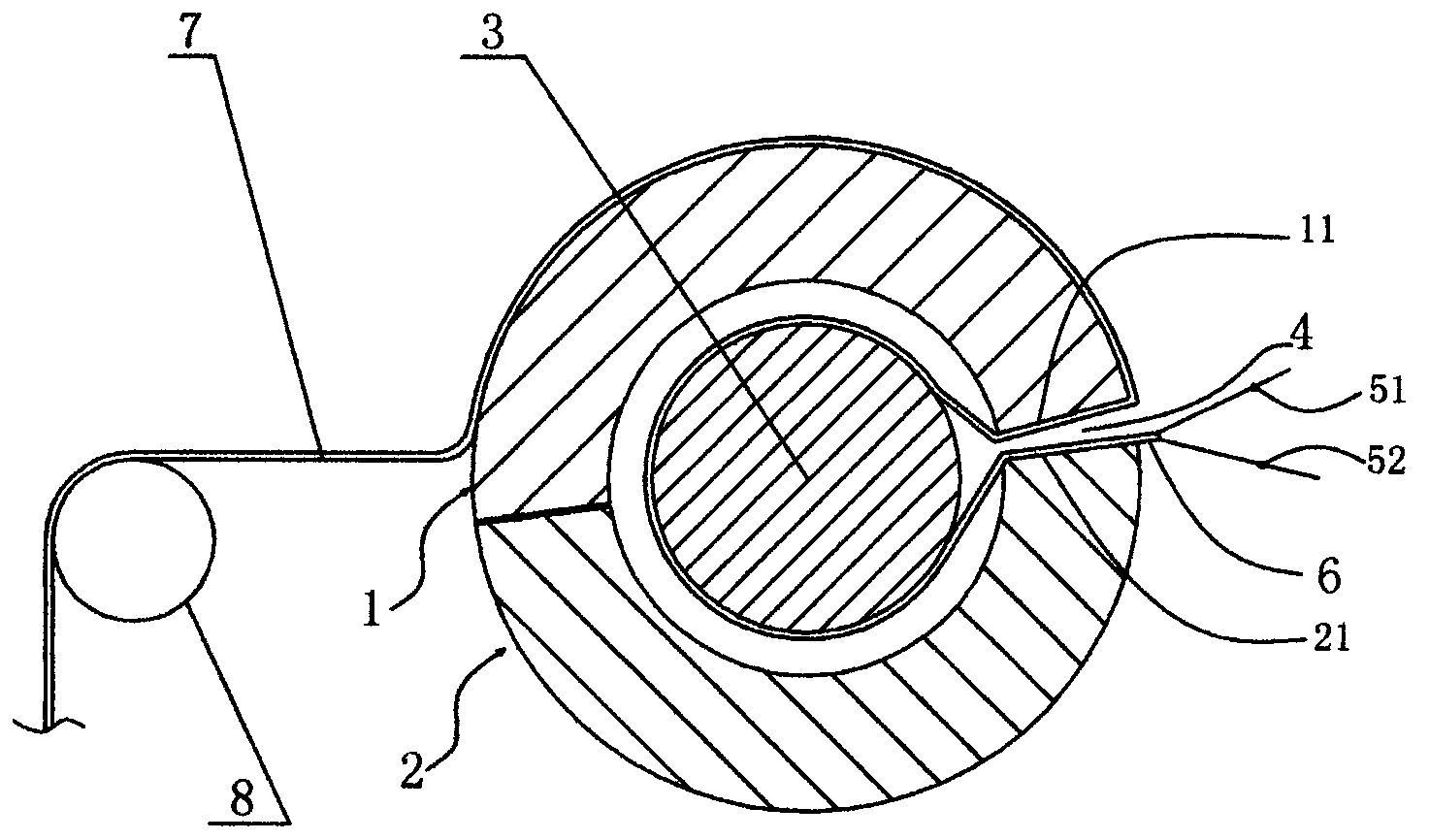

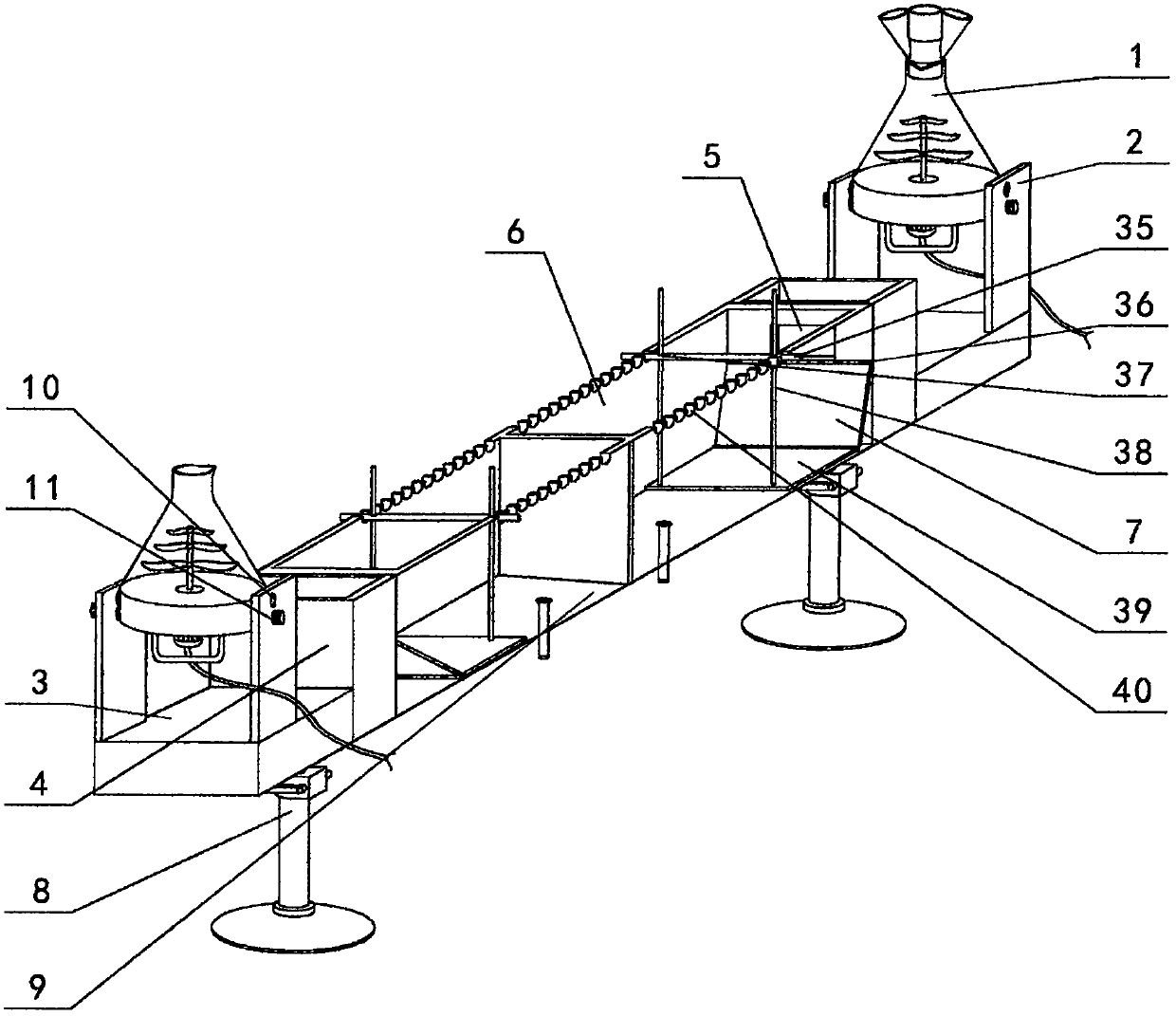

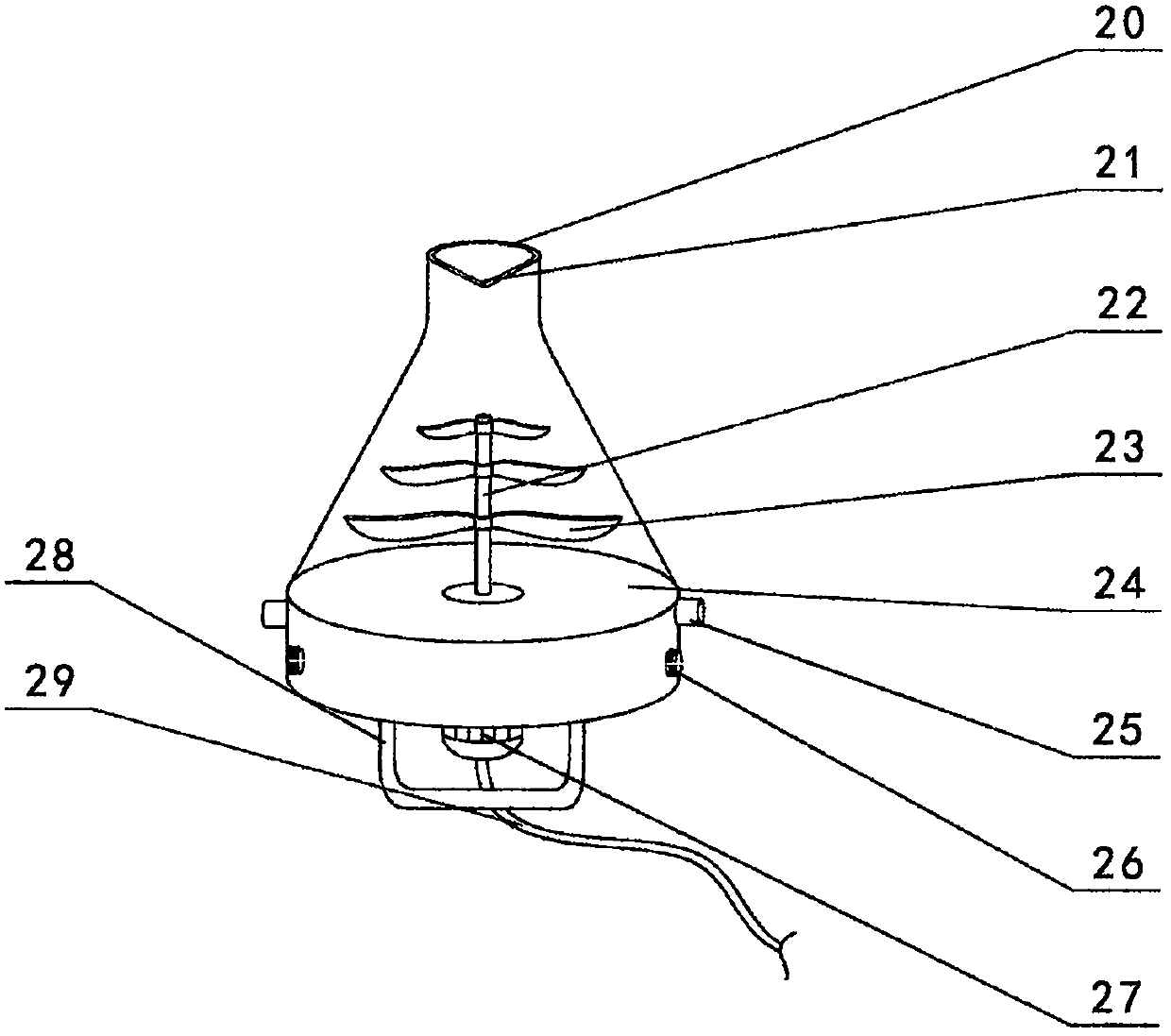

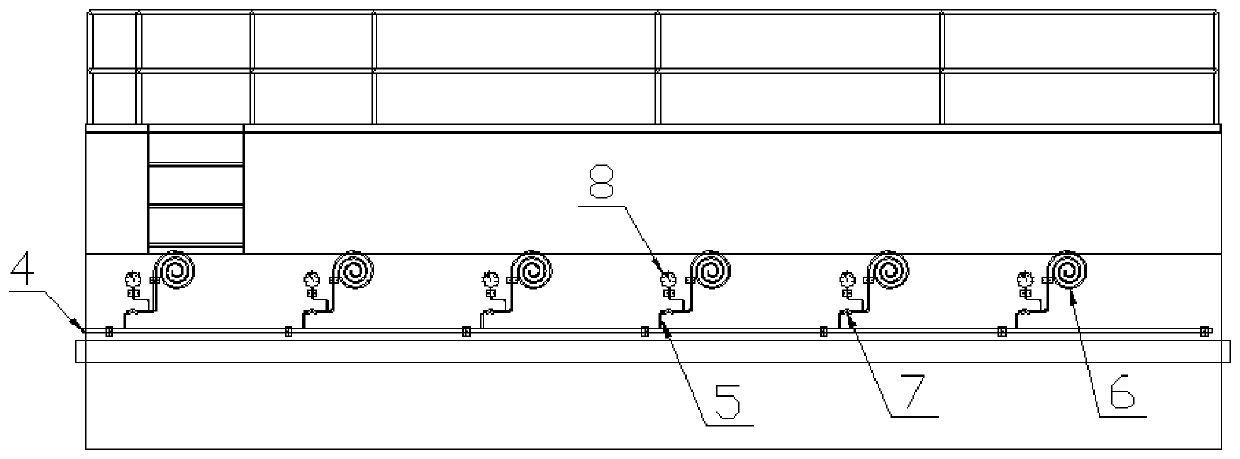

Omnidirectional feeding machine for aquaculture

InactiveCN109042427AAll-round deliveryServe evenlyClimate change adaptationPisciculture and aquariaElectric machineryEngineering

The invention discloses an omnidirectional feeding machine for aquaculture. The omnidirectional feeding machine for aquaculture comprises a housing, a mixing cavity, a transferring cavity, a scattering cavity and a sealing cavity are sequentially formed in the housing from top to bottom, and a first sealing plate and a second sealing plate are arranged on the upper and lower sides of the transferring cavity respectively for partition; a feeding port through which bait is put in is formed in the top of the housing; a disc-shaped scattering tray is arranged in the scattering cavity and rotatablyconnected with the housing, a plurality of arc-shaped scattering pipes are arranged on the outer wall of the scattering tray in the circumferential direction, and the scattering pipes are arranged inthe tangential direction of the outer wall of the scattering tray. According to the machine, the scattering tray is driven by a motor to rotate, the scattering pipes are arranged on the scattering tray, omnidirectional bait feeding is realized, and uniform feeding avoids bait accumulation and waste; besides, the machine can perform mixing processing on bait before feeding, preparatory processes before feeding are reduced, and the feeding efficiency is improved.

Owner:湖南米笠农业科技有限公司

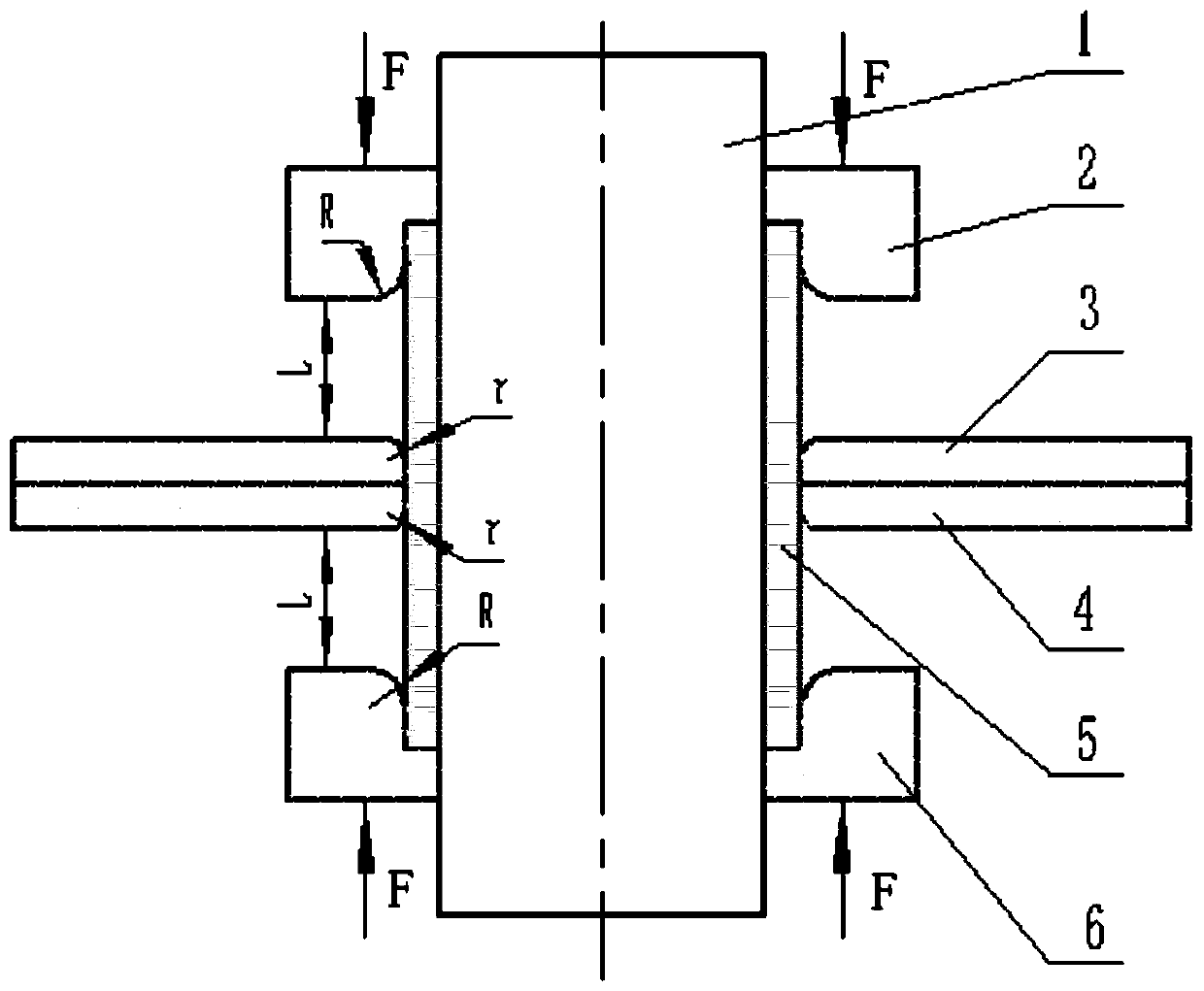

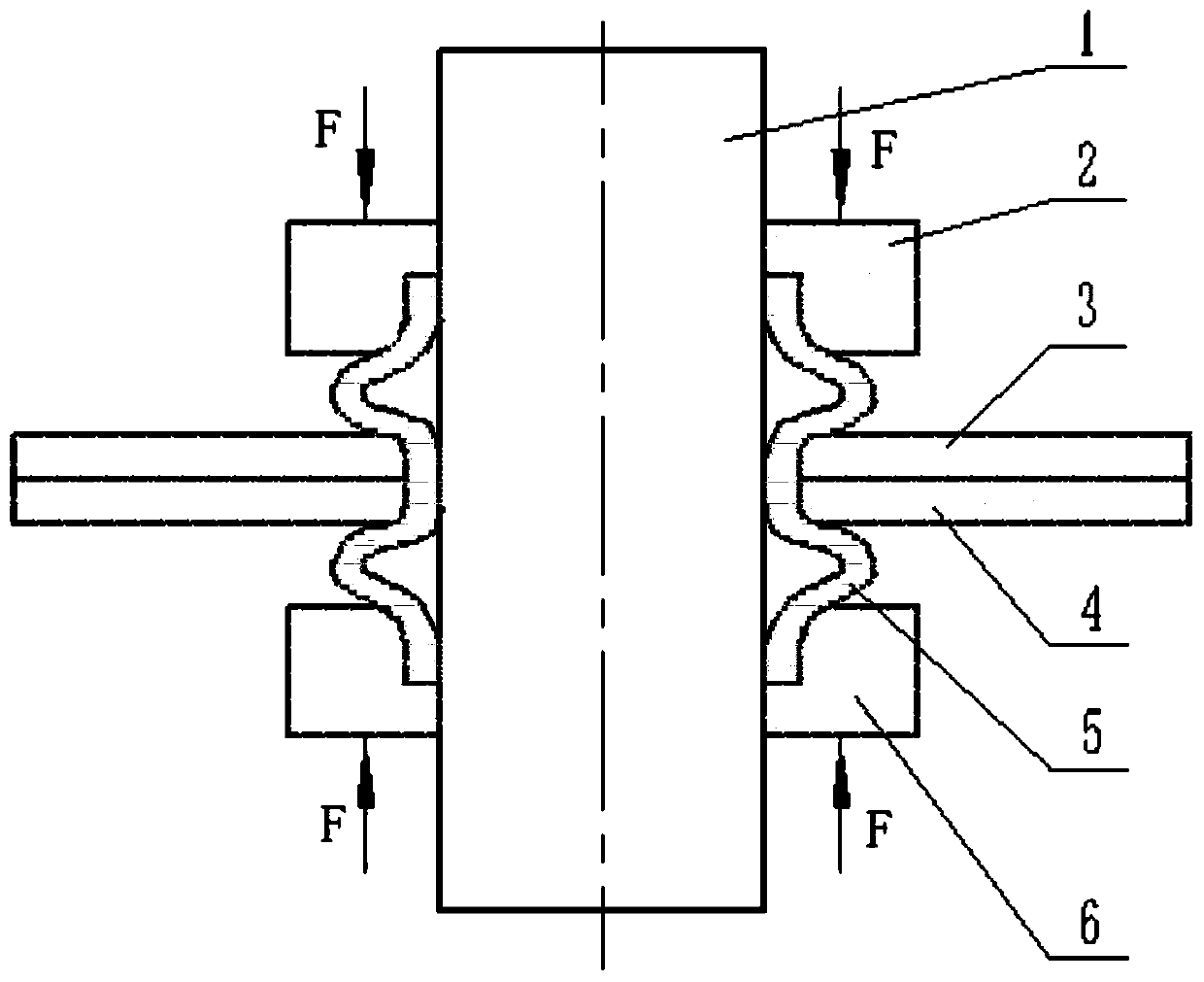

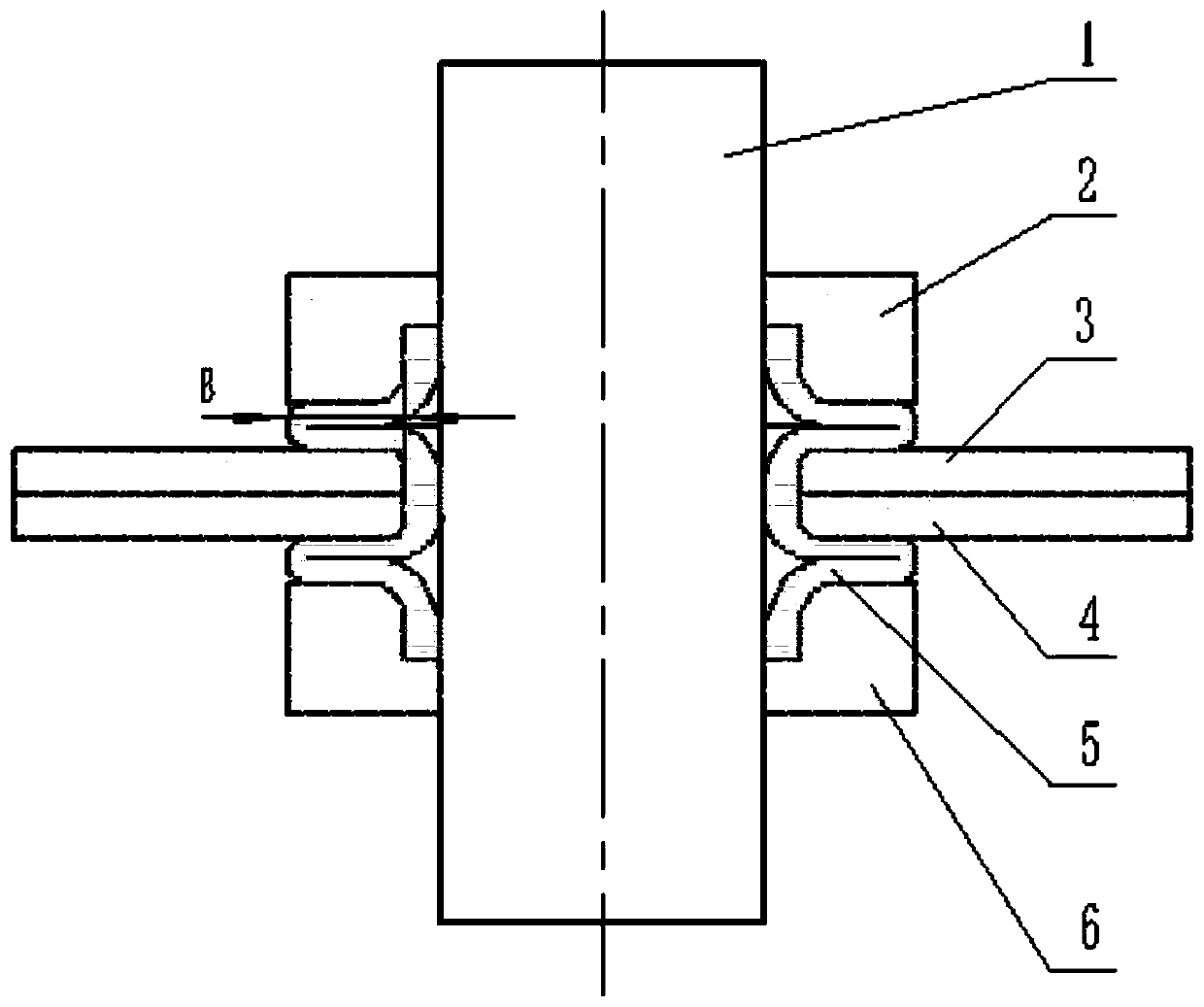

Method for achieving circular ring connection by utilizing wrinkling of metal pipes

ActiveCN110538931AHigh strengthSafe and reliable connectionShaping toolsEngineeringMechanical engineering

The invention discloses a method for achieving circular ring connection by utilizing wrinkling of metal pipes, and belongs to the technical field of material connection. The phenomenon that a connecting pipe deforms plastically under the action of force is utilized, so that the connecting pipe is wrinkled in a non-constraint area, the wrinkles are further compacted so as to achieve the plastic connection between two metal rings. After plastic deformation of the connecting pipe, the strength of the connection part can be enhanced due to deformation strengthening, so that the connection is safeand reliable; and the number of preparatory steps is few, the operation is simple and convenient, the whole connecting process is green and pollution-free, and the operation is simple, convenient andefficient.

Owner:SHAANXI UNIV OF SCI & TECH

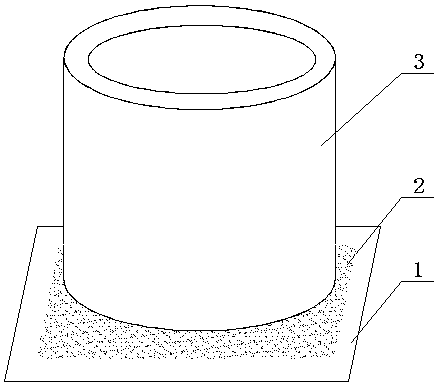

Synchronous shrinkage liner tube for sintering tubular ITO target blank and preparation method thereof

The invention discloses a synchronous shrinkage liner tube for sintering a tubular ITO target blank and a preparation method thereof. A raw material for preparing the synchronous shrinkage liner tubeis tetragonal polycrystalline zirconium oxide powder with the specific surface area of 15-25 m<2>.G<-1> or barium strontium titanate powder with the specific surface area of 18-30 m<2>.G<-1>. The preparation method comprises the following steps: adding deionized water accounting for 50% of the target solid phase content of the slurry into the raw materials to obtain a mixed solution, adding a dispersing agent, regulating the pH value of the mixed solution to 9-10, adding an adhesive accounting for 1.0-1.5% of the mass of the raw materials, uniformly mixing, carrying out ball milling in a ballmill to obtain slurry, pumping the slurry into a prilling tower for prilling to obtain prilling powder, putting the prilling powder into a mold, and carrying out compression molding to obtain the synchronous shrinkage liner tube. The synchronous shrinkage liner tube plays a role in replacing spherical ceramic paving materials, and due to the fact that the shrinkage rate of the synchronous shrinkage liner tube is slightly larger than that of a tubular ITO target material blank, the effect of better reducing sintering shrinkage resistance is achieved, and preparation procedures before sinteringare reduced, so that the production operation is more convenient.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

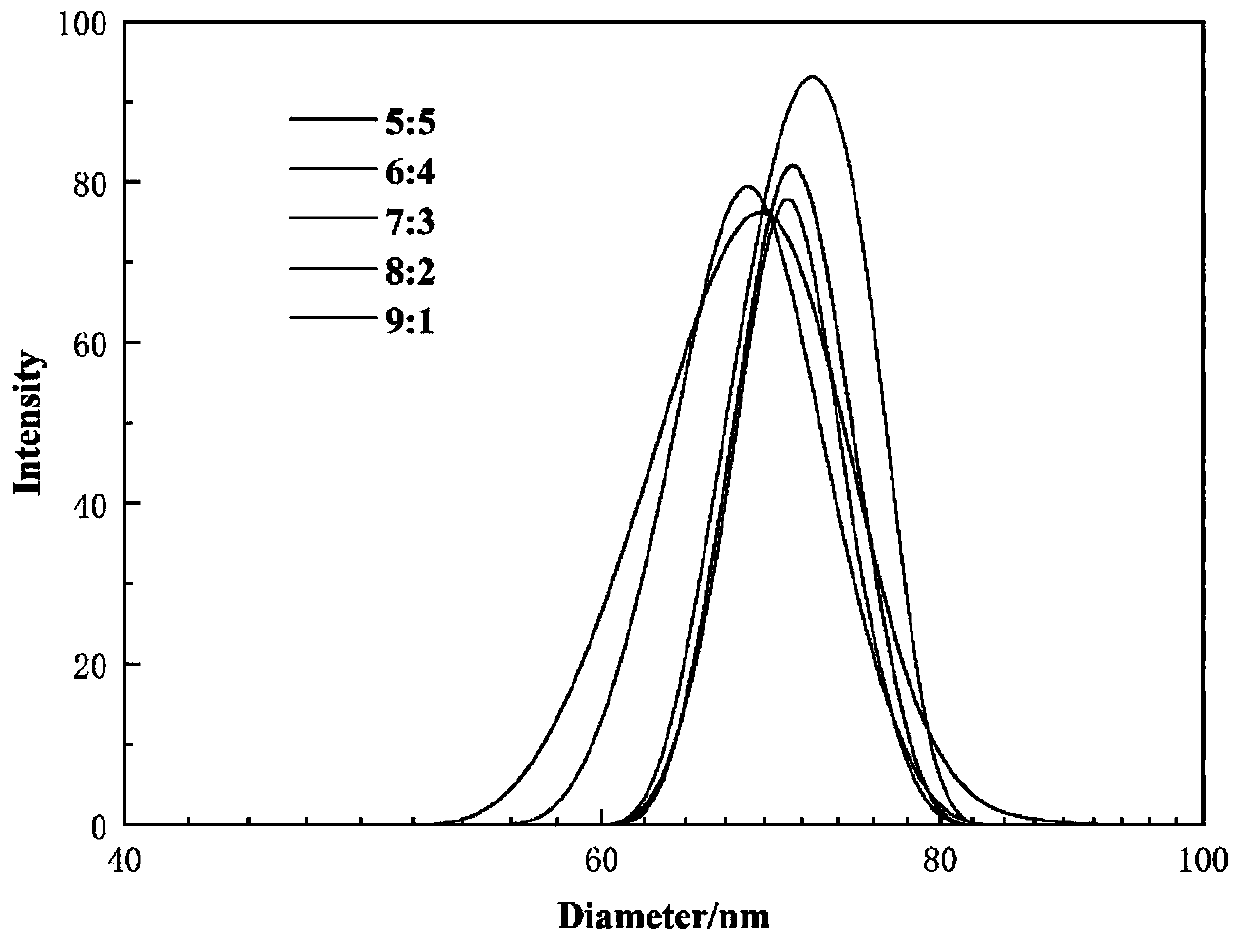

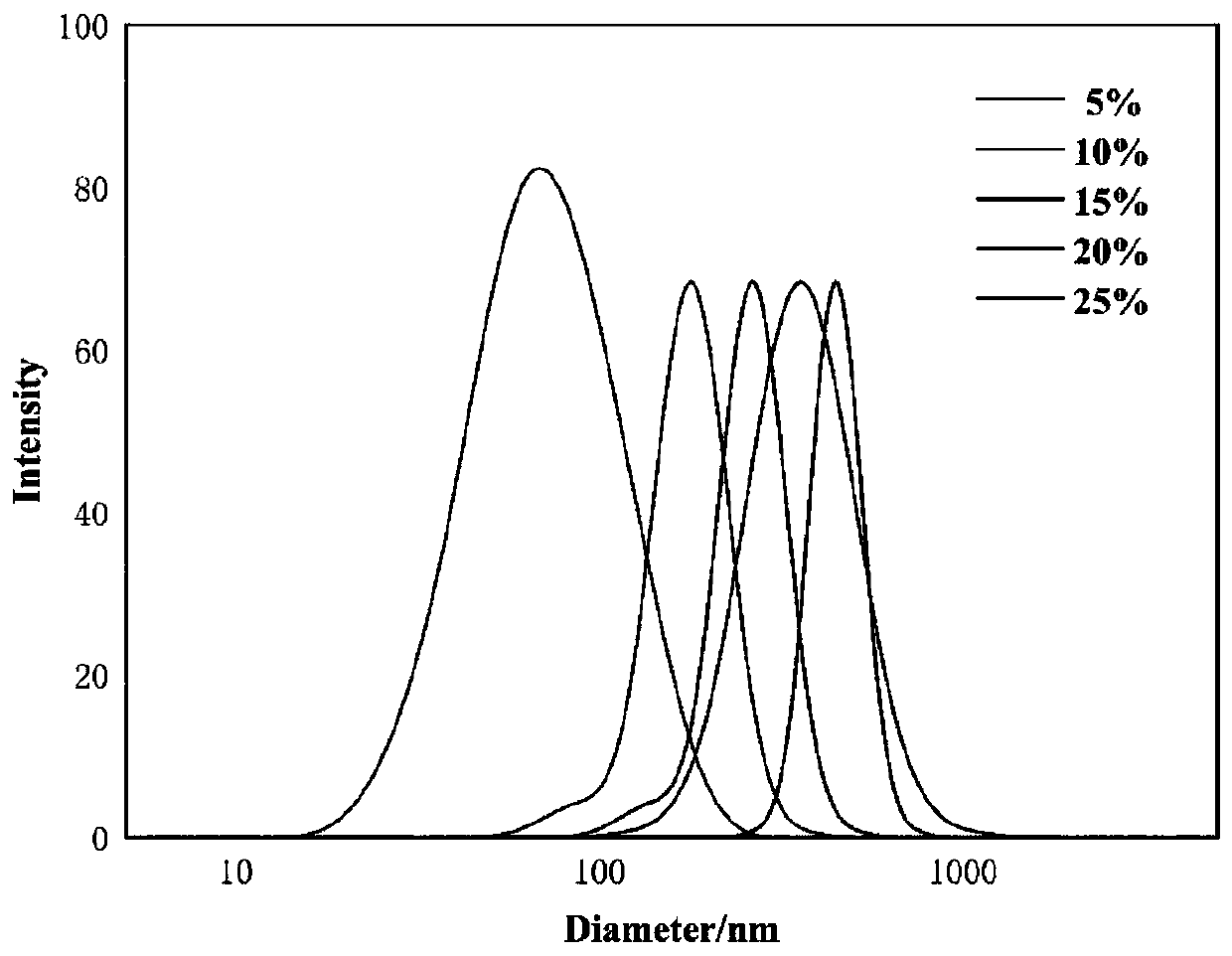

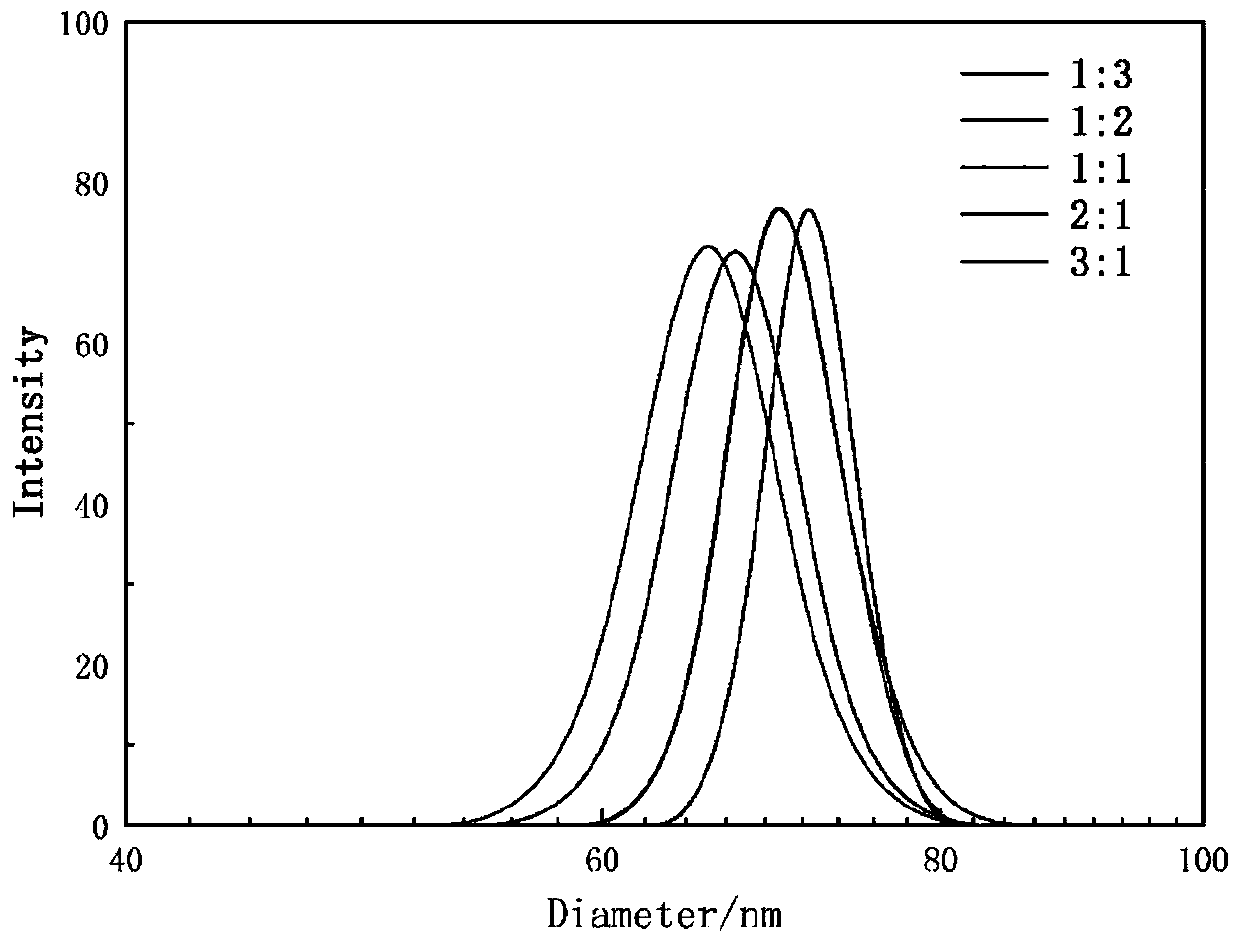

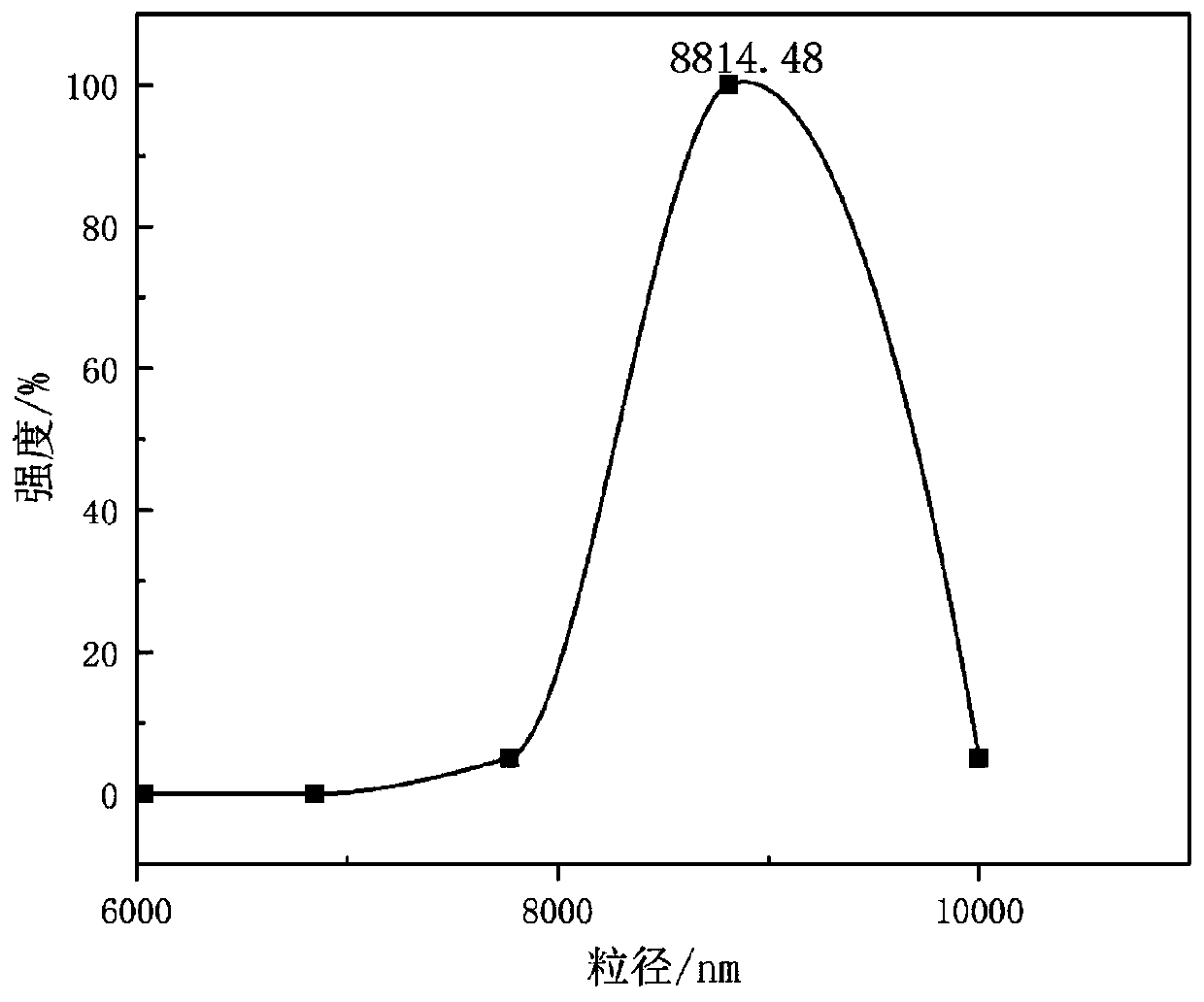

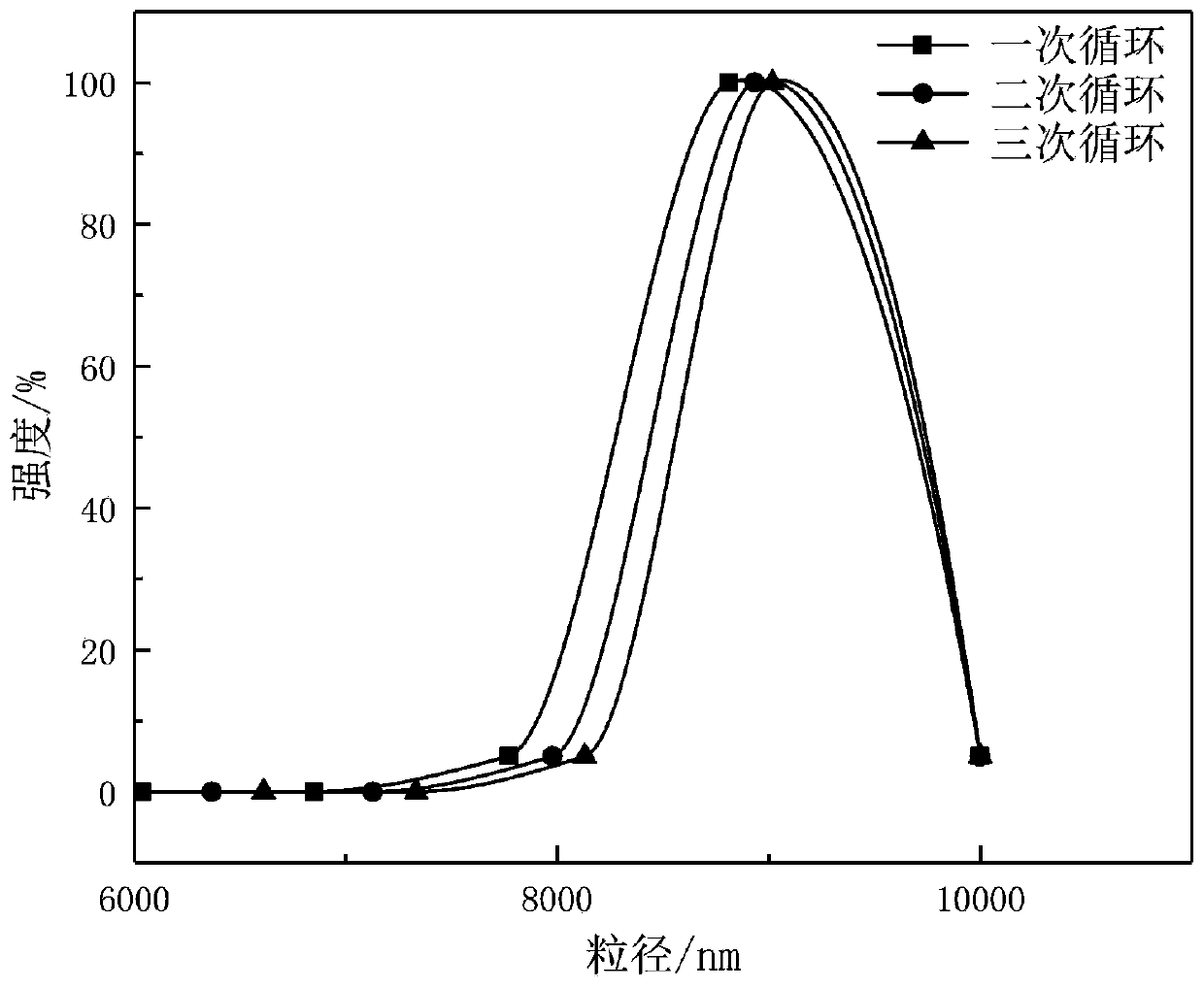

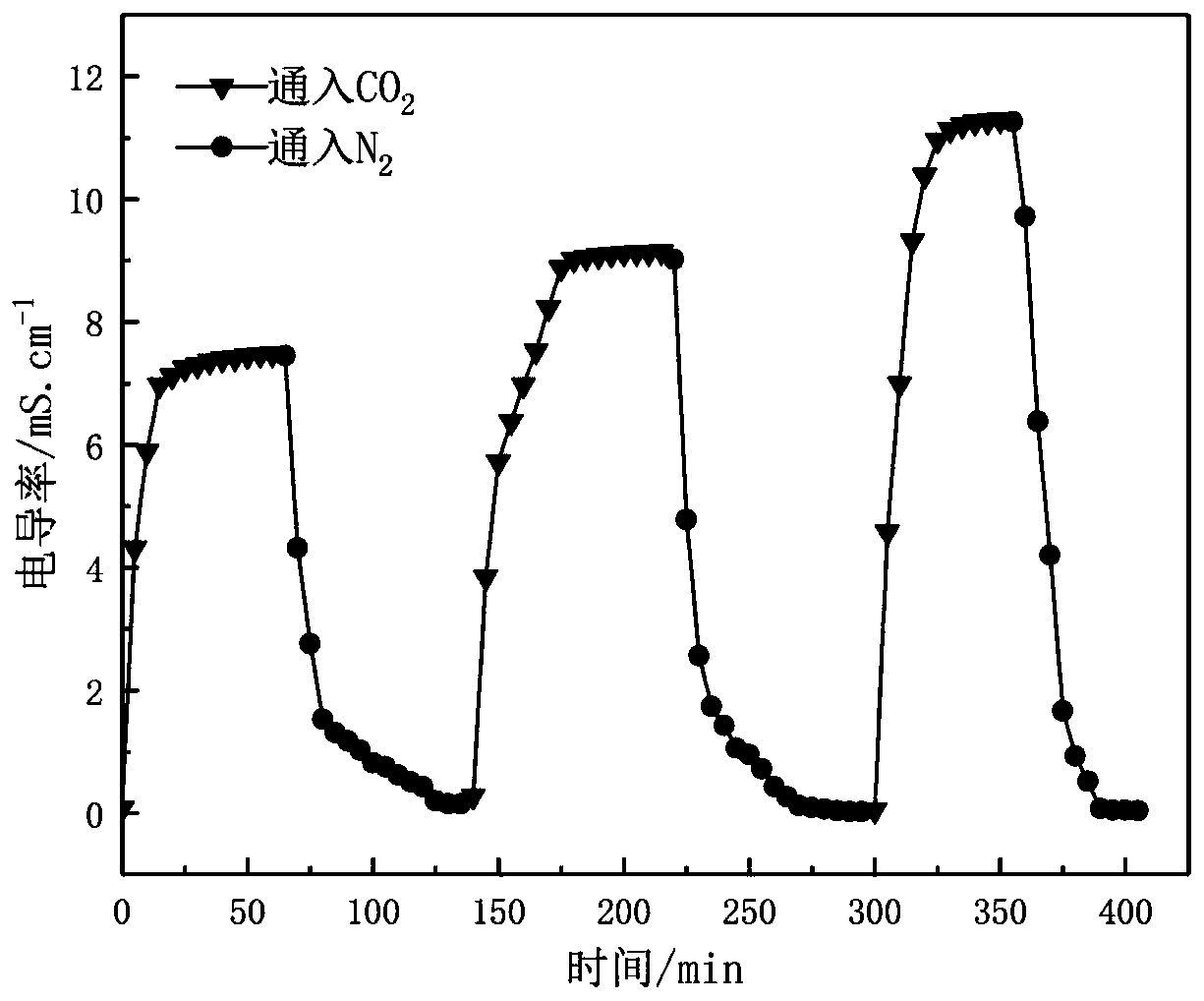

SiO2@paraffin nano-particle with core-shell structure and preparation method thereof

The invention relates to a SiO2@paraffin nano-particle with a core-shell structure and a preparation method thereof, and relates to the technical field of nanoparticles with core-shell structures. TheSiO2@paraffin nano-particle comprises nano SiO2 serving as a core and paraffin serving as a shell. The preparation method specifically comprises the following steps: S1) preparing an oil phase, S2) preparing a water phase, S3) preparing an O / W emulsion, S4) preparing SiO2@paraffin nanoparticles by introducing CO2 into the O / W emulsion, separating out paraffin, coating the paraffin on the surfaceof SiO2 to form SiO2-coated paraffin nanoparticles with core-shell structures, and centrifuging, and S5) carrying out cyclic utilization by introducing N2 into a protonation solvent to obtain an aqueous solution of N, N-dimethylcyclohexylamine and an emulsifier, and carrying out recycling. The preparation method of the SiO2@paraffin nanoparticles has the advantages of simple preparation method, cost saving, small environmental pollution and uniform particle size distribution of the product.

Owner:SOUTHWEST PETROLEUM UNIV

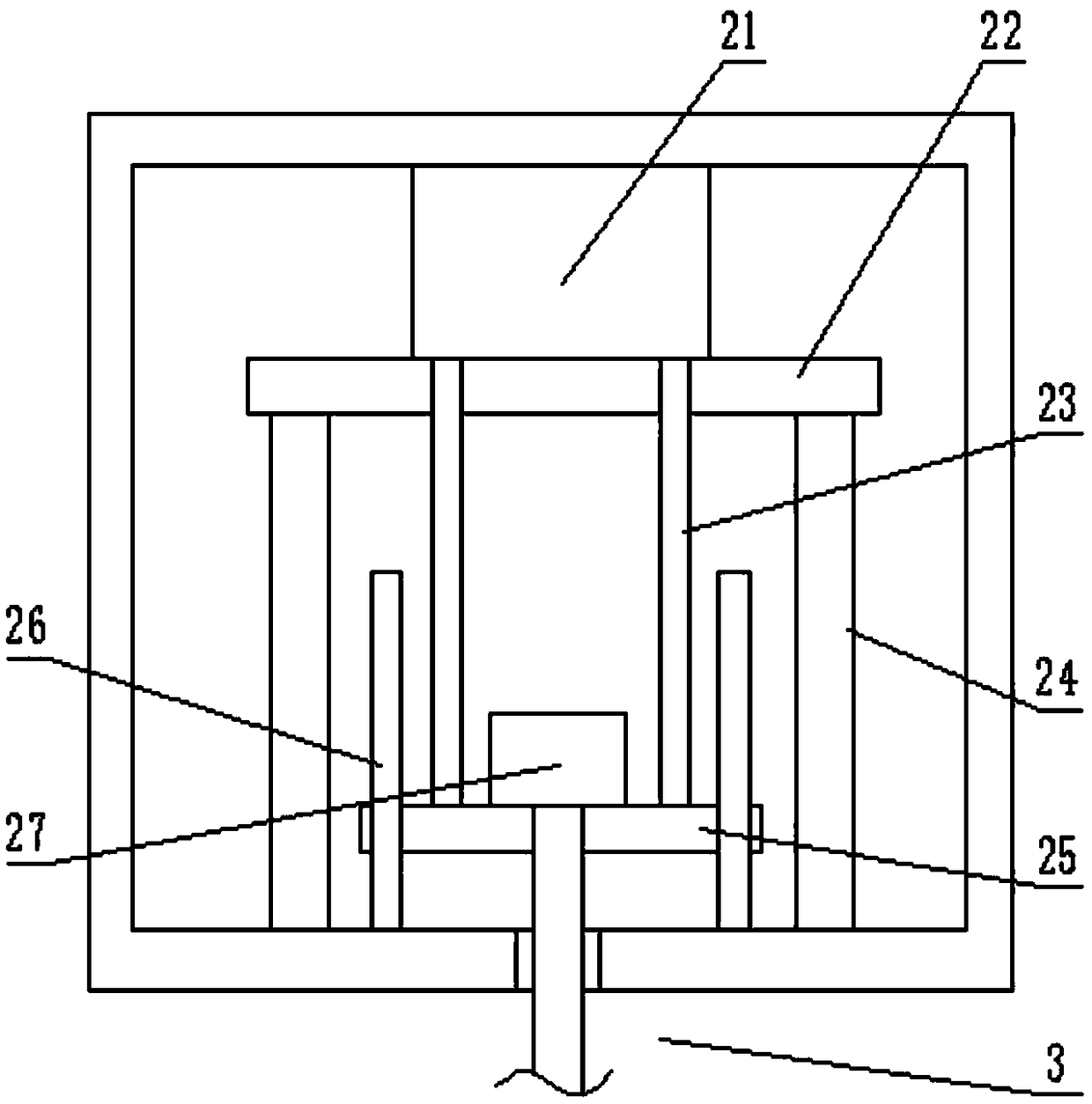

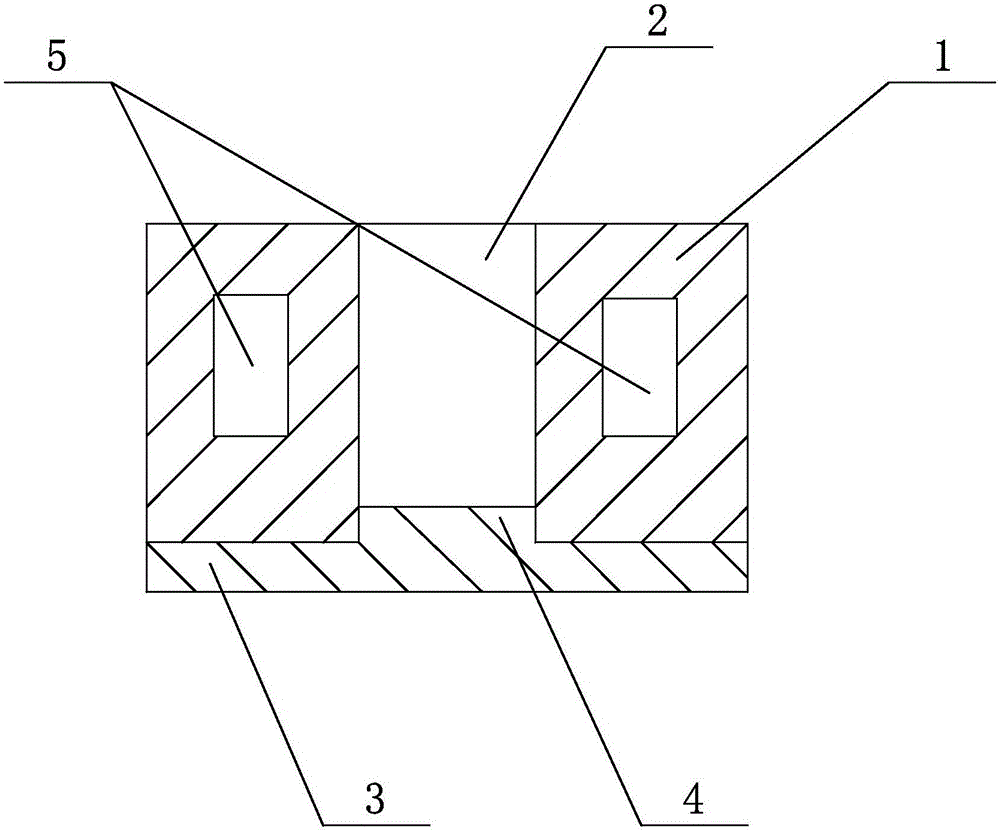

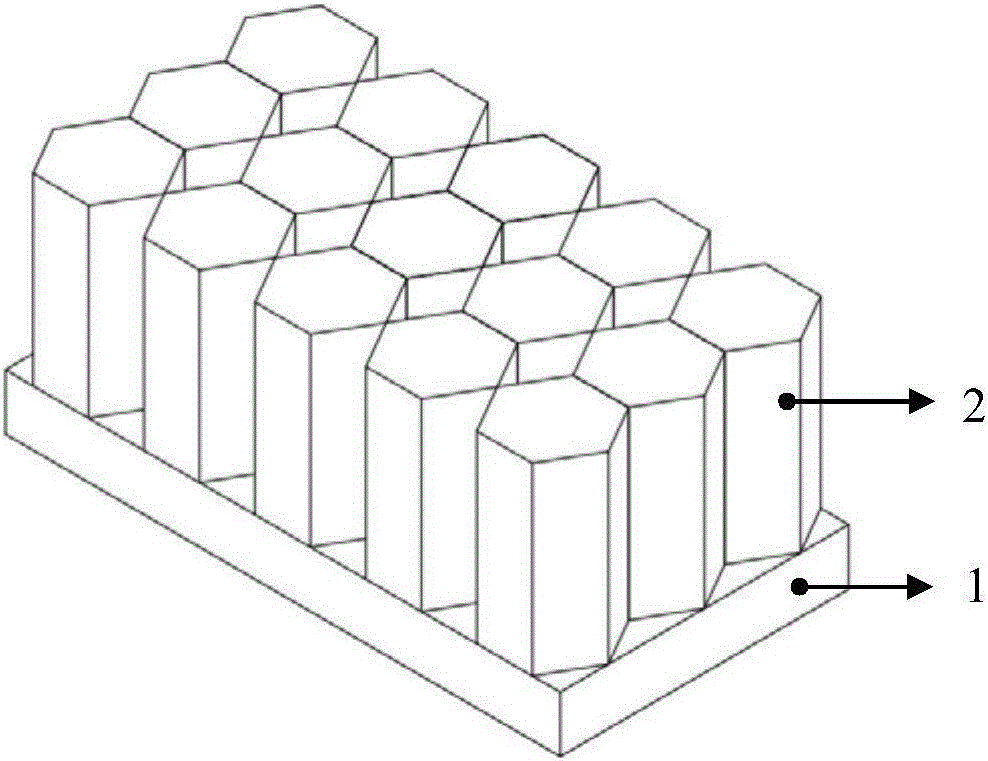

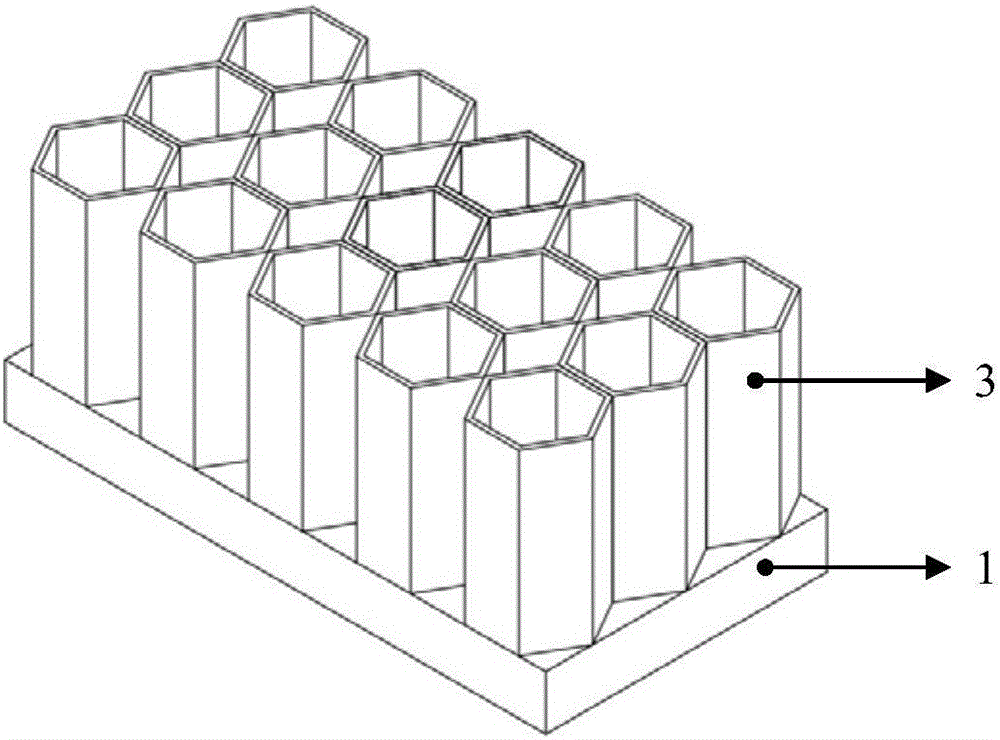

Ceramic preparing and drying mould

InactiveCN106584649AReduce the preparation processImprove work efficiencyMouldsPreparation proceduresCeramic molding

The invention discloses a ceramic preparing and drying mould. The ceramic preparing and drying mould comprises a mould main body, wherein a mould forming cavity is formed in the mould main body; the lower part of the mould main body is connected with a demoulding plate; the mould main body is detachably connected with the demoulding plate; a top block is arranged on the demoulding plate; the top block stretches into the bottom of the mould forming cavity; the shape of the top block is matched with that of the bottom of the mould forming cavity; a plurality of heating cavities are formed in the mould main body; and the heating cavities are positioned at the periphery of the mould forming cavity and are connected with a heat source. The forming and drying mould provided by the invention can dry ceramic at once after the ceramic is formed, does not need the procedure of demoulding and then drying, saves the preparation procedures, improves the work efficiency and improves the quality of the ceramic forming mould.

Owner:CHENGDU TAOMASI BATHROOM

Method for preparing Ag nanowires based on ZnO nanotube templates

InactiveCN106082120AReduce the preparation processLow cost of preparationNanostructure manufacturePore diameterHigh concentration

The invention discloses a method for preparing Ag nanowires based on ZnO nanotube templates. The method adopts plane ITO conductive glass as a substrate, chemically-etched ZnO nanotube templates and Ag nanowires which are electrically deposited in the ZnO nanotube templates. The method comprises the following steps: firstly growing ZnO nanorods on the ITO conductive glass in a water bath manner; secondly dissolving central positions of the ZnO nanorods by using a NaOH solution to form ZnO nanotubes; taking the ZnO nanotubes as templates and electrically depositing Ag nanowires in hollow structures of the ZnO nanotubes via a cyclic voltammetry method; and finally dissolving the ZnO nanotube templates by using a high-concentration NaOH solution. Through the method, conventional AAO templates can be replaced by the ZnO nanotubes; the Ag nanowires can be electrically deposited on a conductive substrate of any shape; Pt and Cu metal nano array structures with controllable sizes and shapes can also be prepared by adjusting the parameters such as pore diameter and depth of the ZnO nanotubes.

Owner:XI AN JIAOTONG UNIV

Synthesis technology of cobalt manganese binary liquid catalyst

InactiveCN101612576AHigh activityQuality improvementOrganic chemistryCatalyst activation/preparationEconomic benefitsManganese

The invention is a synthesis technology of cobalt manganese binary liquid catalyst, comprising the steps of batching, synthesis, impurity removal, settlement and encapsulation to obtain the cobalt manganese binary liquid catalyst with the mol ratio of the cobalt manganese content being 4.6-11. The cobalt manganese binary liquid catalyst has high activity, reliable quality and good stability, the technical and quality index thereof is lower than that of solid index and is convenient in use. The cobalt manganese binary liquid catalyst provided by the invention can reduce the preparing procedure of using the solid catalyst, save labor cost, eliminate safety potential such as pipeline blocking, instability and the like caused by impurities in the preparation process of the solid catalyst and lower unit consumption of raw and auxiliary materials, and is beneficial for lowering use cost and improving economic benefit.

Owner:张玉

Method of preparing microbial oil and microbial oil

InactiveCN105274156AReduce the preparation processReduce manufacturing costFermentationFatty-oils/fats productionChemistryGlycerol

A method of preparing microbial oil includes the steps: performing fermenting to obtain an oil-producing microbial fermentation liquor; concentrating the fermentation liquor to obtain concentrated fermentation liquor having a solid content higher than 10%; adjusting pH value of the concentrated fermentation liquor to 5-8.1, adding phospholipase C into the fermentation liquor, controlling the temperature to be 38 DEG C to 51 DEG C, and performing stirring and cutting for 2-6 h; separating an oil phase and an aqueous phase to obtain the microbial oil having a phosphorus content lower than 5ppm. The degumming procedure and the microbial wall-breaking procedure are combined, so that preparation procedures of the oil are decreased and production cost is lowered; further, the degumming procedure is set before the preparation procedure of crude oil, so that the produced crude oil has higher quality. In another aspect, the phospholipase C can hydrolyze glycerol phospholipids into diglyceride, so that the content of the diglyceride in the oil is increased; since the diglyceride has better emulsifying performance, the emulsifying process for preparing microbial oil microcapsules is facilitated, the embedding rate of the microbial oil can also be increased, thus lowering the surface oil content of the microcapsules and improving antioxidation of the microcapsules.

Owner:CABIO BIOTECH WUHAN CO LTD

Preparation method of paraffin particles based on CO2/N2 switch emulsion and application of paraffin particles

ActiveCN111253970AReduce pollutionEasy to saveWax physical treatmentDrilling compositionParaffin waxCyclohexylamines

The invention relates to a preparation method of paraffin particles based on CO2 / N2 switch emulsion and an application of the paraffin particles, which relate to the technical field of paraffin particles. The preparation method specifically comprises the following steps: S1) preparing an oil phase; S2) preparing a water phase; S3) preparing an O / W emulsion: mixing the oil phase and the water phase, stirring and emulsifying to obtain the O / W emulsion; S4) preparing paraffin particles: introducing carbon dioxide into the O / W emulsion, separating out the paraffin particles, and centrifuging to obtain the paraffin particles and a protonated solvent; S5) performing cyclic utilization: introducing nitrogen into the protonated solvent to obtain N, N-dimethylcyclohexylamine and an emulsifier aqueous solution, and respectively recycling. The invention also discloses the application of the paraffin particles. The invention discloses the preparation method of paraffin particles with recyclable solvent and emulsifier aqueous solution, which saves raw materials, lowers the cost and reduces the environmental pollution. Meanwhile, the invention further discloses the application of the product indrilling fluid.

Owner:SOUTHWEST PETROLEUM UNIV

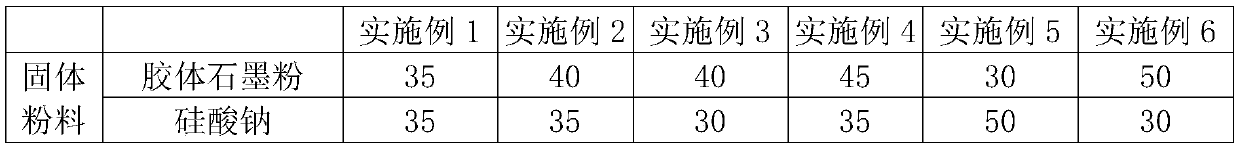

Antioxidant coating as well as preparation method and application thereof

ActiveCN110330819AAvoid pollutionSolve the speed problemLiquid surface applicatorsAlkali metal silicate coatingsTO-18Iron powder

The invention relates to an antioxidant coating as well as a preparation method and application thereof and belongs to the technical fields of metal fabricating and coatings for the metal fabricating.The antioxidant coating is prepared from the following materials in parts by weight: 30 to 50 parts of colloidal graphite powder, 30 to 50 parts of sodium silicate, 10 to 20 parts of iron powder, 5 to 15 parts of aluminum powder, 5 to 18 parts of kaolin, 10 to 30 parts of mica powder and 18 to 35 parts of boron trioxide. The coating is all prepared from solid powder, is applied to the surface ofa nuclear power forging by a spraying method, and can provide convenient antioxidant protection for the nuclear power forging forged and heated at the temperature of 1200 DEG C or above; oxidation weight increase caused by long-time heating process is reduced by 95 percent or above.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

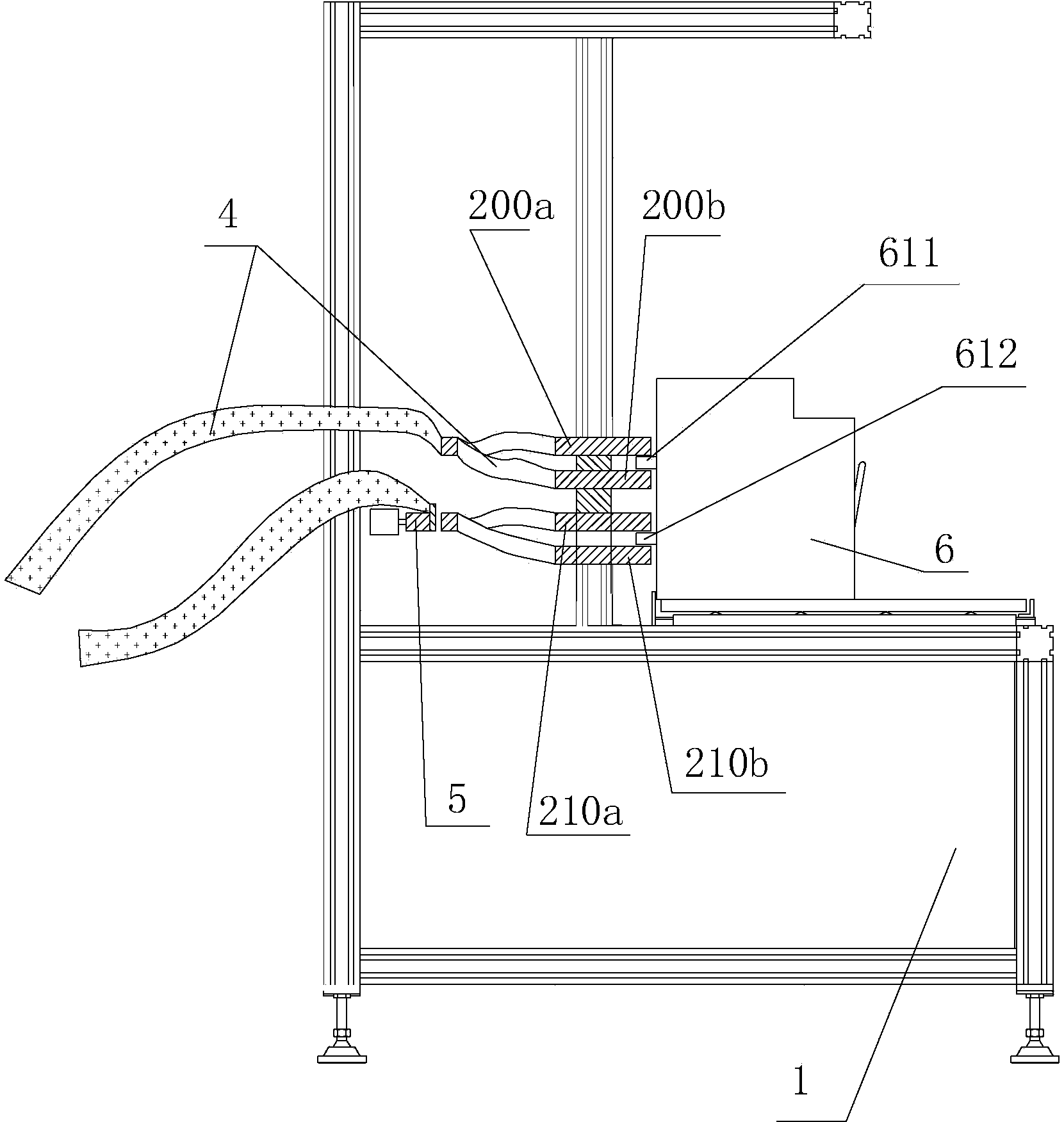

Circuit breaker checking table clamp

ActiveCN104049206ARealize automatic phase changeFast calibrationMeasurement instrument housingCircuit interrupters testingEngineeringCopper

A circuit breaker checking table clamp comprises a clamp support, clamping head copper sheets and a testing power supply. The clamp support is provided with two clamping head groups respectively clamping two rows of buses of a checked circuit breaker, each clamping head group comprises two rows of clamping head copper sheet groups matched with each other to achieve clamping, each row of clamping head copper sheet group comprises at least five clamping head copper sheets corresponding to each clamping head copper sheet in the other row of clamping head copper sheet group of the same clamping head group, and a pair of correspondingly arranged clamping head copper sheets respectively arranged on the two rows of clamping head copper sheet groups forms a clamping head unit. The circuit breaker checking table clamp is quick in checking efficiency and high in automation degree.

Owner:CHINT GROUP CORPORATION +1

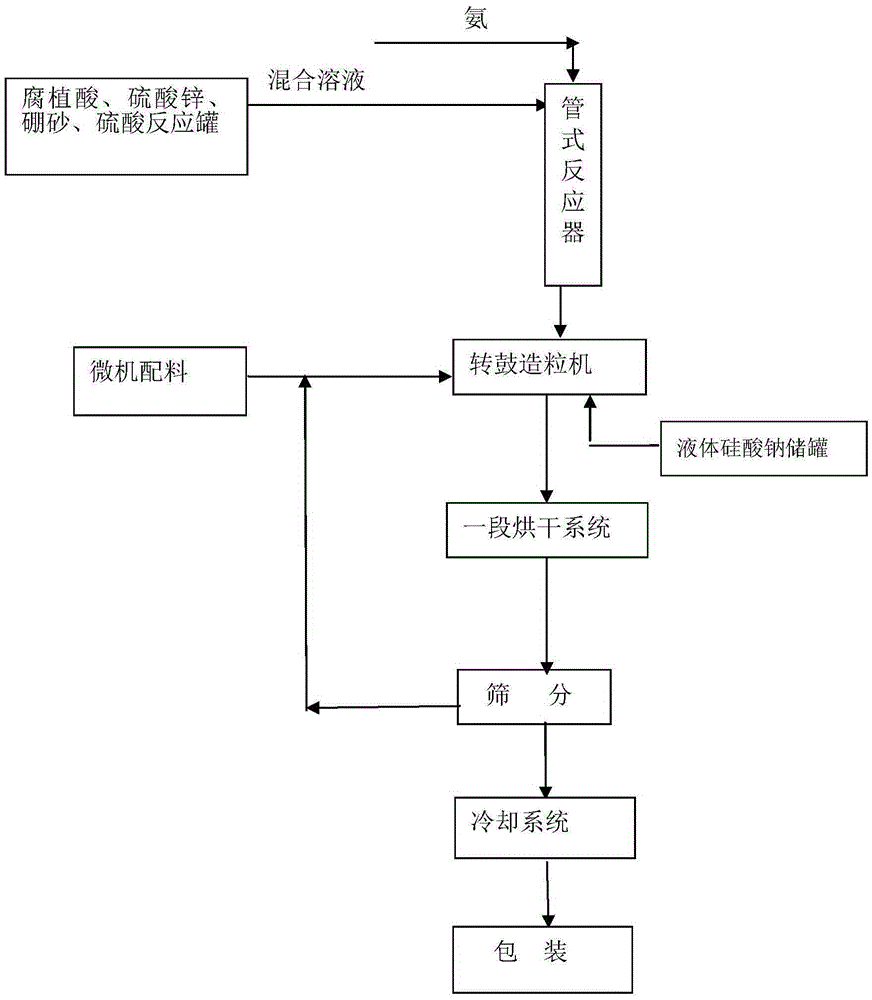

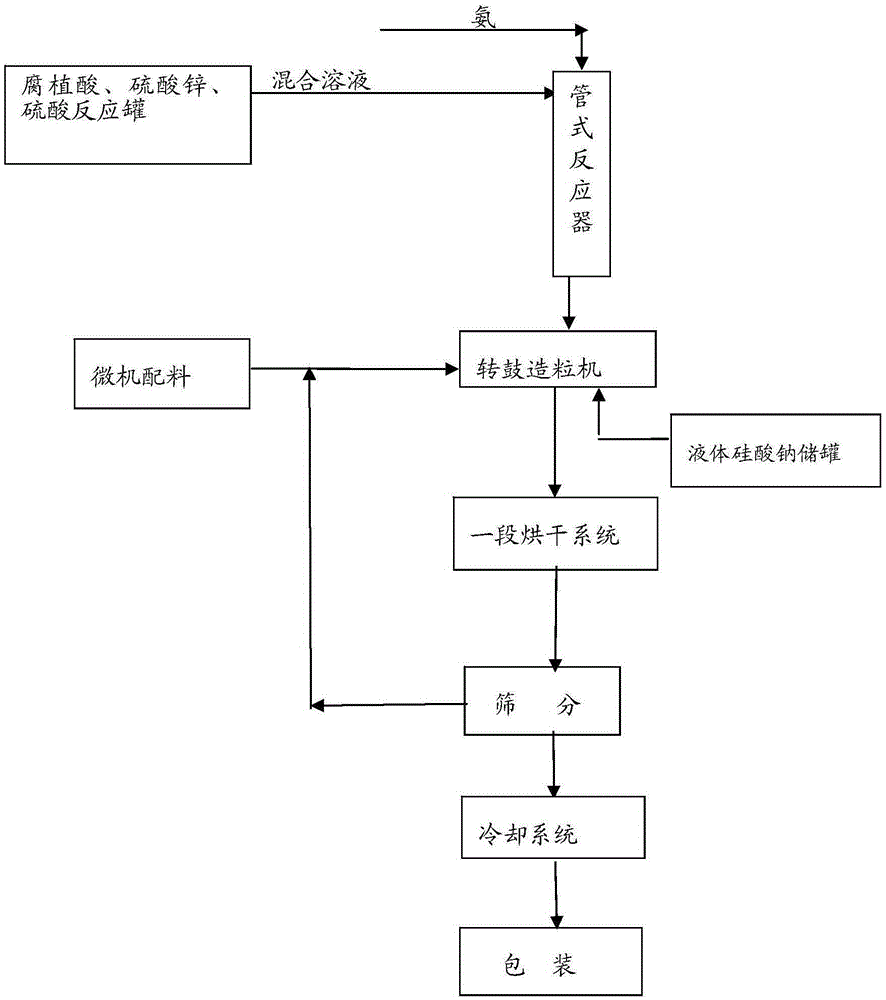

Special humic acid chelated slow-release fertilizer for corn and preparation method of slow-release fertilizer

The invention provides a special humic acid chelated slow-release fertilizer for corn and a preparation method of the slow-release fertilizer. The slow-release fertilizer comprises the following raw materials in parts by weight: 7-11 parts of humic acid, 36-52 parts of urea, 13-22 parts of monoammonium phosphate, 8-20 parts of potassium chloride, 4-7 parts of liquid ammonia, 1.5-3.5 parts of zinc sulfate, 0.5-1.5 parts of borax, 3.5-6.5 parts of liquid sodium silicate and 3.5-5.5 parts of concentrated sulfuric acid. According to the slow-release fertilizer, a slow-release function can be obtained for coating fertilizer grains through liquid sodium silicate; a demand of a whole growth period of the corn can be ensured by once fertilizing; a nutrient ratio, rich medium trace elements and organic matters are more suitable for a growth demand of the corn; and the slow-release fertilizer has effects of promoting synergism, improving and restoring soil, increasing the crop yield and improving the crop quality.

Owner:天津芦阳肥业股份有限公司

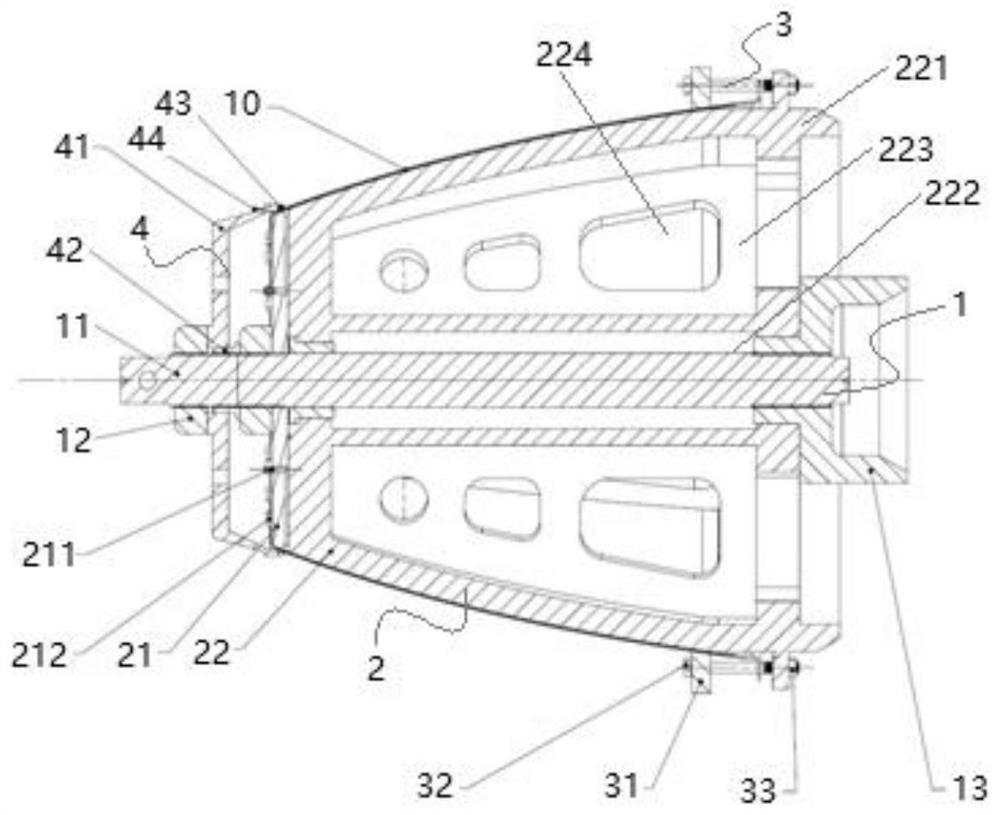

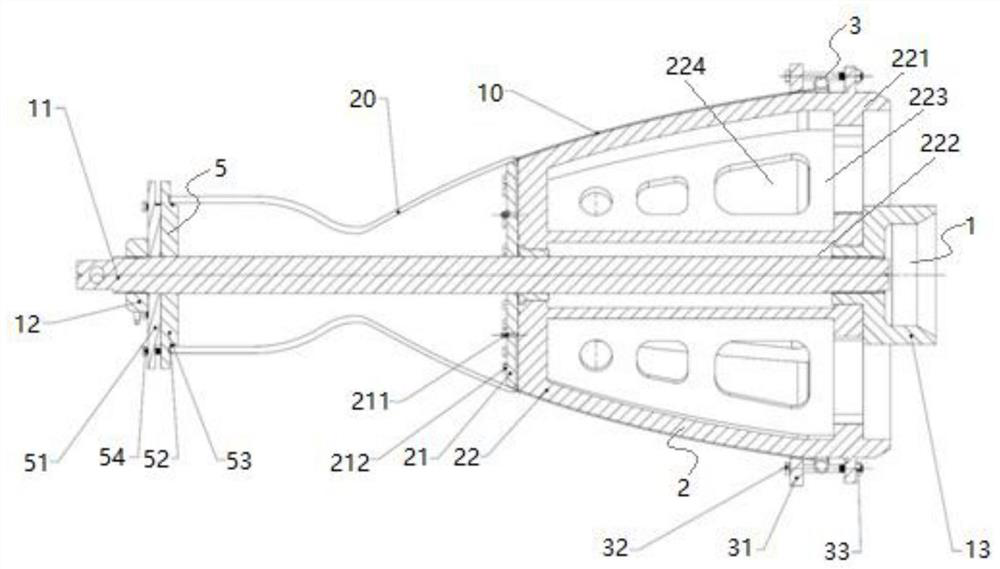

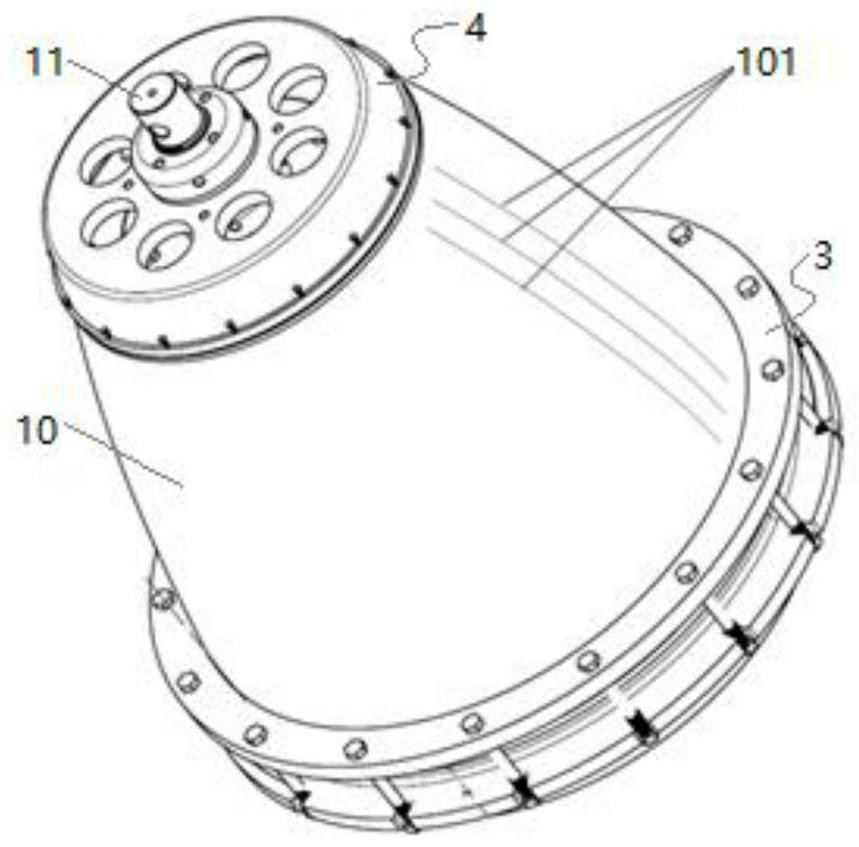

Composite tool for welding spray pipe jacket section of thrust chamber and welding process of composite tool

ActiveCN113210898AReduce manufacturing costFunction increaseWelding/cutting auxillary devicesHydro energy generationThrust chamberStructural engineering

The invention provides a composite tool for welding a spray pipe jacket section of a thrust chamber. The composite tool comprises a mandrel assembly, a jacket tire, a pressing ring assembly and a press-fitting assembly; and the mandrel assembly, the jacket tire, the pressing ring assembly and the press-fitting assembly are used in cooperation to conduct positioning, pressing and press-fitting on the inner wall and the outer wall of the spray pipe jacket section in the thrust chamber so as to assist in welding of the inner wall and the outer wall of the spray pipe jacket section in the thrust chamber. Compared with a plurality of sets of single tools needed by existing spray pipe welding, the composite tool is more complete in function, the number of the single tools can be greatly reduced, preparation procedures before welding are further reduced, the production process is simplified, and the production cost of a spray pipe is reduced.

Owner:BEIJING LANDSPACETECH CO LTD

Humic acid chelating slow release fertilizer special for rice and preparation method thereof

InactiveCN105272518AGood synergyImprove physical and chemical propertiesFertilizer mixturesPhosphatePotassium

The present invention discloses a humic acid chelating slow release fertilizer special for rice and a preparation method thereof, and humic acid, urea, monoammonium phosphate, potassium chloride, liquid ammonia, zinc sulfate, liquid sodium silicate and concentrated sulfuric acid are added during dosing. The preparation method is as follows: by use of ammonia-acid method compound fertilizer production equipment, the humic acid, the zinc sulfate, the sulfuric acid and water are prepared into a mixed solution, the mixed solution and the liquid ammonia are in a tubular reactor to complete humic acid acidification and medium-trace element chelating, and mixed slurry is used as granulation liquid phase amount to complete material granulation process. The humic acid chelating slow release fertilizer can obtain slow-release function by coating of fertilizer granules with the liquid sodium silicate, can ensure the needs of the whole growing season of the rice by one-time fertilizer application, the ratio of nutrients, rich medium-trace elements and organic matters are more suitable for rice growing needs, and the humic acid chelating slow release fertilizer also has the effects of promotion of fertilizer efficiency increase, improvement and repair of soil, and improvement of crop yield and quality.

Owner:天津芦阳肥业股份有限公司

Full-breadth cloth supporting device of rapier jacquard loom

The invention discloses a full-breadth cloth supporting device of a rapier jacquard loom and belongs to the technical field of accessories of the rapier jacquard loom. The full-breadth cloth supporting device comprises a mono-block semicircular cover plate, a mono-block semicircular cloth supporting plate and a single screw movably arranged between the cover plate and the cloth supporting plate, wherein the screw is provided with two continuous threads formed at the middle position of the screw, respectively inclining towards the screw end, identical in screw pitch and opposite n spiral direction, and a fabric inlet-outlet is formed between the front end of the cover plate and the front end of the cloth supporting plate. The screw is round, and the fabric wrapping the screw position is an open roundness. After the technical scheme is adopted, cloth tightly wraps the screw, a holding wrap angle is large, the lifting force of upper-layer warp yarns on a full-breadth fabric and downward pressing force of lower-layer warp yarns on the full-breadth fabric in open motion can be decreased, tension borne by warp yarn tension can be decreased during beating-up motion, continuous evenness and consistency of the tension of the full-breadth fabric is ensured, fabric-breadth weft contractility is small, and warp yarn breakage rate is low.

Owner:ZHEJIANG MAIDILANG TIE WEAVING

Teaching demonstration device for turbidity sediment experiment and teaching method of teaching demonstration device

The invention provides a teaching demonstration device for a turbidity sediment experiment and a teaching method of the teaching demonstration device, and relates to an experimental demonstration device. A water tank body comprises water tanks A (6) and water tanks B (9) which are arranged oppositely in the vertical direction. According to the teaching demonstration device for the turbidity sediment experiment, four blending formulas for water, mud and sand content of sedimentary turbidity current are provided according to the characteristics of four types of sedimentary turbidity current including gravel-rich type sedimentary turbidity current, sand-rich type sedimentary turbidity current, sand-mud mixed type sedimentary turbidity current and mud-rich type sedimentary turbidity current, the geological characteristics of each geologic sedimentary turbidity current are distinguished in a refined manner, the movement characteristics of each type of sedimentary turbidity current are comparatively demonstrated by the two water tanks with adjustable slope, the turbidity current flow rate is adjusted according to size and length of the slope, then sediment discharge in the turbidity current is observed, the geological knowledge of turbidity sediment is obtained, strictness and completeness of experimental operation are guaranteed, and students are helped to master the geological turbidity sediment related knowledge comprehensively and finely.

Owner:YANGTZE UNIVERSITY

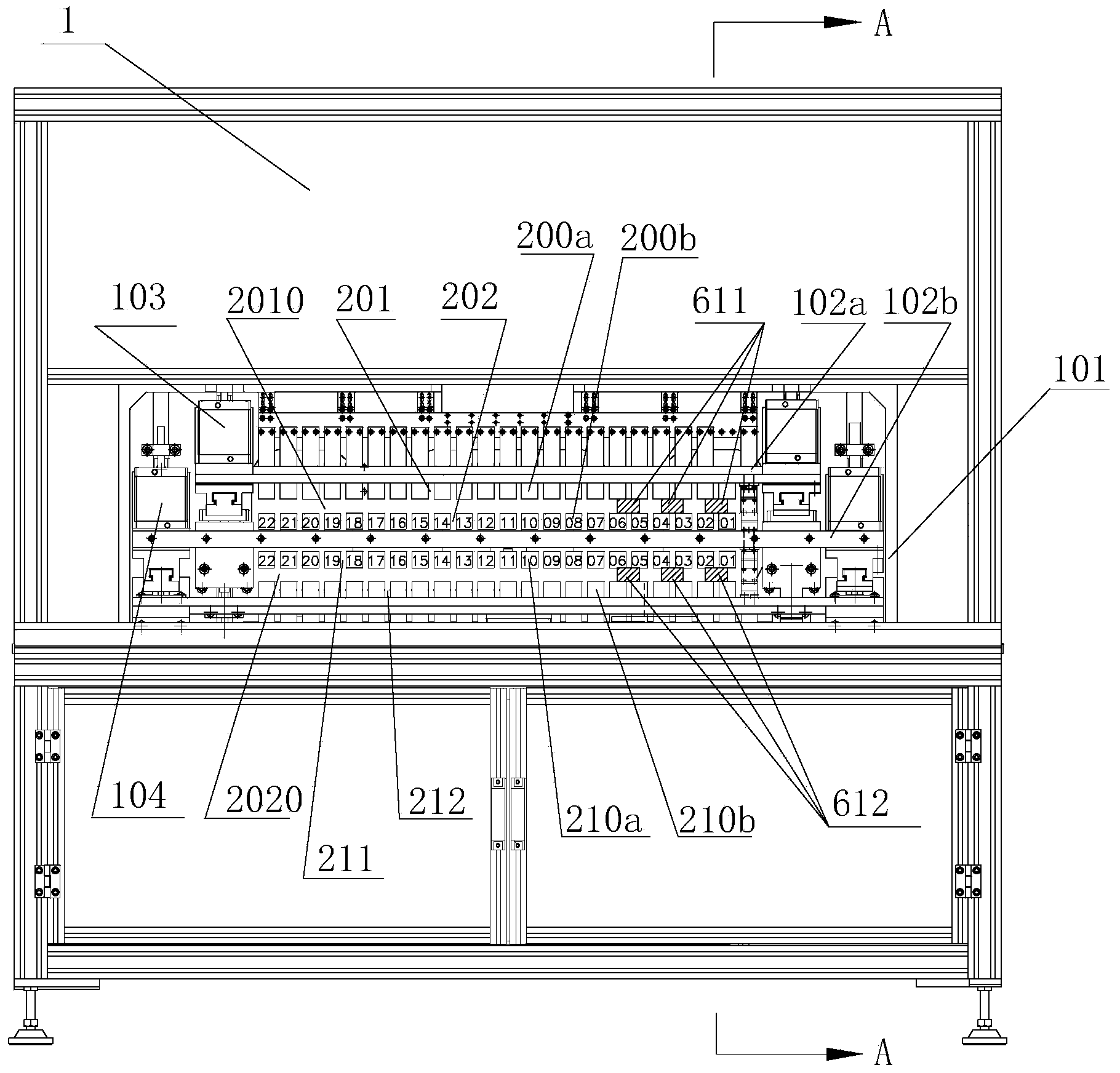

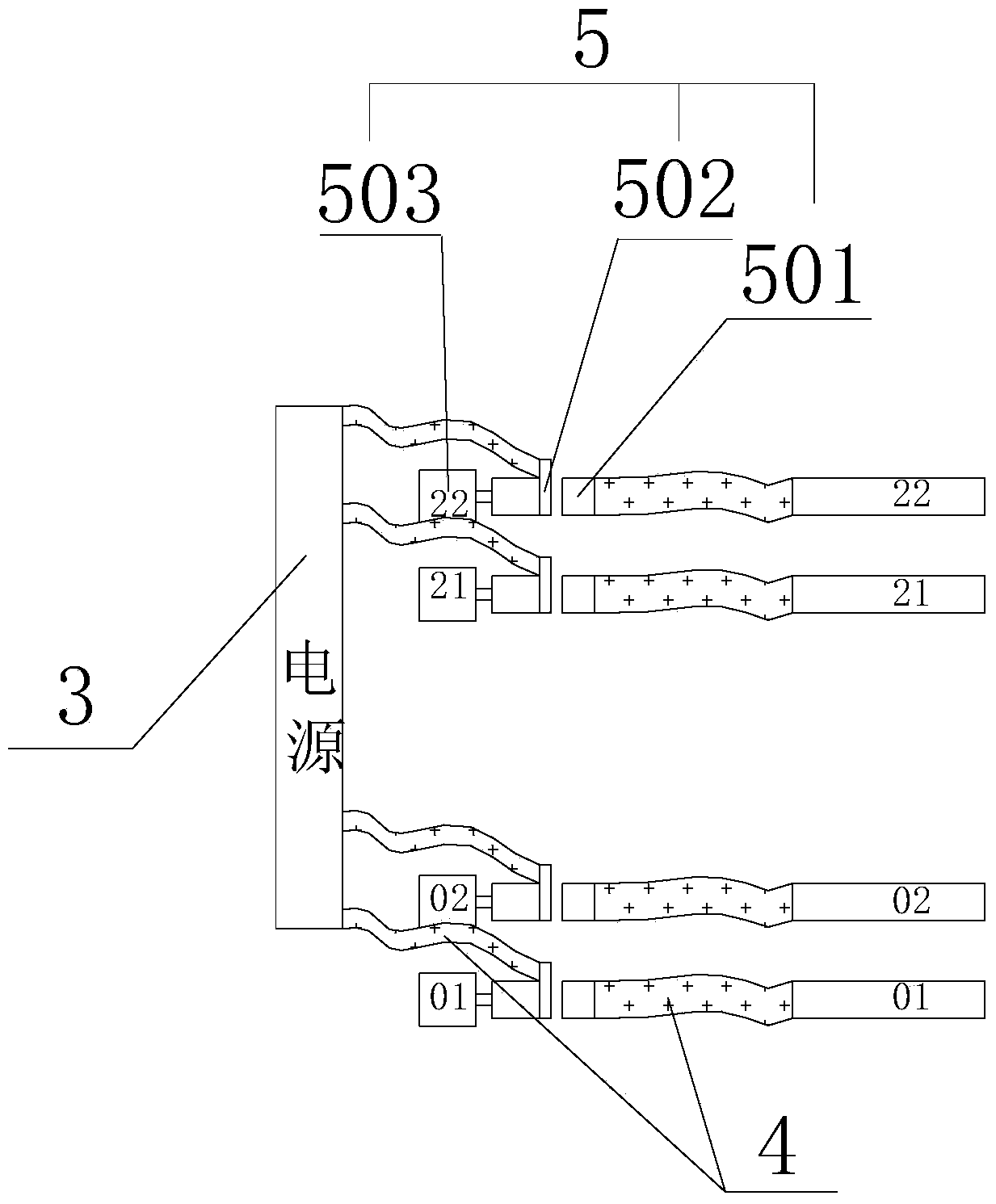

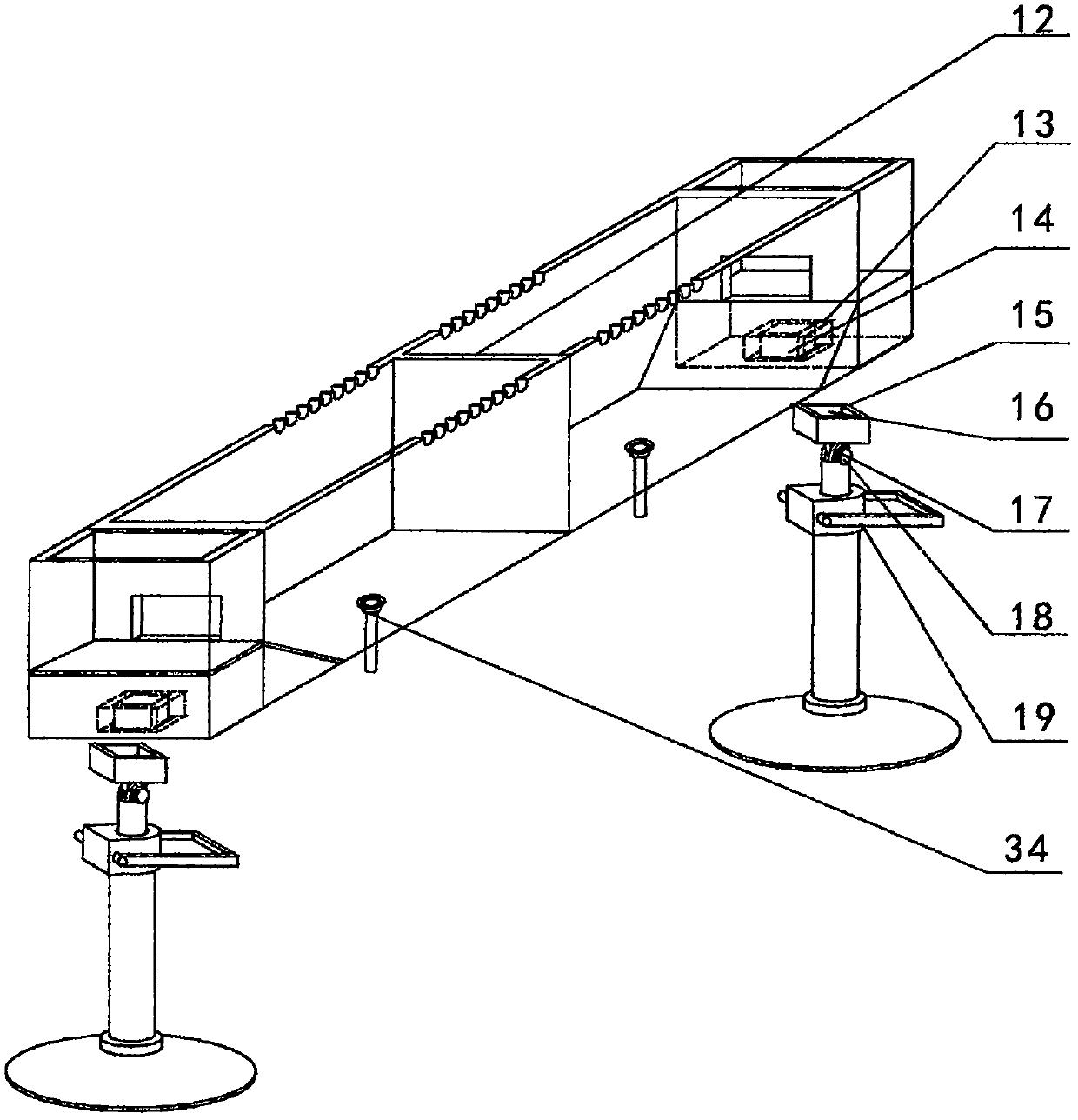

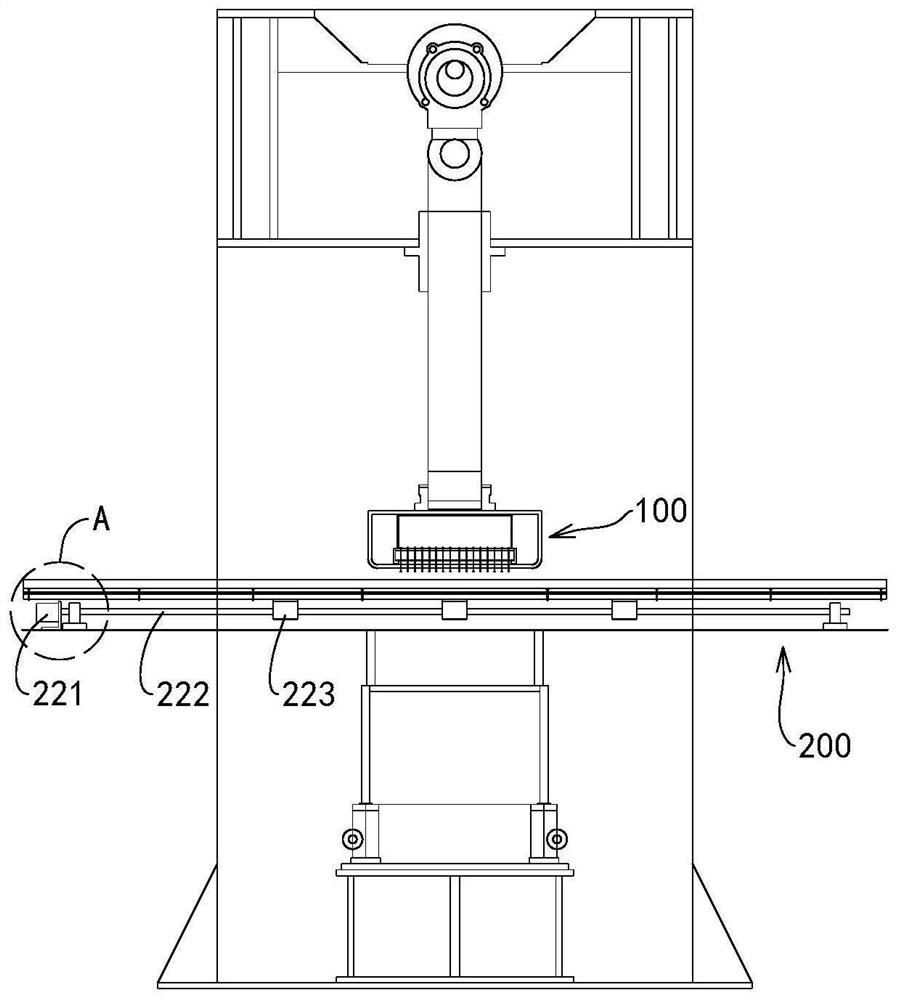

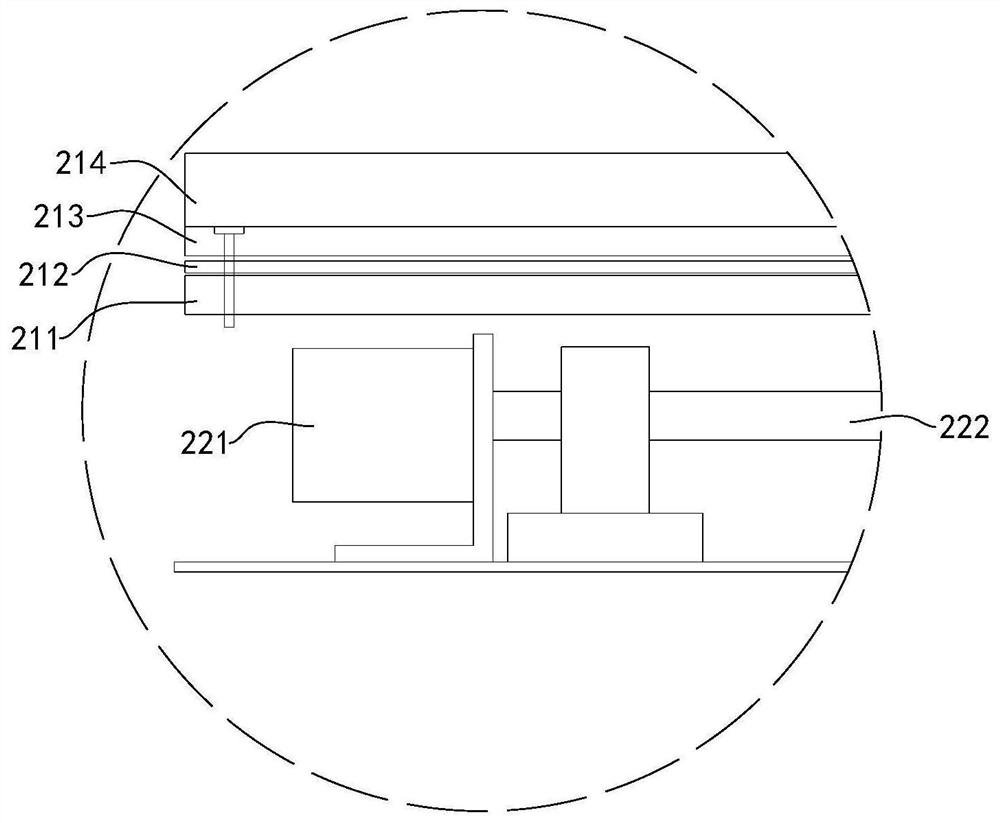

Carbon fiber flat plate preform needling machine

PendingCN111676598AAvoid issues such as porosity inhomogeneityReduce the preparation processNeedling machinesFiberCarbon fibers

The invention provides a carbon fiber flat plate preform needling machine. The carbon fiber flat plate preform needling machine comprises a needling mechanism and a conveying mechanism. The needling mechanism is assembled on a rack, and the conveying mechanism is assembled on the rack and located below the needling mechanism. A preform to be processed is placed on the conveying mechanism, the conveying mechanism drives the preform to move in the longitudinal direction, and the needling mechanism performs needling processing on the preform. The conveying mechanism comprises a supporting assembly and a driving assembly, a space for placing the preform is formed in the supporting assembly, the driving assembly is assembled on the rack and is connected with the supporting assembly, and the driving assembly drives the supporting assembly to linearly reciprocate in the longitudinal direction. According to the needling machine, the supporting assembly is driven to move by a lead screw structure, a net curtain is not required, a foam board or wool felt is adopted to replace a net curtain and a plastic film, and preparation procedures are reduced for operators before needling. In a needlingprocess, the number of operators who convey flat plate preforms back and forth is reduced, and corner deformation and layering due to preform dragging are avoided.

Owner:浙江星辉新材料科技有限公司

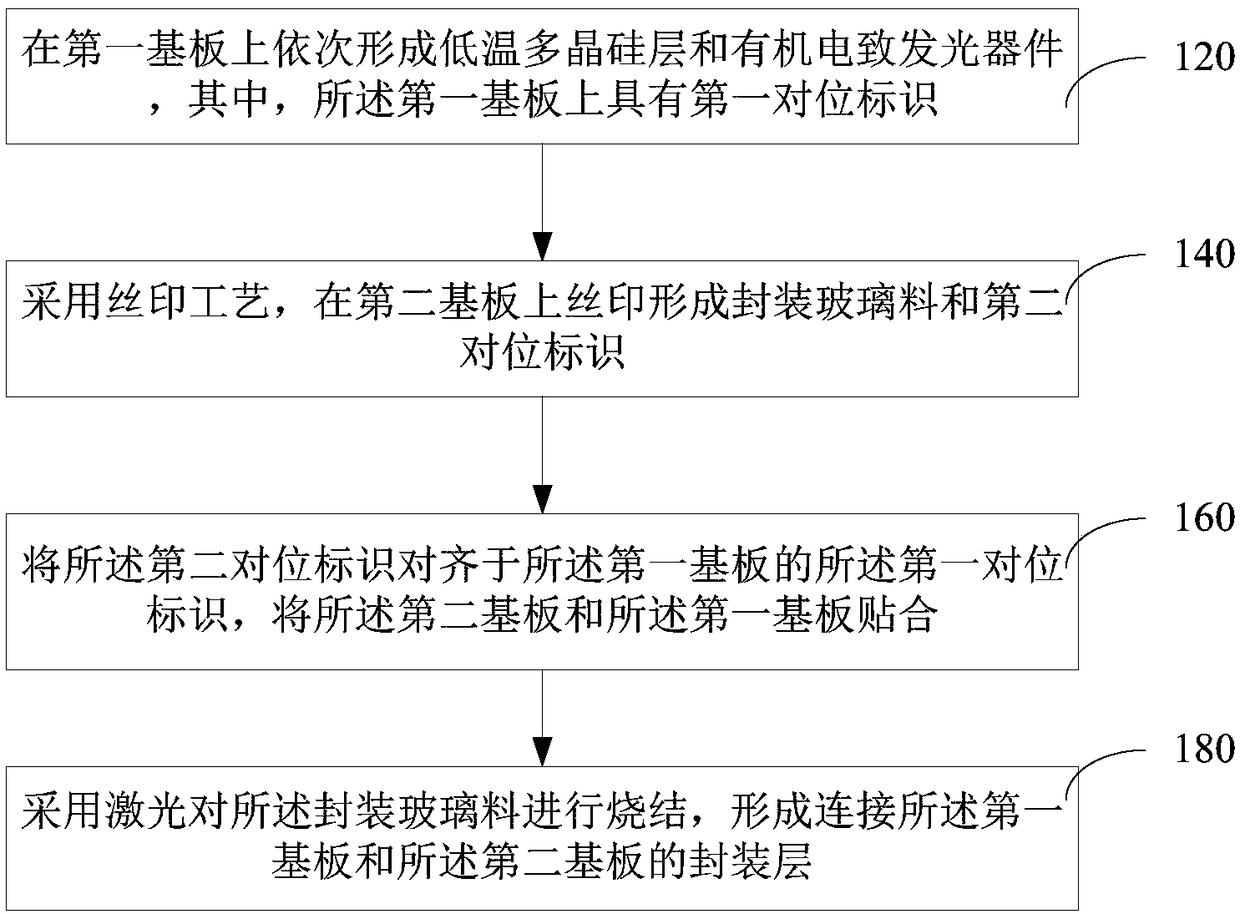

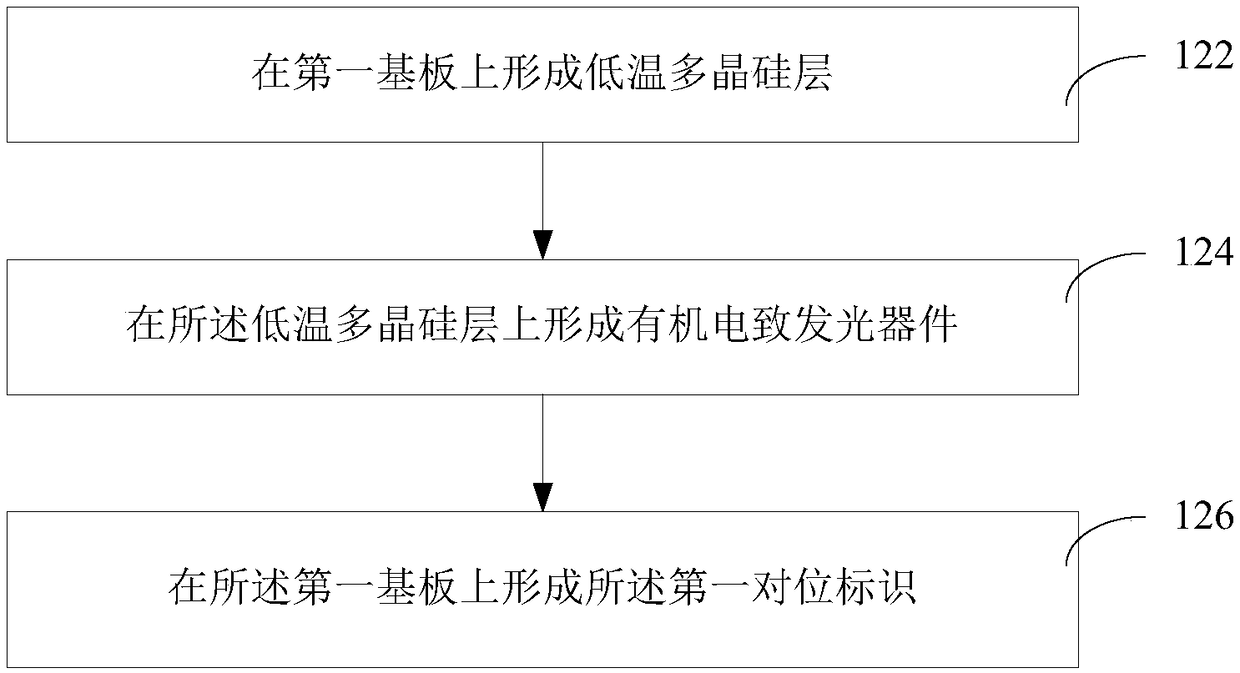

Organic light emitting display device and preparation method thereof

ActiveCN108232037AReduce the preparation processImprove preparation efficiencySolid-state devicesSemiconductor/solid-state device manufacturingOrganic electroluminescenceEngineering

The invention relates to an organic light emitting display device and a preparation method thereof. The method comprises the following steps: a low-temperature polysilicon layer and an organic electroluminescent device are formed on a first substrate sequentially, wherein the first substrate is provided with first alignment marks; silk screen is performed on the second substrate for formation of package frit and second alignment marks; the second alignment marks are aligned with the first alignment marks of the first substrate, so that the second substrate is attached to the first substrate; the package frit is sintered by laser, and a package layer for connecting the first substrate with the second substrate is formed. The package frit and the second alignment marks are formed on the second substrate by silk screen, so that the second alignment marks are more convenient to form, the preparation process is reduced, preparation efficiency is improved, the preparation cost is effectivelyreduced, the second substrate is effectively prevented from receiving laser energy repeatedly, and breakage of the second substrate is avoided in the high-temperature process.

Owner:TRULY HUIZHOU SMART DISPLAY

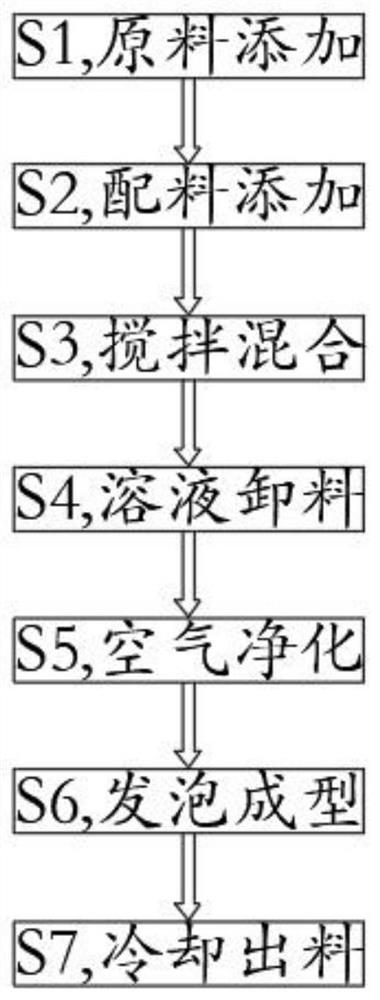

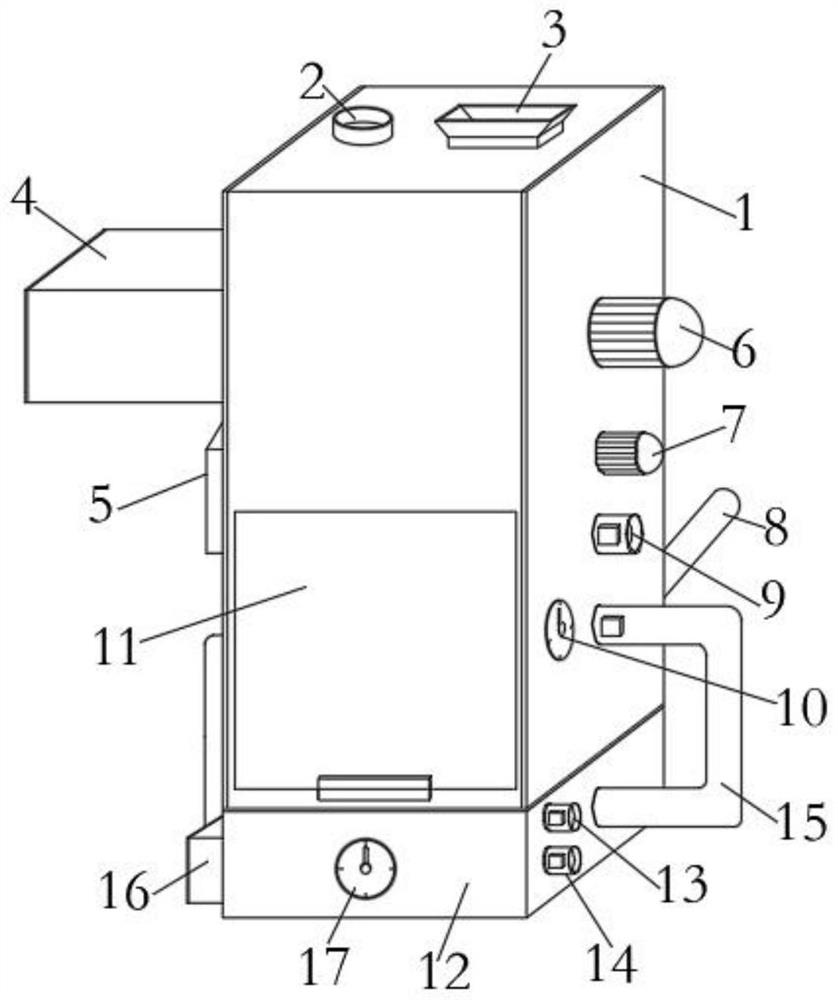

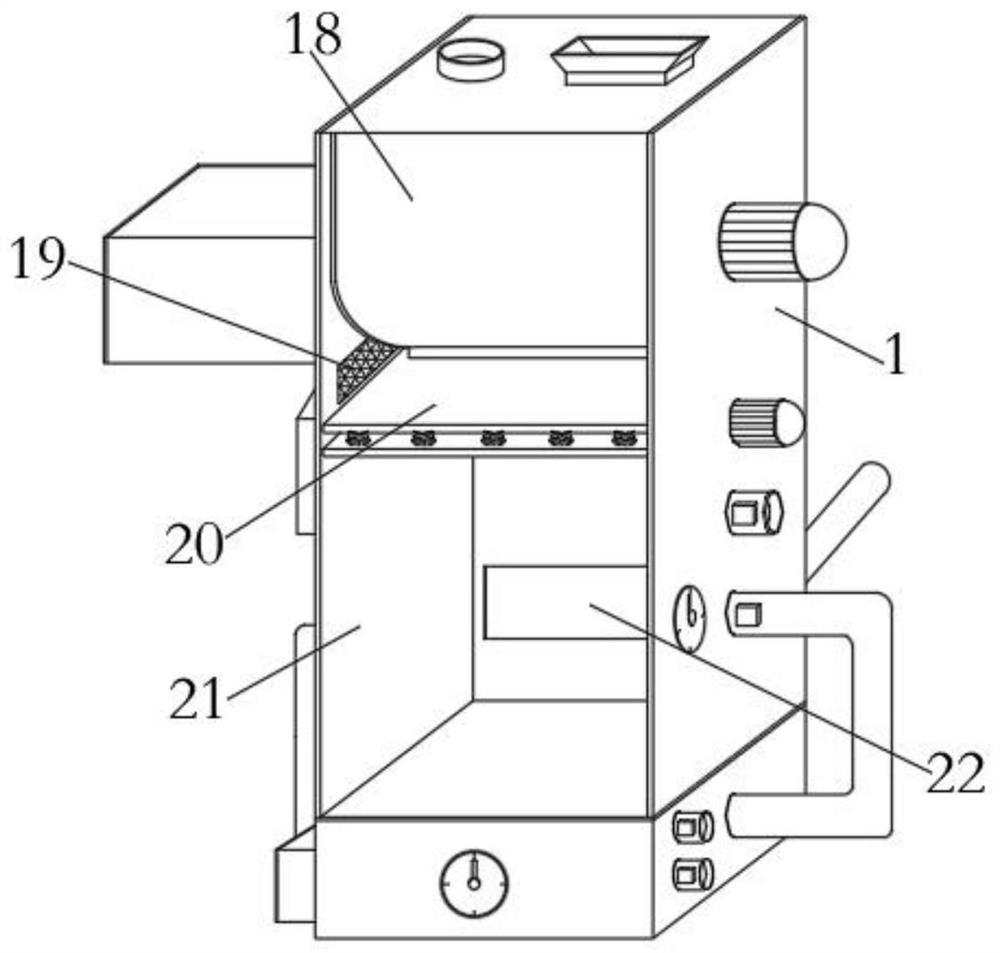

Fiber reinforced foamed plastic preparation process

InactiveCN113524554AEfficient purificationCreate pollutionDispersed particle filtrationProcess engineeringAir purification

The invention discloses a fiber reinforced foamed plastic preparation process, the fiber reinforced foamed plastic preparation process adopts a preparation device for preparation, the preparation device comprises a preparation box, and the top of the preparation box is provided with a raw material inlet and a short fiber particle inlet. According to the foamed plastic preparation process, air purification equipment is arranged on the preparation device, peculiar smell gas left in a box body is introduced into a filter box for purification treatment, the peculiar smell gas is effectively purified through three filtering modes, the foamed plastic is more environmentally friendly, meanwhile, a pushing discharging mode is adopted for foamed plastic subjected to foaming forming, the discharging speed is increased, and discharging automation is realized; and according to the foamed plastic preparation process, cooling equipment is arranged on the preparation device, flowing water transfers heat in a heat transfer mode, the cooling rate is effectively increased, and the whole preparation process is shortened.

Owner:滁州安嘉环保科技有限公司

Process for manufacturing smooth surface roughened electrolytic copper foil

The invention relates to a process for manufacturing smooth surface roughened electrolytic copper foil, which comprises a step of pickling, a step of primary smooth surface roughening, a step of secondary smooth surface roughening, a step of primary smooth surface curing, a step of secondary smooth surface curing, a step of double-size anti-oxidization treatment, a step of double side passivation and a step of smooth surface coupling agent treatment, which are accomplished continuously on the same production line. Compared with the prior art, the smooth surface roughened electric copper foil manufactured by the process for manufacturing the smooth surface roughened electrolytic copper foil has the advantages of short copper teeth, easy etching, and high impedance controllability. When the copper foil is used in production of downstream products, the needs of blackening micro corrosion and toughening treatment are obviated, so the manufacturing process is shortened, and the short circuit rate and open circuit rate are lowered; meanwhile, the copper foil manufactured by the process has the same quality as the conventional high-precision or double-side toughened electrolytic copper foil, is produced at low cost and is more suitable for manufacturing the inner layers of high-precision multilayer plates and high-density fine line printed circuit boards (PCBs).

Owner:合肥铜冠电子铜箔有限公司

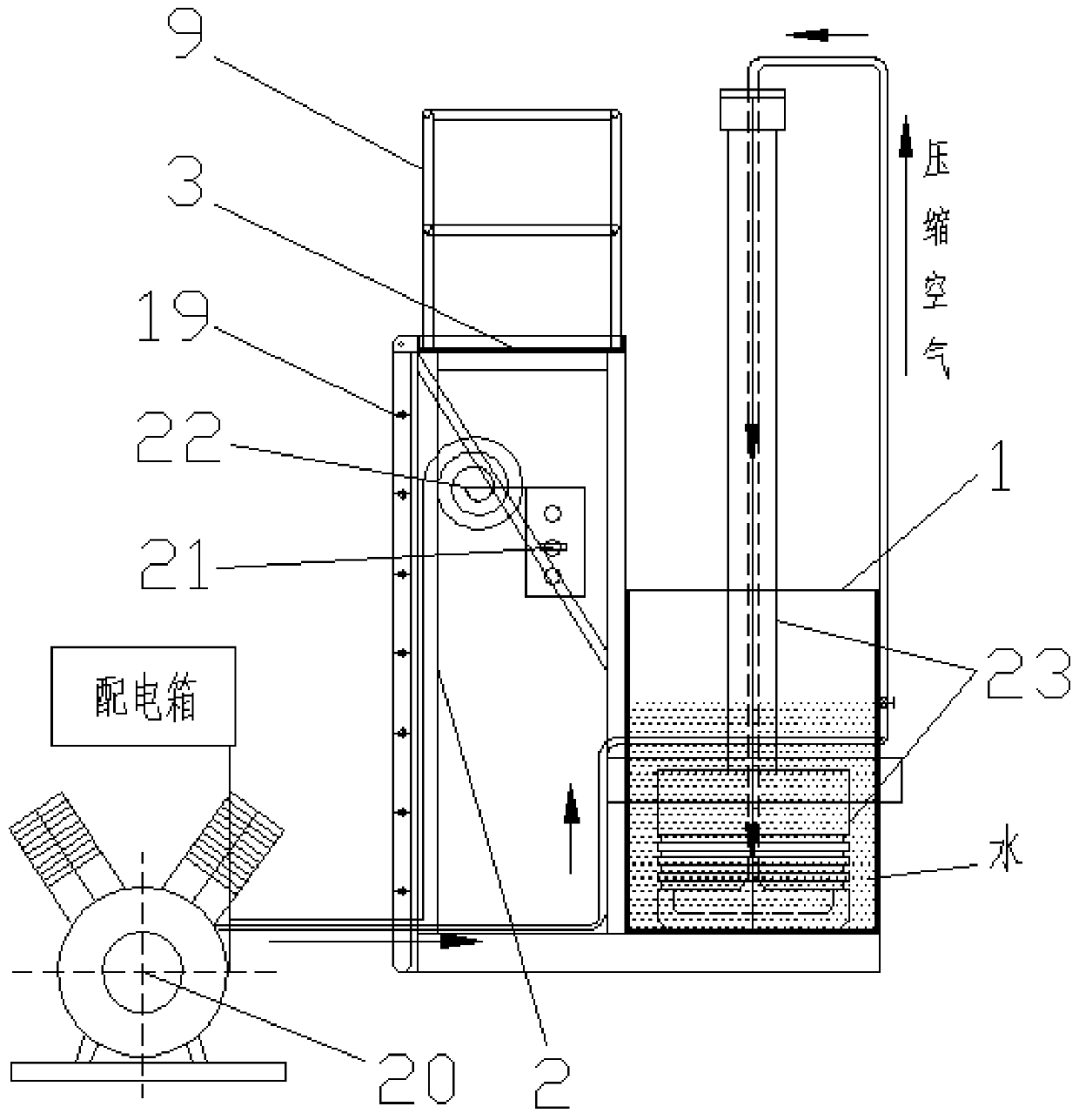

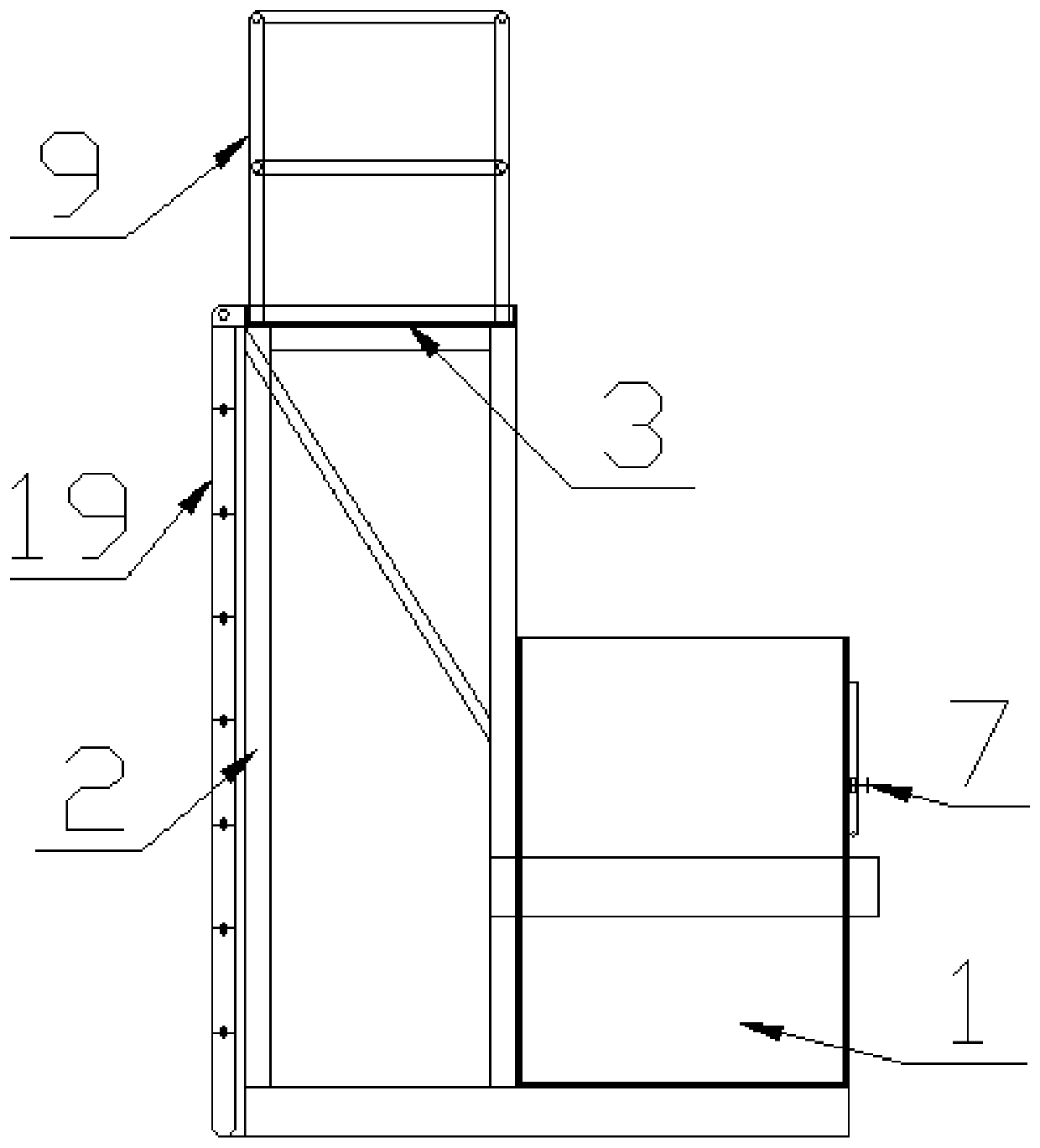

Air tightness test device for piston assembly

ActiveCN111272340AImprove efficiency and safetyIncrease productivityFluid-tightness measurement using fluid/vacuumPistonStructural engineering

The invention relates to the technical field of sealing experiments and relates to a n air tightness test device for a piston assembly The device comprises a machine frame, wherein he upper end of thelong-strip-shaped water tank is open, the machine frame is connected to one side of the long-strip-shaped water tank side by side. The device also comprises a high-position operation platform arranged on the machine frame. A compressed air main pipe is fixed to the other side of the long-strip-shaped water tank in the length direction of the long-strip-shaped water tank. A plurality of compressedair output branch pipes is distributed on the compressed air main pipe at intervals. An output port of the compressed air output branch pipe is connected with a retractable coiled hose, a compressedair switch is arranged on the compressed air output branch pipe, and a pressure gauge is arranged on a pipeline between the compressed air switch and the output port of the compressed air output branch pipe. According to the invention, the efficiency and safety of the air tightness test of the piston assembly are improved.

Owner:CHENGXI SHIPYARD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com