Preparation method of paraffin particles based on CO2/N2 switch emulsion and application of paraffin particles

A paraffin wax and emulsion technology, which is applied in the application of paraffin wax particles and the preparation of paraffin wax particles, can solve the problems of difficulty in preparing micron-sized paraffin wax particles, large particle size of paraffin wax particles, and residual organic solvents, so as to save production labor costs, The effect of saving and streamlining the production process and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] Based on the above technical problems, the inventor provides a CO-based 2 / N 2 The method for preparing paraffin particles of switch emulsion, which specifically includes the following steps: S1) Prepare the oil phase: add paraffin to N,N dimethylcyclohexylamine, and stir until the paraffin is completely dissolved, then add emulsifier A and stir until completely dissolved , to obtain the oil phase;

[0040] S2) Prepare the water phase: add the emulsifier B to deionized water, stir until the emulsifier B is completely dissolved, and obtain the water phase;

[0041] S3) preparing O / W emulsion: after mixing the oil phase and the water phase, stirring and emulsifying to obtain an O / W emulsion;

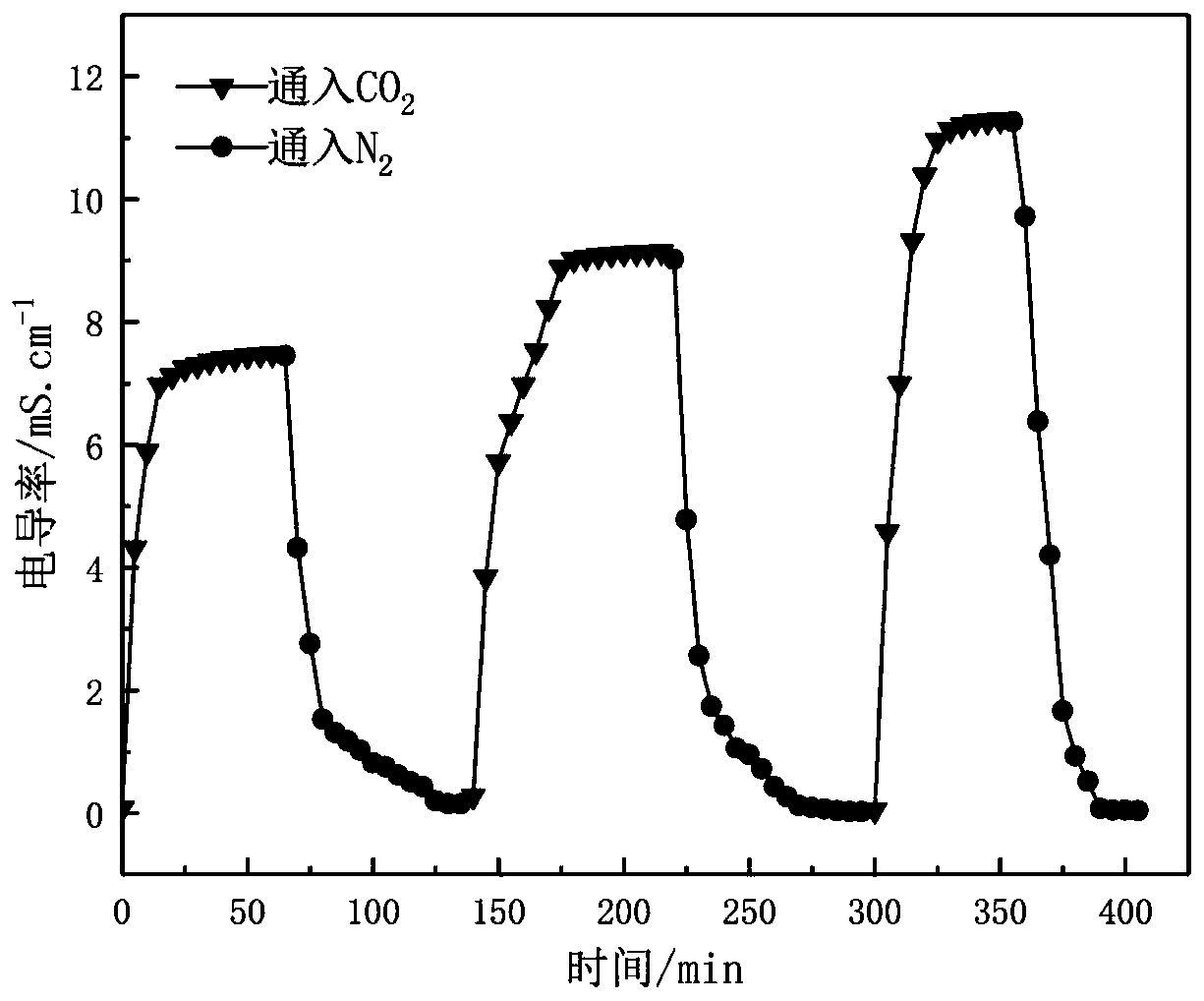

[0042] S4) Preparation of paraffin particles: carbon dioxide is introduced into the O / W emulsion, the paraffin particles are precipitated, and the paraffin particles and protonated solvent are obtained after centrifugation;

[0043] S5) Recycling: Nitrogen gas is passed into the ...

Embodiment 1

[0053] S1) Dissolve 12.5g of paraffin completely in 37.5g of N,N dimethylcyclohexylamine, then add 2.208g of Span-80, and stir until Span80 is completely dissolved to form an oil phase;

[0054] S2) Dissolving 1.472g of Tween-80 in deionized water to form an aqueous phase;

[0055] S3) under stirring conditions, slowly add the oil phase into the water phase, so that the concentration of emulsifier A + emulsifier B is 8%, forming an O / W emulsion;

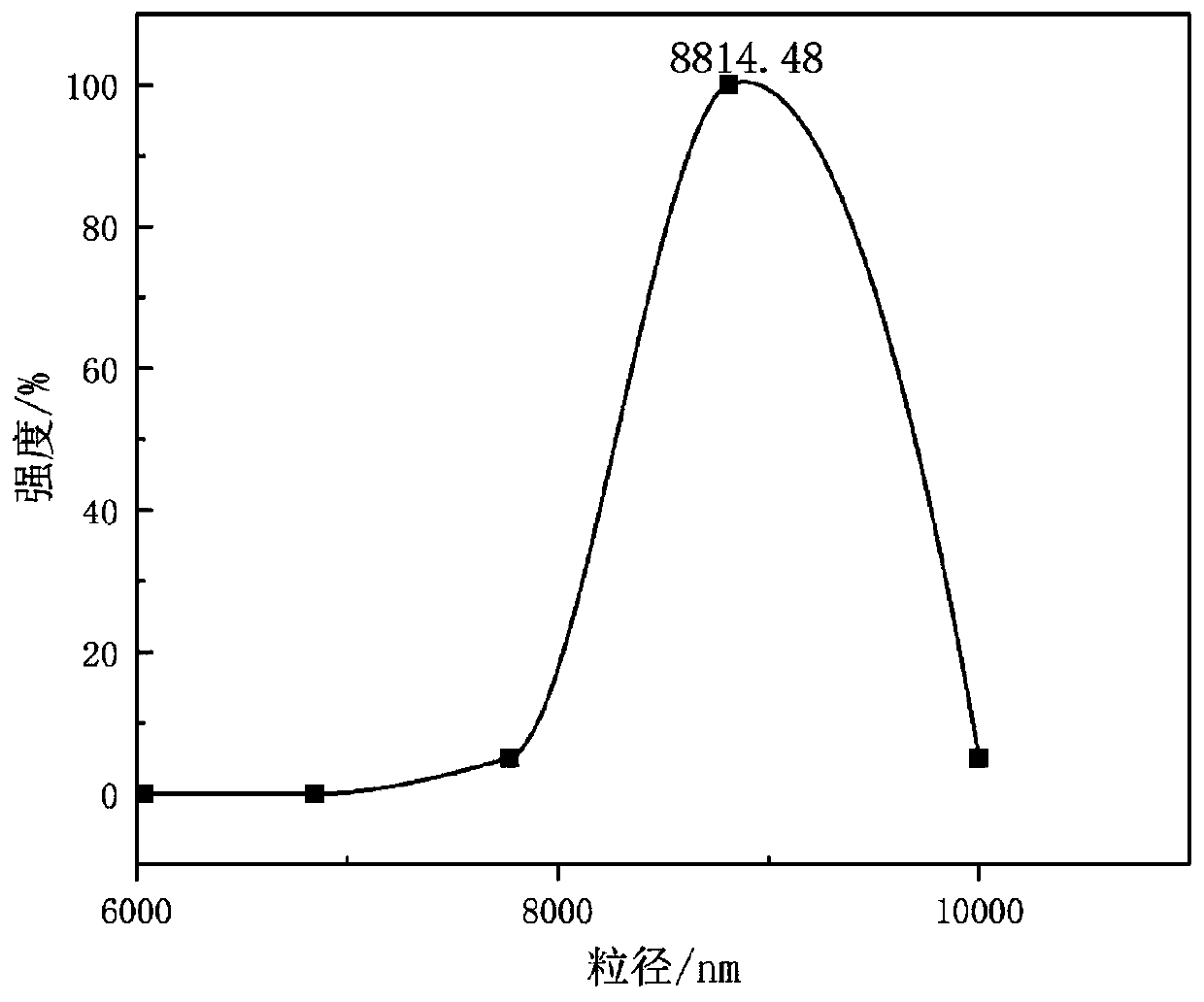

[0056] S4) Pass CO into the emulsion 2 , the solvent N,N dimethylcyclohexylamine was dissolved in water, and centrifuged to obtain paraffin particles;

[0057] S5) The centrifuged supernatant was passed into N 2 , the supernatant is stratified into solvent and emulsifier aqueous solution, and the solvent and emulsifier aqueous solution are separated by a separatory funnel, and continue to be put into recycling.

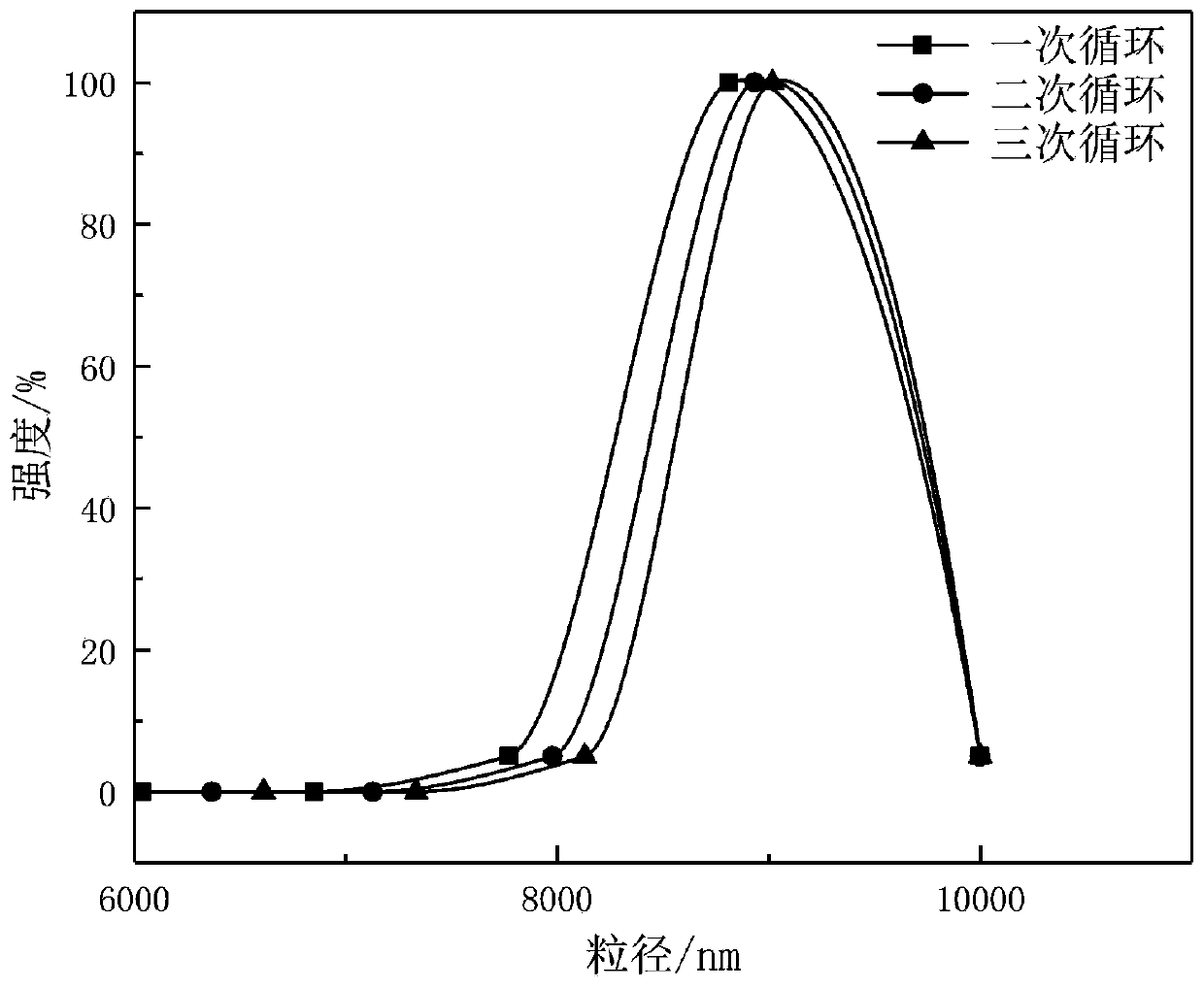

[0058] recycle:

[0059] The solvent and emulsifier aqueous solution obtained after the first preparation above are co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com