Humic acid chelating slow release fertilizer special for rice and preparation method thereof

A special fertilizer, humic acid technology, applied in fertilizer mixtures, applications, fertilization devices, etc., can solve the problems of crop growth restriction, high concentration of harmful ions, unbalanced soil fertility, etc., to reduce energy consumption, improve crop quality and Yield, the effect of promoting fertilizer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

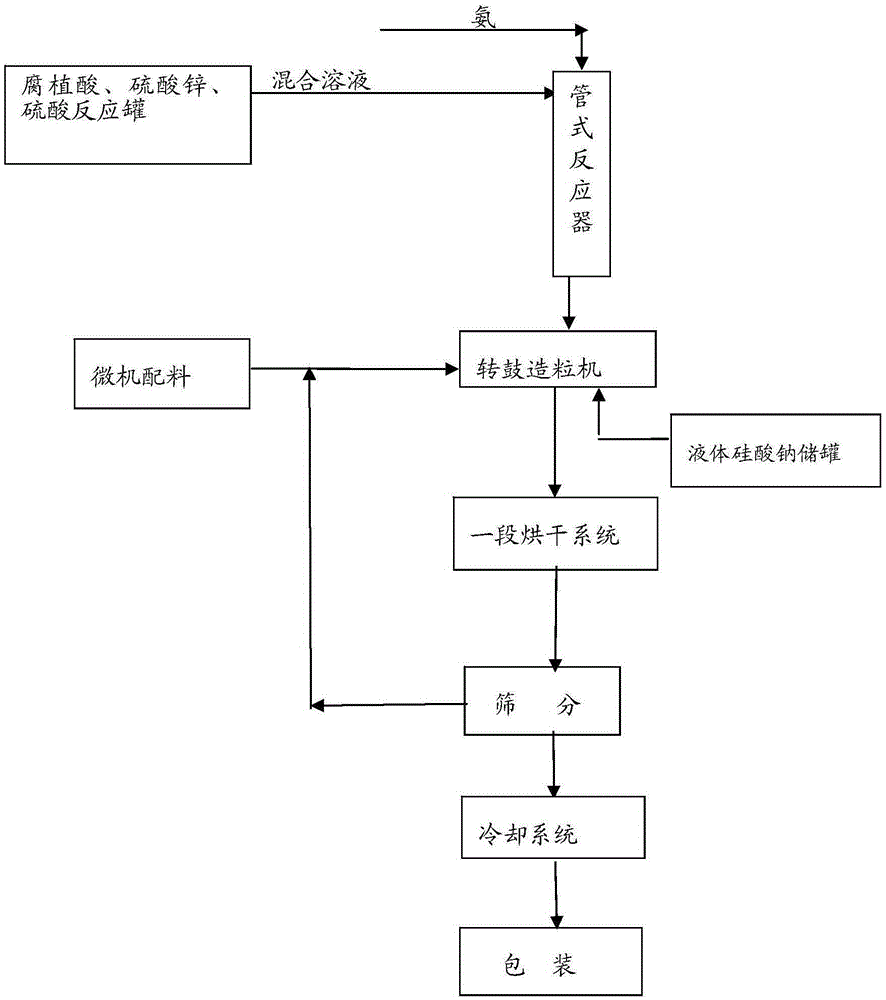

[0024] The preparation method of described humic acid chelated slow-release rice special fertilizer comprises the following steps:

[0025] (1) In the production of compound fertilizer by the acid method, the measured humic acid, zinc sulfate, sulfuric acid and water are added in proportion to the sealed reaction tank, heated and stirred for 10-15 minutes, and the temperature is 60-80°C, A mixed solution with a concentration of 70%-80% by mass percentage, for standby;

[0026] (2) Liquid ammonia is added to the tubular reactor, mixed with the mixed solution prepared from step (1) in the tubular reactor to make a mixed slurry, and the acidification and reaction of humic acid are completed by utilizing a large amount of heat of reaction of the acid reaction The chelation of humic acid and medium and trace elements combines the chelation process of medium and trace elements with the production process of compound fertilizer by the acid method, which reduces the chelation equipmen...

Embodiment 1

[0031] Embodiment 1: 20-13-12 products

[0032] 1. Put 100 kilograms of humic acid (mass percentage, the same below, containing 65 percent organic matter), 20 kilograms of zinc sulfate (containing sulfur and zinc elements), and 40 kilograms of concentrated sulfuric acid (containing sulfur elements) with a concentration of 98% in a reaction tank Neutralize and 105 kg of water to make a mixed solution with a mass percentage concentration of 75% and a temperature of 80°C, heat and stir for 15 minutes, and set aside;

[0033] 2. Add 50 kg of liquid nitrogen to the tubular reactor after metering, pump the mixed solution prepared in step 1 into the tubular reactor to make a mixed slurry, and use the reaction heat of acid to complete the humification Acidification of acid and chelation of humic acid and trace elements;

[0034] 3. Add 280 kg of urea (containing N46.2%) and powdered monoammonium phosphate (containing N12%, P 2 o 5 53%) 250 kg, potassium chloride (containing K 2 (0...

Embodiment 2

[0037] Embodiment 2: 22-13-10 product

[0038] 1. 90 kilograms of humic acid (mass percentage, the same below, containing 65% organic matter), 20 kilograms of zinc sulfate (containing sulfur and zinc elements), and 40 kilograms of concentrated sulfuric acid (containing sulfur elements) with a concentration of 98% are placed in a reaction tank Neutralize and 112.5 kg of water to make a mixed solution with a mass percentage concentration of 75% and a temperature of 80°C, heat and stir for 15 minutes, and set aside;

[0039]2. Add 50 kg of liquid nitrogen to the tubular reactor after metering, pump the mixed solution prepared in step 1 into the tubular reactor to make a mixed slurry, and use the reaction heat of acid to complete the humification Acidification of acid and chelation of humic acid and trace elements;

[0040] 3. Add 325 kg of urea (containing N46.2%) and powdered monoammonium phosphate (containing N12%, P 2 o 5 53%) 245 kg, potassium chloride (containing K 2 (26...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com