Fiber reinforced foamed plastic preparation process

A technology of foam plastics and preparation process, which is applied in the direction of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc. It can solve the problems of high air pollution rate and low cooling efficiency, so as to increase the cooling rate and the feeding rate , avoid the effect of cumbersome process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

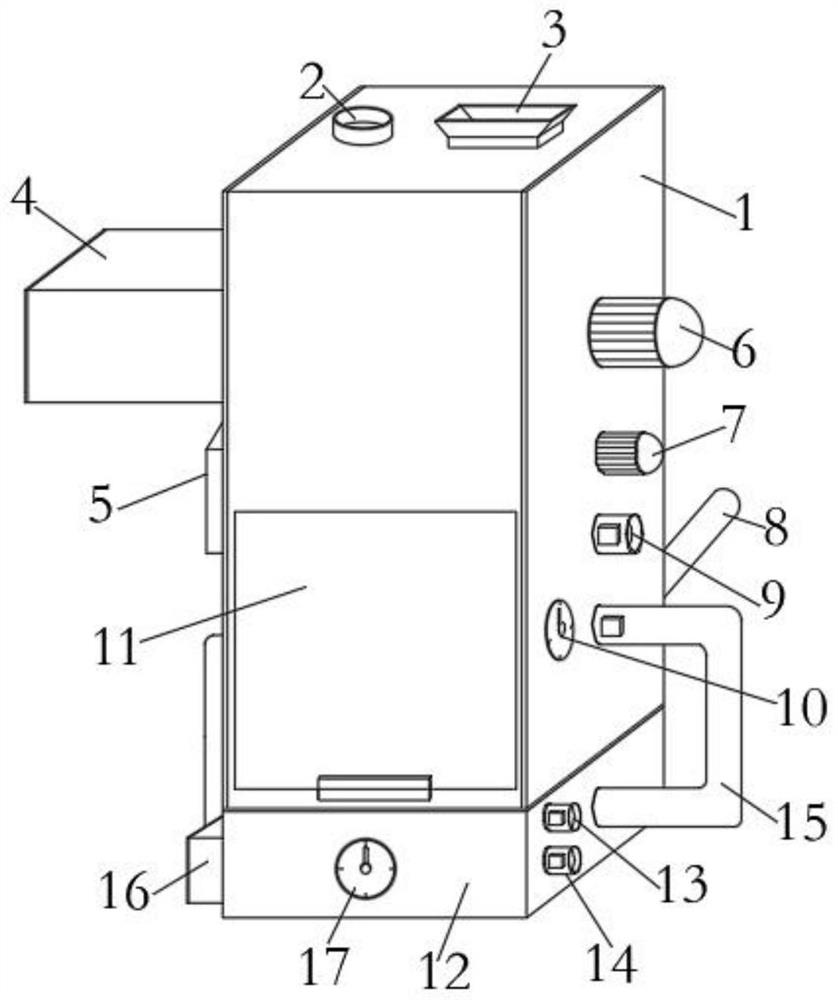

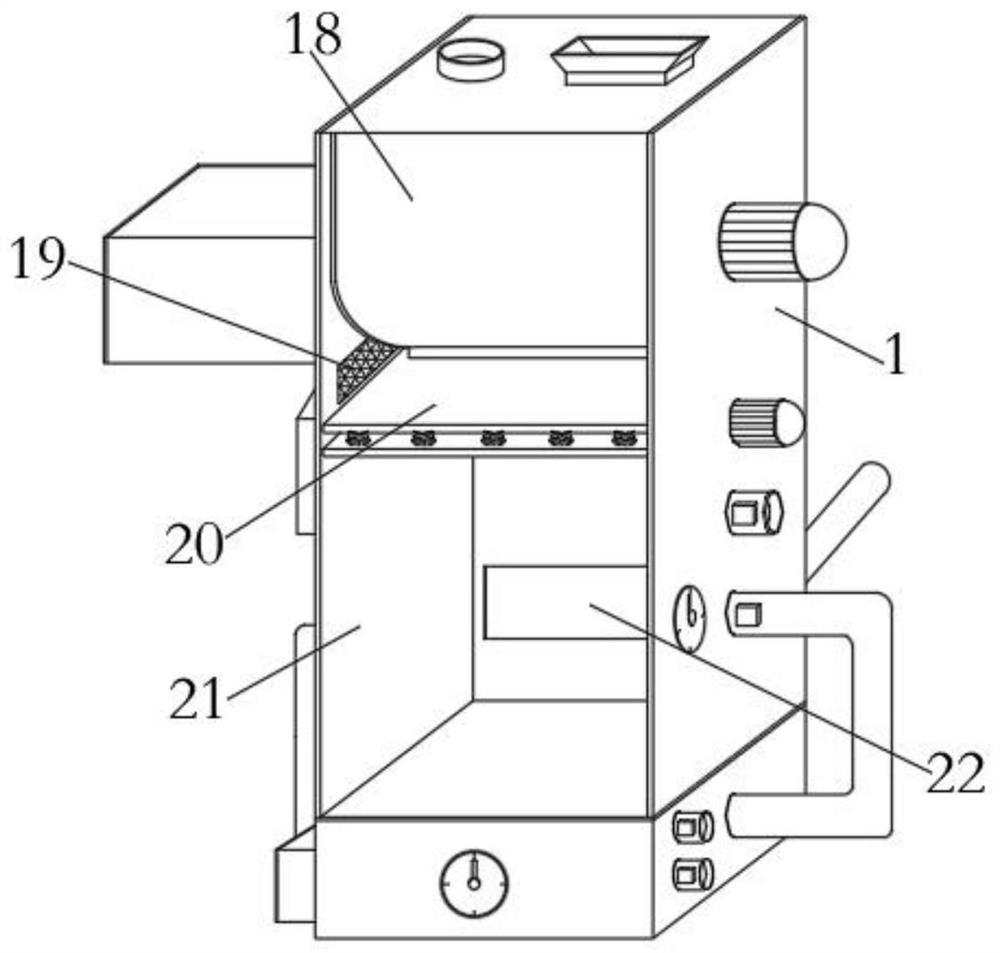

[0035]The invention provides a technical solution: a fiber-reinforced foam preparation process, the fiber-reinforced foam preparation process is prepared by a preparation device, the preparation device includes a preparation box 1, and the top of the preparation box 1 is provided with a raw material inlet 2 and the short fiber particle inlet 3, the bottom of the preparation box 1 is provided with a water tank 12, and the preparation box 1 is provided with an exhaust box 4, a control panel 5, a first motor 6, a second motor 7, and a hydraulic push rod 8 , steam inlet 9, pressure gauge 10 and closing cover 11, the inside of described preparation box 1 is provided with stirring tank 18, pressing plate assembly 20 and foaming tank 21, and the inner wall of described preparation box 1 is provided with exhaust port 19, The stirring tank 18 is communicated with the raw material inlet 2 and the short fiber particle inlet 3, and the inside of the stirring tank 18 is provided with a stir...

Embodiment 2

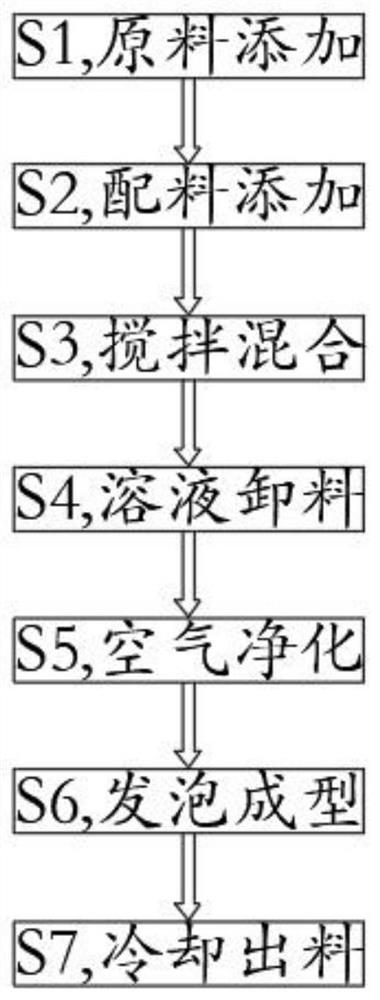

[0051] The preparation process of foamed plastics by crystal foaming is as follows:

[0052] S1, raw material addition: evenly place a certain amount of plastic crystal particles in the foaming mold;

[0053] S2, adding auxiliary materials; according to the ratio of plastic crystal particles and short fiber particles 3:1, place short fiber particles in the foaming mold;

[0054] S3, Stirring and mixing: Stir the plastic crystal particles and short fiber particles manually or with related stirring devices to make them evenly distributed;

[0055] S4, Foam molding: A proper amount of steam is introduced into the foam mold through the steam pipe, and the plastic crystal particles are foamed under high temperature and high pressure conditions, and at the same time, the fusion of plastic crystal particles and short fiber particles is realized;

[0056] S5, cooling: close the control valve on the steam pipe, open the control valve of the air outlet pipe on the foaming mold, the hea...

Embodiment 3

[0059] The traditional foam preparation process by liquid foaming is as follows:

[0060] S1, raw material addition: introduce a certain amount of plastic solution into the relevant mixing device;

[0061] S2, adding auxiliary materials; according to the ratio of plastic solution and short fiber particles 4:1, place the short fiber particles in the mixing device;

[0062] S3, Stirring and mixing: Stir the plastic crystal particles and short fiber particles manually or with related stirring devices to make them evenly distributed;

[0063] S4, foam molding: import the mixed solution into the foam box, close the box cover, and pass an appropriate amount of steam into the foam mold through the steam pipe, and the plastic crystal particles are foamed under high temperature and high pressure conditions, and foam molding After that, syntactic foam will be obtained;

[0064] S5, cooling: open the box cover, and cool down, the cooling time is 5-10 minutes;

[0065] S6, discharging:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com