SiO2@paraffin nano-particle with core-shell structure and preparation method thereof

A nanoparticle, core-shell structure technology, applied in chemical instruments and methods, drilling compositions, etc., to achieve the effects of reducing costs, improving the production process, and shortening the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] This application document also discloses a SiO with core-shell structure 2 @ The preparation method of paraffin nanoparticles, which specifically includes the following steps: S1) S1) prepare the oil phase: paraffin and nano-SiO 2 Add N,N dimethylcyclohexylamine and stir until the paraffin is completely dissolved, then add emulsifier A and stir until completely dissolved to obtain an oil phase;

[0035] S2) Prepare the water phase: add the emulsifier B to deionized water, stir until the emulsifier B is completely dissolved, and obtain the water phase;

[0036] S3) preparing O / W emulsion: after mixing the oil phase and the water phase, stirring and emulsifying to obtain an O / W emulsion;

[0037] S4) Preparation of SiO 2 @paraffin nanoparticles: Introduce carbon dioxide into the O / W emulsion, paraffin is precipitated and coated on SiO 2 SiO with a core-shell structure formed on the surface 2 @paraffin nanoparticles, SiO obtained after centrifugation2 @paraffin nanopar...

Embodiment 1

[0048] The SiO of core-shell structure prepared by the present invention 2 @paraffin nanoparticles were prepared as follows:

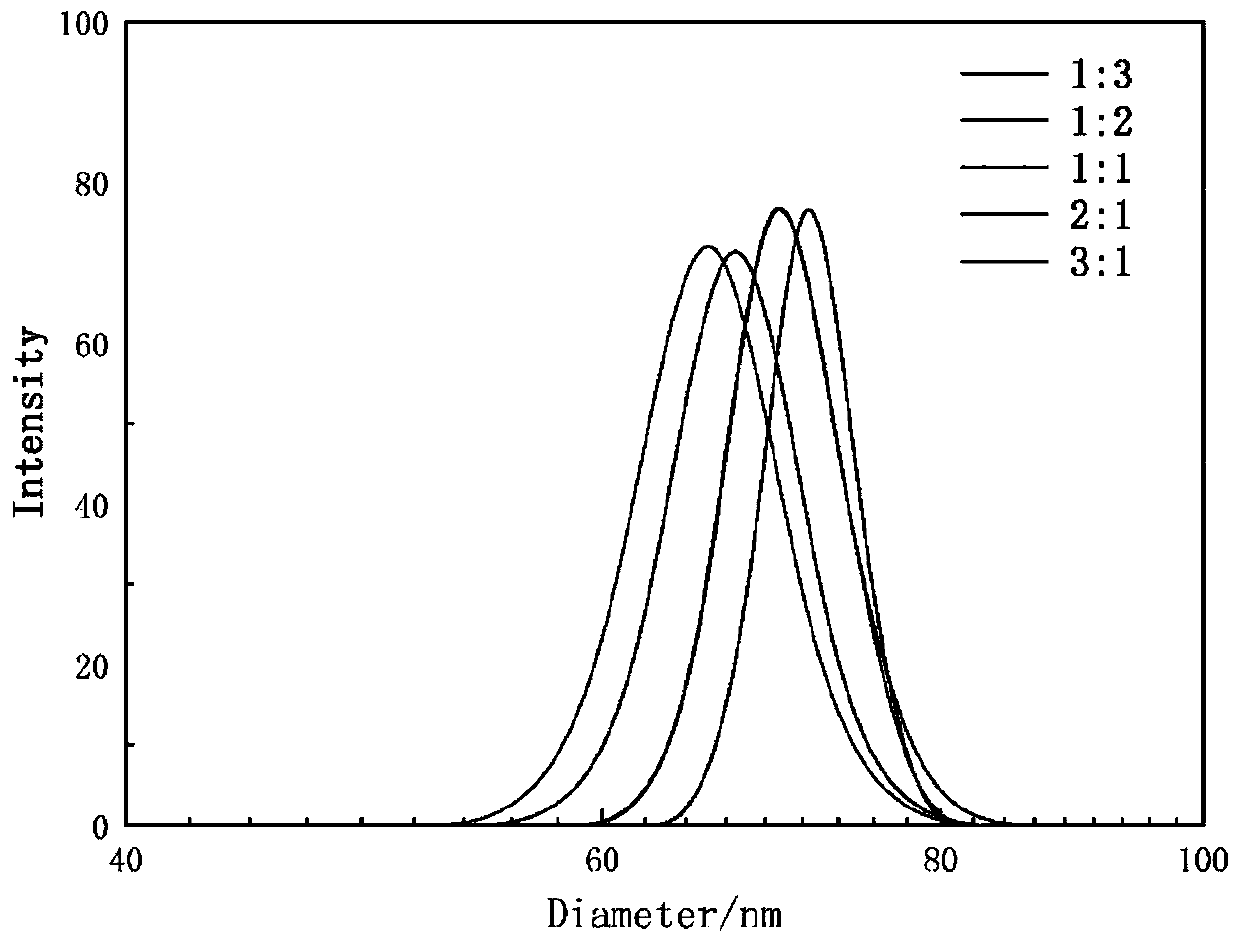

[0049] S1) 0.5g of paraffin and 0.5g of nano-SiO 2 Particles (average particle size: 50nm) are completely dissolved in 5.0g N,N dimethylcyclohexylamine, then add 2.0g Span-80, and stir until Span80 is completely dissolved to form an oil phase;

[0050] S2) Dissolving 8.0 g of Tween-80 in deionized water to form an aqueous phase;

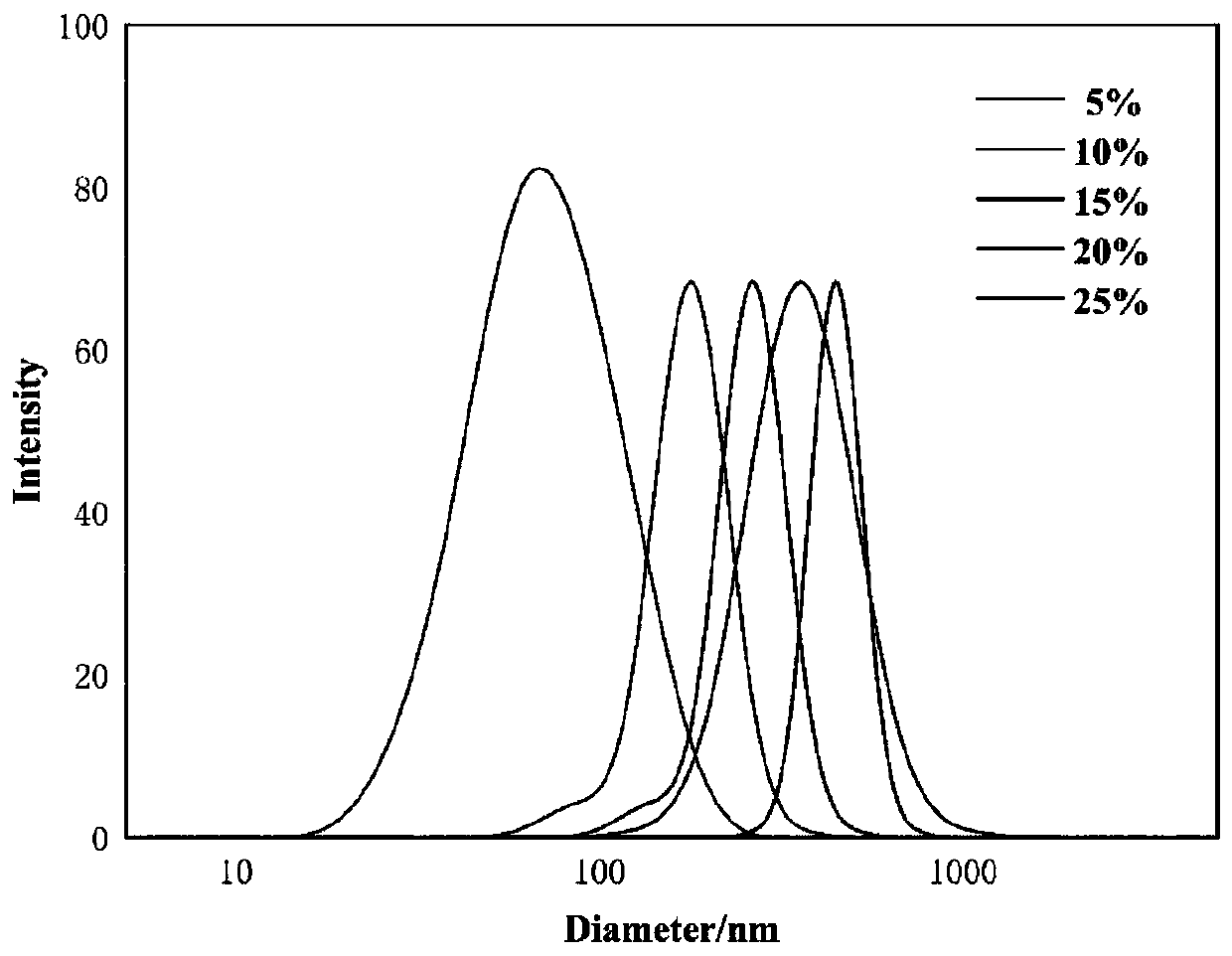

[0051] S3) Under stirring conditions, slowly add the oil phase into the water phase, so that the mass fraction of emulsifier A+emulsifier B in the system is 25%, forming an O / W emulsion;

[0052] S4) Pass CO into the emulsion 2 , the solvent N,N dimethylcyclohexylamine was dissolved in water and centrifuged to obtain SiO 2 @paraffin nanoparticles;

[0053] S5) The centrifuged supernatant was passed into N 2 , the supernatant is stratified into solvent and emulsifier aqueous solution, and the solvent and emulsifier aqueo...

Embodiment 2

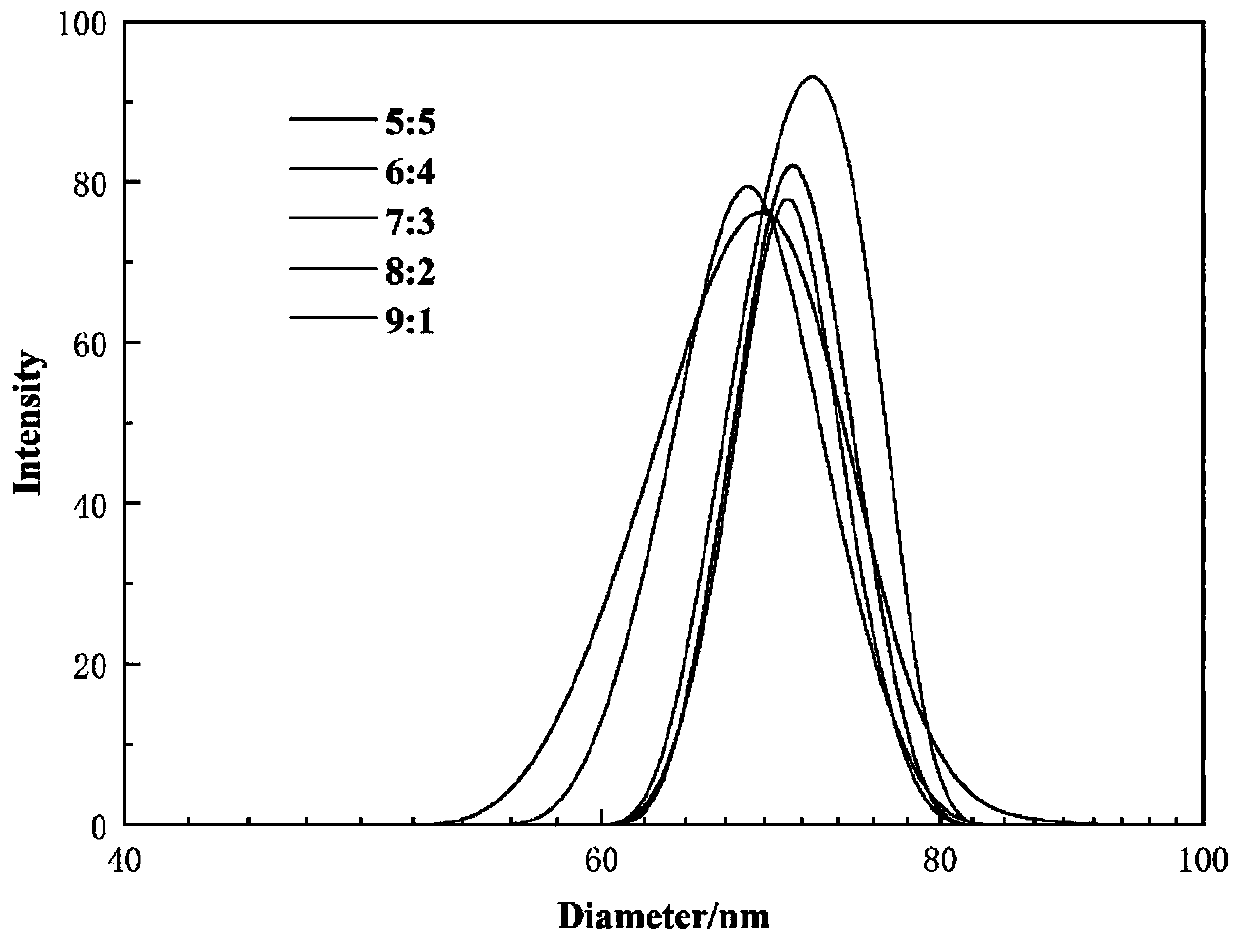

[0058] The SiO with core-shell structure prepared in this example 2 @ Paraffin nanoparticles are prepared according to the following method: Paraffin and nano-SiO in step S1) 2 The mass ratio of the particles was adjusted to 9:1, 8:2, 7:3, and 6:4, and the products were prepared respectively to obtain the products. The preparation method was basically the same as that of Example 1, so no further details were given.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com