Process method for producing tool through caulking groove substrate

A process method and substrate technology, which is applied in the process field of producing knives by using embedded groove substrates, can solve the problems of large capital occupation, scrap rate, high production cost, etc., reduce the use of consumables, reduce the preparation process, and uniform welding connection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Below in conjunction with embodiment, further illustrate the present invention.

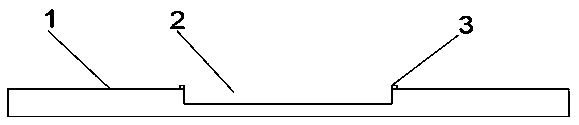

[0051] see Figure 5 , Image 6 As can be seen, in the cutting tool machining process of the prior art, the blade portion hardness of cutting is high, generally is by making groove platform 6 on the substrate 1 of the steel material of cutter body, lays solder powder, solder layer 7, High speed steel bar 4.

[0052] The processing of the existing technology is cumbersome, the efficiency is difficult to improve, and the production cost is high. It uses solder powder and solder, which has low welding efficiency and affects the quality of the tool. At the same time, the subsequent processing cost after welding is also high. A detailed description.

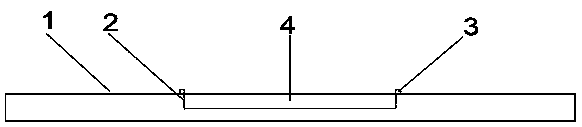

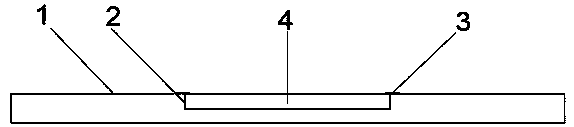

[0053] see Figure 1-Figure 4 It can be seen that a process method of the present invention for producing a cutting tool by using a slotted substrate comprises the following steps:

[0054] (1) The substrate 1 is prepared by cold drawing proc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com