Omnidirectional feeding machine for aquaculture

An all-round technology for aquaculture, applied in the field of agricultural machinery, can solve the problems of limited feeding area, restriction, labor occupation, etc., and achieve the effects of avoiding feeding, improving feeding efficiency, and reducing preparation procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

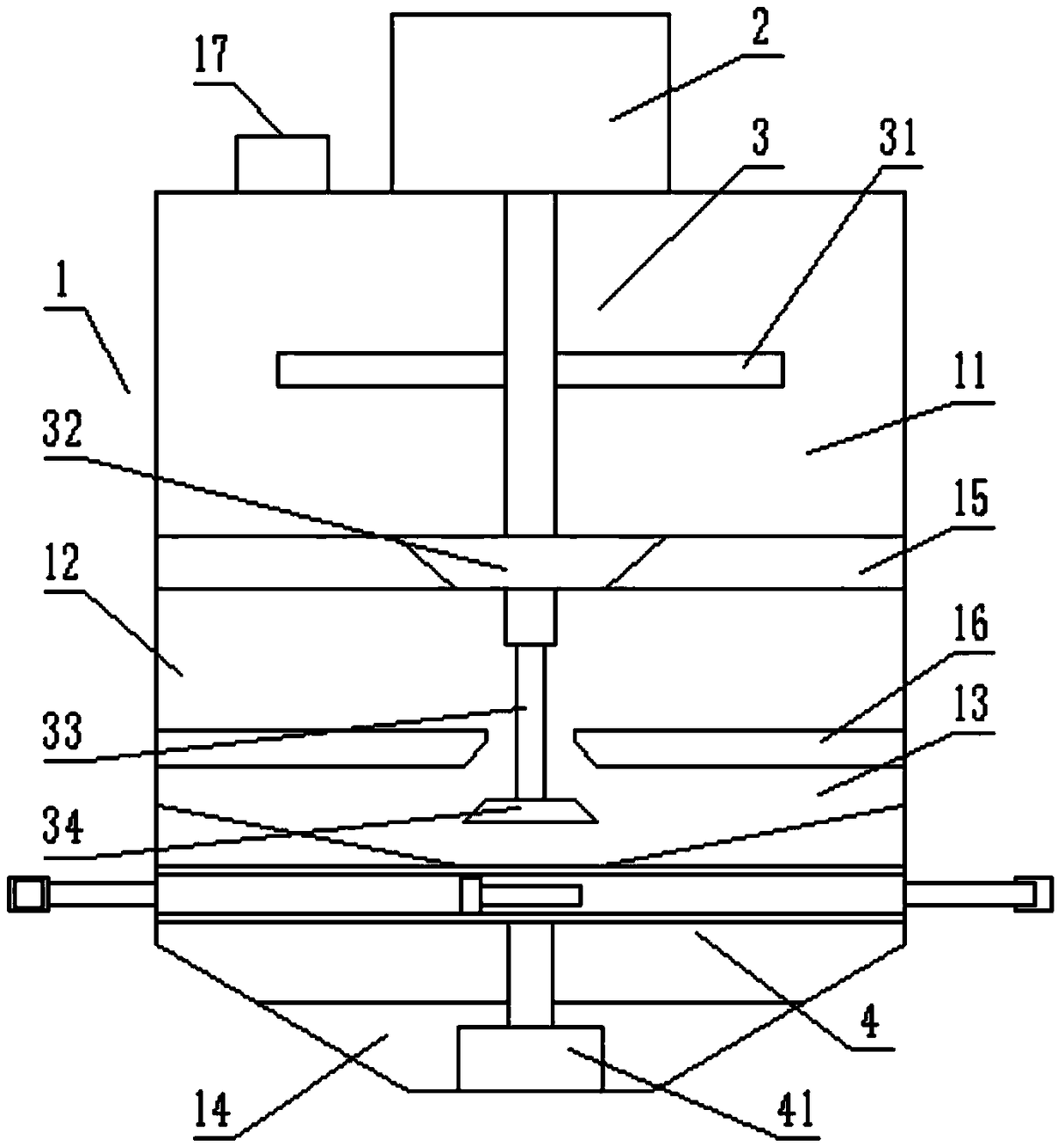

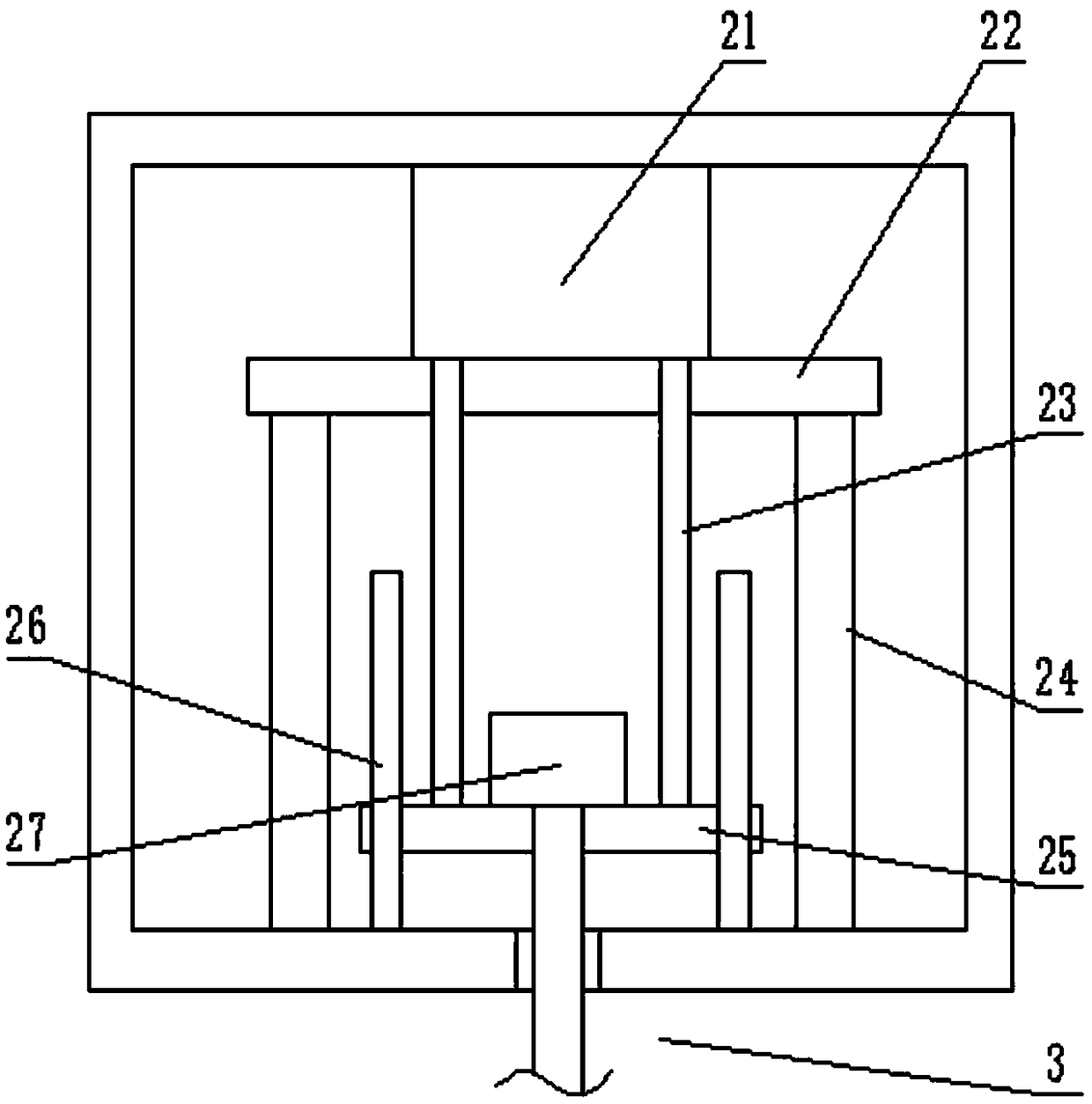

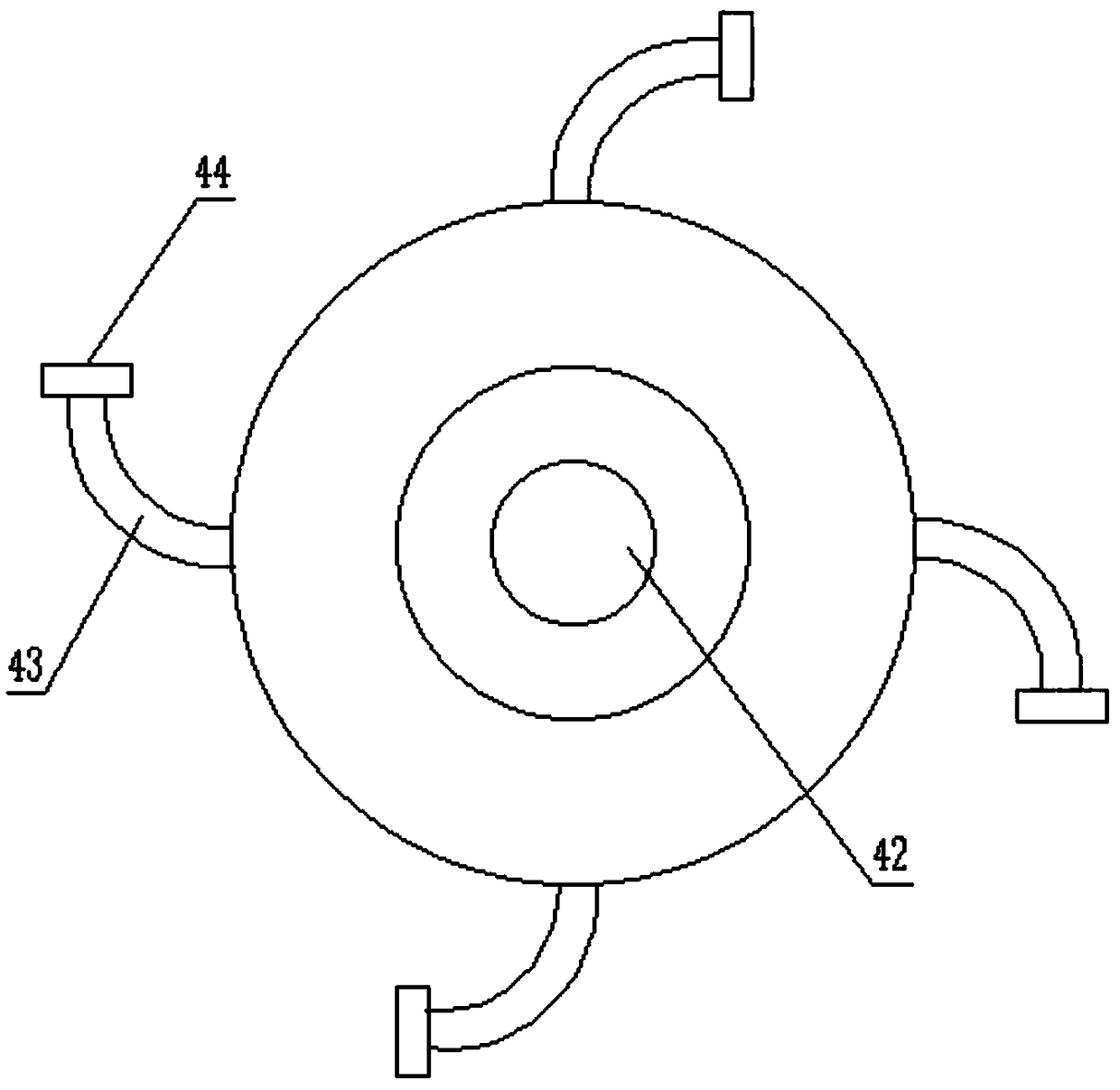

[0019] see Figure 1-3 , an all-round bait feeding machine for aquaculture, comprising a casing 1, the interior of the casing 1 is sequentially composed of a mixing chamber 11, a transfer chamber 12, a throwing chamber 13 and a sealing chamber 14 from top to bottom, and the upper and lower sides of the transfer chamber 12 are respectively provided with The first sealing plate 15 and the second sealing plate 16 are used to separate; the top of the shell 1 is provided with a feeding port 17 for putting the bait into; the throwing chamber 13 is provided with a throwing material for throwing the bait in all directions Disc 4, the throwing tray 4 is disc-shaped and connected to the shell 1 in rotation, and a number of arc-shaped throwing tubes 43 are arranged on the outer wall of the throwing tray 4 along the circumferential direction. The tangential direction of the outer wall is arranged, and the front end of the throwing pipe 43 is provided with a square discharge port 4 with th...

Embodiment 2

[0023] The difference from Embodiment 1 is that both the first sealing plate 32 and the second sealing plate 34 are in the shape of a truncated cone, and the first sealing plate 32 is in a downward closing shape, and the second sealing plate 34 is in an upward closing shape. The inclined structure on the side makes it possible to keep a tight fit when sealing the first sealing plate 15 and the second sealing plate 16, further avoiding the leakage of bait.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com