Circuit breaker checking table clamp

A circuit breaker and calibration platform technology, which is applied in the field of electrical calibration, can solve the problems of poor efficiency, increase the preparation process, and reduce the calibration efficiency, so as to achieve the effect of improving the degree of automation, reducing the preparation process, and improving the calibration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

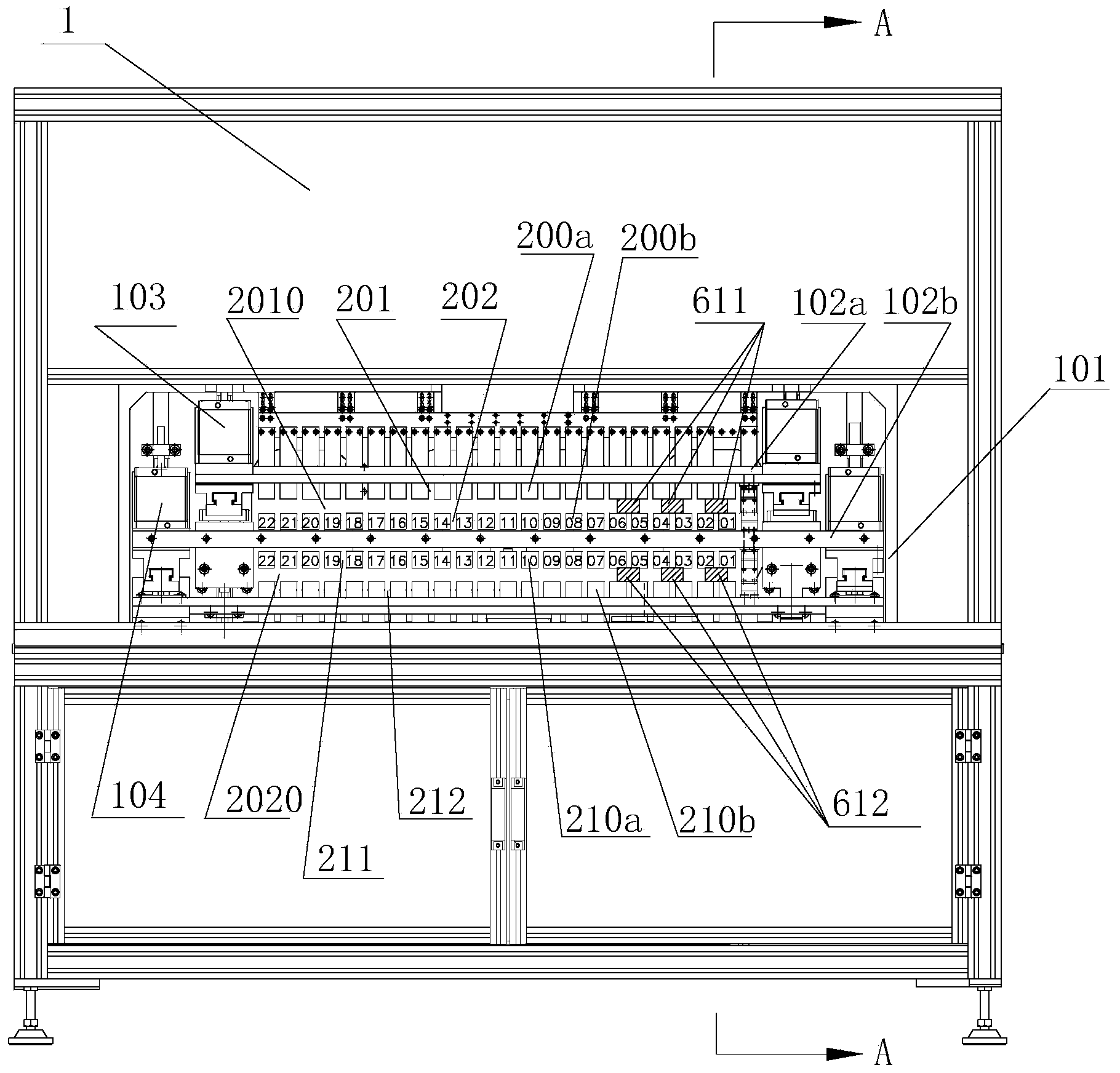

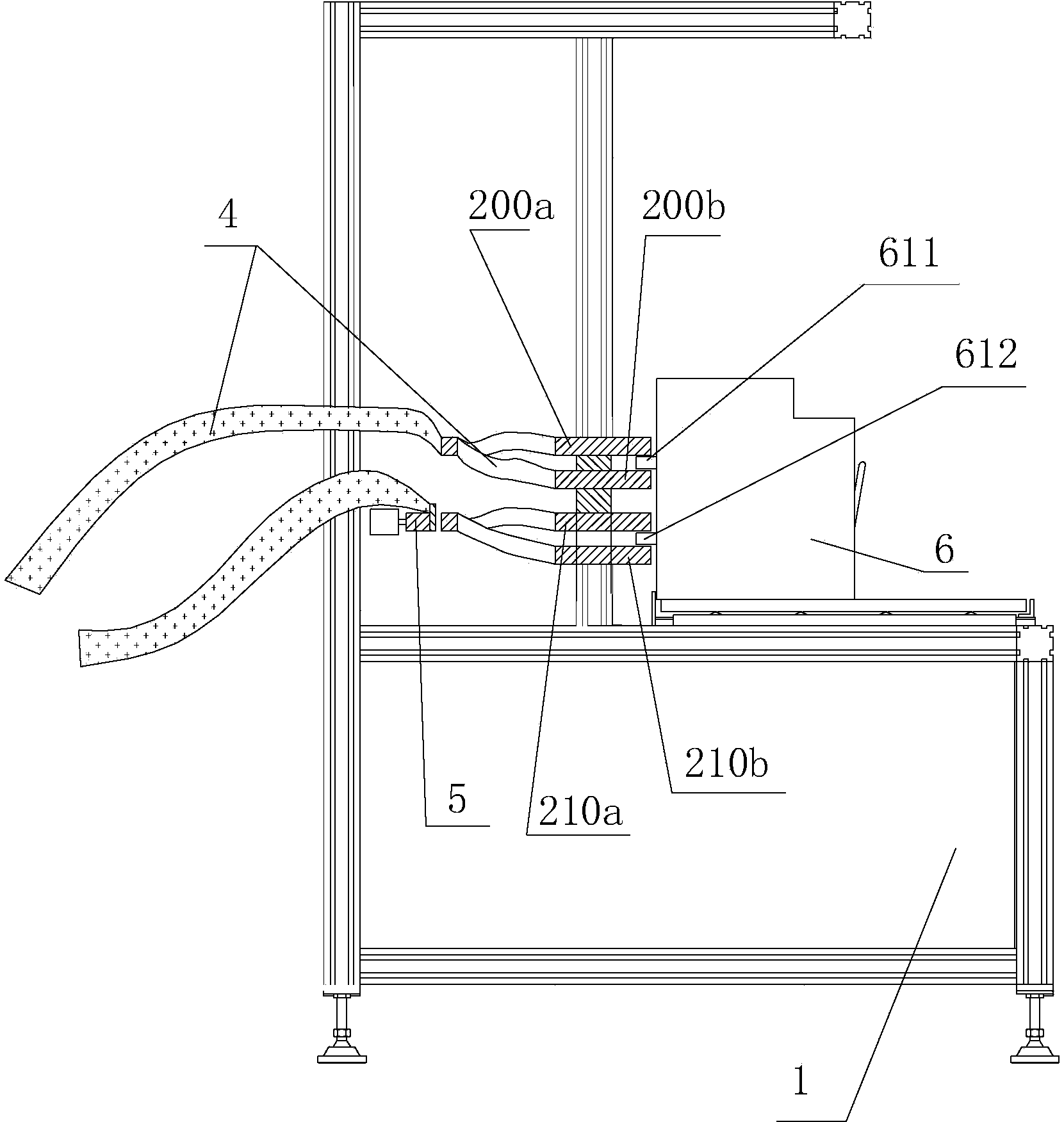

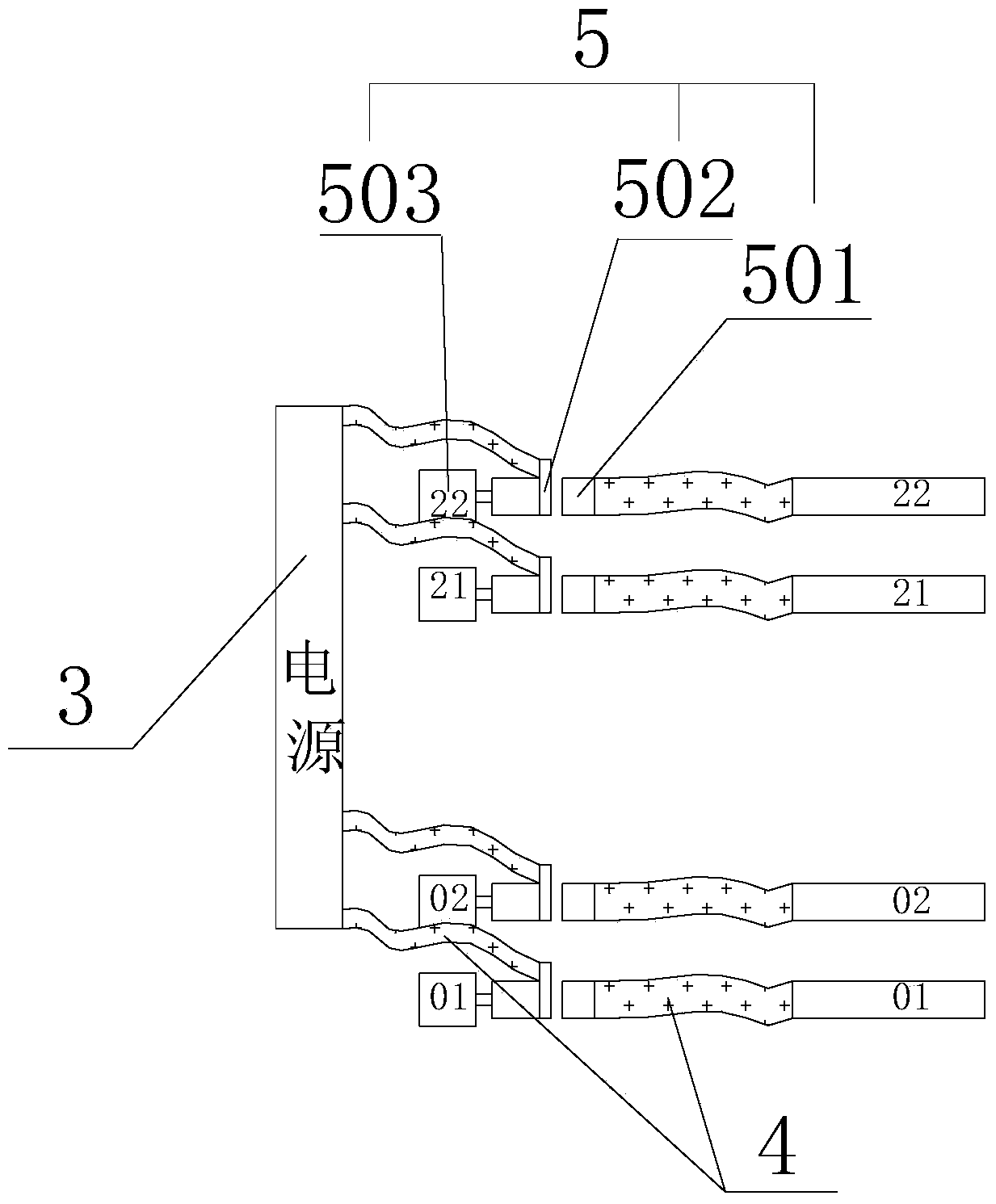

[0023] The circuit breaker calibration bench fixture of the present invention includes a fixture bracket 101, a chuck copper sheet and a test power supply 3. The fixture bracket 101 is provided with two sets of chucks that respectively clamp the two rows of busbars of the circuit breaker 6 to be verified. , each set of collets includes two rows of collet copper sheets that cooperate with each other to achieve clamping, and each row of collet copper sheets includes at least five collets with each other in the same set of collets. The collet copper sheet is correspondingly arranged with the collet copper sheet. A pair of collet copper sheets correspondingly arranged on the two rows of collet copper sheets form a collet unit, and a pair of collet units corresponding to two sets of collet groups form a collet unit group, and two sets of collets Each chuck unit group in the group is connected to the test power supply 3 in parallel. At least one clamp unit in each clamp unit group ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com