Teaching demonstration device for turbidity sediment experiment and teaching method of teaching demonstration device

A demonstration device and turbidity flow technology, applied in teaching models, educational tools, instruments, etc., can solve the problems of inconvenient simulation of deposition characteristics, inconvenient fixing of water tanks, high labor intensity, etc., and achieve the effect of ensuring rigor and integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

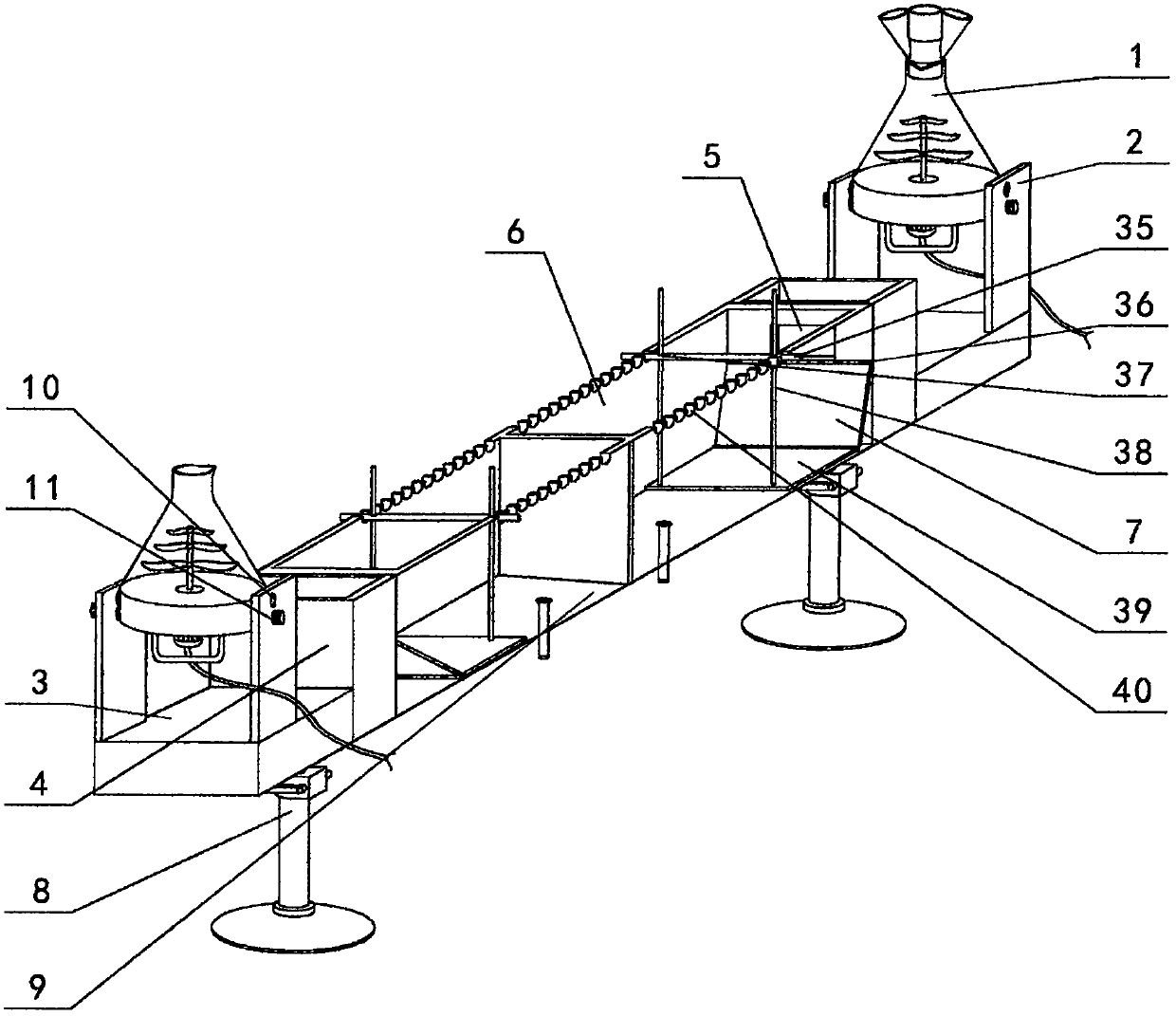

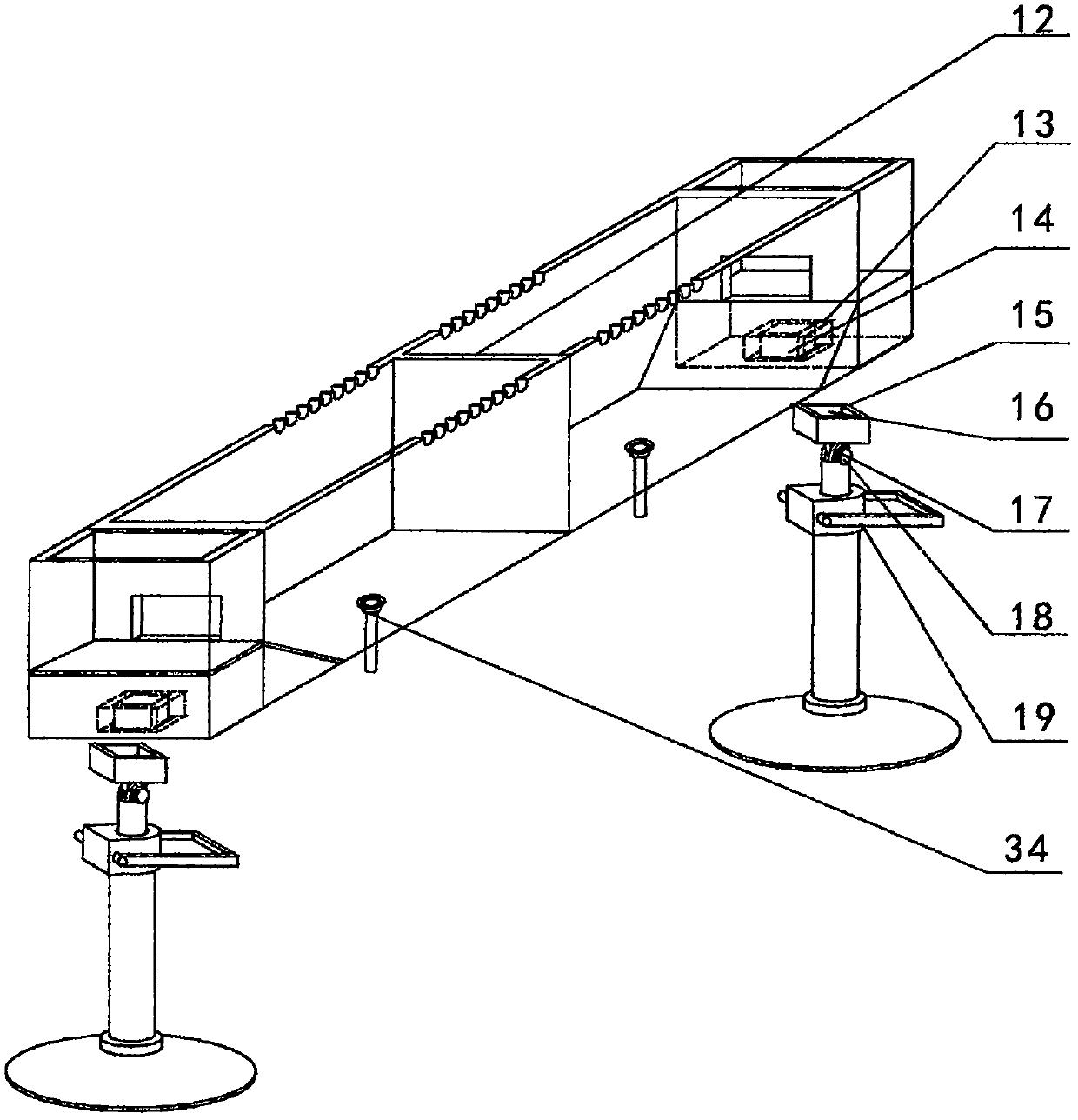

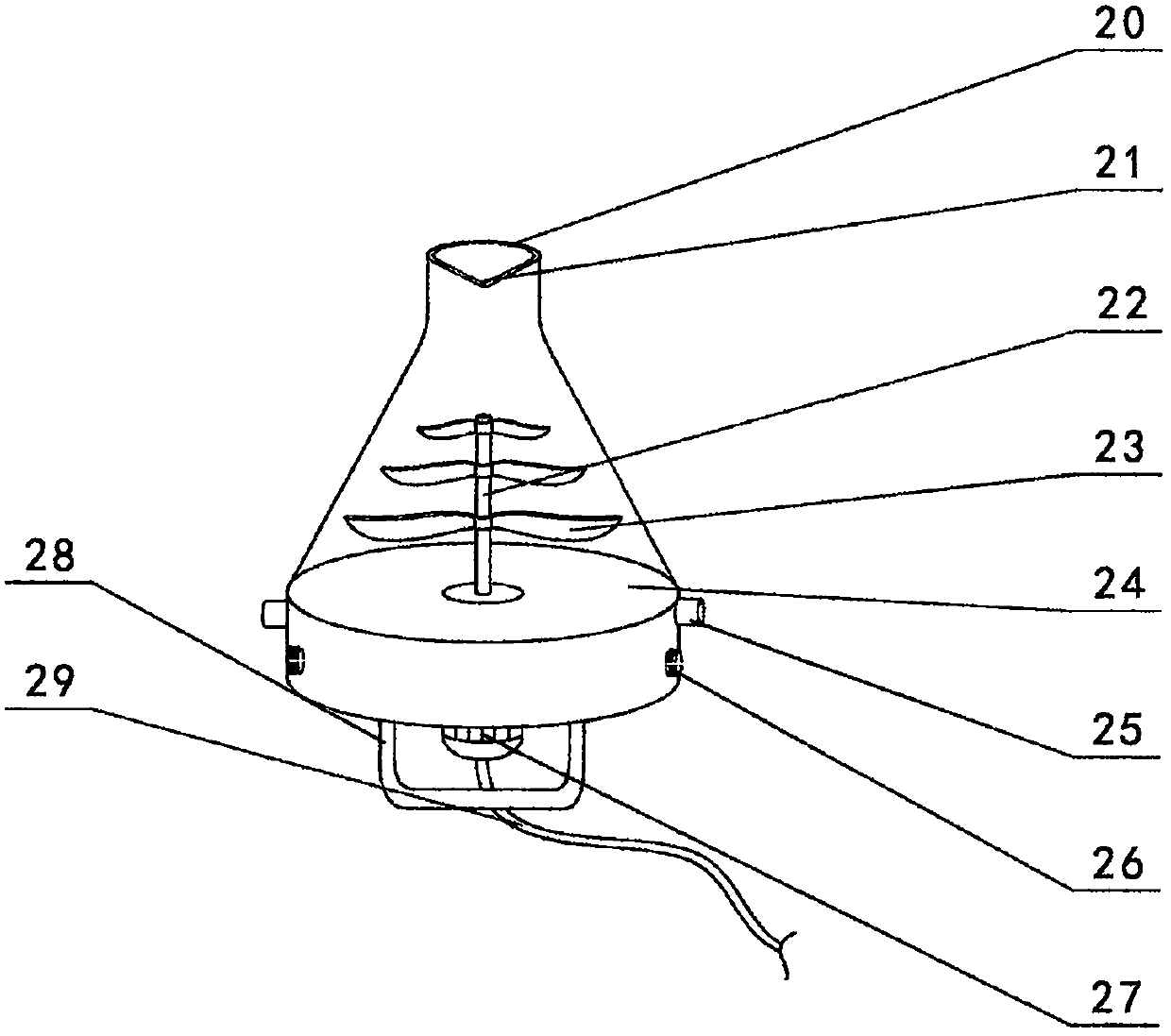

[0057] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0058] combined with figure 1 --The structure given in 4 is a teaching and demonstration device for turbidity current deposition experiments. The tank body is composed of tanks A6 and B9 arranged vertically opposite each other. Both tanks A6 and B9 are made of transparent plastic or made of glass material, and the lower surface of the water tank A6 and the water tank B9 are respectively provided with a drain 34, and the described drain 34 is a plugging spring type drain or a plugging flap type drain, in the described The opposite end of the water tank A6 to the water tank B9 is provided with a dividing plate 12, and the other end of the water tank A6 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com