Method for preparing Ag nanowires based on ZnO nanotube templates

A technology of nanotubes and nanowires, which is applied in the field of preparing Ag nanowires based on ZnO nanotube templates, can solve the problems of cumbersome preparation process and application limitations, and achieve the effects of simplifying the process, reducing the preparation cost and reducing the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing and embodiment case, the present invention is described in further detail:

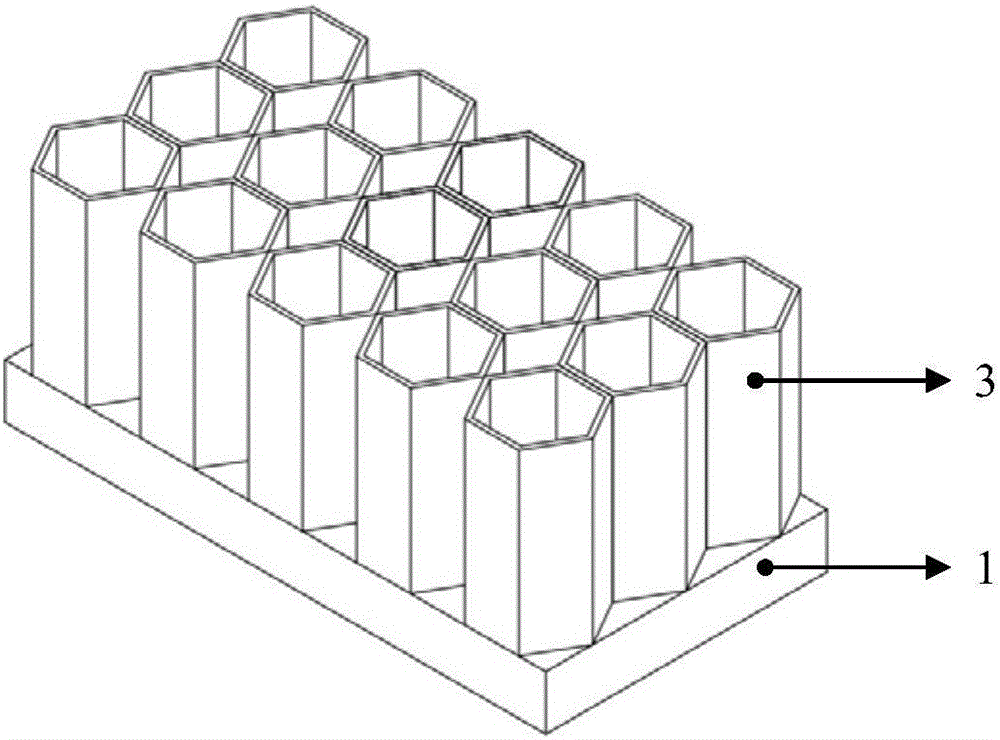

[0034] Such as Figure 4 , the present invention includes planar ITO conductive glass 1 as a substrate, chemically etched ZnO nanotubes 3, and Ag nanowires 4 electrodeposited in ZnO nanotube templates.

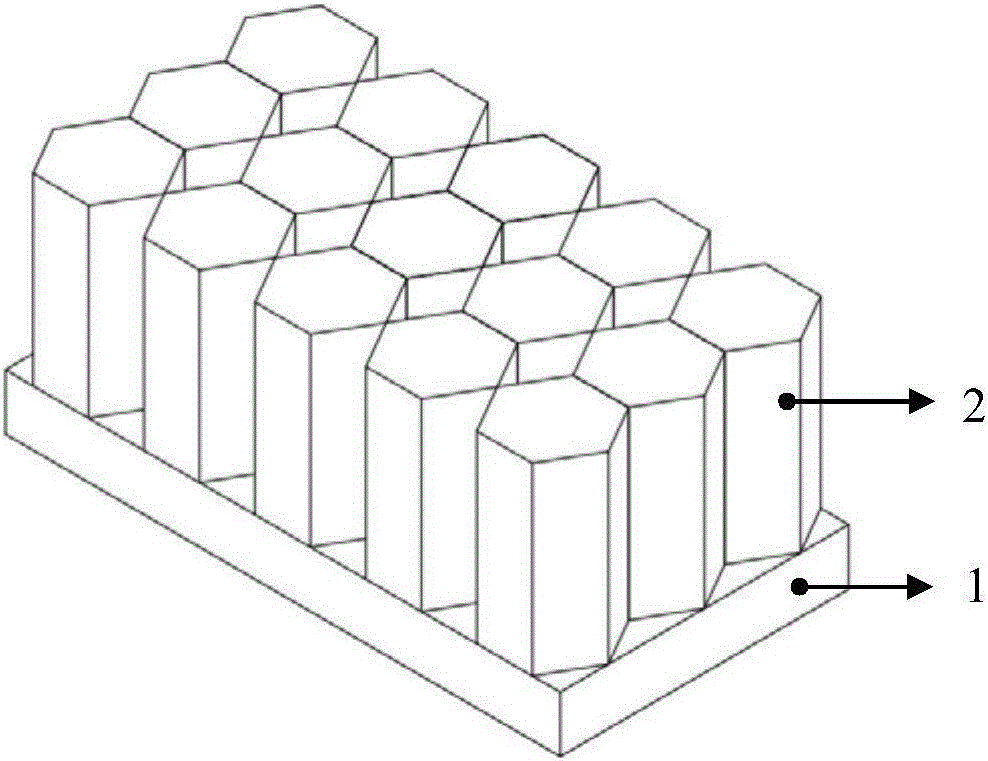

[0035] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 as shown,

[0036] The above-mentioned method for preparing Ag nanowires based on ZnO nanotube templates comprises the following steps:

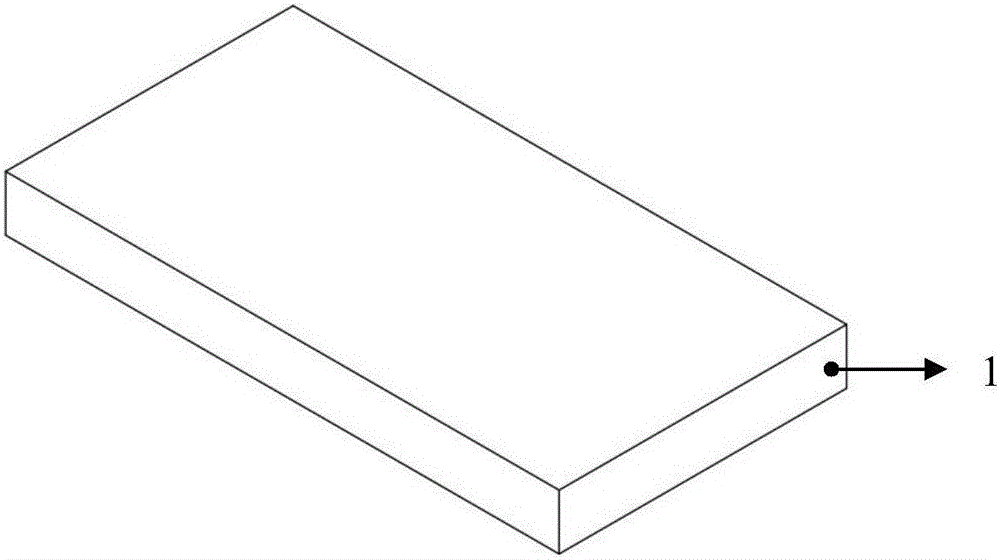

[0037] 1) Cut the ITO conductive glass 1 whose length, width and thickness are 10mm, 5mm and 1.1mm respectively, clean it ultrasonically with acetone, absolute ethanol and deionized water in sequence, and dry it at room temperature, as figure 1 shown;

[0038] 2) 11.0mg Zn(CH 3 COO) 2 2H 2 O and 4mg NaOH were dissolved in 500mL absolute ethanol and kept at 65°C for 30min to obtain Zn 2+ Concentration is the ZnO seed layer solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface root mean square roughness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com